8 Product description

2 Product description

2.1 Performance features

The AM-T100 is a ToF camera with an image rate of up to 60 fps and a

resolutionof640x480pixels.Withaeldofvisionof67"x51"andhigh-

performance IR illumination, it can detect objects within a range of up to 6

metres1).

ThecameraisconguredusingtheCONSAM-Tapplicationsoftware,which

allowsforcreationandmonitoringofthecomplex3Dzones.Ifthecamera

detectsobjectswithinthesezones,digitaloutputsareswitched.Inaddition,

digitalinputscanbeusedtoswitchbackandforthbetweendierent3Dzones.

The AM-T100 can also supply image data for common image processing

software via the standardised GigE Vision and GeniCam interfaces. The

integratedSDKallowssoftwaredevelopersandintegratorstocongurethe

cameraandcreatecustomer-specicsoftwareapplications.

1) Depending on the remission properties of the target objects, a range of up to 30 m can be

achieved.

2.1.1 CONSAM-T application software

The CONSAM-T application software for Windows is used for camera

conguration.Thesettingsaresavedinaprojectleandtransferredto

the camera. A detailed description can be found in chapter 6 “CONSAM-T

application software user interface” from page 30.

2.1.2 AM-T100 OS operating system

The AM-T100 OS is the operating system that is pre-installed on the camera,

that runs on the camera autonomously and that can be called via a browser.

A detailed description can be found in chapter 7 “AM-T100 OS operating system

user interface” from page 53.

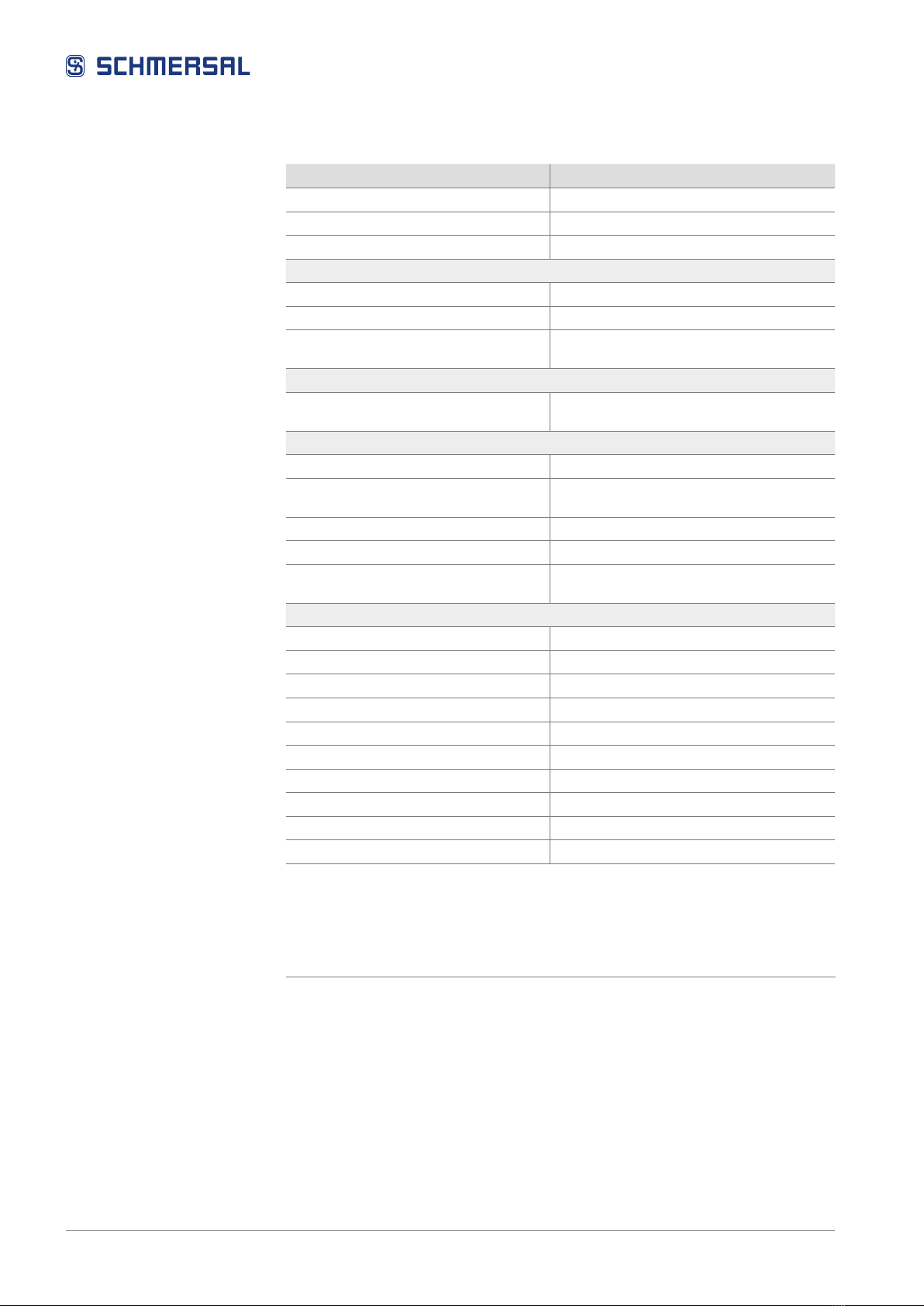

2.1.3 System requirements

The following system requirements apply to operation of the AM-T100 camera

and the CONSAM-T application software:

– 2 GB free disc space

– 1 x Ethernet 100/1000 MBit/s – RJ45

– Windows 10 as of version 21H1

– Optional: PoE-capable switch or PoE injector, standard IEEE 802.3bt

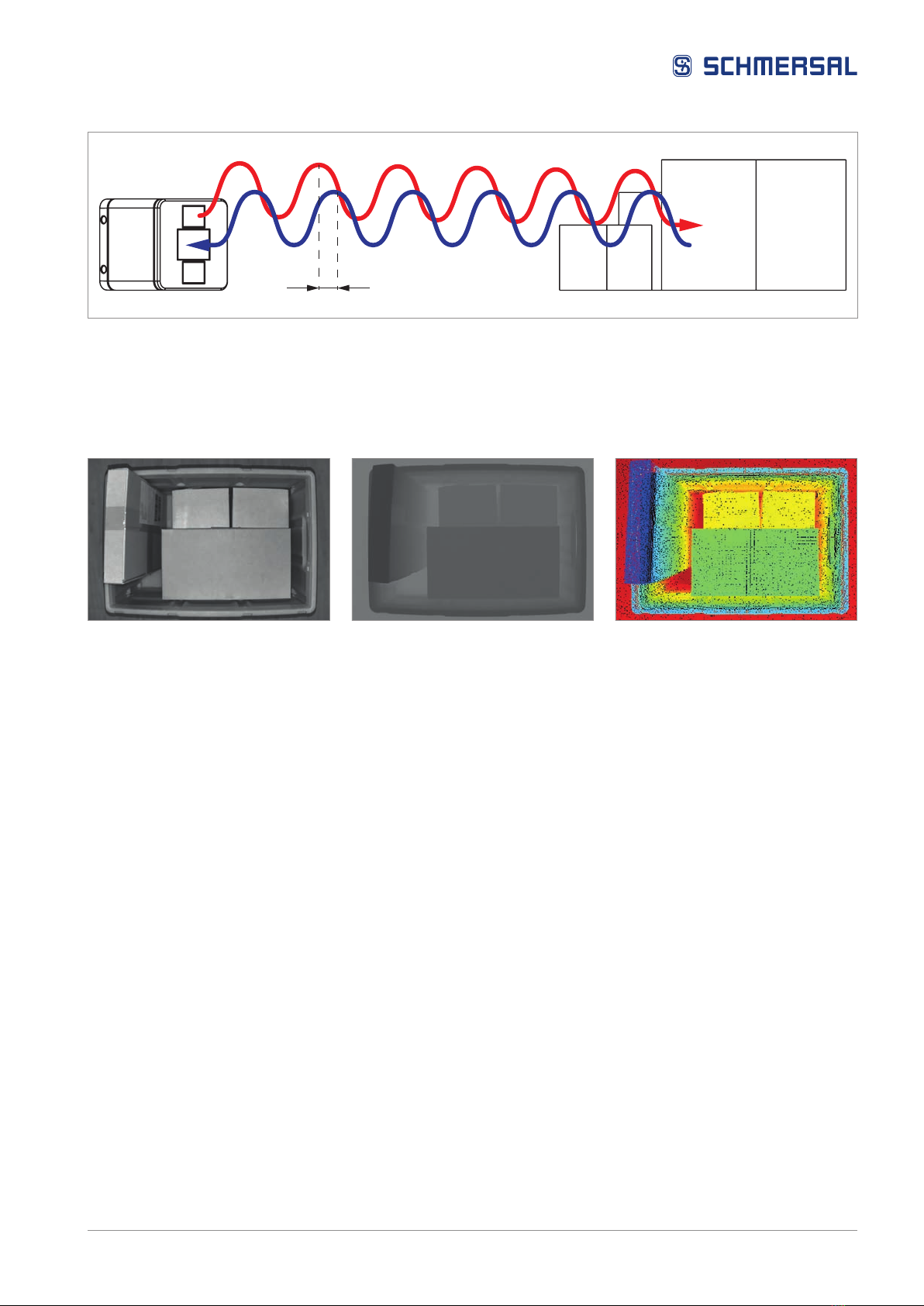

2.2 Mode of operation

TheAM-T100ToFcameraworksaccordingtotheindirecttimeofight

measurement principle, whereby the camera emits a continuous beam of

modulated light and measures the phase shift between the emitted and

reectedlight.Thisphaseshiftisusedtodeterminethedistancebetweenthe

sensorandthereectingobject.Thegreaterthephaseshift,thefartheraway

the object. The camera can then calculate the distance travelled by the light and

thus determine the distance between the camera and the object. The phase

shift is determined for each individual pixel in the image.