9

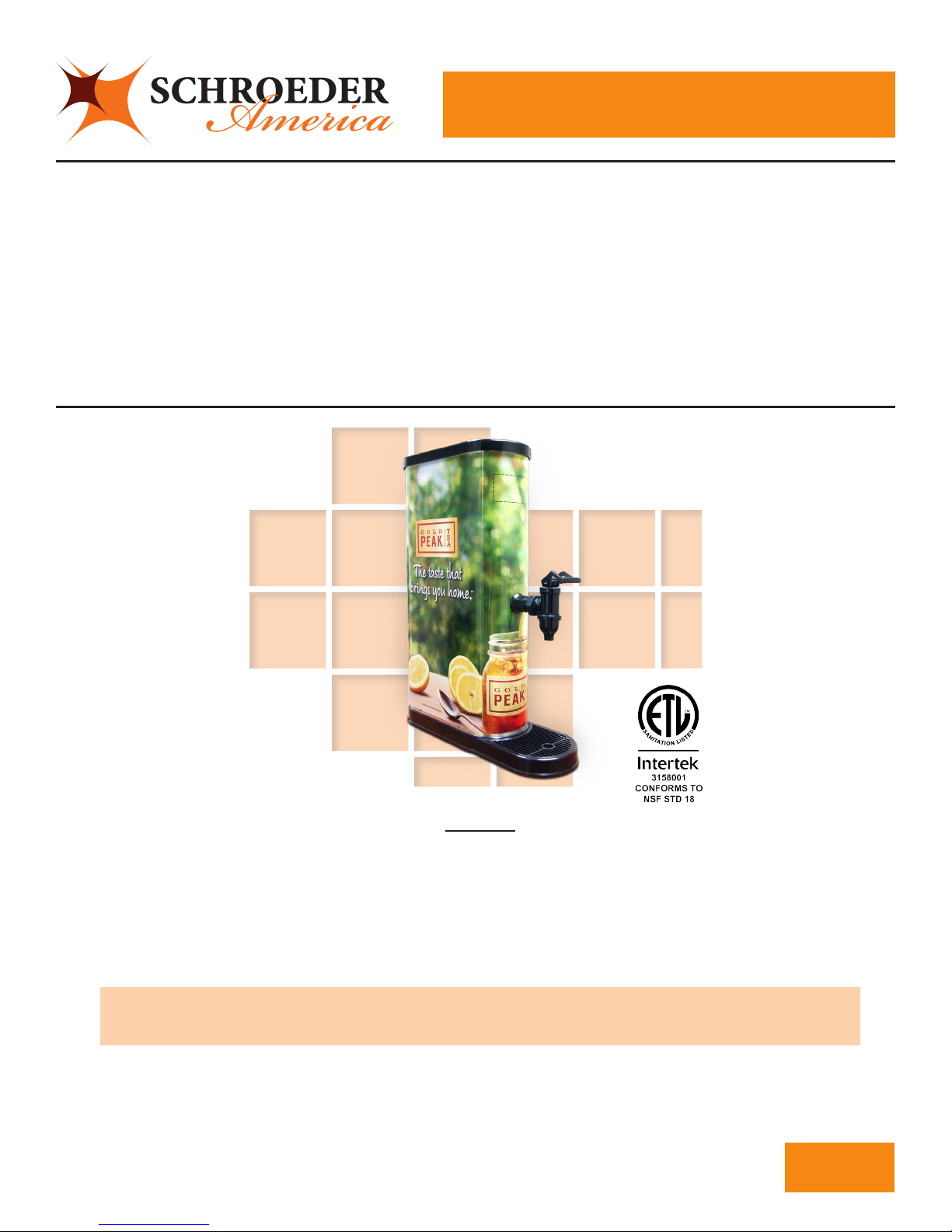

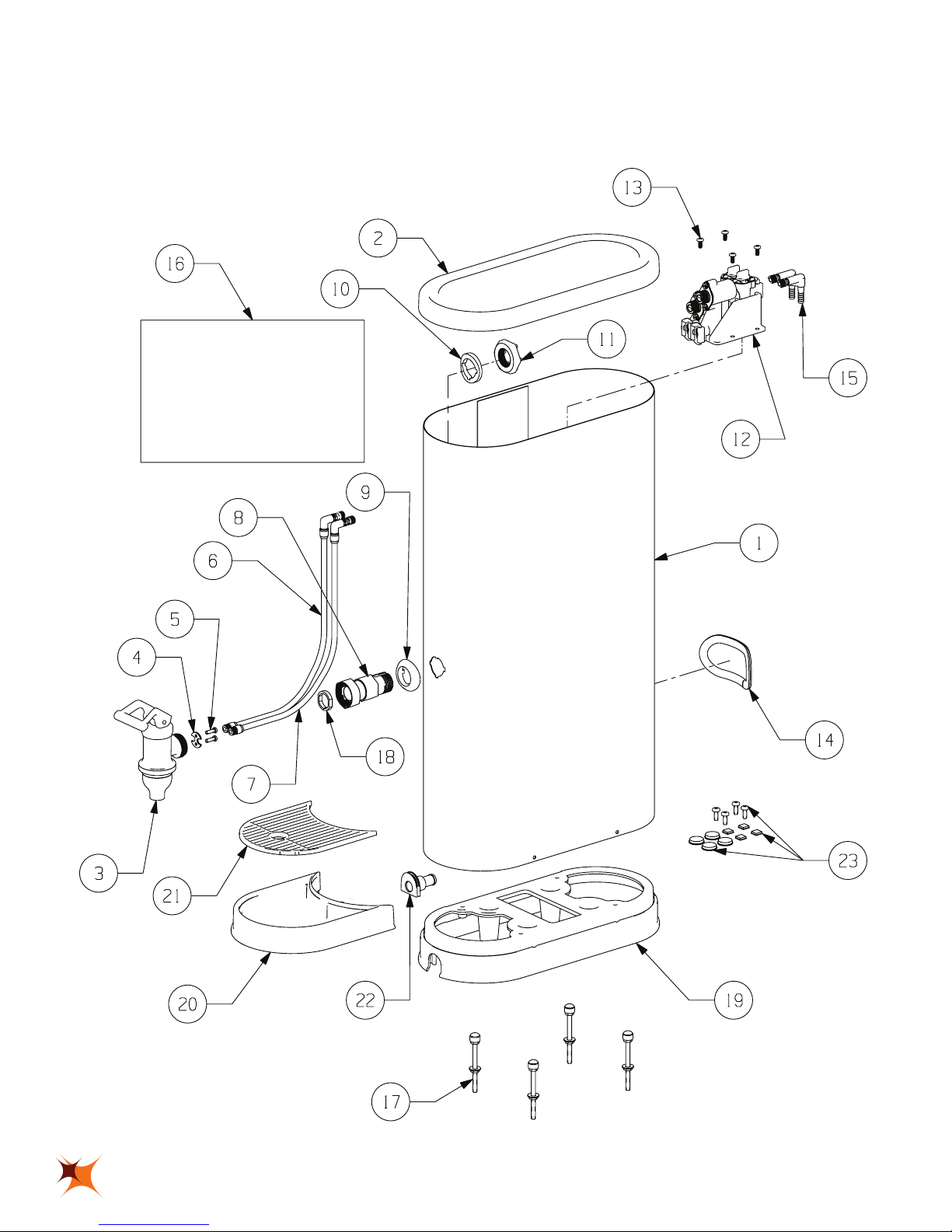

OVAL CAN ASSEMBLY

OVAL ASSEMBLY

ITEM SCHROEDER PN DESCRIPTION

1 634-0105 CAN ASSY, COKE TEA

2 265-0350 LID, OVAL, 5.75”

3 637-0015 ASSY, VALVE, POSTMIX,W/O ADA LEVER

4 256-0021 PLATE, VALVE, TEA

5 224-0006 SCREW, 6-19x.500, PLASTITE, PH, PHD

6 632-0143 SUB-ASSY, WATER, PMV W/O ADA LEVER

7 632-0144 SUB-ASSY, S1, PMV W/O ADA LEVER

8 645-0173 SHANK ASSY, PMV

9 265-0374 SPACER, PMV TO 5.75” CAN

10 265-0377 SPACER, INSIDE, 5.75” CAN

11 265-0382 NUT, HEX, 1-16, NYLON

12 660-1003 VALVE/BRACKET ASSY, 2V, BLK, TEA

13 220-0037 SCREW, 8-32x.375, PH, PHD, 18-8SS

14 210-0030 GROMMET,CAN,BACK,TEA

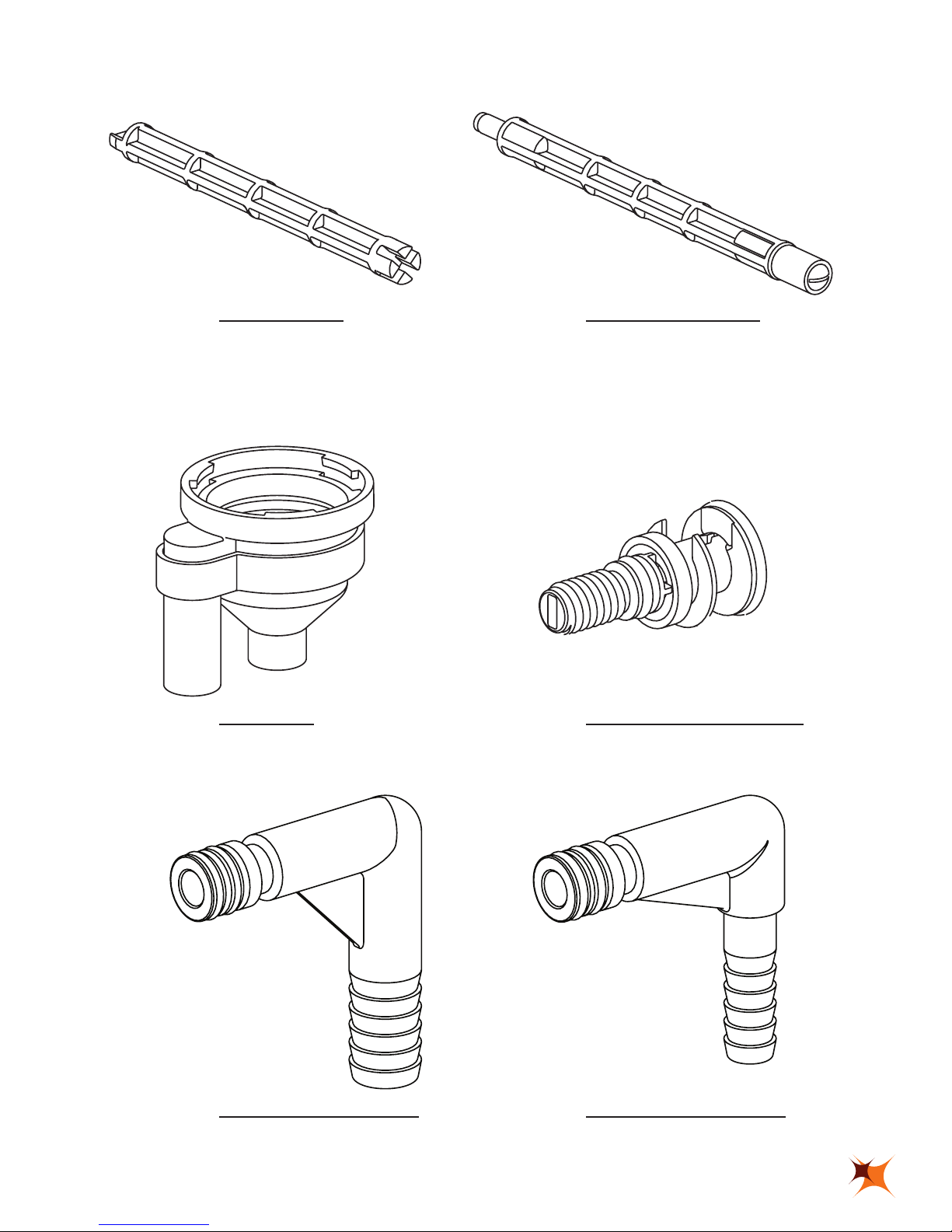

15 670-0033 PKG, INSTALL, 2 EA 1/4 BARB 90 DEG FITTINGS

17 670-0013 PACKAGE,INSTALL,SCREWS,TEA URN -

FOR MOUNTING TO COUNTER WITH NO BASE

18 210-0046 GASKET,SHANK,PM VALVE

19 265-0544 BASE,TEA,SINGLE

20 631-0132 DRIPTRAY ASSY,1V,W/DRAIN,REMOVABLE CUPREST

21 265-0550 CUPREST,DRIPTRAY,1V TEA

22 675-0062 KIT,DRAIN ADAPTER,DRIPTRAY,TEA

23 675-0081 KIT,BUMPERS & SCREWS

AVAILABLE GRAPHICS

16 812-**** GRAPHICS, TEA URN - PARTIAL AND FULL WRAPPERS AVAILABLE

AVAILABLE ACCESSORIES

670-0030 PKG, INSTALL, 2 EA 3/8 BARB 90 DEG FITTINGS

675-0059 KIT,ROUND FEET AND SCREWS FOR BASE,TEA

675-0060 KIT,SQUARE FEET FOR DRIPTRAY,TEA

OTHER AVAILABLE KITS

675-0042 KIT, RETAINER, & SCREWS, PMV : ITEMS 4 AND 5

675-0082 KIT, POSTMIX VALVE W/O ADA LEVER : ITEMS 3, 4, AND 5

675-0044 KIT, SHANK ASSY, PMV: ITEMS 8, 9, 10, AND 11