SDI PPS-2RM-B User manual

PPS-2RM-B

1 PPS GENERATOR

OPERATING MANUAL

SPECTRADYNAMICS, INC • 1849 Cherry St. Unit 2. • Louisville, CO 80027

Phone: (303) 665-1852 • Fax: (303) 604-6088

www.spectradynamics.com

SPECTRADYNAMICS, INC

PPS-2RM-B, 1 PPS Generator Operating Manual

Copyright © 2021 SpectraDynamics, Inc. All rights reserved.

PPS-2RM-B:R00-2021/MD

Contents

1.0 Introduction 1

2.0 Safety and preparation for use 2

2.1 Electrical 2

2.2 Instrument 4

3.0 Front panel description 5

4.0 Back panel description 6

5.0 Operation 7

6.0 Specifications 8

7.0 Warranty 9

1.0 Introduction

Page 1

The PPS-2RM-B is a dual 1 pulse-per-second (1 PPS) generator. This instrument requires

a sine-wave input signal of 1 MHz, 5 MHz or 10 MHz to generate the 1 PPS.

The PPS-2RM-B generates two pairs of independent 1 pulse-per-second outputs with

variable pulse width. The input frequency and pulse width may be configured by DIP switch

settings. The 1 PPS output can be synchronized to an external event. The synchronization

is good to +/-1/2 of the input clock cycle. The outputs are designed to drive low impedance

loads and long 50 or 75-ohm cables. The channel-to-channel delay differences are less

than 500 ps.

The pulse per second generators are available in a 1U full rack mount enclosure that

operate on 100 to 240 VAC. Optional DC operation option is available for all models upon

request.

PPS Options:

Part Number Description AC Operation DC Operation

OPTION

PPS-2RM-AOne generator, two outputs

Rear panel connectors

PPS-2RM-A-DC One generator, two outputs

Rear panel connectors

PPS-2RM-B

Two generators,

Two outputs per generator

Rear panel connectors

PPS-2RM-B-DC

Two generators,

Two outputs per generator

Rear panel connectors

PPS-2RM-B1

Two generators,

Two outputs per generator

FRONT panel connectors

PPS-2RM-B1-DC

Two generators,

Two outputs per generator

FRONT panel connectors

2.0 Safety and Preparation for Use

Page 2

The PPS-2RM-B was designed for indoor use only and is not intended for operation

outdoors or in a wet environment. The instrument may be mounted in a standard 19-inch

instrumentation rack or may be used on a laboratory bench. Inspect the instrument and

power cords for damage before first use.

2.1 Electrical safety and preparation for use.

Voltages capable of causing injury or death are present in this instrument. Use

extreme caution whenever the instrument cover is removed.

Line Voltage

This instrument is designed to operate with a 100 to 240 VAC, 47 to 63 Hz power source.

This instrument is also capable of operating with a DC power source that can supply +12

to +36 VDC at 2 Amperes when the DC option is acquired.

Fuse

A 1.0 Ampere 250V 5X10mm slow-blow fuse is used for 100 to 240 VAC operation.

A 2.0 Ampere 250V 5X10mm slow-blow fuse is used for DC power operation.

Only replace fuses with the same type and specifications.

AC Power

The instrument has a detachable three wire power cord for connection to a grounded AC

power source. The enclosure of the unit is directly connected to the outlet ground to

protect against electrical shock. Always use an outlet with a protective ground and do not

disable this safety mechanism. Detaching the AC power cord is the only option of

disconnecting the unit from the AC mains supply. Make sure you have access to the rear

panel or provide an external accessible AC disconnect means for your PPS-2RM-B.

DC Power

The PPS-2RM-B may be acquired with a DC power option to allow the instrument to be

powered by +12 to +36 VDC, 2 Amp source. The DC supply operation may be used as

backup power to prevent loss of signal during power outages or as a mains supply source.

The switching from AC to DC supply operation is affected by a Schottky diode network and

charge storage capacitors to ensure glitch free operation.

If the PPS-2RM-B was acquired with the DC operation option a 6 pin DC connector will be

available on the back panel.

2.0 Safety and Preparation for Use

Page 3

The configuration for the DC connector, if available, is as follows:

Pin 1 NC

Pin 2 NC

Pin 3 NC

Pin 4 +12 to +36 VDC power return

Pin 5 +12 to +36 VDC power

Pin 6 Chassis GND /Earth GND

Verify that the connector of the external DC power supply providing voltage to the unit has

the same pin configuration mentioned above. Do not apply AC voltage to the DC power

connector. Failure to follow these directions may cause injury or death to personnel, cause

irreparable damage to the instrument and voids all warranties.

Please note that the power return (pin 4) is NOT connected to the instrument case ground

internally, however both ground connections (pin 4 and pin 6) are available at the DC

power connector and may be connected together at this point.

The following specifications should be used to ensure optimum performance:

DC Supply voltage +12 to +36 VDC, 2 Amps

Line regulation +/- 0.05% for a 10% line change

Load regulation +/- 0.05% for a 50% load change

Output ripple < 5 mV peak-to-peak

Detaching the DC power cord is the only option of disconnecting the unit from the DC

mains supply. Make sure you have access to the rear panel or provide an external

accessible DC disconnect means for your PPS-2RM-B.

2.0 Safety and Preparation for Use

Page 4

2.2 Instrument safety and preparation for use.

Reference Frequency Configuration

The PPS-2RM-B may be configured to operate on 1 MHz, 5 MHz or 10 MHz frequency

reference. The default configuration for the unit is 5 MHz. To change the input reference

frequency, the unit must be unplugged from the power source(s). Remove ONLY the top

cover of the instrument. Once the cover is removed you will find an aluminum bracket

cover in the middle section of the instrument. Locate the DIP switch labeled S5 on the pps

module(s).

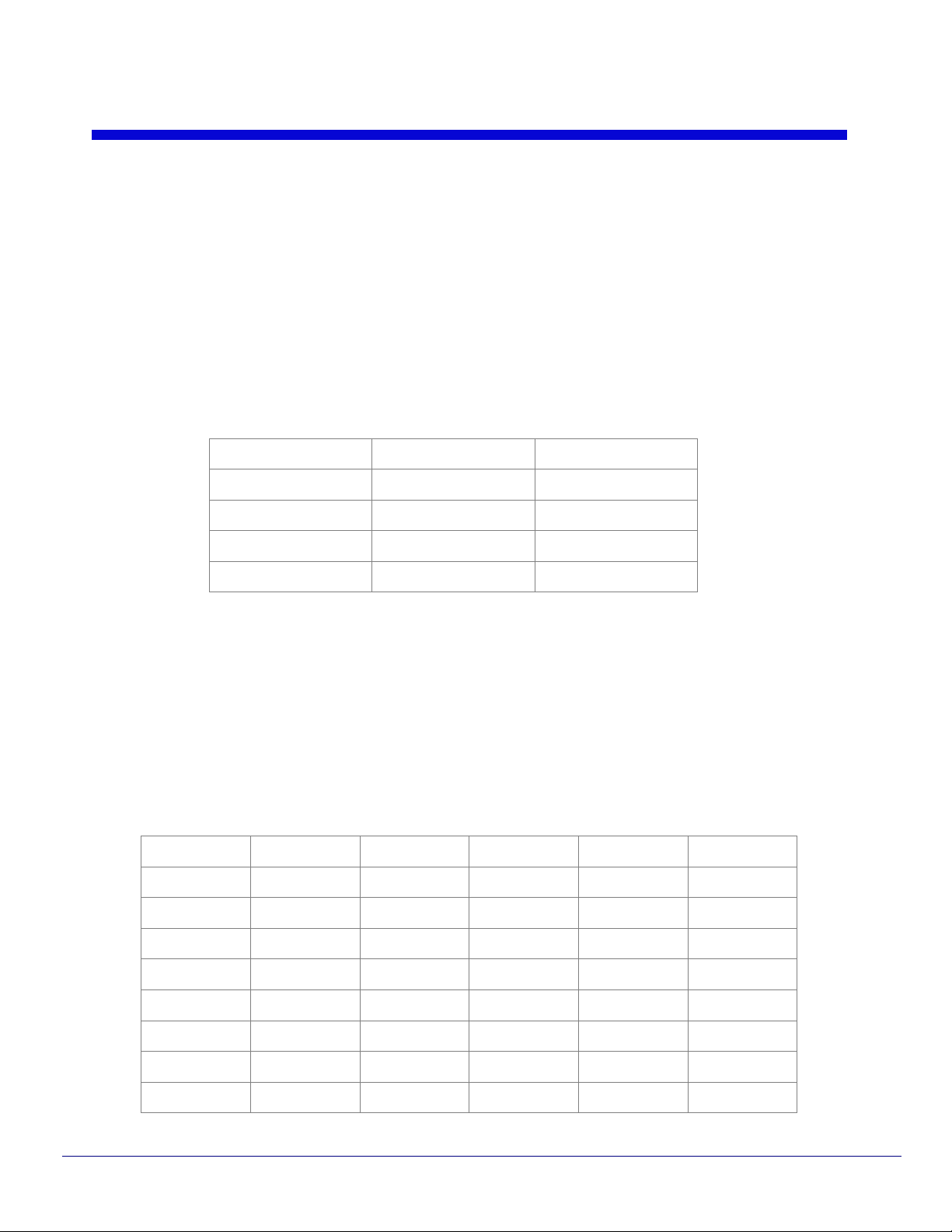

Modify the setting to reflect the selection of your choice following the next table.

Pulse Delay Settings

The PPS-2RM-B pulse generator can be configured for different pulse widths. The default

configuration for the unit is 51.2 us pulse-width. To change the pulse-width selection,

the unit must be unplugged from the power source. Remove ONLY the top cover of the

unit. Locate the DIP switch labeled S5 on the module(s) to be configured. The pulse width

of the generator is a multiple of the clock period and can be set according to the table

below.

DIP SW 1 DIP SW 2 FREQUENCY

ON ON 10 MHz

ON OFF 5 MHz

OFF ON 1 MHz

OFF OFF RESERVED

DIP SW 3 DIP SW 4 DIP SW 5 1 MHz pw 5 MHz pw 10 MHz pw

OFF OFF OFF 4.096 ms 819.2 us 409.6 us

OFF OFF ON 2.048 ms 409.6 us 204.8 us

OFF ON OFF 1.024 ms 204.8 us 102.4 us

OFF ON ON 512 us 102.4 us 51.2 us

ON OFF OFF 256 us 51.2 us 25.6 us

ON OFF ON 64 us 12.8 us 6.4 us

ON ON OFF 16 us 3.2 us 1.6 us

ON ON ON 4 us 0.8 us 0.4 us

3.0 Front Panel

Page 5

AC Power LED

The LED will turn on when AC power is applied to the instrument.

DC Power LED

If the instrument was acquired with the DC operation option the DC power LED will light up

when DC power is applied to the unit.

EXT PPS1 LED

The LED will flash on the rising edge of the 1 PPS external synchronization signal from the

first module.

EXT PPS2 LED

The LED will flash on the rising edge of the 1 PPS external synchronization signal from the

second module.

PPS1 LED

The LED will flash on the rising edge of the 1 PPS output signal from the firts PPS

generator module.

PPS2 LED

The LED will flash on the rising edge of the 1 PPS output signal from the second PPS

generator module.

4.0 Back Panel

Page 6

AC POWER

The PPS-2RM-B is configured to operate on 100 to 240 VAC

DC POWER

If the instrument was acquired with the DC operation option a DC connector will be

available on the back panel. Operation on DC from +12 to +36 VDC will be possible as the

main power supply or as backup power in case of AC power outages when both, AC and

DC, are powering the instrument.

PPS 1 INPUTS

Ref - Receives a sine-wave input signal of 1 MHz, 5 MHz or 10MHz. Power level must be

in the range of +3 to +13 dBm.

Ext. 1 PPS - Receives a 1 PPS synchronization input. The 1PPS signal must conform

to TTL specifications.

PPS 1 SYNC

Enable - When the switch is positioned to “Enable” selection, the 1 PPS output will have

the possibility to be synchronized to an external 1 PPS signal. Warning!!! After a

synchronization event this switch should be returned to the off or down position to prevent

accidental synchronization.

Trigger - When synchronization is enabled and a 1 PPS signal is present on the Ext.

1 PPS input, the 1 PPS synchronization event can be triggered by the push button. Only

one synchronization will occur for each trigger.

Phase - Selects the reference clock edge of the synchronization event. The 1 PPS will be

synchronized to the next reference clock rising edge after the incoming synchronization

PPS input when the switch is in the Enable position. When the switch is in the down

position, the 1 PPS will be synchronized to the reference clock falling edge that occurred

before the incoming synchronization PPS input. Warning!!! Toggling the Phase switch will

cause loss of synchronization.

PPS 1 OUTPUTS

1 and 2 - Two 1 PPS outputs will be available at the SMA connectors labeled 1, 2.

5.0 Operation

Page 7

To operate the PPS-2RM-B, locate the AC power entry module on the rear of the

enclosure and/or the DC connector and connect the power cord(s). Plug the unit into

appropriate power outlet(s). The LED on the front panel labeled AC will turn on when AC

voltage is applied. If you also apply DC voltage, the LED labeled DC on the front panel

should light up.

Please remember that there are two independent modules in the PPS-2RM-B. In order to

generate a second 1 PPS, an input reference signal for each module is required.

Attach a frequency reference signal to the SMA connector on the back panel labeled PPS

INPUTS Ref. The unit will generate one pulse per second signals at each of the output

ports of the module receiving the reference signal. An LED on the front panel will flash on

the rising edge of each pulse.

To synchronize the output pulses to an external event, connect the external reference

pulse signal to the input labeled Ext. 1 PPS on the back panel. Enable the synchronization

sequence by moving the Enable switch to the Enable position. The Trigger button will arm

the synchronization sequence to occur on the next rising edge at the Ext. 1 PPS input.

Only one synchronization event occurs per push of the Trigger button.

The 1 PPS will be synchronized to the reference clock rising edge after the incoming

synchronization PPS input when the switch labeled Phase is in the up position. When the

Phase switch is in the down position, the 1 PPS will be synchronized to the reference clock

falling edge that occurred before the incoming synchronization PPS input. It is important to

turn off the synchronization enable switch by moving it to the down position to disable

further inadvertent synchronization events.

6.0 Specifications

Page 8

Rackmount chassis 1U H, 19“ W, 14” D

Storage temperature -10 to +75 ºC

Operation environment 0 to +50 ºC

Humidity 5% to 95% Non-condensing

AC Input Voltage Range 110 to 240 VAC, 8 W, 47-63 Hz

DC Input Voltage Range +12 to +36 VDC, 6 W

Weight 10 lbs.

PARAMETER CONDITIONS MIN TYP MAX UNITS

Rise time 10 - 90 % - 1.5 2 ns

Fall time 10 - 90 % - 1.5 2 ns

Differential delay Channel - Channel - 200 500 ps

Impedance input

output

-

-

50

10

-

-

Ohms

Input High Level

Input Low Level

Input signal into 50

ohm load

Input signal into 50

ohm load

2

-0.7

-

-

5

0.8

V

Output High Level

Output Low Level

50 ohm load

50 ohm load

3

-

4

0.1

5

0.2

V

Input Signal Level 1 MHz, 5 MHz and

10 MHz

0 +7 +13 dBm

External Sync. Error 1 MHz

5 MHz

10 MHz

-

-

-

+/- 500

+/- 100

+/-50

-

-

-

ns

Temperature-delay

Coefficient

0 - 50 ºC -

3

5

ps/ºC

7.0 Warranty and Service

Page 9

WARRANTY

The PPS-2RM-B is warranted to be free of defects under normal operating conditions,

as specified, for one year from date of shipment from SpectraDynamics, Inc (SDI). SDI’s

obligation and liability under this warranty is expressly limited to repairing or replacing, at

SDI’s option, any product not meeting the said specifications. This warranty shall be in

effect for one (1) year from the date a PPS-2RM-B is sold by SDI. SDI makes no other

warranty, express or implied, and makes no warranty of the fitness for any particular

purpose. SDI’s obligation under this warranty shall not include any transportation charges

or costs of installation or any liability for direct, indirect, or consequential damages or

delay. Any improper use, operation beyond capacity, substitution of parts not approved by

SDI, or any alteration or repair by others in such manner as in SDI’s reasonable judgement

affects the product materially and adversely shall void this warranty. No employee or

representative of SDI is authorized to change this warranty in any way or grant any other

warranty.

SERVICE

Do not attempt to service or adjust the instrument unless another person, capable of

providing first aid or resuscitation, is present. Please remember that any alteration or repair

may void the warranty. Contact SDI with any questions or to request an RMA if a repair is

needed.

SpectraDynamics, Inc.

1849 Cherry Street Unit 2.

Louisville, CO 80027

USA

Tel: (303) 665-1852

Fax: (303) 604-6088

www.spectradynamics.com

EC Declaration of Conformity

This Product has been designed and manufactured in accordance with the below

referenced Standards and complies with all essential requirements of the Directives listed

below.

Directives:

2014/35/EU of the European Parliament and of the Council of 26 February 2014 on

the harmonization of the laws of the Member States relating to the making available on the

market of electrical equipment designed for use within certain voltage limits.

2014/30/EU The Electromagnetic Compatibility Directive and its amending directives.

2011/65/EU of the European Parliament and of the Council of 8 June 2011 on the

restriction of the use of certain hazardous substances in electrical and electronic

equipment.

Standards:

EN 55011 2009 + A1: 2010, Product family standard for Industrial, Scientific and

Medical (ISM) equipment.

EN 61010-1:2010 Safety Requirements for Electrical Equipment for Measurement,

Control and Laboratory Use – Part 1: General Requirements

EN 61326-1:2013 Electrical Requirements for Electrical Equipment for Measurement,

Control and Laboratory Use – Part 1: General Requirements

Table of contents

Popular Portable Generator manuals by other brands

WORMS

WORMS ACCESS 3400 Instructions for use

Champion Global Power Equipment

Champion Global Power Equipment 200921 quick start guide

PowerGrip

PowerGrip YG-2 Operation manual

Champion Power Equipment

Champion Power Equipment 200965 quick start guide

Shindaiwa

Shindaiwa DGK20FS Owner's and operator's manual

WARRIOR

WARRIOR 6000S operating manual