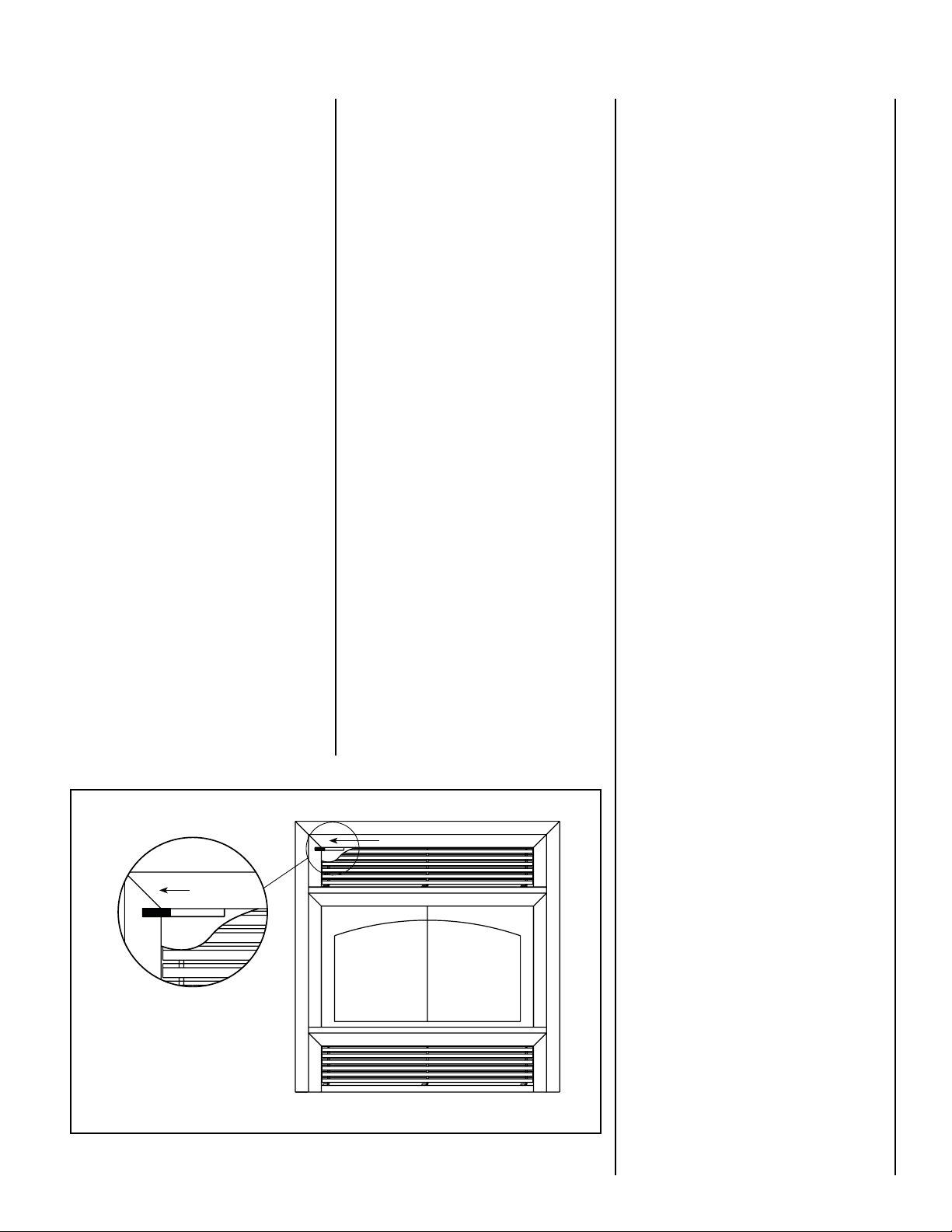

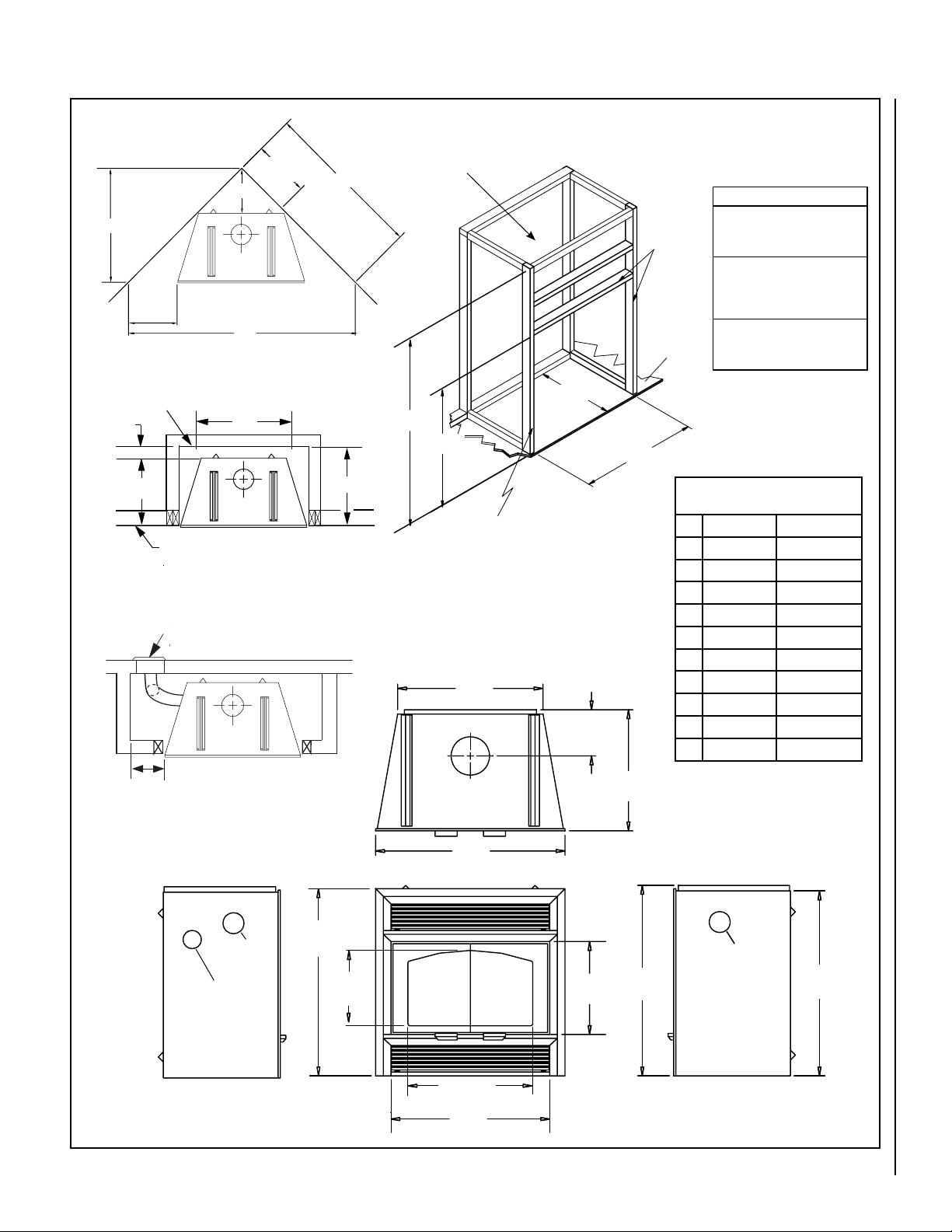

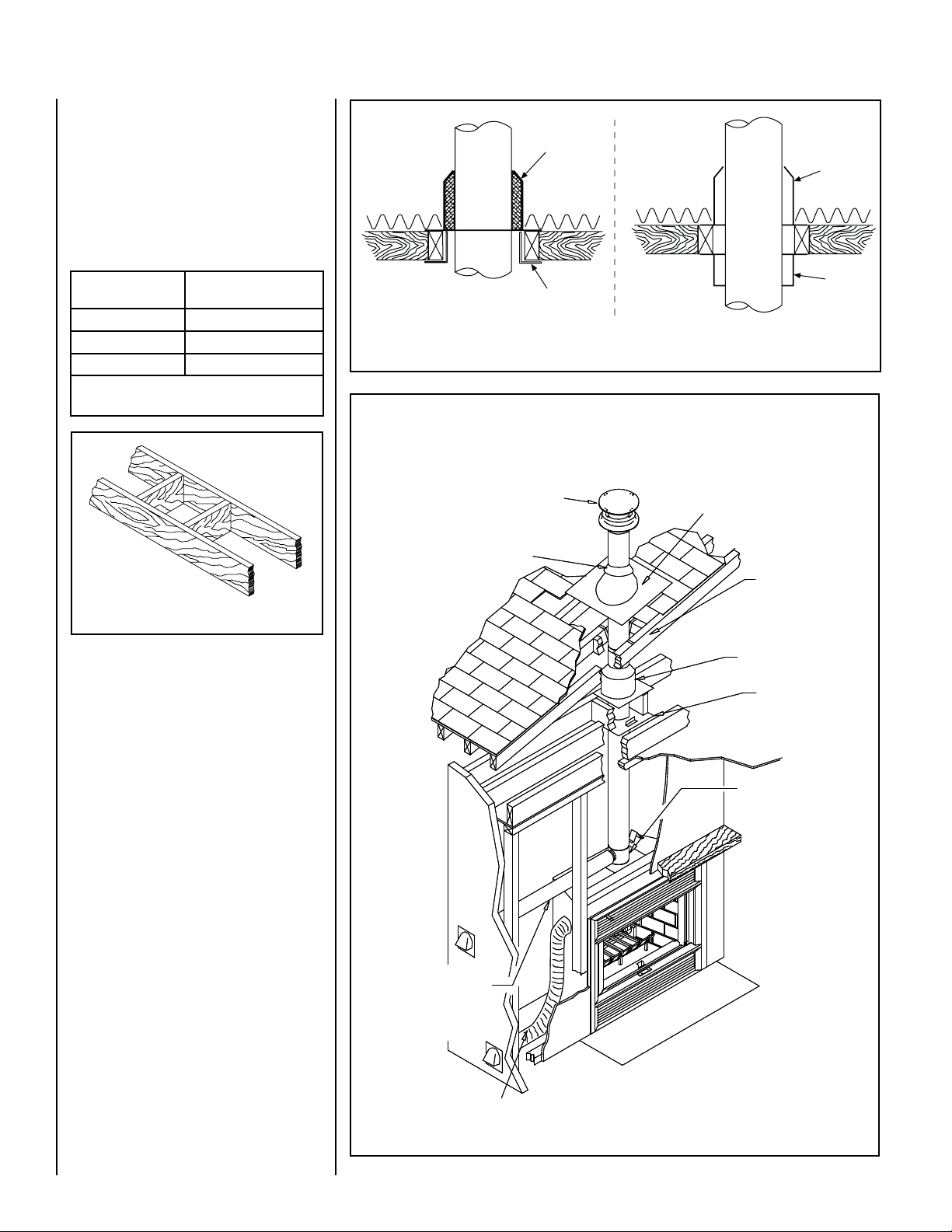

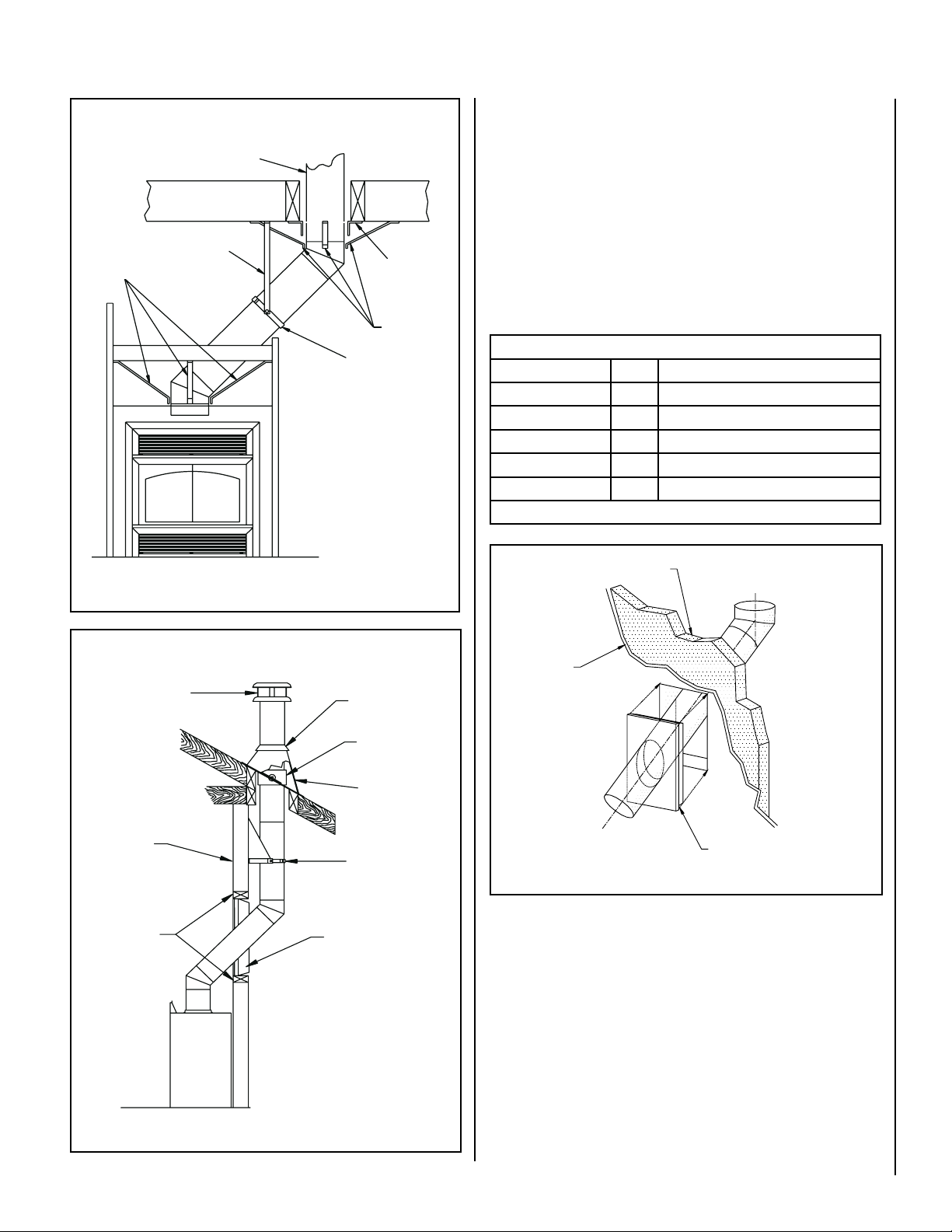

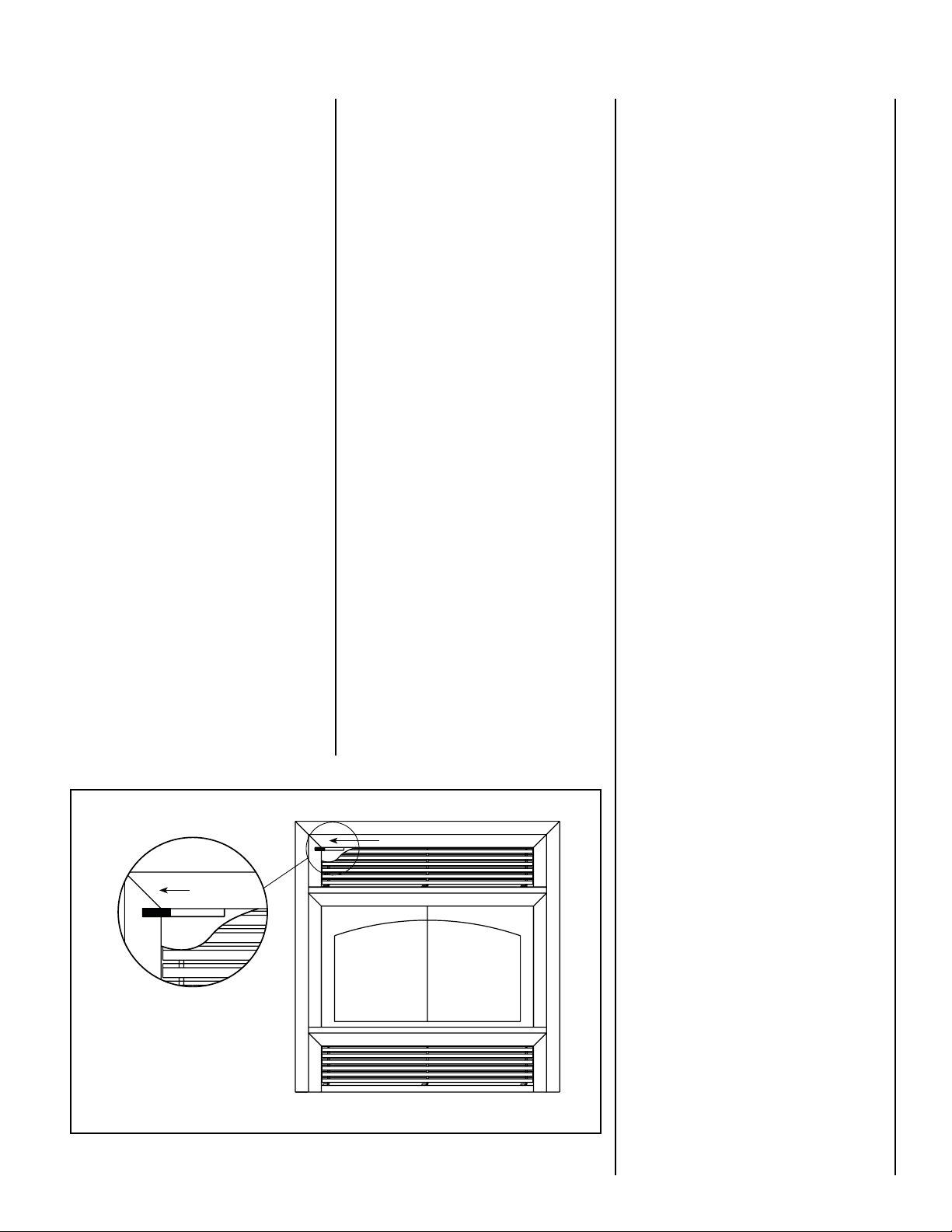

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE. 5

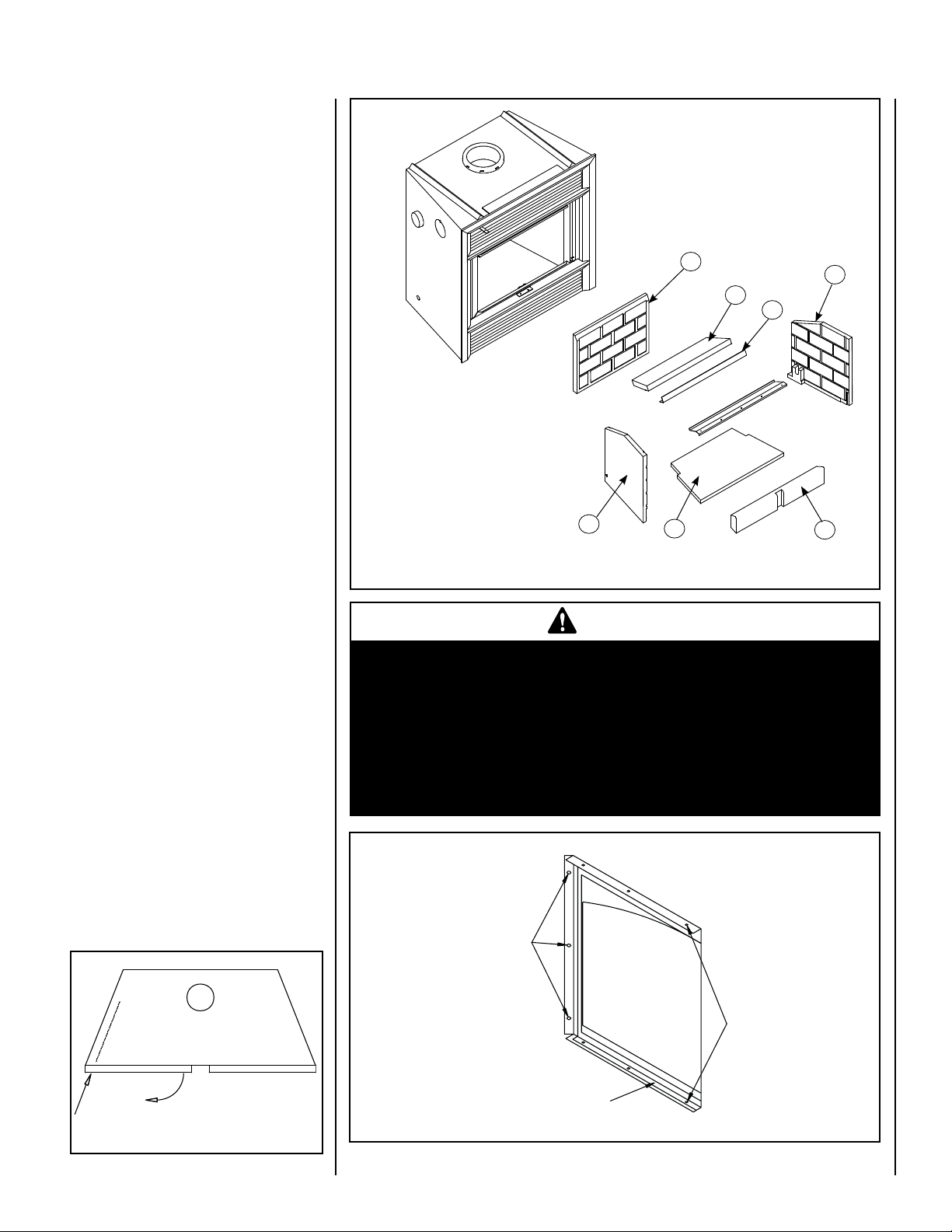

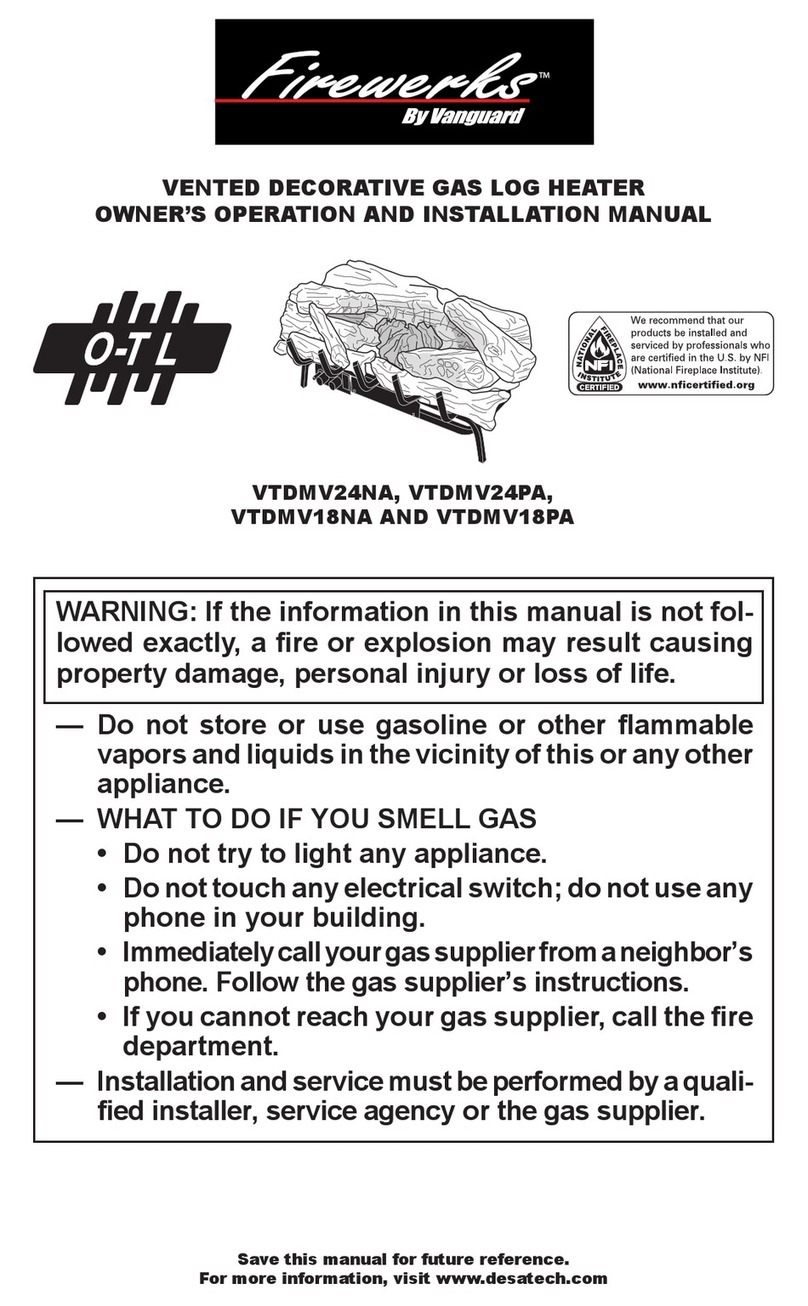

Figure 1 - Outside air Register

D. Wet wood

Wetor tarredwoodwillsmoulderandsmoke

instead of burning properly. Your dealer can

help you determine if you have properly

seasoned wood for burning.

E. Dirty or blocked chimney

Check to make sure the chimney is clear and

clean. If dirty call a certified chimney sweep

or use a properly sized chimney brush to

clean.

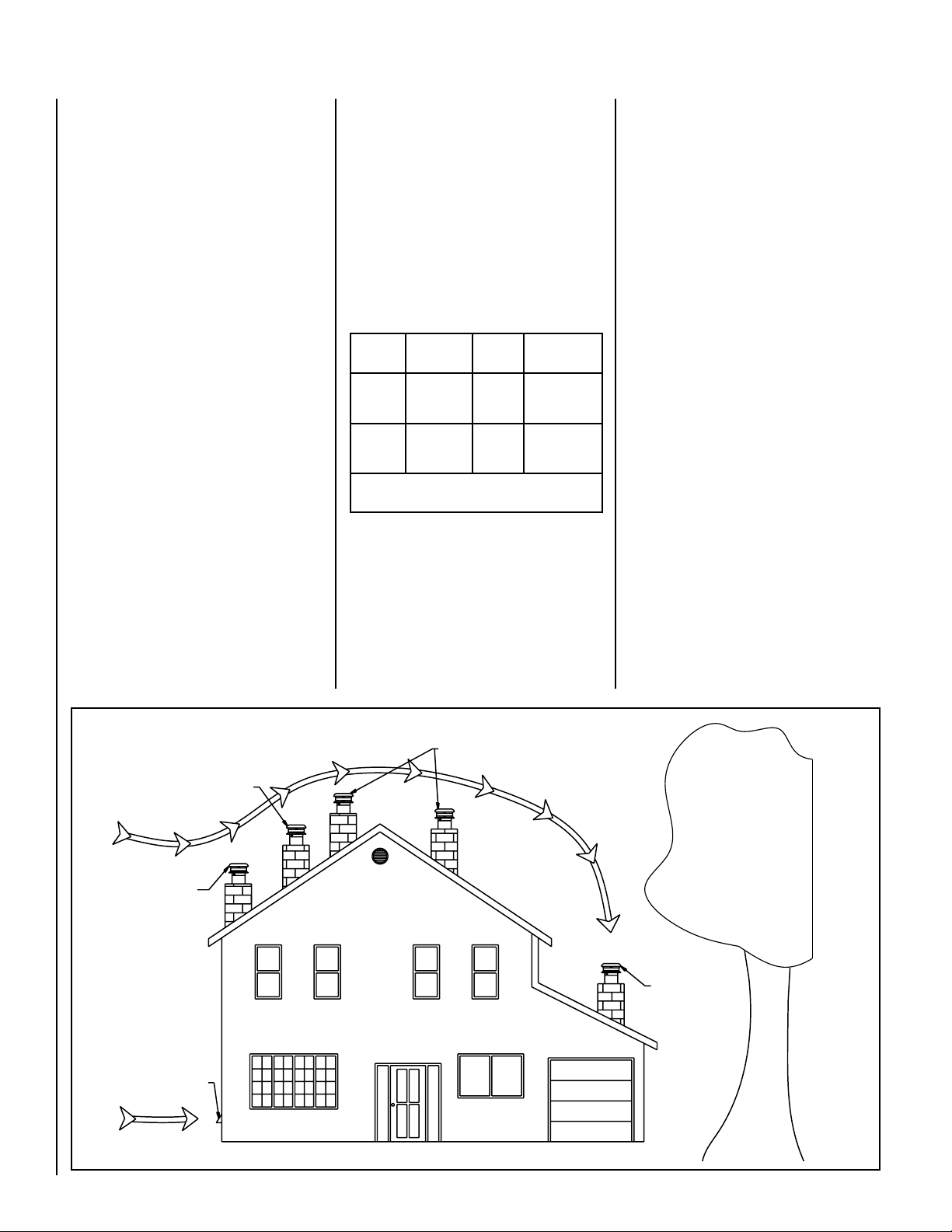

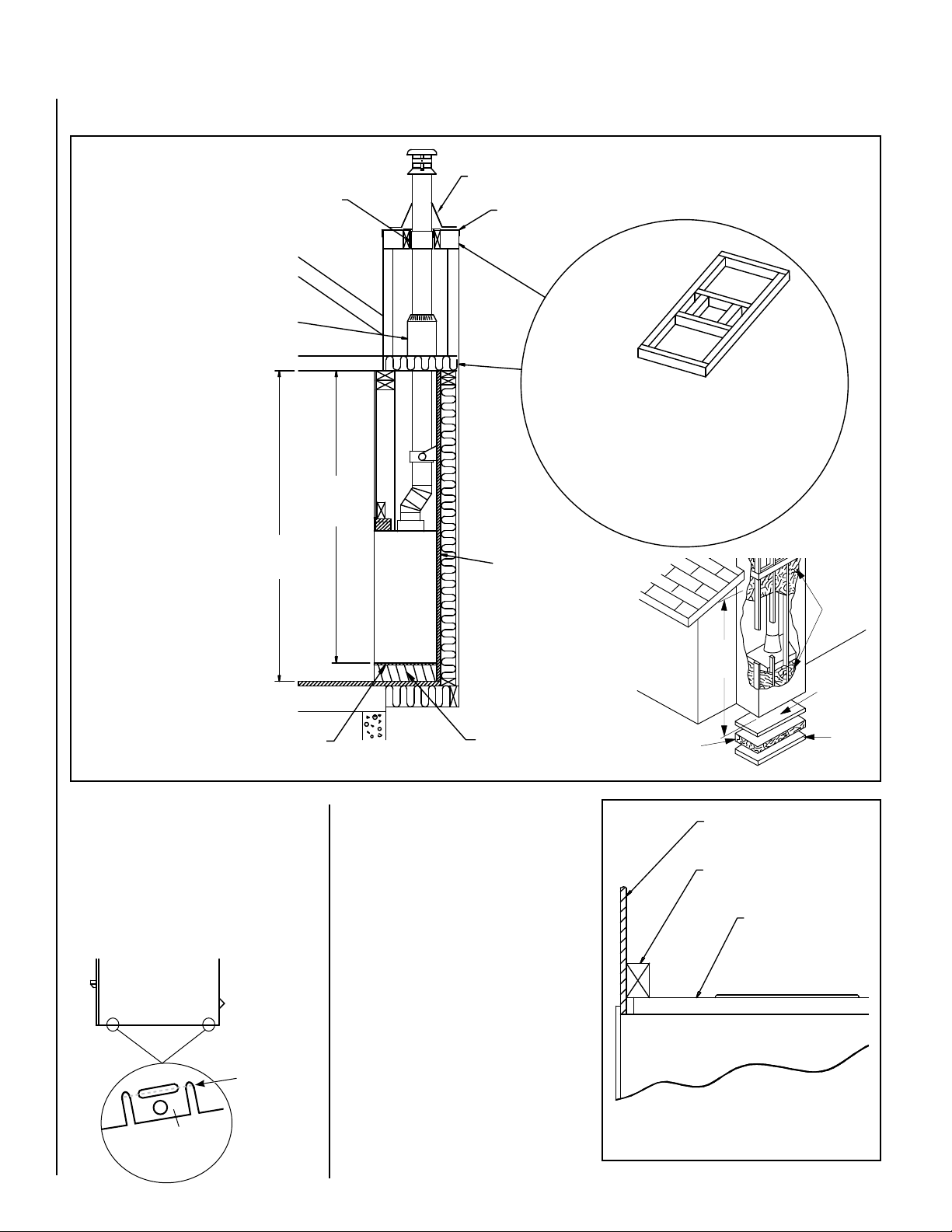

F. Chimney not long enough

The minimum chimney height is twelve (12)

feet(3.7m)notincludingthefireplaceheight.

The chimney must extend at least three (3)

feet (915 mm) above its point of contact

with the roof and at least two (2) feet (610

mm) higher than any roof or wall within ten

(10) feet (3 m) of it. When installed with

one offset, the minimum chimney height

is fifteen (15) feet. Additional height will

increase draftandwilldecreasethe tendency

to smoke.

G. Poor chimney draft

With no fire, there should be sufficient draft

to exhaust cigarette smoke introduced under

the chimney. Chimneys installed against an

outside wall without protection may generate

back draft problems which will cause start-up

problems. To prevent this, open a nearby

window, roll up a piece of paper and light it.

Then, hold it in the upper part of the firebox

to warm up the chimney. Wait until the draft

is sufficient, then start the fire.

IMPORTANT CAUTIONS

A. Donotblockthehotairvents tothefireplace

as this will cause the fireplace to overheat.

B. Never use gasoline, gasoline-type lantern

fuel, kerosene, charcoal lighter fluid, or

similar liquids to start or ‘freshen up’ a fire

in this fireplace. Keep all such liquids well

away from the fireplace while it is in use.

C. Do not burn coal. The sulphur in coal will

corrode the firebox and chimney.

D. Keep combustible materials at least 48”

(1.2 m) away from the front of the fireplace

opening.

E. Never leave children unattended when

there is a fire burning in the fireplace.

F. Do not use the HE43-2 as an incinerator

to burn paper, cardboard or construction

material such as pressed wood, plywood

or lumber. Use only untreated wood. Wood

protectors, metallic paper, coal, plastic,

waste, beach wood, Christmas tree, sul-

phur and/or oil will damage the fireplace.

G. Donotburndriftwood whichhasbeenin the

ocean or salt water. The salt will corrode

the firebox and chimney.

H. Do not burn wood in the area in front of

the log retainer.

I. Do not allow the wood to smoulder or burn

without flame, since this will produce

excessive creosote in the unit as well as

increased particulate emissions.

Push to open

Push to open

HOWTOUSETHEOUTSIDEAIRREGISTER

(FIREPLACE)

The outside air register is located on the up-

per left part of the top louver. The outside air

register supplies oxygen to the fire and allows

control of the fire when the doors are closed.

The fresh air must come from outside the house

(the air intake must not draw air from inside the

house). This will minimize negative pressure in

the house. The more you slide the register to

the left, the more fresh air into the firebox and

the more accelerated combustion you will get

(see Figure 1). When starting a fire, the register

should always be fully opened.

Forinformationonwhenyoushouldstartclosing

the register, see "Refueling" section.

REFUELING

The HE43-2 fireplace will operate best if at-

tention is given to operating the unit with the

outside air register fully opened (see Figure

1)after refueling in order to bring the firebox

and the chimney system up to their optimum

operating temperature. Combustion efficiency

is relative to firebox temperature. To obtain this

temperature, the fireplace must be operated

with the primary air fully opened during 10 to

20 minutes after reloading, depending on the

heat and on the moisture content of the wood.

Onceyouhavereached the desiredtemperature,

the outside air register control can be set to a

medium setting. The benefit of this technique

will be cleaner glass, less creosoting, greater

efficiency and the most pleasing fire for your

enjoyment.

Settheairregistertothefullopenpositionbefore

opening the doors to reduce the possibility of

smoke entering the home from the fireplace.

CLOSING THE DOORS

As soon as a layer of embers covers the surface

under the log retainer, it is possible to close

the doors with the outside air register opened.

Closing the doors prematurely may result in:

• Thereboxllingwithsmoke;

• Theameintensitycutsdownexcessively.

Meaning the fireplace is not hot enough to

close the doors.

SMOKING –

CAUSES AND TROUBLESHOOTING

To reduce the likelihood of smoking when

opening the door, set the outside air register to

the left before opening the door. Your fireplace

has been designed and tested to provide smoke

free operation. Occasionally, there may be a

small amount of smoking upon lighting the fire,

until the chimney heats up but this should not

continue. If the fireplace continues to smoke

it is probably for one of the following reasons:

A. The doors are partially opened

When you open the doors, open them

completely.

B. Negative pressure in the house

As the fire burns, air goes up the chimney.

This air must be replaced through leakage

into the house or through the outside air

duct. When operating the HE43-2 fireplace,

open a nearby window temporarily to check

if there is adequate replacement air supply.

C. Fans operating (e.g.: range hood)

Fans such as range hoods or bath fans draw

air out of the house and may actually cause

a negative pressure in the house. Turn off all

fansandopena nearbywindowtodetermine

if this is the cause of the problem.