5

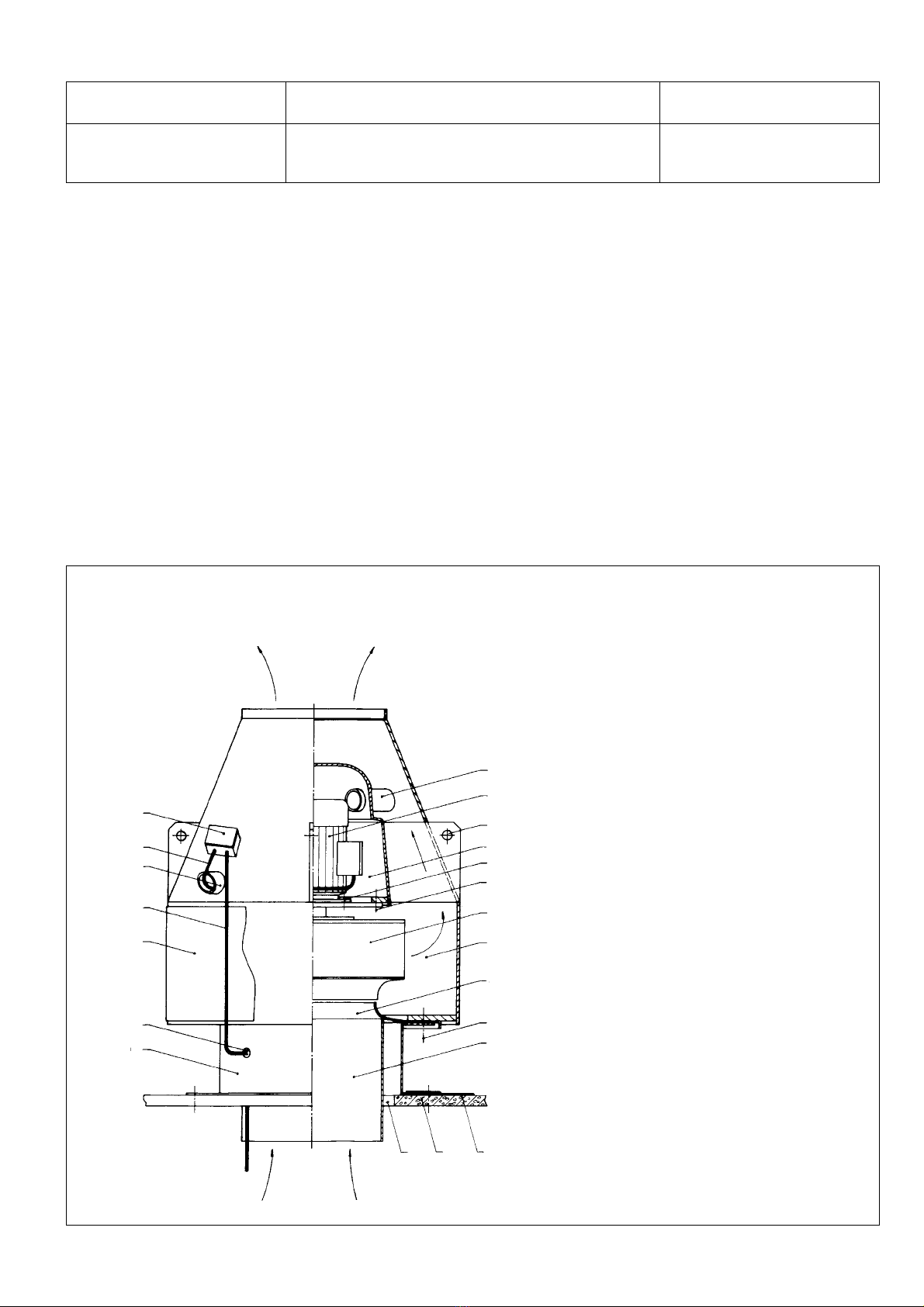

housing are ready wired before the fans are

dispatched.

• The supply to the fan terminal box must be laid be-

tween liner and roof mount and sealed at the wall

penetration by means of a heavy-gauge moisture-proof

union.

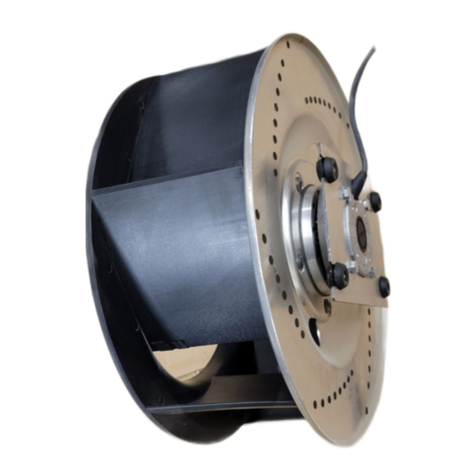

6. Drive

• As standard, the centrifugal roof fans are driven by three-

phase a.c. motors to IEC recommendation, type of

enclosure IP54 or EExe, design B5.

If required, motors for other voltages and frequencies,

pole-reversing or also variable-speed motors are used.

• The centrifugal roof fans are in principle supplied with

the drive motor fitted. The test run after final installation

confirms the performance and operational safety of the

fan.

• If the motor is installed by the customer, the manu-

facturer’s product liability does not apply.

7. Installation of the motors

• When installing the electrical wiring for the motors and

any necessary switchgear, the VDE (German electrical

engineers’ association) regulations and the motor

manufacturer’s instructions must be observed.

• The installation is made according to the wiring diagram

contained in the terminal box and must only be carried

out by appropriately qualified technical personnel.

Check voltage, rpm and direction of rotation. Direction

of rotation of the motor must conform to the rotation

symbol on the fan enclosure.

• When using pole-reversing motors, a further change

from high to low speed must be provided. The delayed

switching must be bumpless.

• A motor protection facility must be provided on principle.

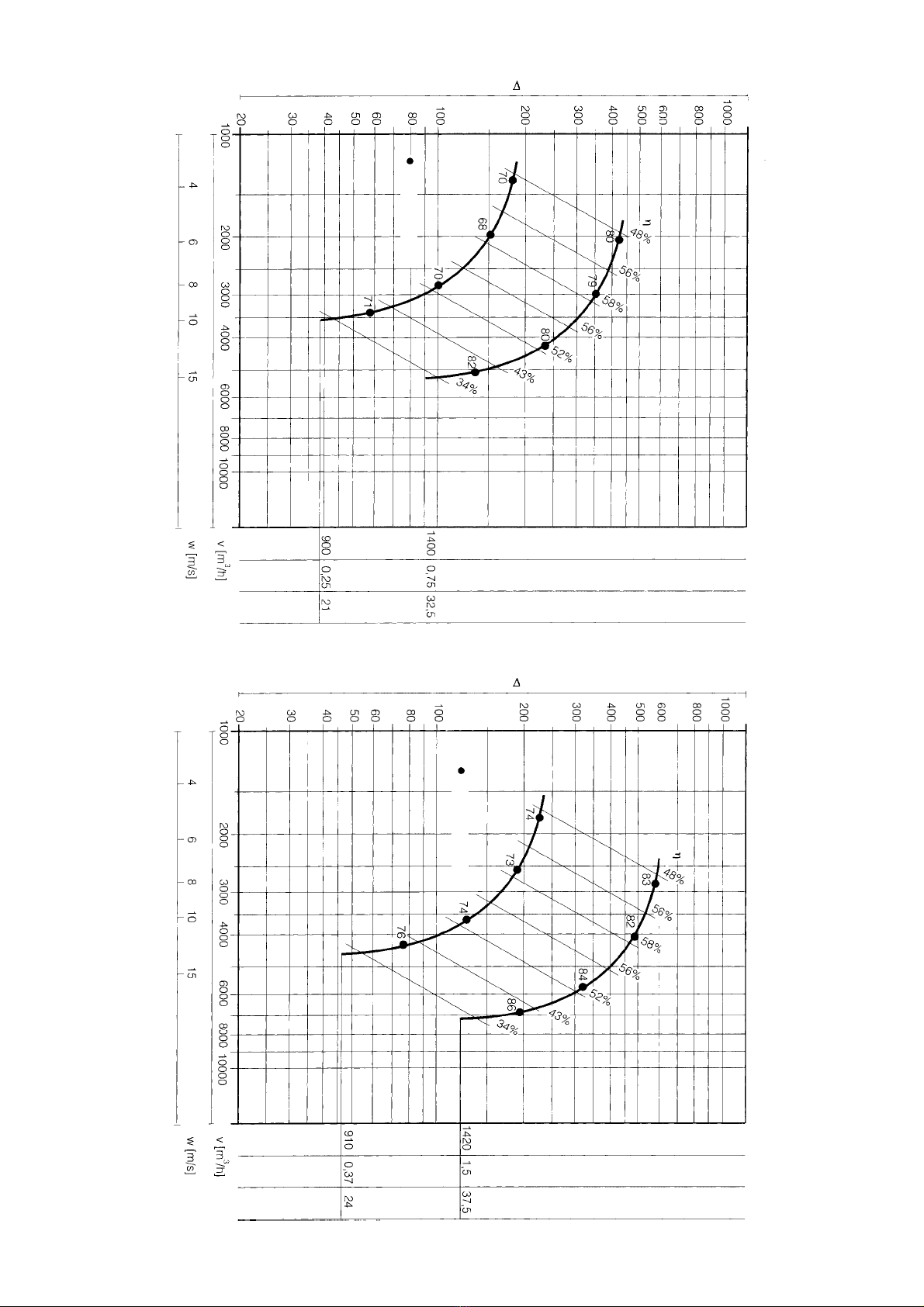

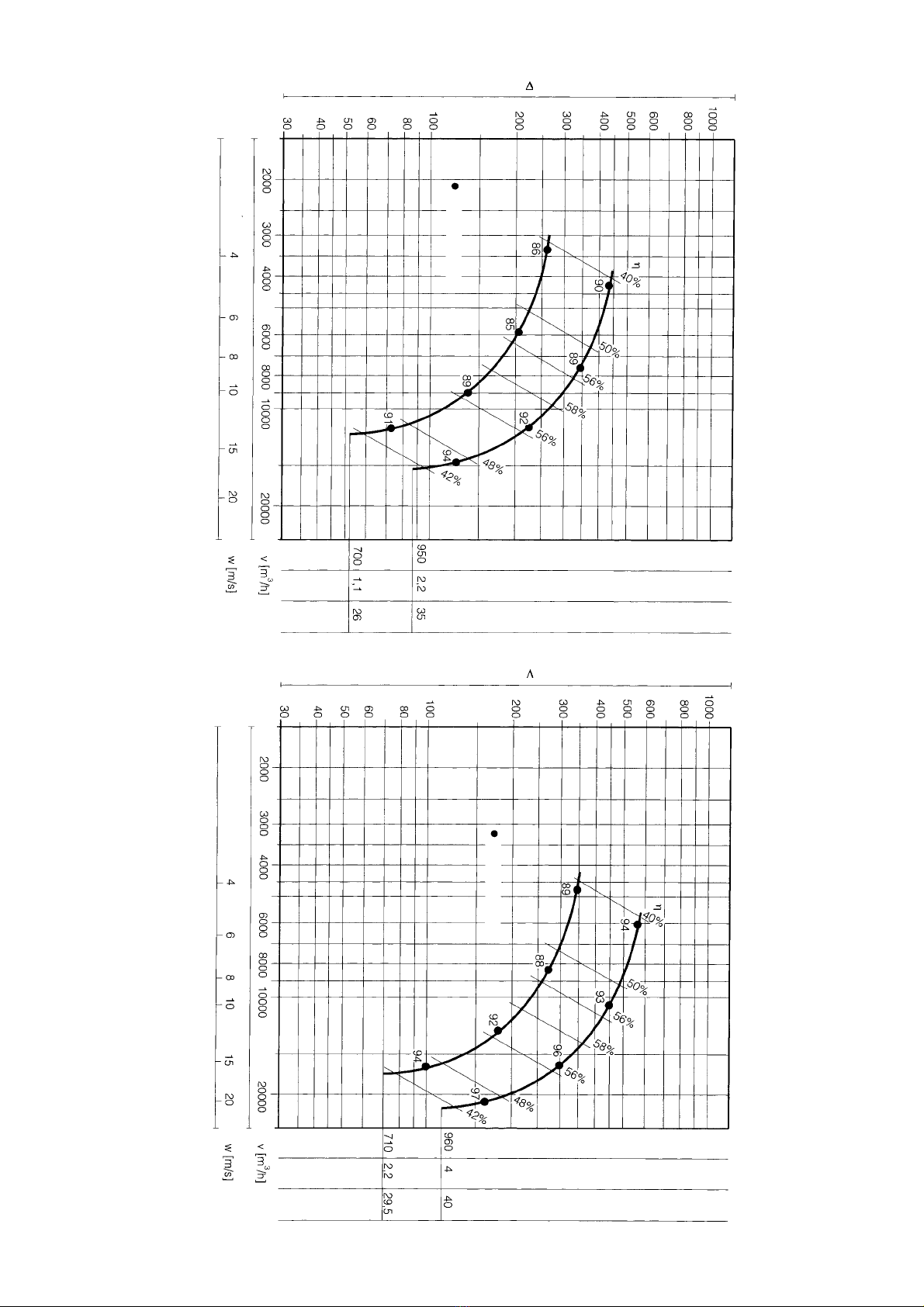

If the fans are installed in positions where the temperature

of the cooling air exceeds 40oC, a performance reduction

of the motors must be taken into account. Values are

shown in the catalogues of the motor manufacturers.

8. Commissioning

Commissioning and operation of the fans must only be

carried out by appropriately trained persons who are familiar

with the applicable operating and safety regulations. After

installation of the fan and connection of the suction-side duct

system as in Item 5, the following must be checked or carried

out:

• All visible screw connections must be checked for

tightness.

• Protective devices must be checked for proper attach-

ment (casing splinter protection, with open-inlet fans

intake protection grille).

• Check motor venting hoses and the condensate drain

bore in the housing base for clear passage.

• Foreign bodies (forgotten tools or installation material

etc.) must be removed from the internal spaces of the

fan and from the upstream ducts and assemblies.

• All possibly existing regulating elements (gate valves,

butterfly valves) must be sufficiently closed before

starting so that only approx. 10% of the cross-section

remains open.

When starting the fan, proceed as follows:

• Expel unauthorized personnel from the fan area!

• Switch on the main switch and the motor switch (note

permissible motor starting frequency).

• After nominal speed has been reached, open any control

elements until the required working point establishes

itself.

After starting, pay special attention to:

• Power input of the motor

• Quiet running of the fan.

After 12 hours of operation, check all visible screw

connections for firm seating and retighten if necessary.

Issued: PA S Operating manual No. 28.95.103 Valid from: Serial No. 29956

Date: 01.03.2001 Plastic Radial Roof Mounted Fans

SDR 63 Sizes 355-710