Shivvers BLUE FLAME II FH1527C1P240LP Manual

P-13246

01-07-2020

BLUE FLAME II

CROP DRYER FOR SINGLE WIDTH,

SINGLE INLET CENTRIFUGAL FANS

Installation &

Operating Instructions

For Models:

FH1527C1P240LP -- 15 Hp, 1 Phase, 240V, LP, CSA W/ CONTROLS

FH1527C1P240NG -- 15 Hp, 1 Phase, 240V, NG, CSA W/ CONTROLS

FH1527-1P240LP-CSA -- 15 Hp, 1 Phase, 240V, LP, CSA

FH1527-1P240NG-CSA -- 15 Hp, 1 Phase, 240V, NG, CSA

FH1527-3P230LP-CSA -- 15 Hp, 3 Phase, 230V, LP, CSA

FH1527-3P230NG-CSA -- 15 Hp, 3 Phase, 230V, NG, CSA

FH1527-3P460LP-CSA -- 15 Hp, 3 Phase, 460V, LP, CSA

FH1527-3P460NG-CSA -- 15 Hp, 3 Phase, 460V, NG, CSA

FH1527-3P575LP-CSA -- 15 Hp, 3 Phase, 575V, LP, CSA

FH1527-3P575NG-CSA -- 15 Hp, 3 Phase, 575V, NG, CSA

FH2030-3P230LP-CSA -- 20 Hp, 3 Phase, 230V, LP, CSA

FH2030-3P230NG-CSA -- 20 Hp, 3 Phase, 230V, NG, CSA

FH2030-3P460LP-CSA -- 20 Hp, 3 Phase, 460V, LP, CSA

FH2030-3P460NG-CSA -- 20 Hp, 3 Phase, 460V, NG, CSA

FH2030-3P575LP-CSA -- 20 Hp, 3 Phase, 575V, LP, CSA

FH2030-3P575NG-CSA -- 20 Hp, 3 Phase, 575V, NG, CSA

For outdoor installation only.

Use heated air for non-occupied spaces only.

Shivvers Manufacturing, Inc.

614 West English St.

Corydon, IA 50060 USA

Ph. (641)872-1005 ** Fax (641)872-1593

2

www.shivvers.com

WARNING: Improper installation, adjustment, alteration,

service or maintenance can cause property damage, injury or death.

Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

WARNING: If the information in this manual is not followed exactly,

a fire or explosion may result causing property damage, personal

injury or loss of life.

-Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

-WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Extinguish any open flames.

• Do not touch any electrical switch.

• Immediately call your gas supplier. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier, call the

fire department.

-Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

FOR YOUR SAFETY

The use and storage of gasoline and other flammable vapors and

liquids in open containers in the vicinity of this appliance is hazardous.

3

TABLE OF CONTENTS

PAGE

DEALER INFORMATION ........................……………………………………. 4

INTRODUCTION .....................................…………………………………….……. 5-6

SAFETY INFORMATION ..................................…………………………….…….. 7-8

LOCATION OF SAFETY DECALS ON CROP DRYER ...……………….………. 9-10

LOCATION OF OTHER DECALS ON CROP DRYER ……………………..……. 11-15

IDENTIFICATION OF PARTS ..............................………………………….…….. 16-22

MECHANICAL INSTALLATION …………………………………………………… 23-39

DRYING BIN LAYOUT ………………………………………………………. 24

PAD LAYOUT ………………………………………………………………... 25-26

HEATER INSTALLATION ………………………………………………..…. 27-30

FAN INSTALLATION …………………………………………………..……. 31

FAN CONTROL INSTALLATION …………..….………………………..…. 31

OPERATING CONTROL & TRANSITION HI LIMIT INSTALLATION … 32-36

LIQUID PROPANE INSTALLATION AND GAS HOOKUP …………..… 37-38

NATURAL GAS INSTALLATION AND GAS HOOKUP…..…………..… 39

PAINT …………………….……………..…………………………..………… 39

ELECTRICAL INSTALLATION ………………………………………..…………… 40-48

INCOMING FAN POWER HOOKUP ………………………………...……. 40-41

15 HP C-FAN 1 PHASE WITH VFD INCOMING POWER WIRING…….. 41

OTHER C-FAN INCOMING POWER WIRING ………………………..……. 42

OTHER C-FAN WIRING FROM CONTROL TO MOTOR…………..……. 42

15 HP C-FAN WIRING FROM DRIVE TO MOTOR……………………….. 43

FIELD INSTALLED CONTROL WIRING …………………………….……. 44

TYPICAL FIELD INSTALLED CONTROL WIRING CONDUIT RUNS…. 45

CONTROL WIRING FOR FAN CONTROL PANEL ON BACK OF FAN.. 46-47

INITIAL CHECKOUT ……………………………………………………..….. 48

OPERATING INSTRUCTIONS ………………………………………………………. 49-52

MAINTENANCE ...............................……………………………………………….. 53

OPERATING CONTROL SCHEMATIC ……………………………………………... 54

LP HEATER SCHEMATIC…………………………………………………………….. 55

FAN CONTROL SCHEMATIC …………………….………………………………….. 56

FAN VFD CONTROL SCHEMATIC …………………….………………...………….. 57

4

DEALER INFORMATION

DEALER

Name:

Address:

Phone #:

INSTALLING CONTRACTOR (if different from above)

Name:

Address:

Phone #:

SERVICE CONTRACTOR (if different from above)

Name:

Address:

Phone #:

MODEL: □ FH1527C1P240LP □ FH1527C1P240NG

□ FH1527-1P240LP-CSA □ FH1527-1P240NG-CSA

□ FH1527-3P230LP-CSA □ FH1527-3P230NG-CSA

□ FH1527-3P460LP-CSA □ FH1527-3P460NG-CSA

□ FH1527-3P575LP-CSA □ FH1527-3P575NG-CSA

□ FH2030-3P230LP-CSA □ FH2030-3P230NG-CSA

□ FH2030-3P460LP-CSA □ FH2030-3P460NG-CSA

□ FH2030-3P575LP-CSA □ FH2030-3P575NG-CSA

SERIAL NUMBER:

DATE OF INSTALLATION:

5

INTRODUCTION

COMPLETELY READ THIS MANUAL BEFORE INSTALLING OR USING THE BLUE

FLAME II CROP DRYER (FAN AND HEATER), CSA Version.

This manual is intended for use with the Shivvers 15 or 20 Hp Blue Flame II Crop Dryer

which is CSA (Canadian Standards Association) certified. The Crop Dryer consists of a

Blue Flame II heater connected to a Shivvers 15 or 20 Hp Centrifugal Fan. The heater

may not be used with any other manufacturer’s centrifugal fan. The complete crop

dryer is shipped in three or four separate pieces which must be installed and wired

together at the installation site.

FH1527C1P240LP

118X-001A 15 Hp C-Fan

119M-001A BFII Heater, LP, 15 Hp, CSA

119N-001A Op. Control & H.L.

E-6617 Freq. Drive, 240V,1P

FH1527-1P240LP-CSA

118Y-001A 15 Hp C-Fan, 1 Phase

119M-001A BFII Heater, LP, 15 Hp, CSA

119N-001A Op. Control & H.L.

FH1527-3P230LP-CSA

118X-001A 15 Hp C-Fan

119M-001A BFII Heater, LP, 15 Hp, CSA

119N-001A Op. Control & H.L.

FH1527-3P460LP-CSA

118X-001A 15 Hp C-Fan

119M-001A BFII Heater, LP, 15 Hp, CSA

119N-001A Op. Control & H.L.

FH1527-3P575LP-CSA

118Z-001A 15 Hp C-Fan, 575V

119M-001A BFII Heater, LP, 15 Hp, CSA

119N-001A Op. Control & H.L.

FH2030-3P230LP-CSA

118AA-001A 20 Hp C-Fan

119P-001A BFII Heater, LP, 20 Hp, CSA

119N-001A Op. Control & H.L.

FH2030-3P460LP-CSA

118AA-001A 20 Hp C-Fan

119P-001A BFII Heater, LP, 20 Hp, CSA

119N-001A Op. Control & H.L.

FH1527C1P240NG

118X-001A 15 Hp C-Fan

119Q-001A BFII Heater, NG, 15 Hp, CSA

119N-001A Op. Control & H.L.

E-6617 Freq. Drive, 240V,1P

FH1527-1P240NG-CSA

118Y-001A 15 Hp C-Fan, 1 Phase

119Q-001A BFII Heater, NG, 15 Hp, CSA

119N-001A Op. Control & H.L.

FH1527-3P230NG-CSA

118X-001A 15 Hp C-Fan

119Q-001A BFII Heater, NG, 15 Hp, CSA

119N-001A Op. Control & H.L.

FH1527-3P460NG-CSA

118X-001A 15 Hp C-Fan

119Q-001A BFII Heater, NG, 15 Hp, CSA

119N-001A Op. Control & H.L.

FH1527-3P575NG-CSA

118Z-001A 15 Hp C-Fan, 575V

119Q-001A BFII Heater, NG, 15 Hp, CSA

119N-001A Op. Control & H.L.

FH2030-3P230NG-CSA

118AA-001A 20 Hp C-Fan

119R-001A BFII Heater, NG, 20 Hp, CSA

119N-001A Op. Control & H.L.

FH2030-3P460NG-CSA

118AA-001A 20 Hp C-Fan

119R-001A BFII Heater, NG, 20 Hp, CSA

119N-001A Op. Control & H.L.

6

FH2030-3P575LP-CSA

118AB-001A 20 Hp C-Fan, 575V

119P-001A BFII Heater, LP, 20 Hp, CSA

119N-001A Op. Control & H.L.

FH2030-3P575NG-CSA

118AB-001A 20 Hp C-Fan, 575V

119R-001A BFII Heater, NG, 20 Hp, CSA

119N-001A Op. Control & H.L.

For best results and ease of installation and service, the Shivvers 565D-001A Transition

and 74C-001A or 74D-001A Entrance Collars are recommended.

The Blue Flame II heaters provide from approx. 0.75 million to 3.6 million BTU/Hr of

heat utilizing Liquid Propane or Natural Gas fuel. This heater would not normally be

considered a low temperature rise heater for applications such as drying rice. The LP

Heater is equipped with a built in vaporizer. The pipe train is configured in a hi-low-off

configuration for a wide temperature operating range. A 3-wire thermostat system is

included to control the heater.

This series of Blue Flame II heaters are similar to the centrifugal heaters manufactured

by Shivvers in the past. These dryers use a flame sensing system called flame

rectification. There are no moving parts in the flame rod. It just has to be in the flame

but not touching the burner element or housing. The flame sense module will apply an

AC current to the flame rod. If a flame is present, the flame will rectify or change it to a

DC current. If the flame sense module detects this DC current, it will turn off the ignition

transformer and the burner will continue to burn. If the DC current is not detected, the

flame sense module will lockout the burner, and the heater power switch will have to be

shut off for a few seconds, then turned back on and re-started, to reset the module.

The Blue Flame II Crop Dryers, CSA versions, were first introduced in the fall of 2015.

Additional models were added in 2019.

The equipment shall be installed in accordance with the Natural Gas and Propane

Installation Code, CSA B149.1 and the Propane Storage and Handling Code, CSA

B149.2, or applicable Provincial Regulations, which should be carefully followed in all

cases. Authorities having jurisdiction should be consulted before installations are made.

7

SAFETY INFORMATION

The operator of this machinery must assume the responsibility for his own safety, and

that of those who are working with him. He must also make sure the equipment was

installed properly. Factors that contribute to the overall safety of operation are: proper

use, maintenance, and frequent inspection of the equipment. All of these are the

operator's responsibility.

If any items covered in this manual are not completely understood, or there is a concern

with the safety of the product, contact SHIVVERS Manufacturing Incorporated at the

address shown on the front cover.

SHIVVERS is genuinely interested in providing the safest practical equipment to our

customers. If you have a suggestion which you believe will enhance the safety of this

product, please write us and let us know.

The safety alert symbol will be accompanied by one of three signal words whose

definitions are given as:

DANGER: Red and white. Indicates an imminently hazardous situation that, if not

avoided, will result in death or serious injury. This signal word is to be

limited to the most extreme situations, typically for machine components

that, for functional purposes, cannot be guarded.

WARNING: Orange and black. Indicates a potentially hazardous situation that, if not

avoided, could result in death or serious injury, and includes hazards that

are exposed when guards are removed. It may also be used to alert

against unsafe practices.

CAUTION: Yellow and black. Indicates a potentially hazardous situation that, if not

avoided, may result in minor or moderate injury. It may also be used to

alert against unsafe practices.

TAKE NOTE ANYTIME THIS SAFETY ALERT

SYMBOL APPEARS.

YOUR SAFETY, AND THAT OF PERSONS AROUND

YOU IS AT STAKE.

8

Be sure to observe these common sense rules when working with the dryer equipment:

1). All units must be equipped with a main power disconnect switch. This disconnect

switch must shut power off to the complete drying system. It must have the

capability of being locked into the OFF or OUT position. Disconnect and LOCK

OUT this main power disconnect switch before conducting any inspection,

maintenance, repair, adjustment, or cleaning of the drying system. When you

must have the electrical power on to troubleshoot equipment, do it from a safe

distance, and always from outside the bin.

2). Keep the bin entrances locked at all times. To unlock the bin, first lower the

Level-Dry (if so equipped), then shut the main power disconnect off. Take the

safety lock off the bin entrance and place it on the main power disconnect before

opening the bin entrance. Never enter the drying bin unless the Level-Dry (if

so equipped), is completely lowered, and all power is disconnected and

locked out.

3). Always keep all shields and guards in place. If shields or guards must be

removed for inspection or maintenance, replace them before unlocking and

turning the power back on.

4). Be sure everyone is clear of all the drying and transferring equipment, and

outside of all bins, before unlocking and turning the power on. Some equipment

may run upon re-application of power.

5). Make sure that all decals are in place and are easy to read. Do not operate the

equipment with missing or illegible decals. If replacements are needed, contact

SHIVVERS Manufacturing Incorporated or your dealer.

6). Prior to use, inspect all equipment to insure that it is in good operating condition.

Do not operate with missing, damaged, or worn parts. Use only SHIVVERS

approved replacement parts.

7). Metal edges can be sharp. Wear protective clothing and handle equipment and

parts with care.

8). Keep children and bystanders away from drying and transferring equipment at all

times.

9). If going up the bin ladder and/or performing maintenance on the top of the bin,

take precautions to prevent accidental falls. When on top of the bin, wear a

safety harness or other safety device.

10). At least annually, review all operating and safety manuals with any personnel

working with this equipment. Always train new employees before they operate

the drying equipment. Insist that they read and understand the operating and

safety manuals.

9

LOCATION OF SAFETY DECALS ON CROP DRYER

This manual shows the location of safety decals that apply to the Blue Flame II Crop

Dryer.

LOCATION OF SAFETY DECALS ON FAN

LOCATION OF SAFETY DECALS ON FREQUENCY DRIVE (if used)

P-10221 (QTY 1)

DECAL, WARNING,

ROTATING BLADES

10

LOCATION OF SAFETY DECALS ON HEATER

P-11146 (QTY 1)

DECAL, DANGER,

ELECTROCUTION

HAZARD

P-11157 (QTY 1)

DECAL, CAUTION,

HOT SURFACES

P-10367 (QTY 1)

DECAL, WARNING,

READ MANUAL

11

LOCATION OF OTHER DECALS ON CROP DRYER

LOCATION OF OTHER DECALS ON HEATER

P-13234 (QTY 1)

DECAL, CROP

DRYER, CSA

P-13236 (QTY 2, ONE

ON OTHER SIDE, ON

ACCESS DOOR)

DECAL, FLAMMABLE

LIQUIDS

12

LOCATION OF OTHER DECALS ON CROP DRYER

PRESSURE RATINGS DECAL, MODEL SPECIFIC

P-13239 (QTY 1)

FOR 15 HP LP

UNITS

P-13440 (QTY 1)

FOR 20 HP LP

UNITS

P-13441 (QTY 1)

FOR 15 HP NG

UNITS

P-13442 (QTY 1)

FOR 20 HP NG

UNITS

OR

OR OR

13

LOCATION OF OTHER DECALS ON CROP DRYER

RATINGS, SERIAL TAG DECAL, MODEL SPECIFIC

P-13243 (QTY 1)

FOR 15 HP LP

UNITS

P-13443 (QTY 1)

FOR 15 HP NG

UNITS

P-13444 (QTY 1)

FOR 20 HP LP

UNITS

P-13445 (QTY 1)

FOR 20 HP NG

UNITS

OR

OR OR

14

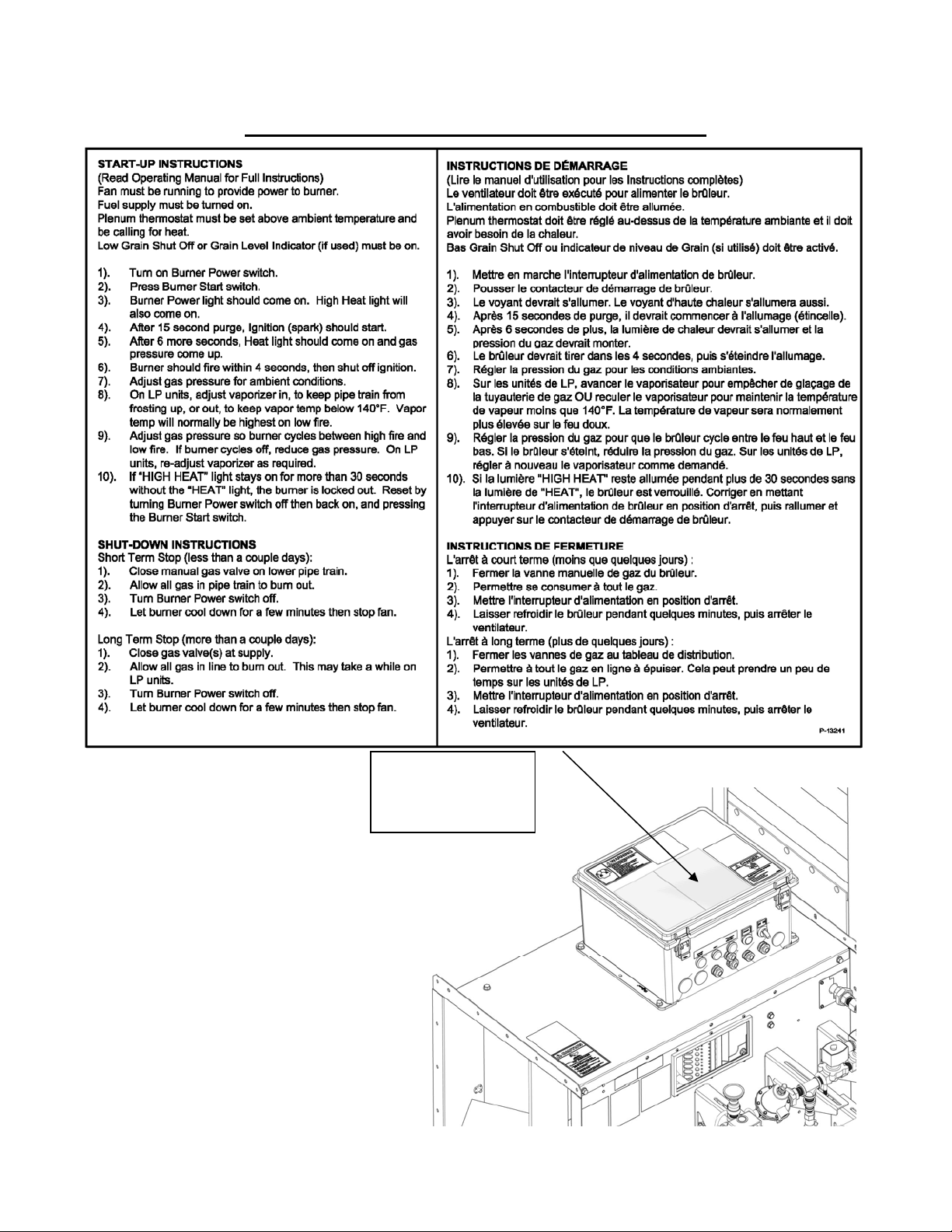

LOCATION OF OTHER DECALS ON HEATER

P-13241 (QTY 1)

DECAL, START-UP

INSTRUCTIONS

ENGLISH/FRENCH

15

LOCATION OF OTHER DECALS ON HEATER

LOCATION OF OTHER DECALS ON FAN

P-8875 (QTY 1)

DECAL, DIRECTION

OF ROTATION, CCW

P-13227 (QTY 1)

DECAL,

VAPORIZER HI-

LIMIT (LP ONLY)

16

IDENTIFICATION OF PARTS

Refer to other installed equipment manuals for a complete understanding of the total

drying and grain handling system.

FAN

118X-001A, 118Y-001A, OR 118Z-001A (15 HP)

118AA-001A OR 118AB-001A (20 HP)

LIFT BRACKET

689-091P (15 HP

AND 20HP)

MOTOR, 15 HP 3

PHASE

M-5387 (118X-001A)

MOTOR, 15 HP

1 PHASE

M-5411 (118Y-001A)

MOTOR, 15 HP 3

PHASE, 575V

M-5422 (118Z-001A)

MOTOR, 20 HP 3

PHASE, 230/460V

M-5423 (118AA-001A)

MOTOR, 20 HP 3

PHASE, 575V

M-5424 (118AB-001A)

TOP MOUNT,

CONTROL BOX

119-282P (15 HP

AND 20 HP)

BOTTOM MOUNT,

CONTROL BOX

119-283P (15 HP)

or

CONTROL BOTTOM

SUPPORT

119-296P (20 HP)

FAN GRILL GUARD

118-153W (15 HP)

FAN GRILL GUARD

118-172W (20 HP)

17

Identification of parts, con’t:

FAN FREQUENCY DRIVE CONTROL (if used)

E-6617

15 Hp, 1 Phase Input

18

Identification of parts, con’t:

LIQUID PROPANE HEATER

MANUAL GAS

VALVE, 3/8”

(

H-2956

)

NOT SHOWN:

69-220A – IGNITION WIRE, 37”

119-233P – VAPORIZER

E-6273 – IGNITION PLUG, SIDE

WIRE (For LP)

119-276A – 20” STRAIGHT

BURNER ASSEMBLY, LP

CONTROL BOX

LIQUID FILLED

PRESSURE GAUGE

30 PSI (H-2618)

SOLENOID VALVE W/

ORIFICE (691-081A)

SOLENOID VALVE

ASSY. (691-090A)

STRAINER

(H-2810)

LIQUID SOLENOID

VALVE ASSY.

(691-084A)

1/2” LP HOSE (H-1304)

VAPOR TEMP.

THERMOMETER

(H-2646)

VAPOR HIGH LIMIT OPEN

AT 120 DEG., AUTO RESET

(E-6564)

PRESSURE REGULATOR

(H-1209)

3/8” LP HOSE

(H-1306)

SAFETY VALVE

50 PSI (H-2929)

PIPE AWAY ADAPTER

(H-2880)

(FIELD INSTALLED)

RELIEF VALVE

375 PSI (H-2957) (QTY 3)

PIPE AWAY ADAPTER

(H-2879) (QTY 3)

KNOB, 3 ARM

(H-2635) (QTY 2)

19

Identification of parts, con’t:

NATURAL GAS HEATER

NOT SHOWN:

69-220A – IGNITION WIRE, 37”

E-6701 – IGNITION PLUG,

SHORT REACH (For NG)

119-291P – SPACER RING

119-300A – 20” STRAIGHT

BURNER ASSEMBLY, NG

MANUAL

REGULATING

GAS VALVE, 3/4”

(H-3126)

RELIEF VALVE

26 PSI (H-3057)

PIPE AWAY ADAPTER

(H-2880)

CONTROL BOX

SILICONE FILLED

PRESSURE GAUGE

10 PSI (H-3127)

WITH

VENT PLUG (H-3130)

3/4” SOLENOID

VALVE W/ ORIFICE

(119-288A)

3/4” SOLENOID

VALVE W/ TEST

PORTS (E-6693)

Y STRAINER

(H-3125)

20

Identification of parts, con’t:

BLUE FLAME II CONTROL BOX, CSA

119-278A 15HP LP, 119-292A 15 HP NG

119-294A 20HP LP, 119-295A 20HP NG

RELAY (E-5764)

RELAY SPRING

(E-6068)

RELAY SOCKET

(E-6069)

LIGHT AND LIGHT

LENS, C22

(E-6622, E-6623) (3)

TERMINAL BLOCK

4 COND. WAGO

(E-6368) (14)

DECAL, 1-14

(P-13237)

TERMINAL END

PLATE W/ FLANGE

(E-6367)

PUSHBUTTON

SWITCH, START,

1NO

(E- 6624)

(E-6625)

SWITCH TOGGLE,

OFF/ON, 6 AMP

(E- 6557)

(E-6558)

GROUND BAR KIT

(E-6289)

FUSE

HOLDER

(E-6556)

DIN RAIL

(E-6568)

FUSE , 5 AMP

SLO-BLO

(E-5267) (2)

BURNER HIGH-LIMIT

220 DEG. F, MANUAL

RESET

(E-5133)

FENWAL HARNESS

(691-091A)

FENWAL FLAME

SENSE MODULE

(E-6569)

FLAME ROD ASSY.

(119-261A)

IGNITION

TRANSFORMER 120

VAC PRIMARY 6000

VOLTS SEC.

(E-6195)

AIR FLOW SWITCH

ASSEMBLY

(119-279A, 0.75”

W.C.)(15 Hp)

Or

(119-293A, 1.5”

W.C.)(20 Hp)

This manual suits for next models

15

Table of contents

Popular Dryer manuals by other brands

Beko

Beko B5T692343WBPB user manual

LG

LG Steam Dryer DLEX7177SM User's guide & installation instructions

Hotpoint

Hotpoint TCEL 87C Instruction booklet

Pneumatech

Pneumatech PE Series owner's manual

Ingersoll-Rand

Ingersoll-Rand TS1A Operation and maintenance manual

Ingersoll-Rand

Ingersoll-Rand D127NC Operator's manual