SMARTFOX Pro Heater 6K Manual

1

SMARTFOX

Pro Heater 6K

Installation & Operating Instructions

V9.0-07.2023

2

Version

Date

Description

V1.0

02.05.2023

WG: Document creation

V8.0

29.06.2023

WG: Release Document

V9.0

04.07.2023

WG:

Edit

We have checked the contents of this documentation for conformity with the hardware and software

described. Nevertheless, deviations, remaining errors and omissions cannot be ruled out, so that we cannot

accept any liability for any damage that may result. However, the information in this publication is checked

regularly and any necessary corrections are included in subsequent editions. We are grateful for any

suggestions for improvement.

This original documentation is protected by copyright. All rights reserved, in particular the right of reproduction and

distribution as well as translation. No part of this manual may be

reproduced in any form (by photocopy, microfilm or any other method) or stored, processed, duplicated or

distributed using electronic systems without the written permission of DAfi GmbH. Infringements may result

in criminal prosecution.

pull.

All rights & technical changes reserved.

© DAfi GmbH

3

Table of contents

1.

Introduction 6

1.1

Foreword 6

1.2

Contact details 6

1.3

Labelling 7

1.4

Warranty and liability 7

1.5

Content and purpose of this documentation 8

1.6

Validity 8

1.7

Recommendation 8

2.

Limits of use 9

2.1

Intended use 9

2.2

Reasonable foreseeable misapplications 9

2.3

Application limits 9

2.4

Target group and previous knowledge 10

2.5

Principle 10

3.

Security 10

3.1

General safety instructions 10

3.2

General provisions 11

3.3

Warning, mandatory and prohibition signs on the product 12

3.4

Safety elements & temperature monitoring 12

4.

Commissioning / Start-up 12

4.1

Transport 12

4.2

Prerequisites for the installation 13

4.3

Storage 13

4.4

Site 13

5.

Important notes 14

6.

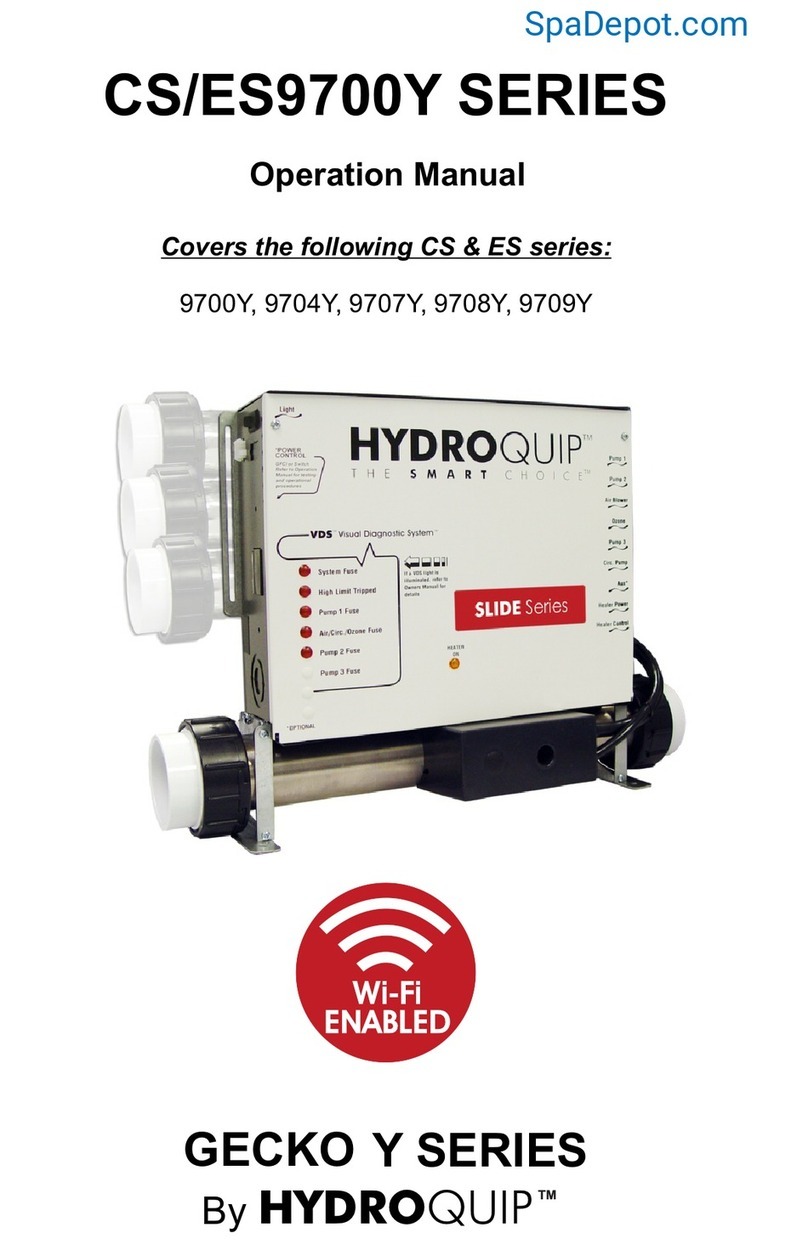

Product overview 15

6.1

Technical data 15

6.2

Scope of delivery 17

7.

Installation & Assembly 17

7.1

Installation recommendation 18

4

8.

Connection 21

8.1

Electrical connection 21

8.1.1

Wiring diagram Mains connection 22

8.1.2

Mains plug connection 23

8.2

Communication connection 23

8.2.1

RS485 connection diagram 24

8.2.2

Full RS485 expansion stage 25

8.2.3

Wiring diagram 4-20mA 26

8.2.4

Connection communication plug 27

9.

Settings on the heating rod 28

9.1

DIP switch settings 28

9.1.1

DIP switch 1 Terminating resistor 28

9.1.2

DIP switch 2 "Stand Alone" operation 29

9.1.3

DIP Switch 3-6 Modbus Address 29

9.1.4

DIP Switch 7-8 Modbus Parity 30

9.1.5

DIP switch 9-10 Modbus baud rate 30

10.

Control via SMARTFOX Energy Manager RS485 31

10.1

Required articles 31

10.2

Registration web portal my.smartfox.at 32

10.3

Add SMARTFOX Energy Manager

33

10.4

Software / Software update Energy Manager 35

10.5

Parameterisation SMARTFOX Energy Manager 36

10.6

Software / Software update SMARTFOX Pro Heater 40

11.

Control via SMARTFOX Energy Manager 4-20mA 42

11.1

Required articles 42

11.2

Registration web portal my.smartfox.at 44

11.3

Add SMARTFOX Energy Manager

45

11.4

Software / Software update Energy Manager 47

11.5

Parameterisation SMARTFOX Energy Manager 48

12.

Operation 51

12.1

Display & operating elements 51

12.1.1

Live

overview

51

12.1.2

Charging modes 52

12.1.3

Status LED 53

12.1.4

Control thermostat (RT) 53

12.1.5

Reset safety temperature limiter (STB) 54

13.

Maintenance 55

13.1

Inspection 55

5

13.2

Cleaning 55

13.3

Maintenance 55

13.4

Spare and wear parts 56

13.5

Repair 57

13.6

Periodic inspection 57

13.7

Decommissioning 57

13.8

Disassembly 57

13.9

Disposal 58

14.

Appendix 59

14.1

Technical drawings 59

14.2

Compatibility table Energy Manager 60

14.3

EU Declaration

of

Conformity

61

14.4

Notes 62

6

1.

Introduction

For reasons of easier readability, the usual masculine form of speech is used in these operating instructions for

personal nouns and pronouns. However, this does not imply any discrimination against the female gender, but is to

be understood as gender-neutral in the sense of linguistic simplification.

With the SMARTFOX Pro Heater 6K, you have a product that is state of the art in terms of safety for

operation and operational safety. The system may nevertheless present hazards if it is used improperly or

not as intended (see chapter 3 Safety), whereby hazards are indicated by safety instructions throughout the

documentation.

1.1

Foreword

This documentation serves to ensure safe working on and with the heating rod. It contains safety instructions

that must be observed! All persons working on and with the heating rod must have the documentation

available when carrying out their work and must observe the information and instructions relevant to them.

The documentation must always be complete and perfectly legible. DAfi GmbH is not liable for technical or

typographical defects in this documentation, nor is any liability assumed for damage directly or indirectly

attributable to the delivery, performance or use of this documentation.

1.2

Contact details

If faults occur in the product, the cause of which you cannot rectify on the basis of this documentation,

please contact SMARTFOX Support.

DAfi GmbH

Niedernfritzerstraße 120

5531 Eben im Pongau

T: +43 (0)720 302 555

support@smartfox.at

www.smartfox.at

7

1.3

Labelling

The product is clearly identified by the contents of the type plate.

CE marking acc:

•

Directive 2014/35/EU of the European Parliament and of the Council on the making

available of electrical equipment designed for use within certain voltage limits

•

Directive 2014/30/EU of the European Parliament and of the Council on electromagnetic

compatibility

•

Directive 2011/65/EU of the European Parliament and of the Council on the restriction of

the use of certain hazardous substances in electrical and electronic equipment

The product is provided with the CE mark according to the specifications of the European Union

for the marking of products.

The corresponding declaration of conformity is available at DAfi GmbH and can be

requested.

1.4

Warranty and liability

The warranty period of the screw-in heating element is 3 years and begins with the successful

commissioning. These operating instructions are intended to ensure trouble-free and safe use of the product.

Compliance is a prerequisite for the fulfilment of any warranty claims.

Excluded from the warranty are such defects that arise from arrangement and assembly not carried out by

the seller, inadequate set-up, non-observance of the installation requirements and conditions of use,

overloading of the parts beyond the performance specified by the seller, negligent or incorrect handling and

use of unsuitable operating materials; this also applies to defects that are attributable to material provided

by the buyer.

Wear parts according to chapter (13.4 Spare and wear parts) are also excluded from the warranty.

The Seller shall only be liable for damages outside the scope of application of the Product Liability Act if it is

proven that it acted with intent or gross negligence, within the scope of the statutory provisions.

Claims for damages shall lapse in particular in the event of:

•

Improper use

•

Faulty assembly, electrical and mechanical installation and fusing

•

Operating with defective or improperly fitted safety devices and

guards.

•

Disregarding instructions in this documentation

•

Non-use of original spare parts

8

•

Conversions or extensions, if this has not been agreed in writing with DAfi GmbH and approved

•

Improperly carried out repairs

•

Catastrophic events, foreign body impact and force majeure

The seller is also not liable for damage caused by the actions of third parties, atmospheric discharges,

overvoltages and chemical influences. The warranty does not apply to the replacement of parts that are

subject to natural wear and tear.

Furthermore, the General Terms and Conditions of Delivery of the Austrian Electrical and Electronic

Manufacturers' Association shall apply exclusively to warranty claims and claims for damages. These can

be found at www.feei.at or will be sent to you on request. Deliveries are made subject to retention of title.

1.5

Content and purpose of this documentation

This documentation contains relevant information to enable you to work on the product as safely as possible.

Observing the instructions in this document serves to avoid dangers and prevent damage to the product. In

addition to these operating instructions, the regulations for accident prevention and environmental protection

applicable in the country of use and at the installation site must also be observed.

1.6

Validity

This manual is exclusively valid for the product in question with the identification SMARTFOX Pro Heater 6K,

manufactured by DAfi GmbH. The product was placed on the market by DAfi GmbH.

1.7

Recommendation

We recommend that you have repairs and maintenance work carried out either by DAfi GmbH or by our

certified SMARTFOX partners, who are familiar with and trained in our products, thus offering you the best

possible service.

To report a complaint or repair, please contact technical support.

DAfi GmbH

Niedernfritzerstraße 120

5531 Eben im Pongau

T: +43 (0)720 302 555

support@smartfox.at

www.smartfox.at

9

2.

Limits of use

2.1

Intended use

The SMARTFOX Pro Heater 6K is an electrical appliance for water heating in hot water boilers or heating

buffers. The screw-in heater is only suitable for indoor use.

The product has been built according to the state of the art and the recognised safety rules. Nevertheless,

the use of the product may pose a risk to life and limb of the operator or third parties.

This may result in damage to the product and other property. Intended use also includes observing the

operating instructions and complying with the maintenance requirements. Only use the product when it is in

perfect technical condition.

Use the product as intended and in a safety-conscious manner. Have faults and damage that may affect safety

rectified immediately by DAfi GmbH or a certified SMARTFOX partner.

2.2

Reasonable foreseeable misapplications

The screw-in heating element must be mounted on a suitable 1 1/2" (6/4") socket and be stationary. The

unit must not be put into operation when loose (not firmly mounted).

•

Dismantling, manipulating or deactivating the safety devices is prohibited.

•

No technical changes may be made to the product without consultation with DAfi GmbH.

•

Furthermore, in the event of non-compliance with the intended use, liability and warranty claims

are excluded.

•

The product may only be operated under the operating conditions specified in the

documentation.

2.3

Application limits

Ambient temperature: +5 to +40°C

Installation location: indoors (boiler room, technical

room...) Relative humidity: 5 to 95% (non-condensing)

Operation: also possible daily, depending on

requirements

10

2.4

Target group and previous knowledge

This documentation is addressed to qualified personnel for installation and commissioning as well as to the

user (layman) for operation and maintenance of the product.

User (layman)

Independent operation of the product may only be carried out by laypersons if these

•

have read and understood the operating and maintenance instructions

•

have read and understood all safety instructions

Specialist personnel (electrical specialist, GWH specialist)

Commissioning, inspection and configuration work may only be carried out by qualified personnel. The

qualified personnel must have read and understood these operating and maintenance instructions. We

recommend appropriate certification as a SMARTFOX partner with DAfi GmbH.

Specialist personnel (Certified SMARTFOX Partners)

Commissioning, maintenance, repair, service, inspection, configuration and servicing work may only be

carried out by certified SMARTFOX partners. The qualified personnel must have read and understood

these operating and maintenance instructions.

2.5

Principle

The product corresponds to the state of the art and the applicable safety and health regulations.

Nevertheless, the following hazards may occur in the event of incorrect operation or misuse:

•

for life and limb of users or third parties

•

for the product and other material assets of the operator

•

for the efficient use of the product

3.

Security

This documentation is structured according to the applicable EU regulations and contains safety instructions.

The operator of the product must receive the necessary safety-related information and also read the

documentation. Individuals are responsible for complying with the safety instructions.

3.1

General safety instructions

Even if maximum care is taken in the design and construction of the product and all safety-relevant facts

are taken into account, residual hazards may still exist which have been evaluated by means of a risk

assessment.

11

The following safety rules must be observed during all work on the heating element:

•

Unlock

•

Secure against switching on again

•

Determine freedom from voltage

•

Grounding and short-circuiting

•

Cover or fence off surrounding live parts.

3.2

General provisions

In general, the following safety regulations and obligations apply when handling the product:

•

The product may only be operated when in perfect condition.

•

It is prohibited to remove, alter, bypass or bypass any protection, safety or monitoring device.

•

It is prohibited to modify or alter the product.

•

Malfunctions or damage must be reported to the manufacturer immediately. These must

be remedied immediately with original spare parts.

•

For any activity other than the intended use in the area of the product, it must be disconnected

from the power supply and secured against being switched on again.

•

The safety instructions and operating instructions from the documentation of the

components used must always be observed.

•

All protection, safety and monitoring devices must be regularly checked and maintained by

the operator.

•

Maintenance work can be requested from DAfi GmbH and must be carried out by them or a

certified SMARTFOX partner.

•

After maintenance or repair, the product may only be put into operation with all

guards fitted.

•

The national safety and accident prevention regulations apply to the operation of the product.

12

3.3

Warning, mandatory and prohibition signs on the product

Safety instructions are attached to the product and the product inserts, which draw attention to dangers /

residual dangers. The instructions on the safety label on the product must be followed under all

circumstances. If, in the course of the product's service life, the safety labels fade or become damaged, they

must be replaced immediately with new labels. The legibility and completeness must be checked at regular

intervals. From the time when the signs are not immediately recognisable and comprehensible at first glance,

the product must be taken out of service until the new signs are fitted.

3.4

Safety elements & temperature monitoring

The product is equipped with the following safety features:

•

Safety temperature limiter (STB)

The safety temperature limiter switches off the heating rod when 93°C is reached at the measuring point.

The safety temperature limiter must be reset manually when the temperature in the medium has cooled

down sufficiently (see chapter 12.1.5 Resetting the safety temperature limiter (STB)).

4.

Commissioning / start-up

Commissioning is covered in the following chapters. This includes requirements for transport, storage, the

installation site, assembly and commissioning.

4.1

Transport

The product is usually delivered to the customer by DAfi GmbH.

If the product is not delivered by DAfi GmbH or transported by the customer,

appropriate packaging

(original packaging), as well as a suitable

transport company, must be chosen for the

transport.

The

assembly work of the product may only be

carried out by a qualified specialist. Moving parts must be

secured accordingly. Sensitive parts must be protected from external influences with cardboard packaging or

similar material.

The product must be decommissioned beforehand as described in chapter 13.7

Decommissioning.

13

4.2

Prerequisites for the installation

•

Contact on site for the mains disconnection device in the electrical distribution board.

•

Prepared sufficiently dimensioned and fused supply line (see chapter 8.1 Electrical connection).

•

If the temperature changes by more than 15 °C between transport and installation site,

condensation may have formed. Wait with the installation until the temperature of the charging

station corresponds to the room temperature and the condensation has evaporated again.

•

Direct commissioning without acclimatisation time can lead to damage.

4.3

Storage

The following points must be observed when storing the product.

•

Depending on the environmental conditions, the product must be protected accordingly.

•

In the case of storage with an ambient temperature below 5 °C, special precautions must be

taken against frost damage, especially to the electrical components.

•

The product must be stored in a dry environment.

4.4

Site

•

Ensure that the installation site is level, vibration-free and free from

contamination.

•

The product is assembled by qualified personnel (skilled worker)

•

Prepared, adequately dimensioned and fused supply line (see chapter 8.1 Electrical connection).

14

-

Hint! Useful tips to support you during commissioning. The instructions given are not mandatory, but are

recommended.

Warning! Non-compliance can lead to malfunctions or damage to the unit. The instructions given must

therefore always be followed or implemented.

Attention! Non-compliance can lead to damage to property and personal injury. The instructions given

must therefore always be observed and implemented.

Information! General information and notes on unit parameterisation.

5.

Important notes

Before using the appliance / product, read these instructions and safety instructions carefully and

keep them for future reference. The manufacturer is not liable for damage caused by incorrect

information.

These operating instructions are part of the scope of delivery. They contain the information required for

proper use. They are intended for electrical engineering personnel or specialists who are familiar with the

installation, assembly and commissioning of the product described here. Improper installation and use can

lead to electric shock or fire.

Do not install or operate the unit/product if it is damaged! Do not modify the unit / product and do not carry

out any repairs yourself! If further information is required, additional information (see contact details) can be

requested.

Conformity

This appliance complies with the provisions of the Directive of the Council of the European Communities on

the approximation of the laws of the EC Member States relating to electromagnetic compatibility, EMC

Directive 2004/108/EC, and the Low Voltage Directive 2006/95/EC.

Explanation of symbols & notes

*The current version of these instructions can also

be

downloaded from www.smartfox.at/downloads, or

requested by

telephone / e-mail

. All

rights to translation / interpretation and copyright instructions are reserved.

According to EU Directive 2002/96/EC: Disposal must be carried out in a professional and

environmentally friendly manner at an authorised collection point (e.g. local recycling centre) or at the

dealer. Do not dispose of in household waste!

CE marking: Product that complies with the legal requirements or European legal standards and may

therefore be traded within the European Community.

Recyclable material.

Dispose of

products and packaging in an environmentally friendly manner and sorted by type (plastic

waste, metal waste, electrical waste,

etc. in accordance with legal requirements). Before disposal,

check

the

recyclability of the

components.

15

6.

Product overview

6.1

Technical data

Art.

No.

0767523866338

Heating capacity

220W - 6kW (15 steps)

Voltage

3~400V, 50Hz

Rated current

max. 9A

Hedging

LS

3B13

Standby

consumption

3-4W

Screw head

Screw-in thread

(AG)

G 1 1/2" (6/4")

Width across flats

SW60 (DIN ISO 228)

Material

Brass

Operating pressure

max. 10bar

Radiator

Immersion depth

480mm

Unheated

length

100mm

Jacket material

2.4858 - Alloy 825

Surface load

10W/cm²

Continuous operation

suitability

Yes

Galvanic

isolation

Yes (use in enamelled containers possible)

Field of application

Hot water boiler & buffer tank (suitable for drinking water)

Installation

horizontal

Connection housing

Material

PC + ABS (UL 94 V0)

Protection class

IP54

Electrical

connection

Plug 5-pole Nominal cross-section 1.5mm²

Communication

connection

Plug 5-pole nominal cross-section 0.5mm² (min. 0.4mm² / max. 0.75mm²) incl.

connection cable 5m

Interfaces

RS485 (4-20mA coming soon)

RS485

addressing

Parameters via DIP switch

Temperature sensor

integrated (class B)

Temperature control

Type

Temp. controller (TR) + safety temp. limiter (STB)

Control temperature

(TR)

10-80°C

Switch-off temperature

(STB)

93°C

16

Display

Status display via LED

Measuring unit

Current measurement included

Dimensions

W 135mm x H 189mm x L 603mm

Weight

2 kg

Temperature range (in operation)

Ambient temperature 10-45°C

Humidity (in operation)

5-95% non-condensing

Operating mode

With energy manager: 15-step surplus control,

minimum temperature

maintenance, weekly timer, hygiene function

frost protection & fixed

temperature

Stand alone operation: frost protection & fixed temperature possible

Compatible energy managers

(RS485)

SMARTFOX Pro & SMARTFOX Pro 2

Compatible energy managers

(4-20mA)

All SMARTFOX Energy Managers *not all functions available

Remote control

Via SMARTFOX Energy Manager (my.smartfox.at & APP)

Monitoring

Via SMARTFOX Energy Manager (my.smartfox.at & APP)

Certificates,

standards

CE, EN 14597 STANDARD

17

Attention! During assembly work, there are additional dangers due to improper work. If the

product

is

not

installed properly, it may be damaged or there may be danger to persons and property. Installation may

only be carried out by a GWH specialist.

6.2

Scope of delivery

1)

Cardboard heater

2)

SMARTFOX Pro Heater 6K

3)

Installation & Operating Instructions

4)

Brief installation instructions (electrician)

5)

Brief installation instructions (GWH - specialist)

6)

Plug with connection cable RS485 control (4-20mA coming soon)

7)

Plug Mains connection

7.

Installation & Assembly

The installation is carried out horizontally in a threaded sleeve G 1 ½" (6/4") with suitable sealants, preferably

in closed water heating systems with a nominal pressure of up to 10bar. The length of the threaded socket

must always be smaller than the unheated zone (LU), this can be found in the technical data in the table (see

chapter 6.1 Technical data) The thermally induced medium circulation in the tank must not be obstructed, e.g.

by baffles. The standards and directives applicable at the installation site must be observed during

installation. All work may only be carried out by an authorised specialist. When used in water containing lime,

from about 12°dH, the screw-in heater must be decalcified regularly. The chloride content should not exceed

the limit value of 250 mg/l, according to the drinking water ordinance. To prevent corrosion damage to

enamelled or coated tanks, the tubular heating elements of the screw-in heating element are electrically

insulated from the tank and conductively connected via a resistor, thus increasing the service life of the

protective anode and the screw-in heating element.

18

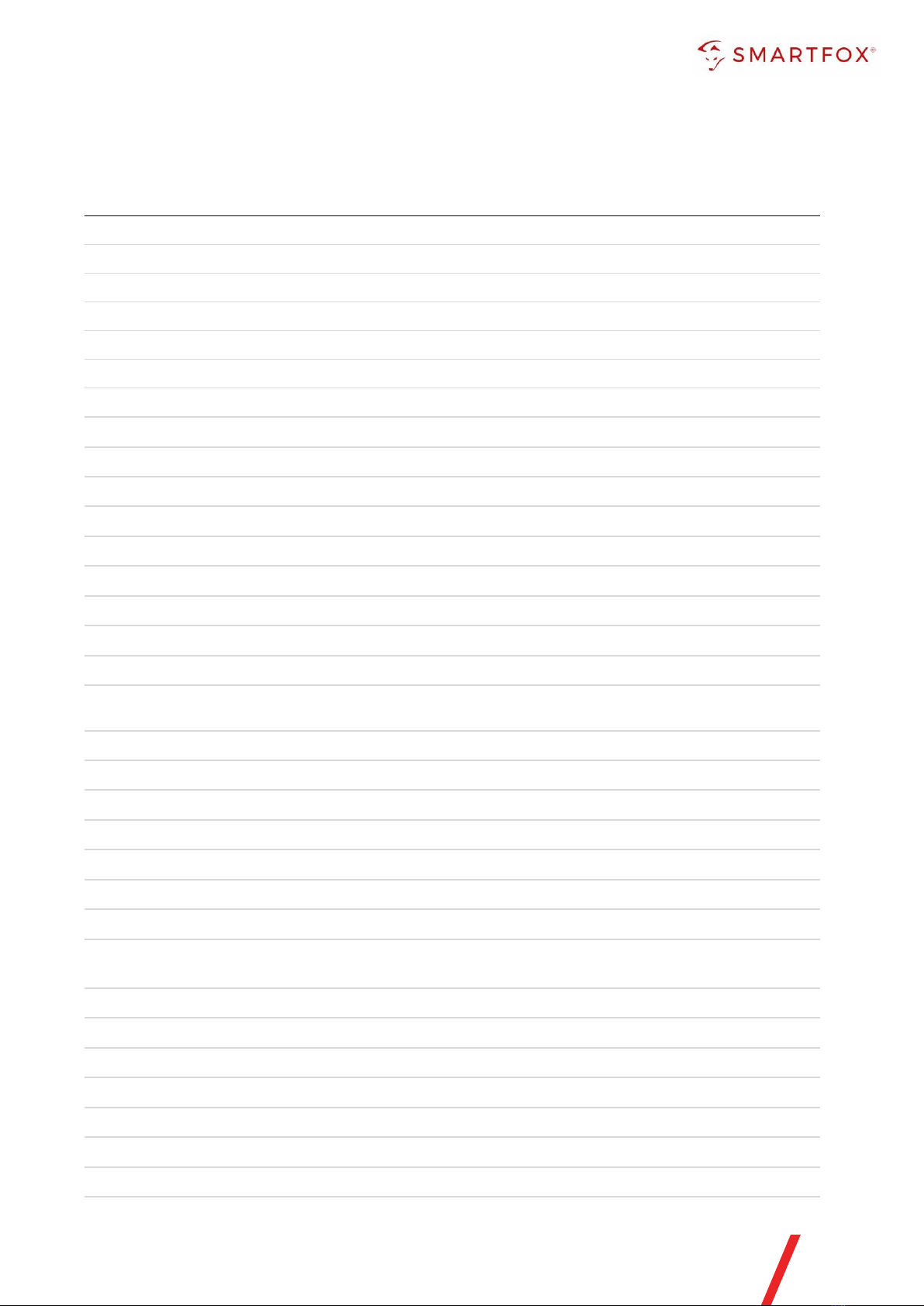

•

Use suitable sealants.

•

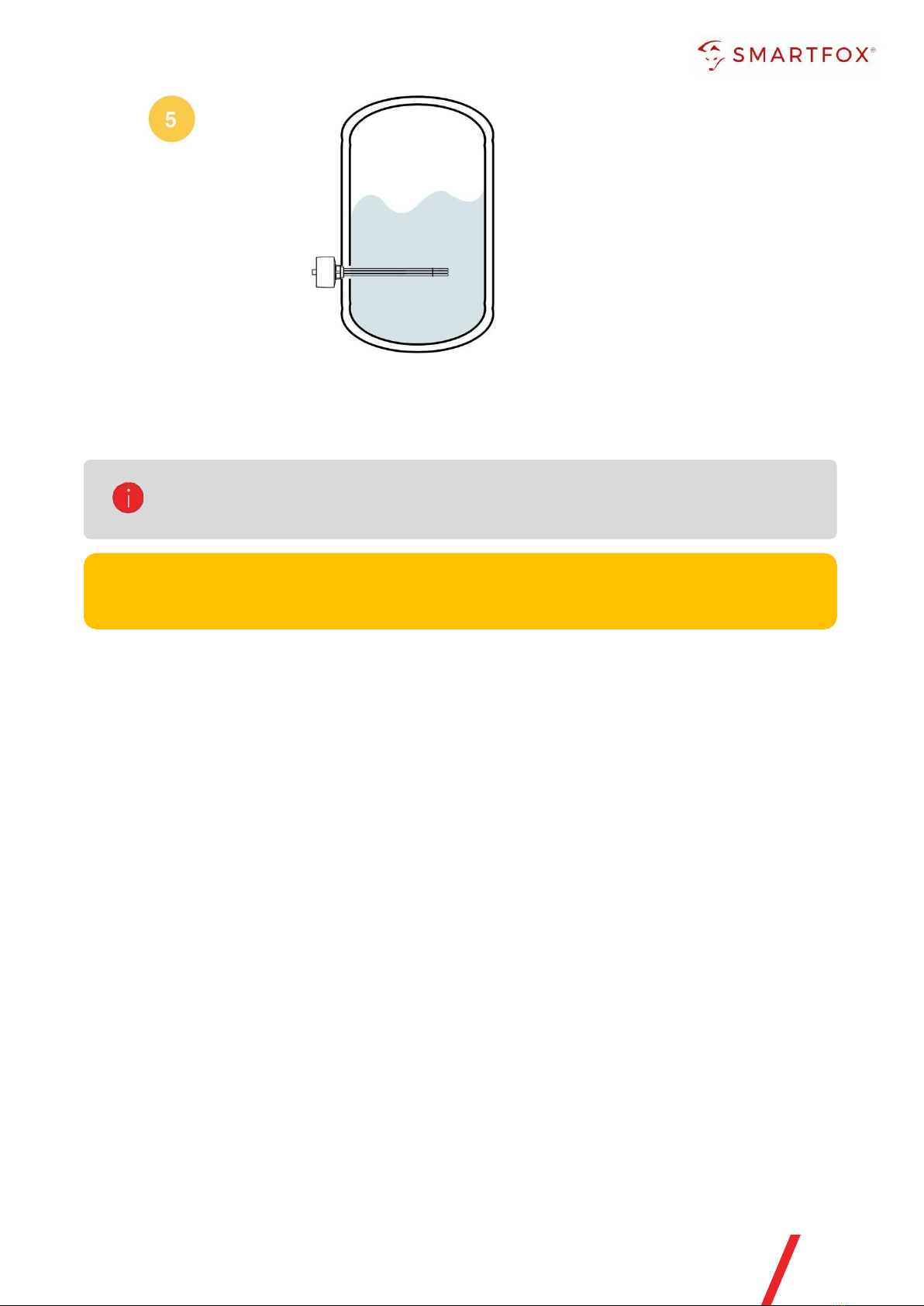

The boiler/buffer in which the heating rod is to be inserted must be drained. The

Attach the heating rod with brass thread to the socket.

7.1

Installation recommendation

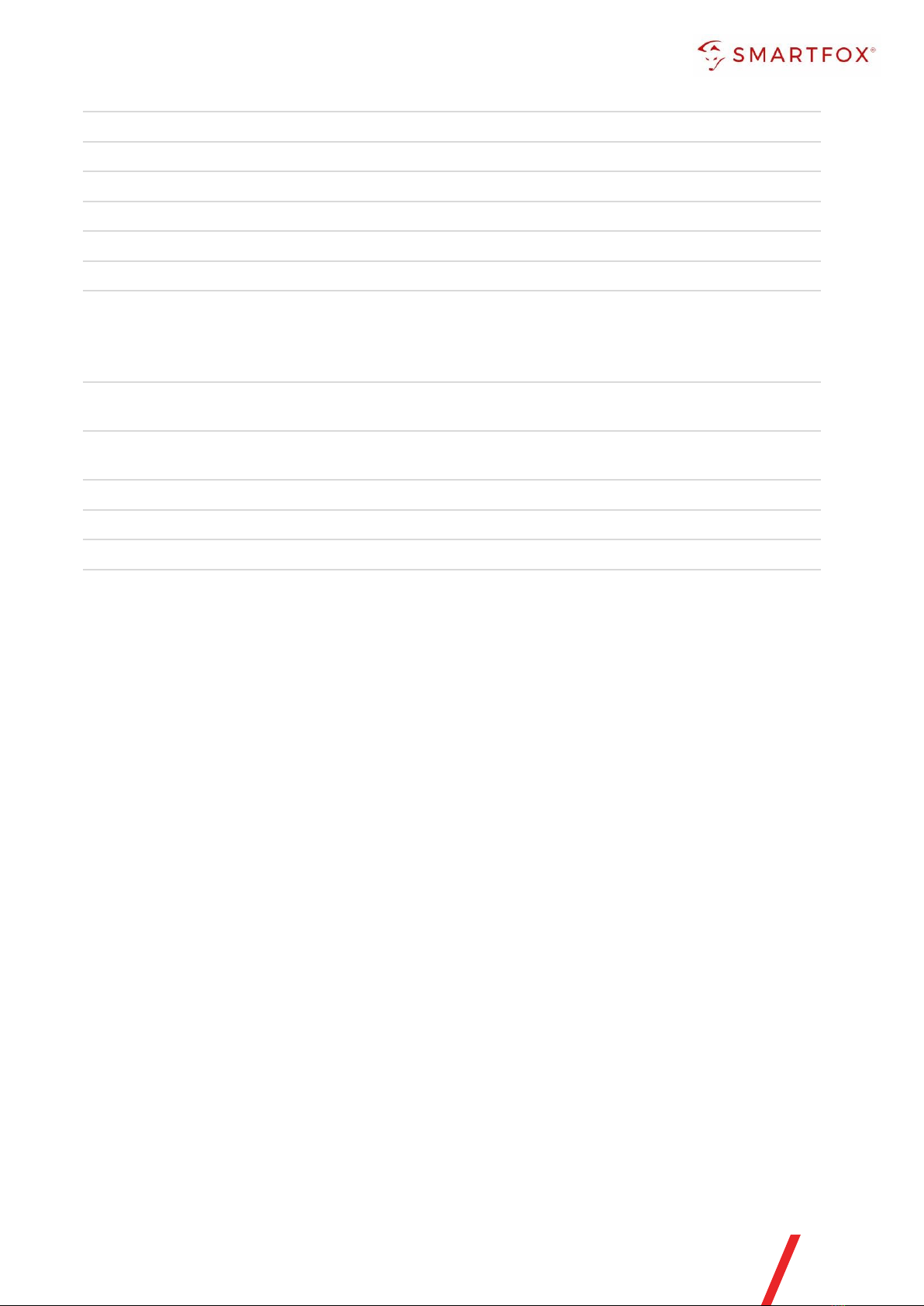

Warning! The threaded sleeve must be shorter than the unheated zone (100mm) of the heating rod.

19

•

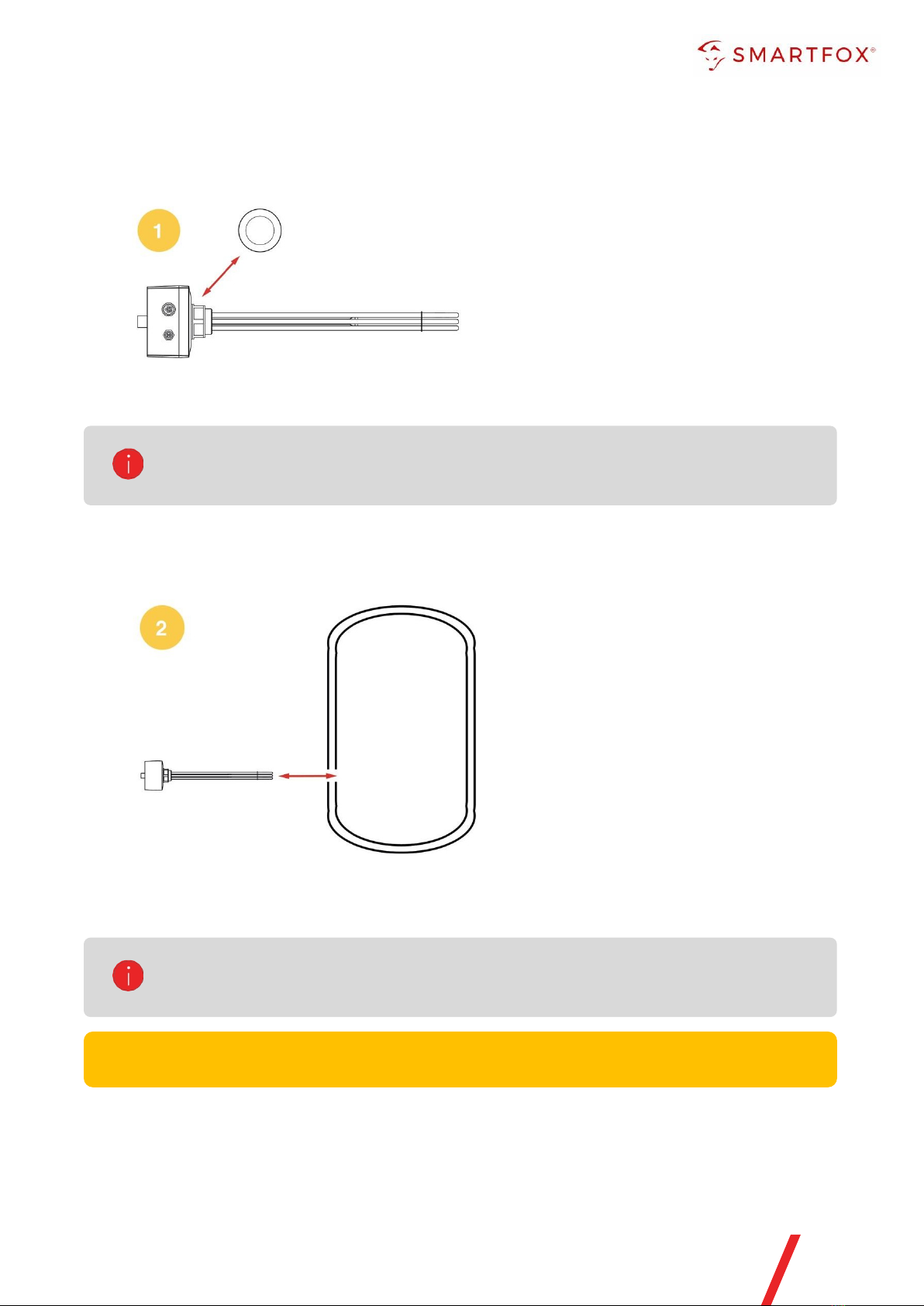

Screw the heating rod into the 1 ½" (6/4") socket.

Warning! Do not screw in by turning the plastic housing!

•

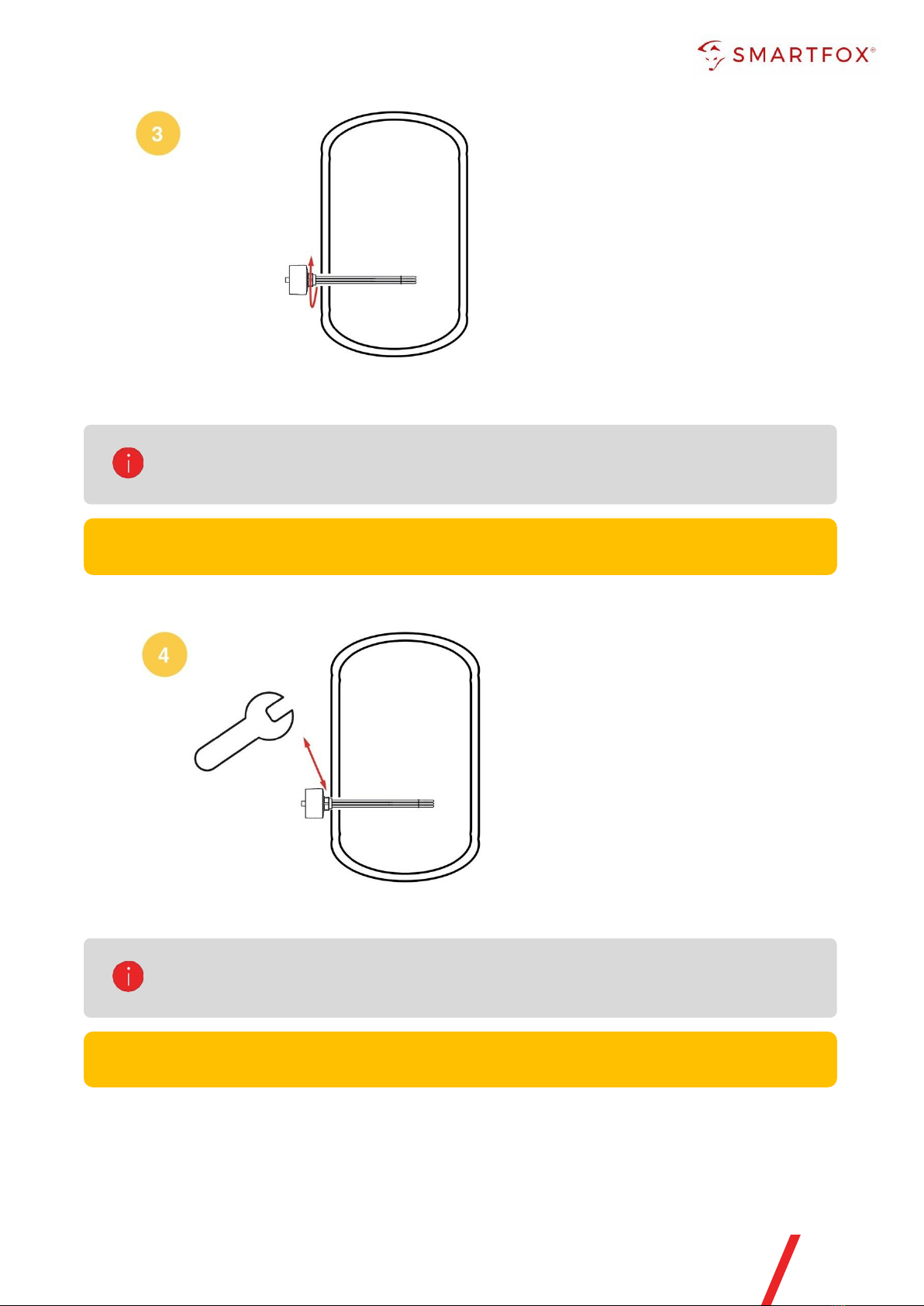

Tighten the heating rod at the brass screw head SW60.

Hint! The heating rod can be locked slightly after tightening so that the housing stands straight.

20

•

Check the connection for leaks and fill the boiler/buffer.

Warning! The heating element must be completely surrounded by water and must not be used in dry

operation under any circumstances.

Table of contents

Popular Heater manuals by other brands

Dura Heat

Dura Heat DH 1050 owner's manual

Johnson & Starley

Johnson & Starley WARMCAIR C36U Installation, commissioning & servicing instructions

MrHeater

MrHeater MH15T Operating instructions and owner's manual

Pro Breeze

Pro Breeze PB-H-23W instruction manual

Comfort Zone

Comfort Zone CZ449E Series instructions

RealFlame

RealFlame ELEMENT 1200 Installation & operating manual