Smith MaxiVac MV-360 Guide

3A5576

EN

Operation, Parts

MaxiVac™and Cyclones

Vacuum for collection of dry concrete and asphalt dust. For professional use only.

Vacuums

Model MV-360 (120V)

Model MV-600 (230V)

Separators

Model MV-SA (20 gallon)

Model MV-SB (32 gallon)

Important Safety Instructions

Read all warnings and instructions in this manual.

Be familiar with the controls and the proper usage

of the equipment. Save all instructions.

MaxiVac MV-SA and MV-SB

Contents

2TBD

Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Component Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

MV-360 and 330 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

MV-SA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

MV-SB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Emptying Collection Tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Shutdown and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Main Assembly Diagram (MaxiVac) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Main MaxiVac Assembly Parts (MaxiVac) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Motor Housing Assembly Diagram (MV-360) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Motor Housing Assembly Parts List (MV-360) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Motor Housing Assembly Diagram (MV-600) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Motor Housing Assembly Parts List (MV-600) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Auto Filter Cleaner Assembly (MaxiVac) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

MV-SA Assembly and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

MV-SA Assembly and Accessories Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

MV-SB Assembly and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

MV-SB Assembly and Accessories Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

SMITH Standard Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Warnings

TBD 3

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation

point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these

symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific hazard

symbols and warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

DUST HAZARD

Grinding concrete and other surfaces can create dust that contains hazardous substances.

To reduce the risk of serious injury:

• Control the dust to meet all applicable workplace regulations.

• Wear a properly fit-tested and government approved respirator suitable for the dust conditions when

emptying collection tank or performing maintenance.

• Do not use without dust bag and filters in place.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause elec-

tric shock.

• Turn off and disconnect power cord before servicing equipment.

• Connect only to grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on power and extension cords.

• Do not expose to rain. Store indoors.

• Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the equipment. Keep

cord away from heat, sharp edges, or moving parts.

• Do not use on wet surfaces.

Warnings

4TBD

GROUNDING

This product must be grounded. In the event of an electrical short circuit, grounding reduces the risk of

electric shock by providing an escape wire for the electric current. This product is equipped with a cord

having a grounding wire with an appropriate grounding plug. The plug must be plugged into an outlet

that is properly installed and grounded in accordance with all local codes and ordinances.

• Improper installation of the grounding plug is able to result in a risk of electric shock.

• When repair or replacement of the cord or plug is required, do not connect the grounding wire to

either flat blade terminal.

• The wire with insulation having an outer surface that is green with or without yellow stripes is the

grounding wire.

• Check with a qualified electrician or serviceman when the grounding instructions are not completely

understood, or when in doubt as to whether the product is properly grounded.

• Do not modify the plug provided; if it does not fit the outlet, have the proper outlet installed by a

qualified electrician.

• This product is for use on a nominal 120V or 230V circuit and has a grounding plug similar to the

plugs illustrated in the figure below.

• Only connect the product to an outlet having the same configuration as the plug.

• Do not use an adapter with this product.

Extension Cords:

• Use only a 3-wire extension cord that has a grounding plug and a grounding receptacle that

accepts the plug on the product.

• Make sure your extension cord is not damaged. If an extension cord is necessary, use 12 AWG

(2.5 mm2) minimum to carry the current that the product draws.

• An undersized cord results in a drop in line voltage and loss of power and overheating.

WARNING

120V US 230V

Warnings

TBD 5

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not leave the work area while equipment is energized. Turn off all equipment when equipment is

not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

• Maintain a safe operating distance from other people in the work area.

ENTANGLEMENT HAZARD

Rotating parts can cause serious injury.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Do not wear loose clothing, jewelery, or long hair while operating equipment.

FIRE AND EXPLOSION HAZARD

Flammable fumes in work area can ignite or explode. To help prevent fire and explosion:

• Do not use to pick up flammable or combustible liquids, such as gasoline, or use in areas where they

may be present.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, inhalation of dust or chemicals, and

hearing loss. This equipment includes but is not limited to:

• Protective eye wear.

• Hearing protection.

• Properly fit-tested and government approved respirator suitable for the dust conditions.

WARNING

Component Identification

6TBD

Component Identification

MV-360 and 330 MV-SA MV-SB

Component

A Auto Filter Cleaner Power Switch

B Vacuum Motor Switch

C Vacuum Motor Switch

D Vacuum Motor Switch (MV-600 only)

E Motor Housing Assembly

F Engagement Lever

G Filter Housing and Body

H Dust Collection Tank

J Vacuum Hookup

K Vacuum Inlet

L Vacuum Outlet

N Separator Lid

O Long Hose

P Short Hose

Setup

TBD 7

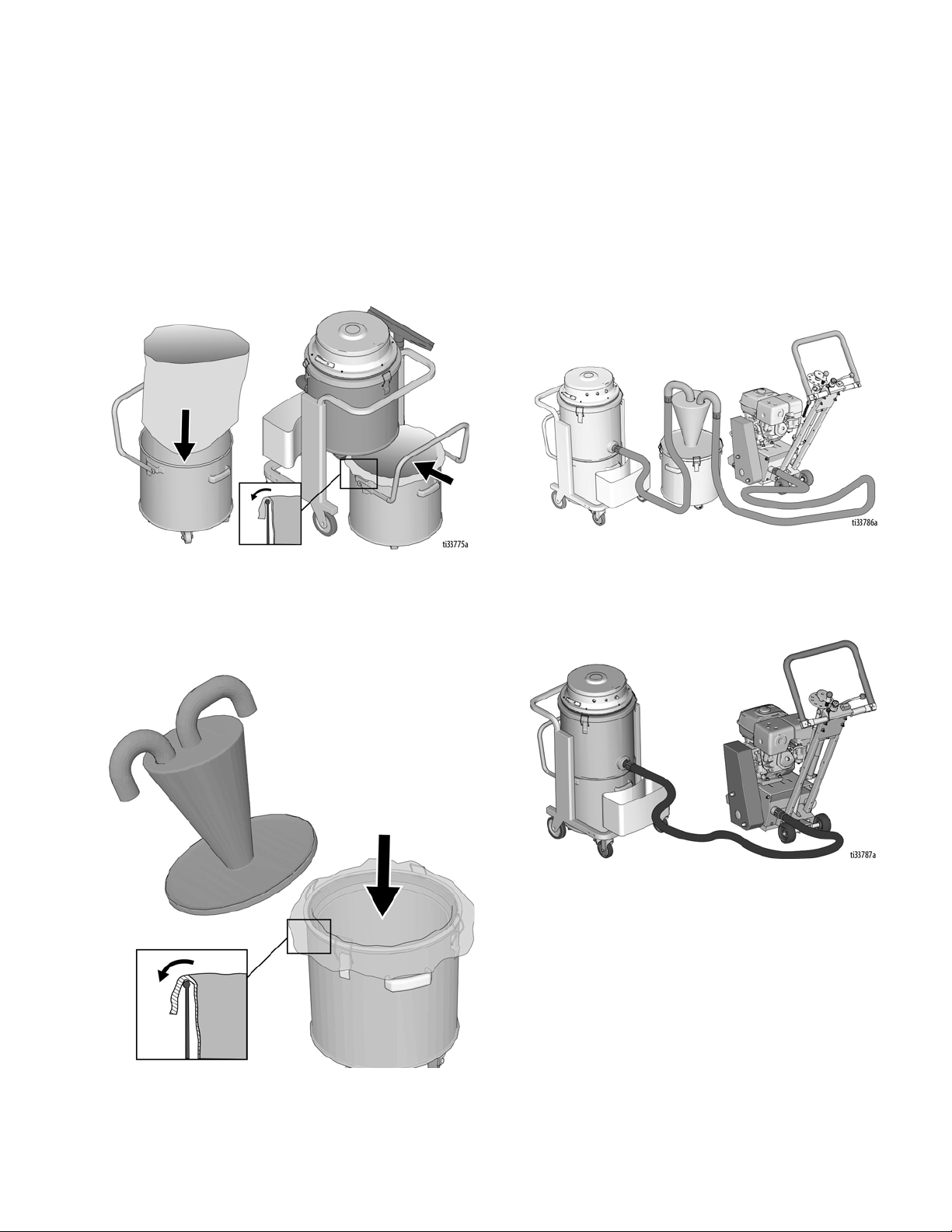

Setup

1. Insert dust collection bags into Dust Collection

Tan k s.

a. Remove Dust Collection Tank by pulling up on

the Engagement Lever and insert the collection

bag into the tank. Wrap the bag around the lip of

the tank and reinsert the tank into the bottom of

the MaxiVac. Lock the tank by pushing down on

the Engagement Lever.

b. If using a Cyclone separator, remove the

Separator Lid and insert the collection bag into

the tank. Wrap the bag around the lip of the tank

and reinstall the Separator lid onto the tank.

2. Connect hoses.

If using a Cyclone separator:

• Connect one end of the short vacuum hose to the

inlet of the MaxiVac. Connect the other end of the

short hose to the outlet of the Cyclone separator.

• Connect one end of the Long Vacuum Hose to the

inlet of the Cyclone separator. Connect the other

end of the long hose to the vacuum hookup on the

GrindLazer.

If not using a Cyclone separator:

• Connect one end of the Long Vacuum Hose to the

inlet of the MaxiVac. Connect the other end of the

long hose to the vacuum hookup on the GrindLazer.

Operation

8TBD

Operation

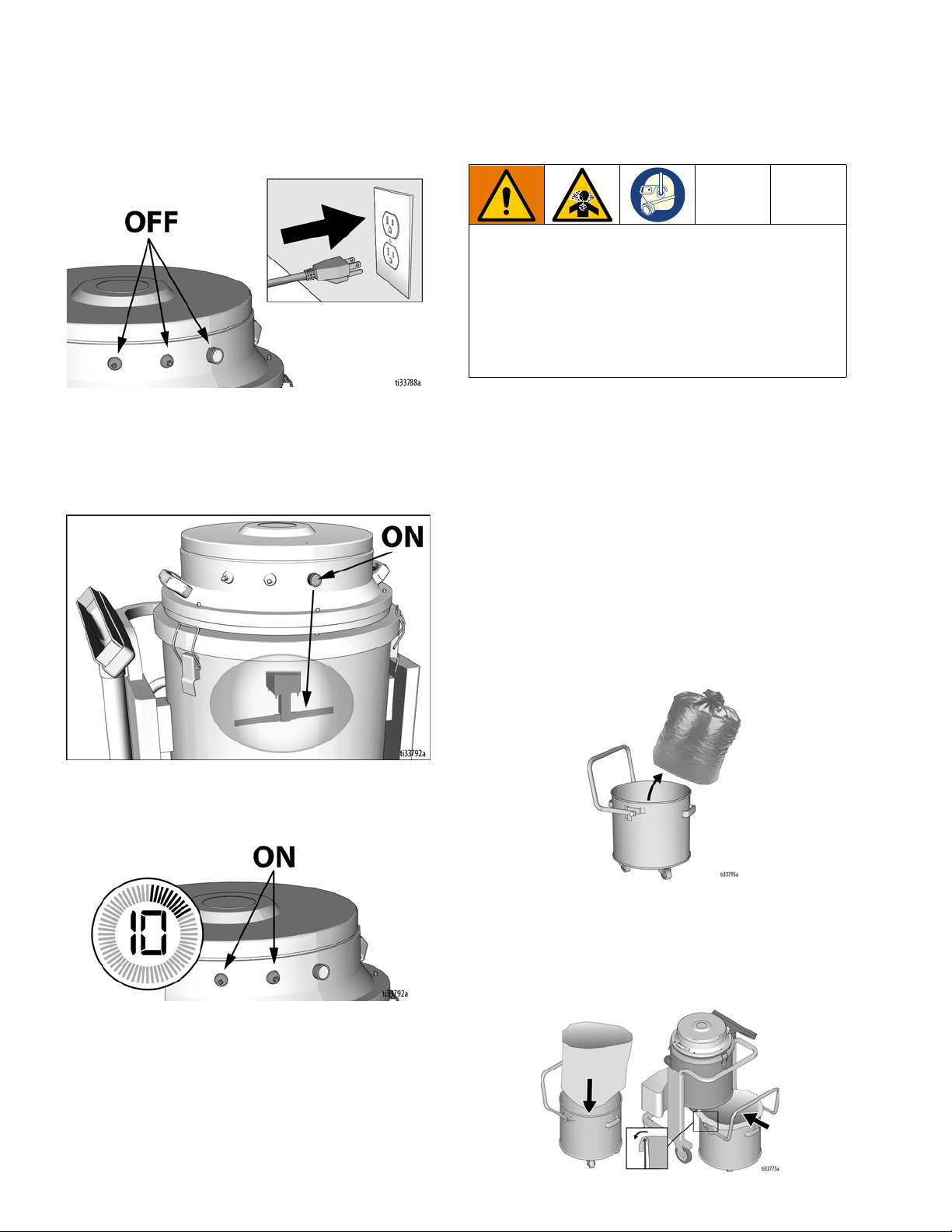

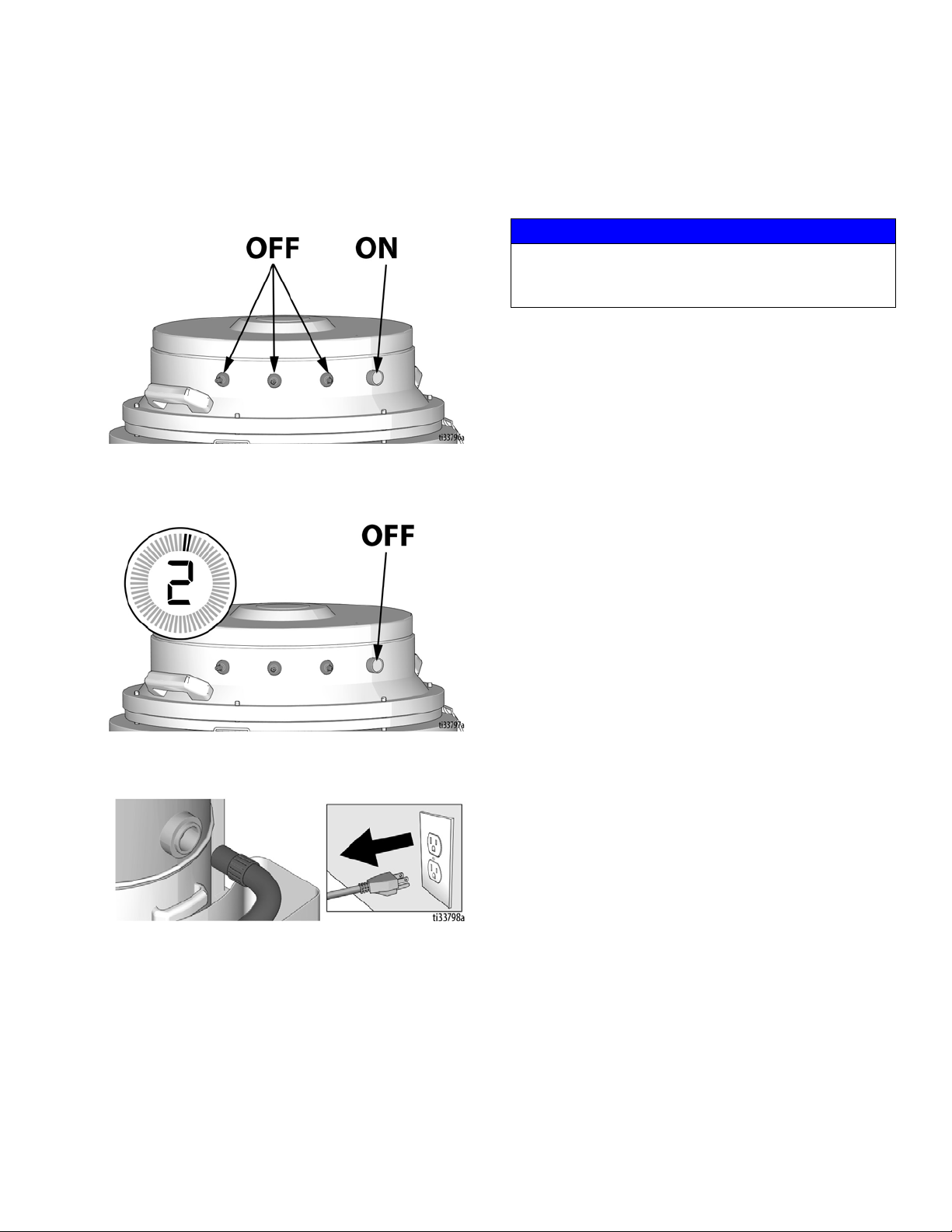

1. Ensure MaxiVac motor switches are turned to

“OFF”. Plug vacuum into grounded power source.

2. Turn Auto Filter Cleaner Power Switch to “ON”.

Ensure the sound of the Filter Cleaner Bar is heard

contacting the inside of the filter. If no sound is

heard, replace the Plastic Inserts on the cleaning

bar. See page 17.

3. After 10 seconds, turn on a Vacuum Motor Switch.

Turn on additional vacuum motors if needed.

4. MaxiVac is now ready for dust collection from the

GrindLazer or other removal equipment.

Emptying Collection Tanks

1. When Dust Collection Tanks are full, turn off all

vacuum motors. Turn Auto Filter Cleaner power

switch to “ON”. After 2 minutes of cleaning the

vacuum filters, turn off cleaning switch and unplug

vacuum from power source.

2. If MaxiVac is full, remove Dust Collection Tank by

pulling up on the Engagement Lever.

3. If Cyclone separator is full, remove the Separator

Lid.

4. Wearing a respirator, gather and secure the top of

the collection bag. Lift and remove the collection

bag, tie up and then dispose. Follow local

ordinances and regulations for disposal.

5. Insert new bags into the collection tanks and

reinsert the tanks into the Cyclone separator and

into the bottom of the MaxiVac. Ensure the Dust

Collection Tank is securely attached to the body of

the vacuum by pushing down on the Engagement

Lever.

DUST HAZARD

Grinding concrete and other surfaces can create dust

that contains hazardous substances. To reduce the

risk of serious injury:

• Respirator must be worn when emptying or

cleaning Dust Collection Tanks or bags.

• Follow local ordinances and regulations for

disposal.

Shutdown and Storage

TBD 9

Shutdown and Storage

Shutdown

1. Turn off all vacuum motors and leave Auto Filter

Cleaner Power Switch to ON.

2. Allow the Auto Filter Cleaner to run for 2 minutes,

then turn to OFF.

3. Unplug MaxiVac from power source and remove

hoses from the vacuum.

Storage

Disconnect power cord before storing. Store indoors.

NOTICE

Do not store in a location with high temperatures or

excessive humidity, in order to prevent damage to

your MaxiVac components.

Maintenance

10 TBD

Maintenance

The following steps should be performed to maintain

proper operation and sustain the life of the MaxiVac.

Daily

• Prior to use, inspect all hoses for holes. Repair or

replace damaged hoses.

• To help maintain performance and dust control,

replace filters when:

- Vacuum filters have tears or are clogged.

- Airborne dust is visible when using the

MaxiVac.

Weekly

• Inspect Filter Ring Seal for damage. If damaged,

replace seal. Ensure seals are installed correctly

and properly sealed.

• Inspect Filter Cleaner Plastic Inserts for wear or

damage. Replace the inserts regularly to help

maintain performance and dust control.

DUST AND SHOCK HAZARD

To reduce the risk of serious injury:

• Respirator must be worn during all maintenance.

• Follow local ordinances and regulations for

disposal of dust.

• Unplug vacuum from power source before

maintenance.

Parts

TBD 11

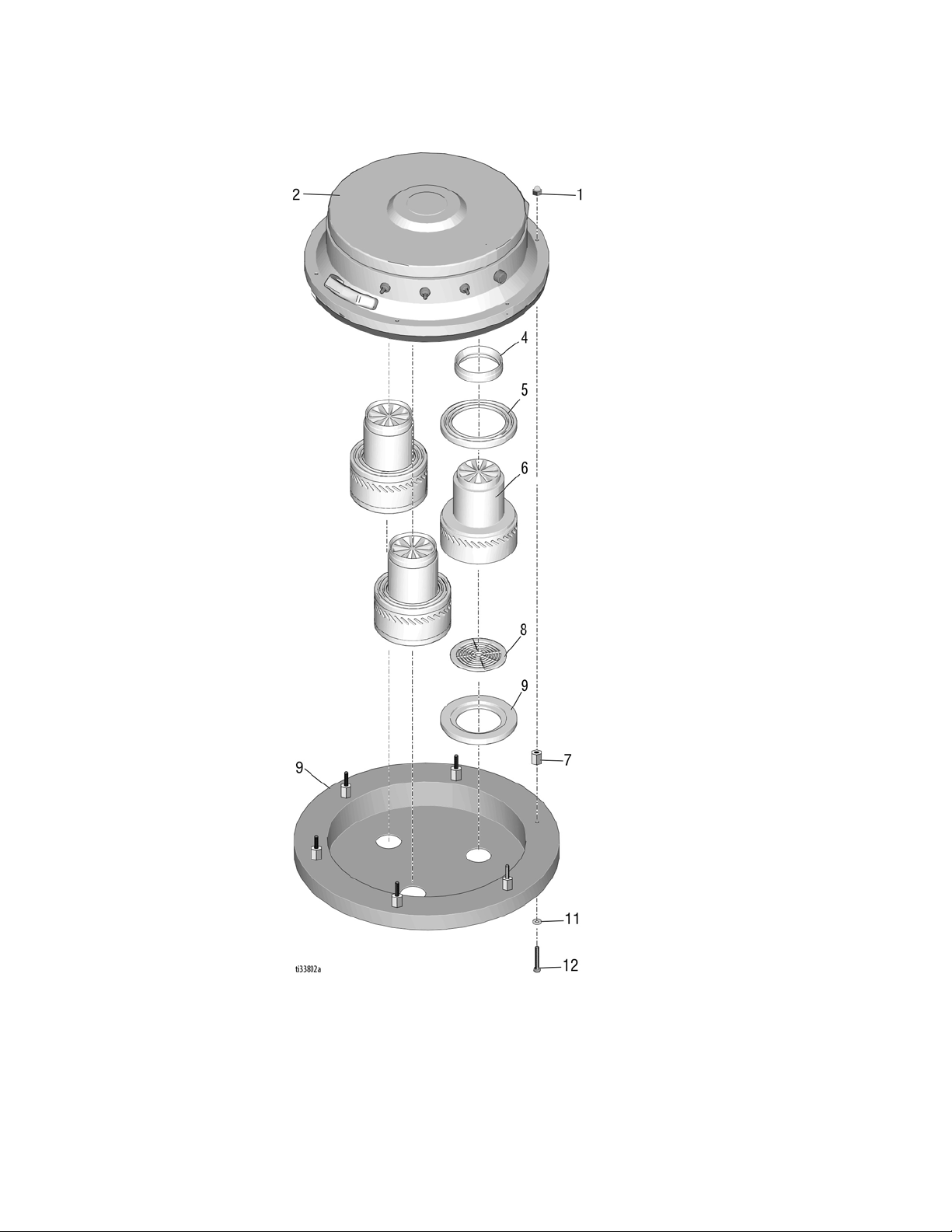

Parts

Main Assembly Diagram

(MaxiVac)

Parts

12 TBD

Main MaxiVac Assembly Parts

(MaxiVac)

Ref Part Number Description Qty

1 See page 13-15 Motor Housing Assembly 1

2 See page 17 Auto Filter Cleaner Assembly 1

3 MV.1.891A Filter 1

4 MV.30 Filter Seal Ring 2

5 17X187 Main Frame 1

6 17X188 Dust Collection Tank 1

9* MV.HS Long Vacuum Hose, Standard, 2” (includes item 19) 1

10 MV.26 Vacuum Extension 2

11 MV.24 Vacuum Large Brush 1

12 MV.22 Vacuum Small Brush 1

13 MV.25 Vacuum Floor Nozzle 1

14 MV.27 Vacuum Elbow 1

15‡

(not shown)

17X522 Warning Label (English, French, Spanish) 1

17X523 Warning Label (English, Chinese, Korean) 1

17X524 Warning Label (Icons) 1

16 MV.1.025 Dust Bag Holder 1

17 MV.3.20 Dust Bag (set of 20) 1

18 MV.Y Y-Connector (MV-360 only) 1

19 MV.23 2” Hose Connector 2

‡ Replacement warning, safety labels, tags, and cards are available at no cost.

*2” Heavy-Duty High-Temperature Hose Available: P/N MV.HS.SD

Parts

TBD 13

Motor Housing Assembly

Diagram (MV-360)

Parts

14 TBD

Motor Housing Assembly Parts

List (MV-360)

Part Number Description Qty

1 AHN.25-20 Acorn Nut 6

2 CH-PART(L)-04-a Motor Housing Cover (includes IEC power cord) 1

3 HN.25-20x1.0 Hex Spacer, Long (not shown, located inside item 2)6

4 MV.1.07 Set of Motor Rubber Rings and Plastic Net 3

6 MV.1.06A Motor, 230V 2

7 HN.25-20x.50 Hex Spacer, Short 6

10 MV.1.010 Motor Table 1

11 FLW.M6 Flat Washer 6

12 HX-CS.25-20x2FT Hex Head Screw Cap 6

20 17Y218 Power Cord, IEC 1

21†17X179 Cord Adapter, US, NEMA 1

22†17A242 Cord Adapter, Australia 1

23†15G961 Cord Adapter, Switzerland 1

24†15G960 Cord Adapter, Denmark 1

25†15G959 Cord Adapter, Italy 1

26†15G958 Cord Adapter, Europe, Schuko 1

27†121249 Cord Retainer for Cord Adapters (not shown) 1

† Cord Adapters sold separately

Parts

TBD 15

Motor Housing Assembly Diagram

(MV-600)

Parts

16 TBD

Motor Housing Assembly Parts List (MV-600)

Part Number Description Qty

1 AHN.25-20 Acorn Nut 6

2 CH-PART(L)-04 Motor Housing Cover (includes IEC power cord) 1

3 HN.25-20x1.0 Hex Spacer, Long (not shown, located inside item 2) 6

4 MV.1.07 Set of Motor Rubber Rings and Plastic Net 3

6 MV.1.06A Motor, 230V 3

7 HN.25-20x.50 Hex Spacer, Short 6

10 MV.1.010 Motor Table 1

11 FLW.M6 Flat Washer 6

12 HX-CS.25-20x2FT Hex Head Screw Cap 6

20 17Y218 Power Cord, IEC 1

21†17Y089 Cord Adapter, US, NEMA 21†

22†17A242 Cord Adapter, Australia 22†

23†15G961 Cord Adapter, Switzerland 23†

24†15G960 Cord Adapter, Denmark 24†

25†15G959 Cord Adapter, Italy 25†

26†15G958 Cord Adapter, Europe, Schuko 26†

27†121249 Cord Retainer for Cord Adapters (not shown) 27†

† Cord Adapters sold separately

Parts

TBD 17

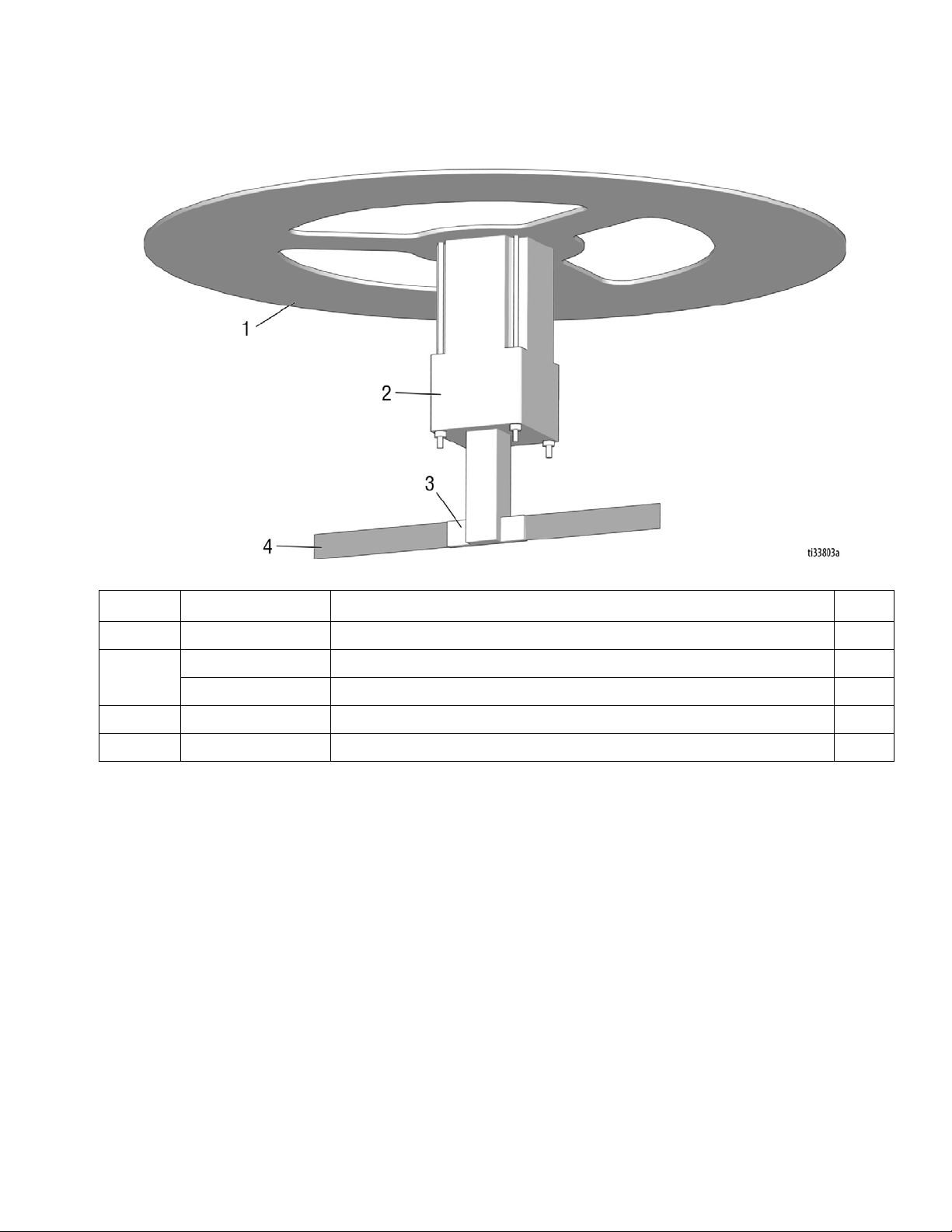

Auto Filter Cleaner Assembly

(MaxiVac)

Part Number Description Qty

1 MV.1.13A Auto Filter Cleaner Assembly Motor Stand 1

2MV.3.12B 120V Filter Cleaner Assembly Motor 1

MV.1.12A 230V Filter Cleaner Assembly Motor 1

3 MV.1.11-C Filter Cleaner Bar, Support (set of 2) 1

4 MV.1.11-D Filter Cleaner Plastic Inserts 2

Parts

18 TBD

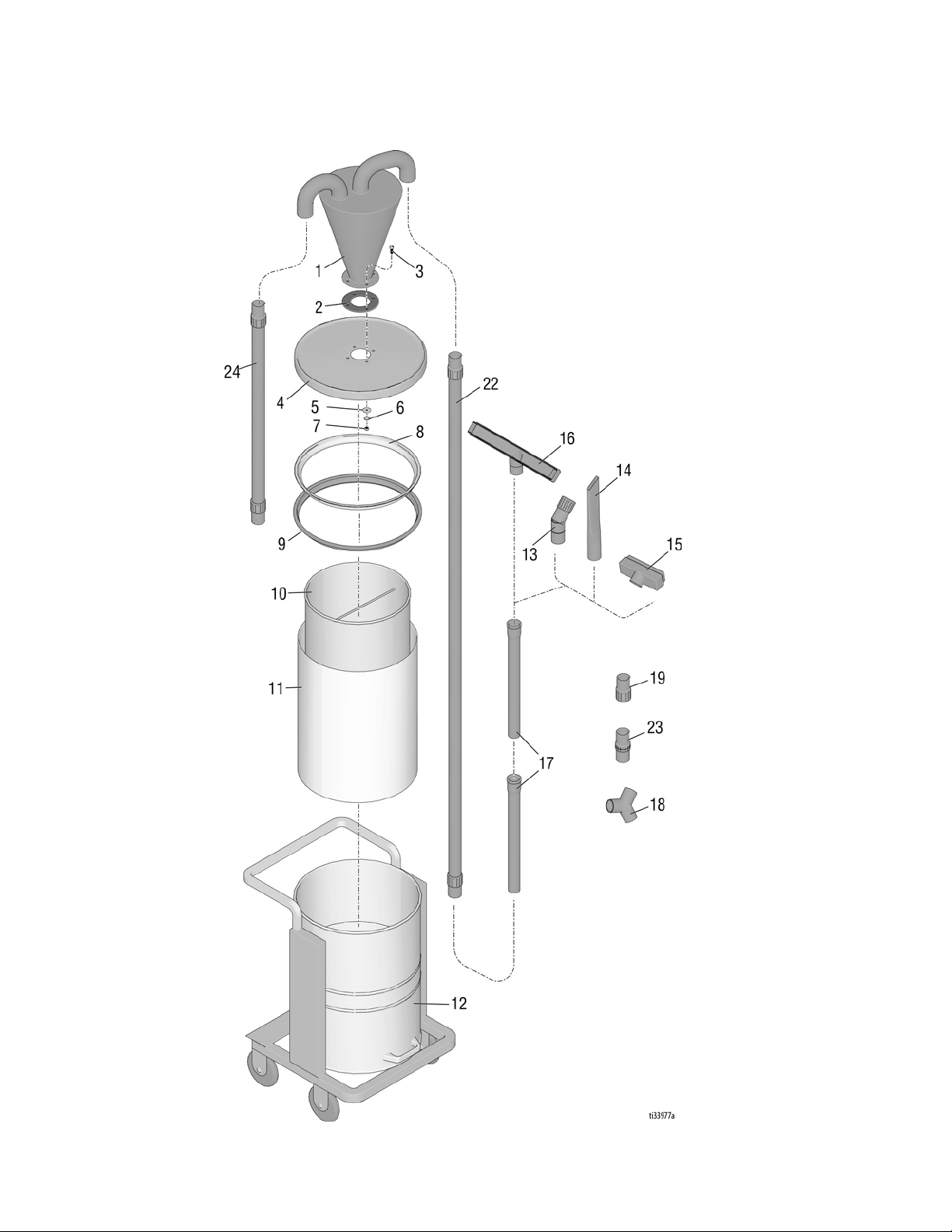

MV-SA Assembly and

Accessories

Parts

TBD 19

MV-SA Assembly and

Accessories Parts List

Part Number Description Qty

10 MV.HS.SD Long Vacuum Hose 1

11 MV.HS.5 Short Vacuum Hose 1

12 17X694 Debris Tank 1

13 MV.3.20 Dust Bag 1

14 MV.1.025 Dust Bag Holder 1

15 MV.30 Cyclone Seal Ring 1

16 MV.31 Cyclone Ring 1

17 MV.SB.4 Cyclone Head 1

18 17X190 Vacuum Extension 2

19 17X191 Vacuum Elbow 1

20 17X192 Vacuum Floor Nozzle 1

21 17X193 Vacuum Small Brush 1

22 17X194 Vacuum Large Brush 1

23 17X700 Y-Connector 1

24 17X701 2” (50 mm) Connector 2

25 VM.24 2” (50 mm) Hose Coupler 1

Parts

20 TBD

MV-SB Assembly and

Accessories

This manual suits for next models

3

Table of contents