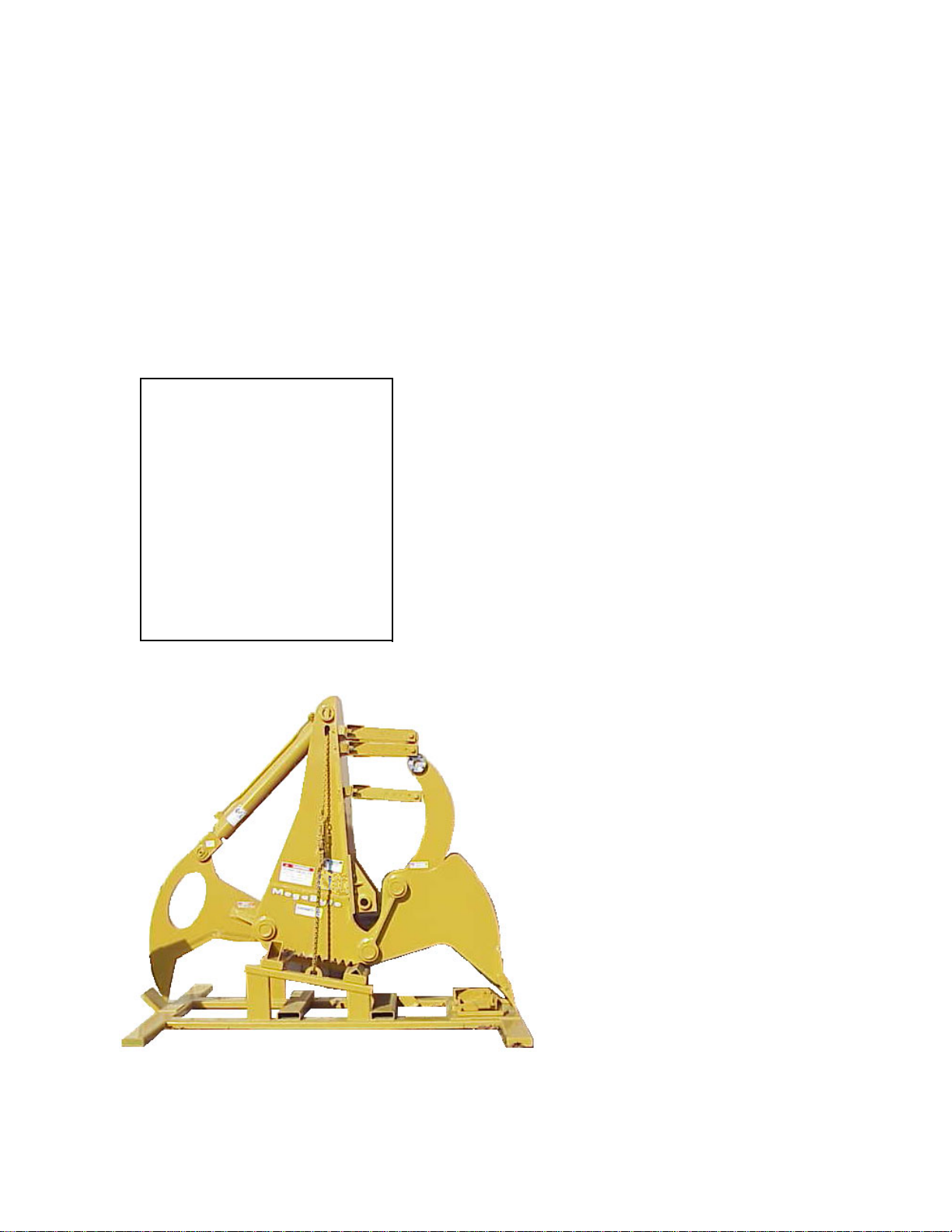

SMORACY MEGABYTE User manual

MEGABYTE™

OPERATING & PARTS MANUAL

BUILT WITH QUALITY AND DESIGN FIRST

Model No: _________________

Serial No: _________________

DEALER:

Name: ____________________

Address: __________________

City/State: _________________

Phone No: _________________

Delivery Date: ______________

MEGABYTE

ATTENTION:

Depending on what

replacement parts

you are ordering, we

willneedthefollowing

information:

SERIAL NUMBER

OF MEGABYTE™

EXCAVATOR MAKE

AND MODEL

MANUFACTURED BY

SMORACY, LLC

6750 Millbrook Road

REMUS, MICHIGAN 49340

PHONE: (517) 561-2270 OR 561-2272

FAX: (517) 561-2273 ~ SALES DEPT.

FAX: (517) 561-2962 ~ PARTS/SERVICE

MEGABYTE™

™

PRINTED 2/01

MEGABYTE™ TABLE OF CONTENTS

Smoracy, LLC

PRINTED 2/01 PAGE 1

TABLE OF CONTENTS

NOTE- ANY PART, PORTION, DESIGN, NUMBER, SPECIFICATION, AND/OR

DIMENSION IN THIS MANUAL IS SUBJECT TO CHANGE WITHOUT

NOTICE BY THE MANUFACTURER.

PAGES

INTRODUCTION & WARRANTY ...................................................2

SAFETY PROCEDURES ...............................................................7

SAFETY DECALS ......................................................................... 9

OPERATING PROCEDURES ......................................................12

INSTALLATION PROCEDURES ................................................. 13

LUBRICATION .............................................................................19

MAINTENANCE ...........................................................................20

HYDRAULIC SECTION ............................................................... 22

REPLACEMENT PARTS SECTION ............................................ 23

MEGABYTE™ INTRODUCTION & WARRANTY

INTRODUCTION

The purpose of this manual is to provide the user with specifications and procedures for the

operation, maintenance and repair of the Megabyte™. As with any piece of equipment, safety should

always be a constant thought while the equipment is being operated, serviced or stored. In order

to highlight this consideration, the material which addresses safety is proceeded by the

following signal words:

Signal Word Likelihood of Occurence Degree of Potential

Injury or Damage

DANGER!

WARNING!

CAUTION!

NOTICE

Will occur if warning is ignored

Can occur if warning is ignored

Will or can occur if warning is ignored

Important, but not hazard related

Severe

Severe

Minor to Severe

Minor

The Megabyte™ is designed and manufactured in accordance with the latest industry standards.

This alone does not prevent injury. It is the operator’s responsibility to use good judgement and

follow the warnings and instructions as indicated in this manual.

WARNING!

Improper use of the Megabyte™ can result in severe personal injury. Personnel using the

Megabyte™must be qualified, trained and familiar with the operating procedures as defined in this

manual.

WARNING!

It is the responsibility of the owner or employer to insure that the operator is trained and practices

safe operation while using and servicing the equipment. It is also the owner’s responsibility to

provide and follow a regularly scheduled preventative maintenance and repair program on the

Megabyte™, using only factory approved replacement parts. Any unapproved repairs or

modifications may not only damage the machine and its performance, but could result in severe

personal injury. Consult the equipment manufacturer!!!

Each machine is shipped with a manual, a customer’s check sheet on the Megabyte™, and any

available parts & service manuals on component parts not produced by this manufacturer.

Additional copies of these manuals and check sheets can be purchased from the manufacturer, or

through the dealer.

NOTE - The producer of the Megabyte™ reserves the right to make any

modifications or revisions to the design or specifications of its equipment without

advance notice. The producer also reserves the right to change equipment and

part prices as needed without advance notice.

Smoracy, LLC

PRINTED 2/01 PAGE 2

MEGABYTE™ SERVICE RECORD

SERVICE RECORD

DATE DESCRIPTION AMOUNT

Smoracy, LLC

PRINTED 2/01 PAGE 6

MEGABYTE™ SAFETY PROCEDURES

SAFETY PROCEDURES

DANGER!

The words Danger!, Warning!, Caution!, and

Notice are used on the safety decals and throughout

this manual, to make you aware of the safety

procedures. These procedures are very important,

read and obey them.

YOUR SAFETY IS VERY IMPORTANT TO US!

This equipment is equipped with safety decals, and

designs for your protection.

Don’t ever take the equipment for granted, always

be cautious and careful when operating your

equipment.

Read and follow all the instructions in your manual

thoroughly. Your safety is dependent on your

knowledge of how to operate and maintain this

equipment. You may obtain additional copies of this

manual from your Smoracy, LLC Dealer.

Before operating Megabyte™, you must have all

potentialoperators; readand understandmanual, and

follow the recommendations.

Regardless of how hard a manufacturer tries to

produce a safe machine, accidents still happen.

Normally accidents are caused by people making

mistakes. They do not read the manual, they ignore

warning decals or do not use lockouts provided for

their safety. This normally happens after the person

has become accustomed to the machinery. In the

initial start up and operation of the machinery, they

are cautious, they are very careful because they do

not understand the machine.

Never split any materials that might contain

wires, stones, nails, or other metal objects which

may damage the blades and become dangerous

projectiles.

WARNING!

Most of the nuts used on the Megabyte™ are self

locking. After the nut has been removed five times, it

should be replaced to insure proper tightness.

Before using the equipment, take a minute to check

a few things. The Megabyte™ should be in an area

restricted from people passing by. This area around

the Megabyte™ must be free of all objects that can

obstruct your movement when working with the

equipment.

DANGER!

Never check for hydraulic leaks by touching

hoses or fittings with your bare hands. Hydraulic

fluid under pressure can penetrate the skin. Use a

piece of cardboard to find leaks. Never use your

bare hands.

To obtain the most from your Megabyte™, for the

least amount of cost, it is a good practice to set and

follow a scheduled preventative maintenance

program. It will eliminate many possible problems

and down time.

DANGER!

Smoracy, LLC

PRINTED 2/01 PAGE 7

FLYING OBJECTS

KEEP WELL AWAY FROM

MACHINE WHILE IN

OPERATION.

MEGABYTE™ SAFETY PROCEDURES

SAFETY PROCEDURES

DANGER!

Torn or loose clothing is more likely to get caught in

movingmachinery parts ortree branches. Keep such

items as long hair, shirt sleeves, and shirt tails

properly contained. Avoid wearing necklaces, rings,

watches, and especially neckties while operating this

machinery. Make sure the machine is in excellent

condition.

Keep children, bystanders and animals clear of

workingarea. Neveroperateequipmentthat isinneed

of repair or adjustment.

Wear all applicable safety equipment examples:

hard hat, safety glasses, gloves, ear protection, etc.

You should always keep a fully charged fire

extinguisher with you while operating or servicing

the equipment.

DANGER!

DO NOT GO NEAR HYDRAULIC LEAKS!

High pressure oil easily punctures skin causing

serious injury, gangrene, or death.

DO NOT use fingers or skin to check for leaks.

Lower load or relieve hydraulic pressure before

loosening fittings.

WARNING!

DANGER!

WARNING!

Operators must at all times be located within easy

reach of all feed control and shut-off devices when

the unit is running.

DANGER!

NEVER work on the Megabyte™ unless the

excavator engine is shut off, the ignition key is

removed and in your pocket, and the battery cables

are disconnected.

Smoracy, LLC

PRINTED 2/01 PAGE 8

DO NOT GO NEAR LEAKS!

•High pressure oil easily punctures

skin causing serious injury,

gangrene or death.

• If injured, seek emergency medical

help. Immediate surgery is

required to remove oil .

• Do not use finger or skin to check

for leaks.

• Lower load or relieve hydraulic

pressure before loosening fittings.

MEGABYTE™ SAFETY DECALS

SAFETY DECALS

Safety Decals located on your Megabyte™ contain useful information to assist you in operating your

equipment safely. Some of the decals on your equipment and their location are shown in this section.

It is very important that all decals remain in place and in good condition on your equipment. Please follow

the care and instructions given below:

1) You should use soap and water to keep your decals clean. Never use mineral spirits or

any other abraisive cleaners.

2) Replace immediately any missing or damaged decals. The location the decal is going

to be applied to must be clean and dry, and at least 40° F (5°C) before applying decal.

3) When the need arises to replace a machine component with a decal attached, be sure

and replace the decal.

4) Replacement decals are available, and can be purchased from the manufacturer or

your Smoracy, LLC Dealer.

5) Spanish, Portuguese and other foreign language decals are available.

EXAMPLES:

Smoracy, LLC

PRINTED 2/01 PAGE 9

GREASE

DAILY

KEEP HANDS CLEAR

THIS MACHINE IS CONVERED

BY ONE OR MORE OF THE

FOLLOOWING PATENTS:

5,362,004

5,372,316

5,413,286

5,863,003

5,988,539

6,000,642

6,016,855

6,032,707

6,036,125

6,047,912

6,059,210

6,176,572 THE OWNER IS RESPONSIBLE

TO REPLACE ANY REMOVED

OR DAMAGED DECALS.

You may also purchase decals in another language.

Mail the translated decals you require to:

PARTS DEPARTMENT

6750 MILLBROOK RD., REMUS, MI 49340.

We will contact you with cost and availability

of the translated decals.

MEGABYTE™ SAFETY DECALS

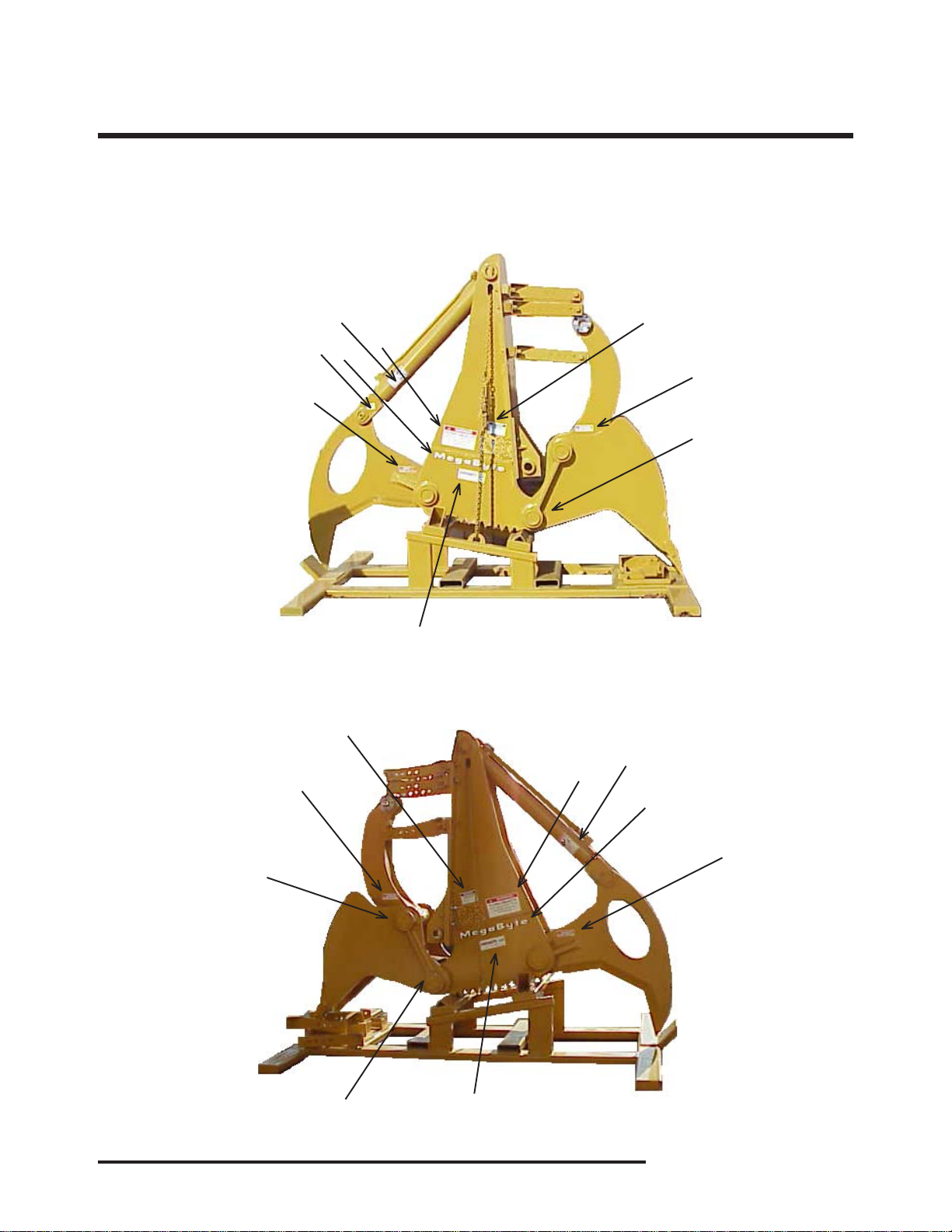

DECAL LOCATIONS - MEGABYTE™

ALTHOUGH LOCATIONS MAY VARY, ALL DECALS MUST BE ON EQUIPMENT DURING OPERATION

IF ANY DECALS BECOME DAMAGED, REPLACE IMMEDIATELY.

Smoracy, LLC

PRINTED 2/01 PAGE 10

2

5

1

6

8

5

73,4

2

5

2

5

3,4

8

6

1

7

2

MEGABYTE™ SAFETY DECALS

DECAL LOCATIONS - MEGABYTE™

Modifications and/or additions of decals to this list will happen.

Consult Megabyte™ dealer or manufacturer for most current decal package.

LOCATION NUMBER DESCRIPTION

1. OOB-150 Smoracy, LLC...

2. OOB-275 Grease Daily

3. OOB-287 Notice Patent Pending

4. OOB-2003 Notice The Owner Is...

5. OBR-400 Danger! Keep Hands Clear...

6. OBR-436 Danger! Flying Objects...

7. OBR-4031 Warning! Do Not Go Near...

8. Megabyte™ Vinyl

Smoracy, LLC

PRINTED 2/01 PAGE 11

MEGABYTE™ OPERATING PROCEDURES

OPERATING PROCEDURES

DANGER!

Do not let anyone operate or maintain this machine until they have thoroughly read this

manual. You can purchase additional Megabyte™ manuals for a nominal fee.

DANGER!

Before operating the equipment make sure that no one is within fifty feet of the Megabyte™.

DANGER!

Always wear a hard hat, safety glasses, gloves, ear protection, etc.

DANGER!

It is very important after you have operated

thenew equipmentforapproximately anhour,

shutdown theequipmentand recheckallnuts

andbolts. It is normal for bolts to loosenonce

ona new piece of machinery. If you tighten

system idle for approximately 15 minutes to

allow the system to warm up to operating

temperature.

This equipment is intended for use by

personnel who are experienced with similar

equipment. Alwaysoperateequipmentsafely.

It is also recommended that someone else is

present while splitting or servicing in case an

injury occurs. Never operate any equipment

while under the influence of drugs or

alcohol.

Smoracy, LLC

PRINTED 2/01 PAGE 12

them now there’s a

good possibility they

won’t loosen again. I n

cold weather situations

let your hydraulic

MEGABYTE™ INSTALLATION PROCEDURES

INSTALLATION PROCEDURES

Smoracy, LLC

PRINTED 2/01 PAGE 13

AT ALL TIMES OBSERVE ALL STANDARD SAFETY PRACTICES!

The Megabyte™ must be sitting on its stand for proper installation. When installing your

Megabyte™ you must follow these instructions.

DANGER!

Step 1: Detaching Bucket and Setting Up Megabyte™.

Step 2: Positioning Excavator Stick.

Step 3: Pin Installation.

Step 4: Saddle Clamp Installation.

Step 5: Attaching Megabyte™ Link, Excavator Link, and

Excavator Hydraulic Cylinder.

Step 6: Auxiliary Hydraulic Installation.

NOTICE

Auxiliary valve hookup is required, if your excavator does not have this accessory, see the

excavator manufacturer for ordering and installation information.

MEGABYTE™ INSTALLATION PROCEDURES

Smoracy, LLC

PRINTED 2/01 PAGE 14

STEP 1

DETACHING BUCKET & MEGABYTE™ SET UP

1) Lower bucket and rest on ground.

2) Shut machine off.

3) Remove pin attaching “Dogbone” on bucket and to stick.

4) Remove pin holding bucket to end of stick. Leaving upper links attached to stick.

5) Remove bucket.

6) Start machine and raise stick high enough to fit the Megabyte™ on its stand under stick.

7) Position Megabyte™ in place.

8) Remove saddle clamps and lay the Megabyte™ link back.

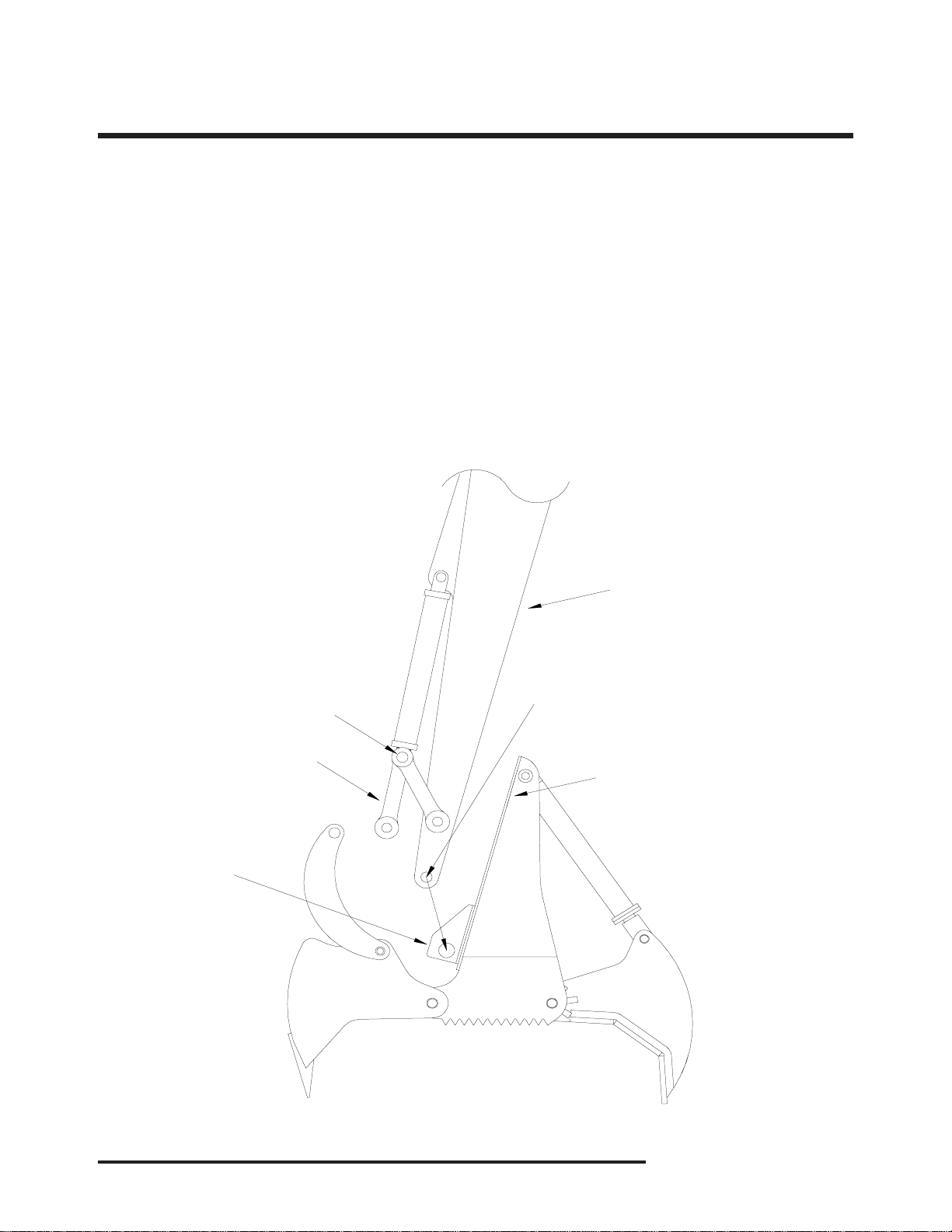

FIGURE 1

SADDLE CLAMP

MEGABYTE™

LINK

ADAPTOR

AND PIN

SADDLE

LOCATOR

SADDLE CLAMP

SADDLE

CLAMP

MEGABYTE™ INSTALLATION PROCEDURES

Smoracy, LLC

PRINTED 2/01 PAGE 15

STEP 2

POSITIONING EXCAVATOR STICK

1) Lower the excavator stick down in between the saddle locators. The excavator stick must

be located to where the center of the pin hole on the bottom of the excavator is centered

with the pin holes on the saddle locators. Make sure that the excavator stick is centered

on the Megabyte™ base plate.

2) Remove the original dogbone from the excavator stick by removing the pin connecting the

dogbone to the excavator cylinder. Do not reinstall pin at this time.

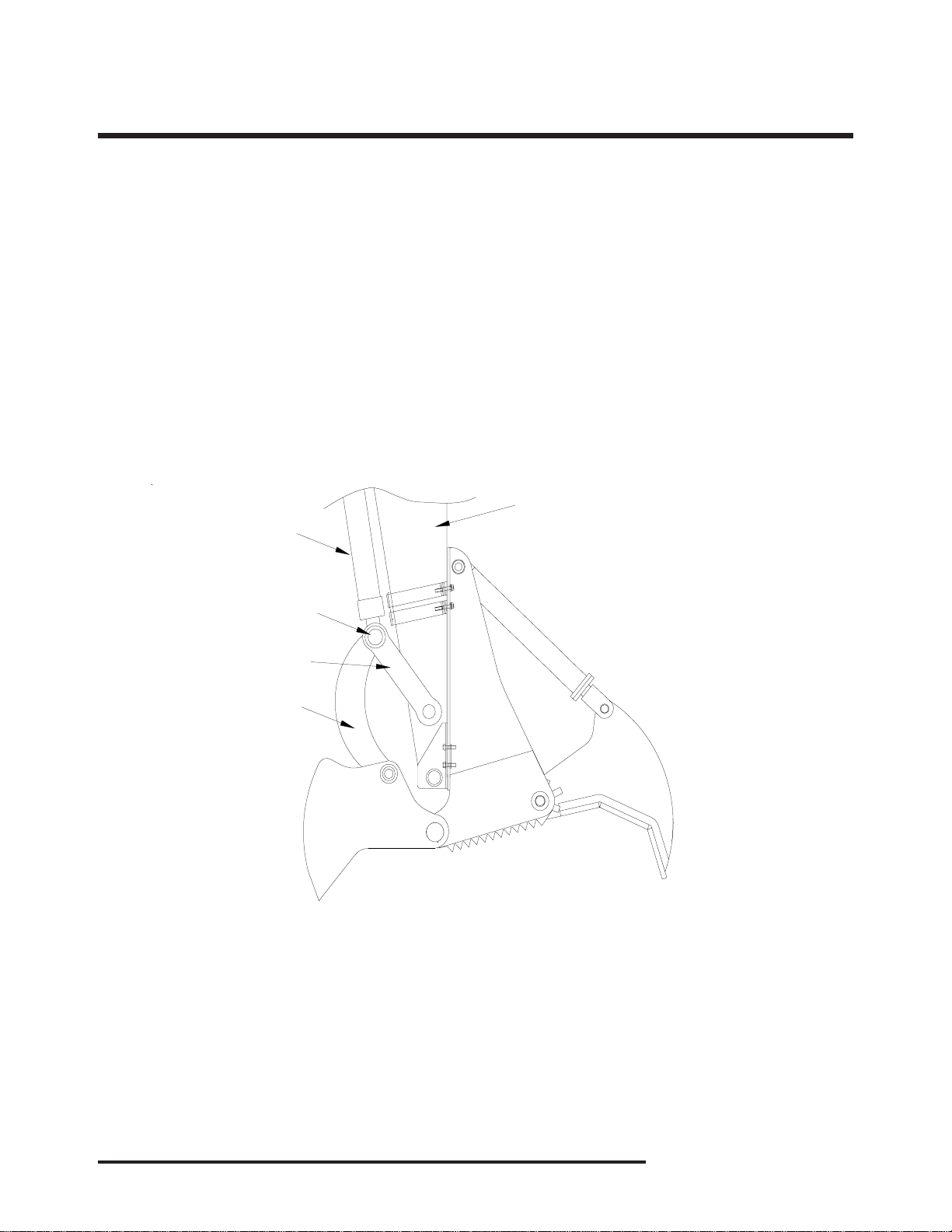

FIGURE 2

EXCAVATOR

STICK

ORIGINAL

DOGBONE

SADDLE

LOCATOR

CENTER UP HOLES

BASE PLATE

REMOVE

PIN

MEGABYTE™ INSTALLATION PROCEDURES

Smoracy, LLC

PRINTED 2/01 PAGE 16

STEP 3

PIN INSTALLATION

1) Position the saddle locator against the excavator stick.

2) Tighten down the bolts on the saddle locator. Torque these bolts to 700 ft./lbs.

3) Drive the pin through one saddle locator, through excavator stick, and into the saddle

locator on the other side.

4) Check the alignment of saddle locator and excavator stick by sliding the pin in and out

of the saddle locators. Make sure pin goes all the way through excavator stick and

both saddle locators. Make sure the saddle locators are in the correct position before

beginning to weld.

5) Use E-7018 stick electrodes to weld saddle locators in place to the base plate with full

perimeter welds. (YOU MUST USE FULL PERIMETER WELDS TOP, BOTTOM, RIGHT

AND LEFT SIDE.) NOTE: Mig process may be used using an equivalent E-70 series

type wire. (See Darkened areas of Figure 3).

NOTICE

Just Tightening bolts on saddle locators will not hold, full perimeter welds Must be done.

FIGURE 3

SADDLE

LOCATOR

SADDLE

LOCATOR SADDLE

LOCATOR SADDLE

LOCATOR

WHEN SADDLE LOCATOR IS

IN POSITION & TIGHTENED

DOWN, WELD ALL SIDES.

BASE

PLATE

ORIGINAL

EXCAVATOR PIN

EXCAVATOR STICK

EXCAVATOR

STICK

MEGABYTE™ INSTALLATION PROCEDURES

Smoracy, LLC

PRINTED 2/01 PAGE 17

STEP 4

SADDLE CLAMP INSTALLATION

1) After installing pin assembly at the end of the excavator stick and welding in place

reattach the saddle clamps from where they were removed.

2) Loosely bolt together the three separate pieces of each clamp.

3) Install saddle clamps over excavator stick and bolt to base plate.

4) Use spacers and tapered washers provided. (See Figure 5)

5) Adjust clamps to fasten down as tight as possible against excavator stick. Once clamps

are adjusted cut off any excess metal from the top of the saddle clamp arms.

6) Tighten down clamps to eliminate any movement front to back and side to side of

excavator stick.

7) Torque bolts to 700 ft./lbs.

8) The kit includes three different width cross-members, use the size needed to keep

saddle clamps tight to excavator sides.

FIGURE 4

FIGURE 5

TAPERED WASHERS

USE SPACERS AS NEEDED

BASEPLATE NUT LOCK

NUT

SADDLE CLAMPS

AND SPACERS

BASE PLATE

EXCAVATOR

STICK

MEGABYTE™ INSTALLATION PROCEDURES

Smoracy, LLC

PRINTED 2/01 PAGE 18

STEP 5

ATTACHMENT OF LINKS

1) Swing Megabyte™ Link so the pinhole can be aligned with excavator link holes.

(See Figure 6).

2) Locate the Megabyte™ Link Pin through the excavator link and into the first bushing

on the Megabyte™ Link.

3) Extend hydraulic cylinder rod until cylinder rod eye is aligned with pin.

4) Install pin through cylinder eye and into second Megabyte™ Link bushing.

5) Swing second excavator link up in line with pin and push pin through.

6) Lock pin in place with bolt on bushing (provided with pin).

FIGURE 6

EXCAVATOR

CYLINDER

PIN LOCATION

EXCAVATOR LINK

MEGABYTE™ LINK

EXCAVATOR

STICK

STEP 6

AUXILIARYHYDRAULIC INSTALLATION

1) Auxiliary hydraulic valve set up should already be installed.

(Per Manufacturers Specifications.)

2) Attach auxiliary hydraulic line from excavator to cylinder on Megabyte™.

3) Run machine to fill lines and cylinder. Check hydraulic fluid level, adjust as necessary.

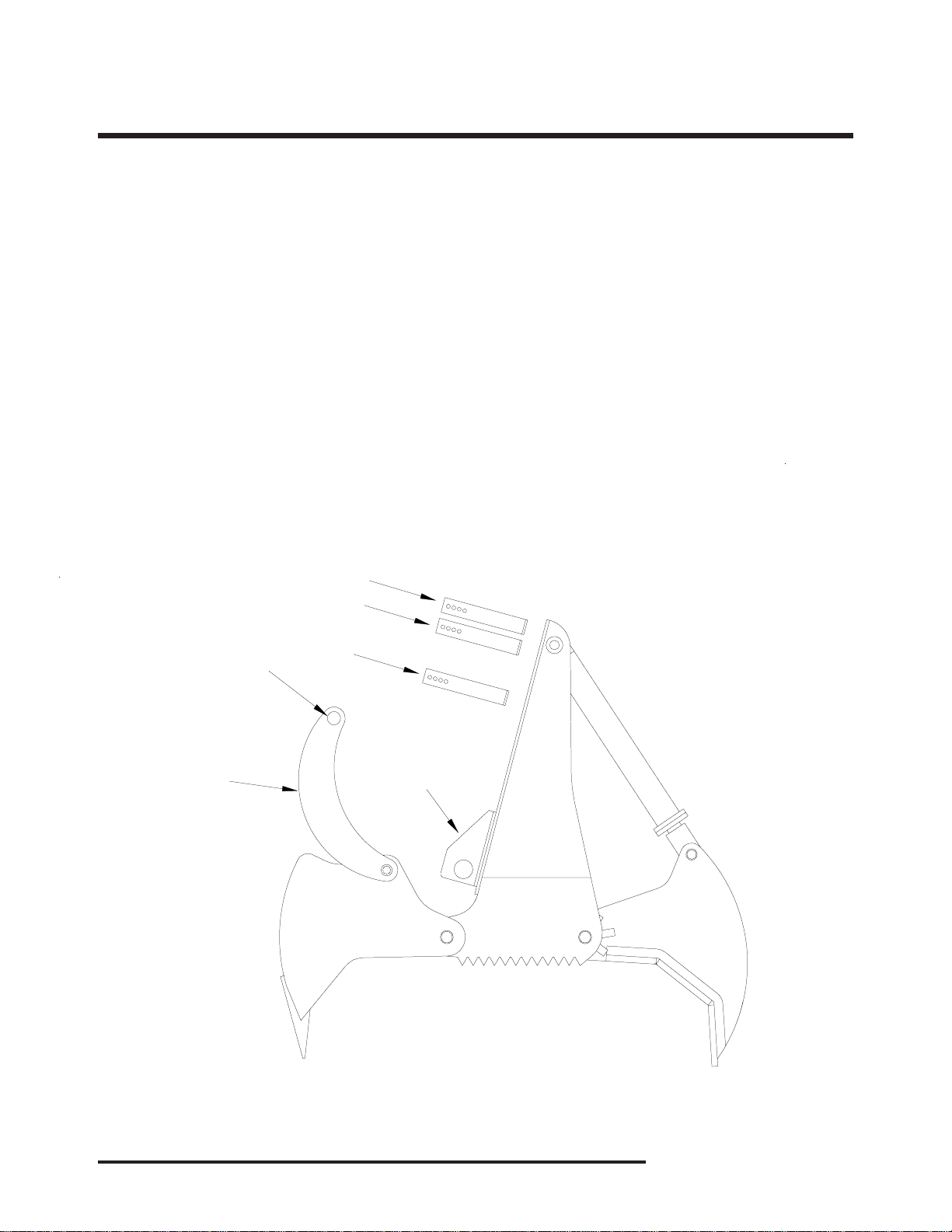

MEGABYTE™ LUBRICATION SECTION

LUBRICATION POINTS

LOCATION DAILY WEEKLY MONTHLY DESCRIPTION

1. X Cylinder Rear Pivot Bushing

2. X Cylinder Clevis Pin

3. X Knife Pivot Bushing

4. X Anvil Pivot Bushing

5. X Anvil Link Bushing

Smoracy, LLC

PRINTED 2/01 PAGE 19

EXCAVATOR ...............................................Follow original equipment manufacturers requirements

for proper lubrication procedures.

CLYINDER REAR PIVOT BUSHING ...........Grease this bushing daily.

CLYINDER CLEVIS PIN ..............................Grease this pin daily.

KNIFE PIVOT BUSHING .............................Grease this bushing daily.

ANVIL PIVOT BUSHING .............................Grease this bushing daily.

ANVIL LINK BUSHING ................................Grease this bushing daily.

1

2

4

3

5

MEGABYTE™ MAINTENANCE

MAINTENANCE SECTION

O.K. Repaired

MONTHLY

1) Check entire machine for loose bolts, nuts, components.

2) Check hydraulic oil level, hoses, fittings.

3) Check the safety decals replace if damaged.

4) Check cutting blade assembly.

5) Check for wear on teeth.

6) Check for wear on wedge.

DAILY

1) Check all hydraulic pressures, reset to correct P.S.I.

O.K. Repaired

ITEMS TO BE SERVICED DAY WEEK MONTH PROCEDURE (Always Replace If Needed)

CHECK

Check Entire Machine X For any loose parts or components

Hydraulic Oil Leaks, Hoses, Fittings X Inspect, tighten, repair or replace

Safety Decals X Replace immediately if damaged

Check Blade, Bolts, and Nuts X SEE BOLT TORQUE CHART

Check Wear On Teeth X If worn out, replace

Check Wear On Wedge X If worn out, replace

Hydraulic Pressure X Check and reset to correct P.S.I

Smoracy, LLC

PRINTED 2/01 PAGE 20

MAINTENANCE PROCEDURES

Table of contents