Menzi Muck IHI 12VXE User manual

Menzi Muck AG Telefon +41 (0)71 727 12 12

9451 Kriessern/Switzerland Fax +41 (0)71 727 12 13

www.menzimuck.com

Operator’s manual

Menzi IHI 12vxe

!

! !

!

"#$$$

"#$$$"#$$$

"#$$$

$%

$%$%

$%&

&&

&

'$

'$'$

'$

($)*$*$)+

(* )INDICATE THE TYPE OF INTERVENTION PERFORMED IN THE NOTES FIELD

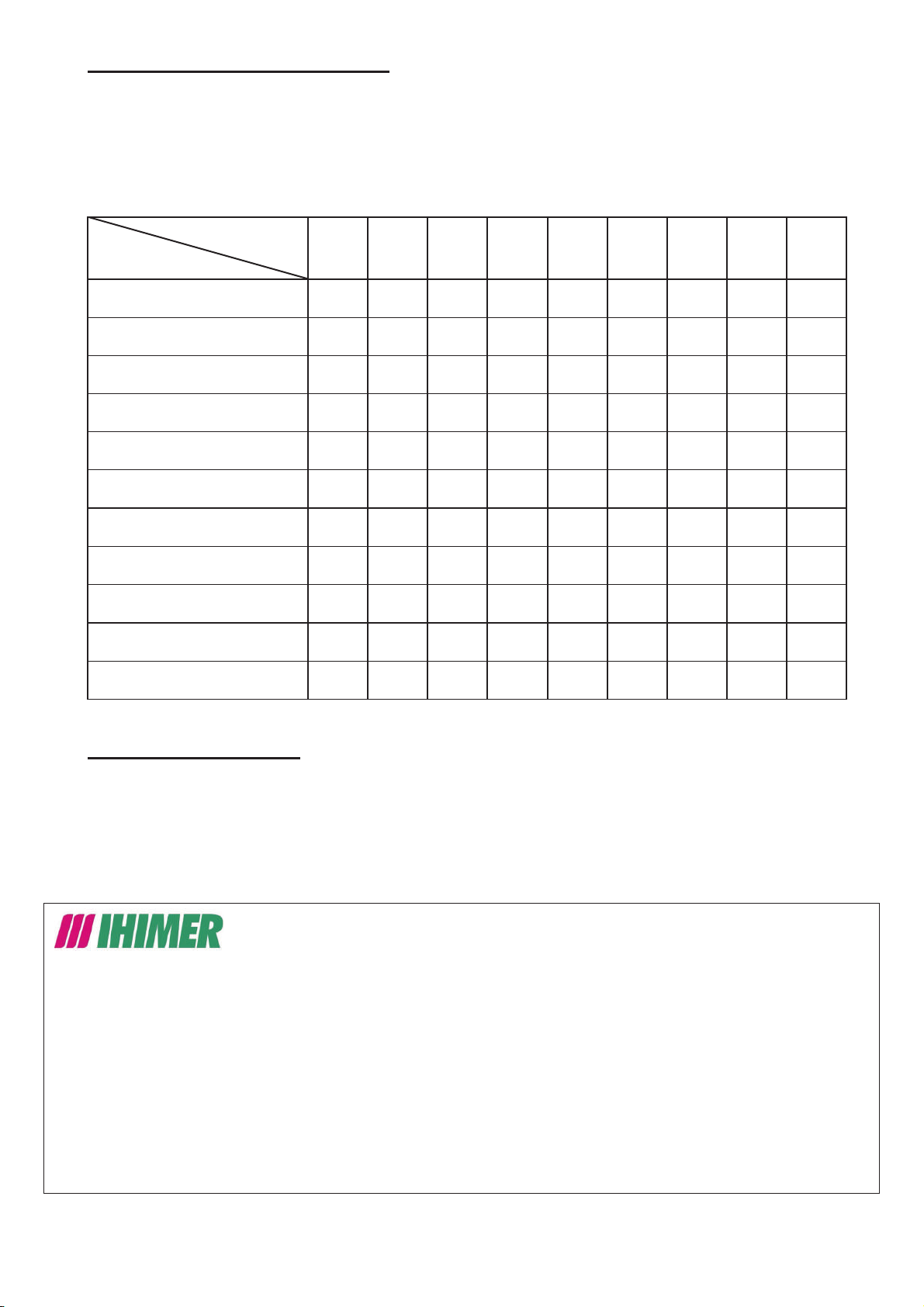

SCHEDULED MAINTENANCE

Proper maintenance is essential to long service life and optimal operation. IHIMER has scheduled a series of

controls and work to be done at our authorised service centres.

WARNING: Scheduled services are required by the Manufacturer. Failure to observe this requirement voids

the warranty.

PROGRAMMED SERVICE TABLE

HOURS

JOB

50 250 500 750 1000 1250 1500 1750 2000

Diesel engine oil and filter

change •

••

• •

••

• •

••

• •

••

• •

••

• •

••

• •

••

• •

••

• •

••

•

Hydraulic circuit return filter

change •

••

• •

••

• •

••

• •

••

• •

••

• •

••

• •

••

• •

••

•

Fuel filter change •

••

• •

••

• •

••

• •

••

• •

••

• •

••

• •

••

• •

••

•

Fan belt inspection and

tensioning •

••

• •

••

• •

••

• •

••

• •

••

• •

••

• •

••

• •

••

•

Engine coolant change •

••

• •

••

• •

••

• •

••

• •

••

• •

••

• •

••

• •

••

•

Setting fasteners •

••

• •

••

• •

••

• •

••

•

Air filter change •

••

• •

••

• •

••

• •

••

•

Check and adjust track

tension •

••

• •

••

• •

••

• •

••

•

Travel gear reducer check •

••

• •

••

• •

••

• •

••

•

Travel gear reducer oil

change •

••

••

••

•

Hydraulic plant fluid and filter

change •

••

••

••

•

SERVICE REGISTER

SPACE RESERVED FOR REGISTERING SCHEDULED SERVICES.

Determine the service schedule from the scheduled service table and indicate the type of work to be done

(SERVICE or REPAIR - indicate in the notes ) fill in all other fields.

JOB N°1

SERVICE

JOB (*)

notes : ____________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

STAMP AND SIGNATURE

DONE AT HOURS : ________ DATE : _________________ _____________________________

(* )INDICATE THE TYPE OF INTERVENTION PERFORMED IN THE NOTES FIELD

JOB N°2

SERVICE

JOB (*)

notes : ____________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

STAMP AND SIGNATURE

DONE AT HOURS : ________ DATE : _________________ _____________________________

JOB N°3

SERVICE

JOB (*)

notes : ____________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

STAMP AND SIGNATURE

DONE AT HOURS : ________ DATE : _________________ _____________________________

JOB N°4

SERVICE

JOB (*)

notes : ____________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

STAMP AND SIGNATURE

DONE AT HOURS : ________ DATE : _________________ _____________________________

JOB N°5

SERVICE

JOB (*)

notes : ____________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

STAMP AND SIGNATURE

DONE AT HOURS : ________ DATE : _________________ _____________________________

(* )INDICATE THE TYPE OF INTERVENTION PERFORMED IN THE NOTES FIELD

JOB N°6

SERVICE

JOB (*)

notes : ____________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

STAMP AND SIGNATURE

DONE AT HOURS : ________ DATE : _________________ _____________________________

JOB N°7

SERVICE

JOB (*)

notes : ____________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

STAMP AND SIGNATURE

DONE AT HOURS : ________ DATE : _________________ _____________________________

JOB N°8

SERVICE

JOB (*)

notes : ____________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

STAMP AND SIGNATURE

DONE AT HOURS : ________ DATE : _________________ _____________________________

JOB N°9

SERVICE

JOB (*)

notes : ____________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

STAMP AND SIGNATURE

DONE AT HOURS : ________ DATE : _________________ _____________________________

(* )INDICATE THE TYPE OF INTERVENTION PERFORMED IN THE NOTES FIELD

JOB N°10

SERVICE

JOB (*)

notes : ____________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

STAMP AND SIGNATURE

DONE AT HOURS : ________ DATE : _________________ _____________________________

JOB N°11

SERVICE

JOB (*)

notes : ____________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

STAMP AND SIGNATURE

DONE AT HOURS : ________ DATE : _________________ _____________________________

JOB N°12

SERVICE

JOB (*)

notes : ____________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

STAMP AND SIGNATURE

DONE AT HOURS : ________ DATE : _________________ _____________________________

JOB N°13

SERVICE

JOB (*)

notes : ____________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

STAMP AND SIGNATURE

DONE AT HOURS : ________ DATE : _________________ _____________________________

1) DECLARATION OF CONFORMITY (ORIGINAL)

(Directive 2006/42/EC , Annex II, 1A)

2) Manufacture: IHIMER S.p.A.

3) Address: località CUSONA - 53037 SAN GIMIGNANO (SI) - ITALY

4) Technical file compiled by: IHIMER S.p.A. Technical department manager

5) Address: località CUSONA - 53037 SAN GIMIGNANO (SI) - ITALY

6) Hereby we declare that the machine category:

EARTH-MOVING MACHINERY / HYDRAULIC EXCAVATOR

7) Type: 12VXE

8) Serial number: EB________

9) Net power installed (kW/rpm): 9.5 / 2200

10) Is in conformity with the provisions of the <<Machinery Directive>> 2006/42/EC, as amended

and the regulations transposing it into national law;

11) Also complies with the provisions “noise emission in the environment by equipment for use

outdoors” directive 2000/14/EC and the regulations transposing it into national law

- Machine category: Hydraulic excavator annex I n°20

- Conformity assessment procedure followed: internal control of production with assessment of

technical documentation and periodical checking, annex VI. (1st procedure)

- The notified body : ECO S.p.A. – via Mengolina, 33 – 48018 Faenza (RA) – Italy

- Measured sound power level: LWA 93 dB

- Guaranteed sound power level:LWA 93 dB

12) The following respective requirements fulfil: 2004/108/ EC (2004)

13) Harmonised EN-standards taken: EN ISO 12100-1 (2003)+A1:2009;

EN ISO 12100-2 (2003)+A1:2009; EN ISO 3744 (2009); EN 474 -1 (2006) +A1:2009;

EN 474 -5 (2006) +A1:2009

14) Place / Date: San Gimignano / …... - …………

…………………………………………

15) Name:

16) Position: President of IHIMER S.p.A.

IITALIAN

(Traduzione)

1) DICHIARAZIONE “CE” DI CONFORMITÁ

(Direttiva 2006/42/CE,allegato II, 1A)

2) Fabbricante:

3) Indirizzo:

4) File tecnico compilato da: Direttore tecnico IHIMERS.p.A.

5) Indirizzo:

6) Dichiara che la macchina categoria: escavatore idraulico

7) Tipo :

8) Numero di serie:

9) Potenza netta installata:

10) È conforme ai requisiti della Direttiva Macchine 2006/42/CE, comemodificata e alla

legislazione nazionale che la traspone:

11) È conforme alle condizioni della Direttiva 2000/14/CE “emissione acustica

ambientale delle macchine ed attrezzature destinate a funzionare all’aperto” e alla

legislazione nazionale che la traspone.

-Categoria macchina: escavatore idraulico allegato I

-Procedure applicate per le valutazioni di conformità: controllo interno della

produzione con valutazione della documentazione tecnica e controlli periodici, all. VI.

- Ente notificato:

- Livello di potenza sonora misurato:

- Livello di potenza sonora garantito:

12) È conforme alle condizioni della seguente direttiva:

13) Sono state applicate le seguenti norme armonizzate:

14) Luogo / Data:

15) Nome:

16) Posizione:

FRENCH

(Traduction)

1) DECLARATION « CE » DE CONFORMITE

(Directive 2006/42/CE, annexe II , 1A)

2) Nom du constructeur:

3) Adresse:

4) Fichier technique rédigé par: Directeur technique IHIMERS.p.A.

5) Adresse:

6) Déclare que la machine décrite ci-dessous désignée: pelle

7) Type dumateriel:

8) Numéro de série:

9) Puissance net installée:

10) Est conforme aux dispositions de la directive «machines » 2006/42/CE modifiée et

aux législations nationales la transposant :

11) Est également conforme aux dispositions de la directive « émissions sonores des

équipements utilisés à l’extérieur des bâtiments » 2000/14/CE et aux législations

nationales la transposant.

- Machine: pelle, annexe I

- Procédure appliquée pour l’évaluation de la conformité :procédure de contrôle

interne de la production, avec évaluation de la documentation technique et contrôle

périodique, annex VI.

- Organisme notifié :

- Niveau de puissance acoustique mesuré :

- Niveau de puissance acoustique garanti :

12) Est égalment conforme aux dispositions de la directive suivantes :

13) Est conformeaux normes harmonisées suivantes:

14) Adresse / Date :

15) Signataire :

16) Qualite du signataire :

SPANISH

(Traducciòn)

1) DECLARACION “CE” DE CONFORMIDAD

(Directriz 2006/42/CE, anexo II, 1A)

2) Fabricante:

3) Direccion:

4) Archivo técnico compilado por: Director técnico IHIMER S.p.A.

5) Direccion:

6) Con el presente documento declaramos que la maquina categoria: excavadora

7) Tipo:

8) Numero de serie:

9) Potencia neta instalada:

10) Cumplela DirectrizMaquinas 2006/42/CE, incluidas les modificationes de la misma:

11) Cumple la Directriz 2000/14/CE sobre “emisiones sonoras en el entorno debidas a

las máquinas de uso al aire libre” incluidas les modificationes de la misma:

-Categoria maquina: excavadora, anexo I

- Procedimiento de evaluación de la conformidad que se ha seguido: control de la

producción con evaluación de la documentación técnica y comprobaciones

periódicas, anexo VI.

- Organismo notificado:

- Nivel de potencia acústica medido:

- Nivel de potencia acústica garantizado:

12) Satisfacen la siguente directriz:

13) Cumplen les normas armonizadas:

14) Direccion / Data:

15) Nombre:

16) Puesto:

GERMAN (Ubersetzung)

1) EG-KONFORMITÄTSERKLÄRUNG

(Direktive 2006/42/EG, Nachtrag II, 1A)

2) Hersteller:

3) Adresse:

4) Technische Datei erstellt von: Technischer Leiter IHIMER S.p.A.

5) Adresse:

6) Erklärt hiermit, dass die Maschine-Kategorie: bagger

7) Typ :

8) Seriennummer:

9) Installierte Nutzleitung

10) Konform ist mit den einschlägigen Bestimmungen der EG-Maschinenrichtlinie (EG-

Richtlinie 2006/42/EG) inklusive deren Änderungen, und der nationalen

Gesetzgebung welch diese Bestimmungen umsetzt:

11) Konform ist mit den Bedingungen der EG-Richtlinie 2000/14/EG über

«umweltbelastende Geräuschemissionen von zur Verwendung im Freien

vorgesehenen Geräten und Maschinen», inklusive deren Änderungen.

- Maschine-Kategorie: bagger, nachtrag I

- Angewandtes Konformitätsbewertungsverfahren : interne fertigungskontrolle mit

begutachtung der technischen unterlagen und regelmässiger prüfung, Anhang VI.

- Der beteiligten benannten Stelle :

- Gemessener Schalleistungspegel :

- Garantiertter Schalleistungspegel :

12) Konform ist mit den folgenden Bedingungen der EG-Richtlinie :

13) Folgende harmonisierte Normen zur Anwendung gelangen:

14) Adresse / Datum :

15) Name :

16) Position:

DUTCH (Vertaling)

1) EG-VERKLARING VAN OVEREENSTEMMING

(EG-Richtljn 2006/42/EG, Anhang II, 1 A)

2) Fabrikant:

3) Adres:

4) Technisch bestand opgesteld door: Technisch directeur IHIMER S.p.A.

5) Adres:

6) Hierbij werklaren wij dat onderstaande machines categorie: graafmachine

7) Type:

8) Serie Nummer:

9) Netto geinstalleerd vermogen:

10) Overeenstemmen met de gewijzigde richtlijn EG-Richtlinie 2006/42/EG en de naar

nationale wetgeving transponerende regelingen.

11) Voldoest bovendien aan de bepalingen van de richtlijn 2000/14/EG

„Geluidsemissein het milieu door materieel voor gebruik buitenshuis“ en de naar

nationale wetgeving transponerende regelingen.

- Machines categorie: graafmachine, anhang I

- Overeenstemmingsbeoordelingsprocedure: interne controle van productie met

beoordeling van technische documentatie en periodieke keuring, bijlage VI.

- Betrokken aangemelde instantie:

- Gemeten geluidsvermogensniveau:

- Gewaarborgd geluidsvermogensniveau:

12) De volgende respectievelijke eisen voldoen:

13) Geharmoniseerde EN-Standaarden:

14) Adres / Datum:

15) Naam:

16) Functie:

DANISH

(Oversættelse)

1) OVERENSSTEMMELSES ERKL RING

(Direktiv 2006/42/EC, annex II, 1A)

2) Produktion:

3) Adresse:

4) Teknisk fil kompileret af: Teknisk direktør IHIMER S.p.A.

5) Adresse:

6) Vierkel re herved at maskinen kategori: gravemaskine

7) Type:

8) Serie nummer:

9) NettoYdelse:

10) Er i overensstemmelse med Direktiv 2006/42/EC, som tilrettet

11) Opfylder bestemmelser med seneste andringer for « stojudslip i miljoet for

undendors udstyr » direktiv 2000/14/EC og reguleringer omsat til national lov :

- Maskinen kategori: gravemaskine, annex I

- Procedure ansogt for opfyldelse af regler vedrorende : intern kontrol af produktion

med fastsattelse af teknisk dokumentation og periodisk kontrol, annex VI.

- Anmeldt til :

- Malt stojnivot :

- Garanteret stojnivot :

12) Folgende respektive krav opfylder

13) Harmoniseret EN-standard er opfyldt

14) Adresse / Dato

15) Navn:

16) Stilling:

IHIMER S.p.A.

Loc. Cusona 53037 San Gimignano (SI) ITALY

Tel. +39 057795121 Fax +39 0577982400

FOREWORD

This manual provides all the procedures and instructions required for operating, checking

and servicing the excavator. The procedures are designed to ensure the best productivity,

efficiency and safety. Bear in mind the following rules:

•Keep the manual on board the machine in the provided compartment or in the pocket in

the operator’s seat.

•Before operating the machine make sure you have understood the contents of this

manual.

•Given that not all the contents of this manual may be understood on a first reading,

read it again until you have acquired a certain skill as operator.

•Experience in operating the machine in real conditions and under supervision will

complement the information given in this manual.

•The illustrations in this manual are intended above all to draw your attention to

hazards.

Some of the illustrations given in this manual may not coincide with your machine due

to the normal technical evolution of the machine. If you have any questions in relation

to your machine or this manual, contact your dealer for

further information.

CONTENTS

FOREWORD

CONTENTS

SAFETY INFORMATION

1. SAFETY MEASURES

1-1 GENERAL INFORMATION ............................................................................................................................. 1-1

1-2 GETTING ON AND OFF THE MACHINE........................................................................................................ 1-5

1-3 BEFORE STARTING THE ENGINE................................................................................................................ 1-6

1-4 STARTING THE ENGINE ............................................................................................................................... 1-6

1-5 BEFORE OPERATING THE MACHINE.......................................................................................................... 1-7

1-6 MANEUVERING THE EXCAVATOR .............................................................................................................. 1-8

1-7 DRIVING SAFELY......................................................................................................................................... 1-22

1-8 TOWING........................................................................................................................................................ 1-25

1-9 TRANSPORT ................................................................................................................................................ 1-26

1-10 PARKING ...................................................................................................................................................... 1-27

1-11 MAINTENANCE ............................................................................................................................................ 1-28

1-12 SAFETY LABELS AND SIGNS ..................................................................................................................... 1-33

2. OPERATING INSTRUCTIONS

2-1 DESCRIPTION................................................................................................................................................ 2-1

2-2 INSTRUMENTS AND CONTROLS ................................................................................................................. 2-2

2-3 CONTROLS BEFORE STARTING UP.......................................................................................................... 2-11

2-4 STARTING THE ENGINE ............................................................................................................................. 2-12

2-5 USING THE BATTERY AND CABLES TO START....................................................................................... 2-13

2-6 PREHEATING THE MACHINE ..................................................................................................................... 2-14

2-7 CONTROL LEVERS...................................................................................................................................... 2-15

2-8 OPERATION OF THE AUXILIARY HYDRAULICS FOR SPECIAL ACTUATORS........................................ 2-17

2-9 MOVING THE MACHINE .............................................................................................................................. 2-19

2-10 RETRACTING/EXPANDING THE CARRIAGE ............................................................................................. 2-22

2-11 LOWERING THE ARM WHEN THE ENGINE IS OFF .................................................................................. 2-23

2-12 TOWING........................................................................................................................................................ 2-23

2-13 LIFTING THE MACHINE............................................................................................................................... 2-24

2-14 LOADING AND UNLOADING THE MACHINE.............................................................................................. 2-25

2-15 PRECAUTIONS WHEN USING RUBBER TRACKS..................................................................................... 2-26

2-16 DRIVING THROUGH LOW OPENINGS ....................................................................................................... 2-27

2-17 PARKING THE MACHINE............................................................................................................................. 2-28

2-18 EMERGENCY STOP .................................................................................................................................... 2-28

3. MAINTENANCE

MAINTENANCE INTERVALS ......................................................................................................................... 3-1

3-1 TABLE OF LUBRICATION AND CHECKS ..................................................................................................... 3-2

3-2 RECOMMENDED LUBRICANT TABLE.......................................................................................................... 3-3

3-3 OCCASIONAL CHECKS AND MAINTENANCE ............................................................................................. 3-4

3-4 DAILY CHECKS AND MAINTENANCE .......................................................................................................... 3-9

3-5 CHECKS AND MAINTENANCE EVERY 50 HOURS.................................................................................... 3-13

3-6 CHECKS AND MAINTENANCE EVERY 250 HOURS.................................................................................. 3-14

3-7 CHECKS AND MAINTENANCE EVERY 500 HOURS.................................................................................. 3-20

3-8 CHECKS AND MAINTENANCE EVERY 1000 HOURS................................................................................ 3-24

3-9 CHECKS AND MAINTENANCE EVERY 2 YEARS....................................................................................... 3-27

3-10 SPECIAL OPERATING CONDITIONS.......................................................................................................... 3-29

3-11 LENGTHY STORAGE................................................................................................................................... 3-32

4. ANALYSING FAULTS

4-1 TROUBLESHOOTING .................................................................................................................................... 4-1

5. HYDRAULIC SYSTEM DIAGRAM

5-1 HYDRAULIC CIRCUIT DIAGRAM .................................................................................................................. 5-1

6. ELECTRICAL CIRCUIT DIAGRAM

6-1 ELECTRIC SYSTEM DIAGRAM ..................................................................................................................... 6-1

7. SPECIFICATIONS

7-1 GENERAL SPECIFICATIONS ........................................................................................................................ 7-1

7-2 DIMENSIONS OF MACHINE .......................................................................................................................... 7-3

7-3 WORK AREA .................................................................................................................................................. 7-4

7-4 WEIGHT DIAGRAM – RANGE - HEIGHT....................................................................................................... 7-6

SAFETY INFORMATION

This manual is a safe, practical guide to the safe operation and control of the machine.

The machine has been designed and manufactured for digging and loading earth, inerts and similar material,

small demolitions and restructuring. It is mainly used in construction and earth moving in general. It can also

be used for agriculture to perform all those jobs requiring working in small spaces. ANY USE DIFFERENT

FROM THAT SPECIFIED IS TO BE CONSIDERED IMPROPER AND THEREFORE FORBIDDEN. It is also

forbidden to perform any unauthorised modifications to the machine.

Before operating the machine, the operator must familiarise himself with its contents. This is the simplest

way to prevent accidents.

Incorrect operation, control or servicing may result in injury or death.

Warnings are marked on the machine and throughout the manual with the symbol

and graded according

to their severity with the words DANGER - WARNING - CAUTION.

The classification is as follows:

A hazardous situation which may result in injury or death if not avoided.

A potentially dangerous situation which may cause injury or death.

A potentially hazardous situation which may result in slight or moderate injury. May also be used to notify the

operator and prevent damage to the machine or its parts.

We have made every effort to prevent accidents when operating the machine, however we cannot be held

responsible for all possible types of danger in all possible situations.

The owner and operator of the machine are responsible for ALWAYS taking care when working with the

machine and for familiarising themselves with the basic information required to it.

DANGER

WARNING

CAUTION

•Before operating, inspecting or servicing the machine, make sure you have read and

understood the contents of this manual.

•Incorrect operation or servicing of the machine may result in accidents, injury or death.

•Keep this manual always near to hand for reference.

•If it is lost or damaged, ask your dealer for a new copy.

•There are a variety of federal, state and local regulations governing construction

machinery. Since these regulations are subject to change and differ from one country to

another, we are unable to include them in this manual. It is the operator’s and owner’s

responsibility to be familiar with these regulations.

•

The machine’s components and specifications are subject to change without notice.

WARNING

1 SAFETY MEASURES

1 - 1

SAFETY WARNINGS

this section explains the safety warnings in the manual and posted on the machine itself. Check the plates

bearing these warnings from time to time. If they are damaged, clean or replace them. For replacements,

contact your dealer with the code number (see spare parts catalogue). Note that the provided safety

warnings cannot cover all types of hazard encountered in using the machine.

1-1 GENERAL INFORMATION

1. TO ENSURE SAFETY, FOLLOW THE

BASIC RULES

The knowledge, experience and ability of the operator are

the most important factors in the safe operation of the

machine. it is therefore important that the operator have

read and understood the instruction and have been

trained.

2. QUALIFIED OPERATORS

The driving and operation of hydraulic excavators must be

entrusted to specialised and trained operators in perfect

psychophysical condition. The operator must be aware of

all hazards and safety measures associated with

operation of the excavator. The operator must therefore

be authorized, trained and sufficiently skilled to do so.

Right!

Right!

1 SAFETY MEASURES

1 - 2

3. FAMILIARISE YOURSELF WITH THE

INSTRUCTIONS AND WARNINGS.

This manual and the plates and stickers on the machine give the

information required for operating it safely and properly. The user

must familiarise himself with this information; failure to do so may

result in serious accidents. Do not leave anything to chance if you

have failed to understand it. Your dealer is always pleased to give

you any supplementary information you require. If you lose or

damage the manual, the plates or stickers, contact your dealer for

new copies.

4. HEALTH

Take special care of your mental and physical health and note

that the operator of a complicated machine should be physically

fit.

NEVER operate the machine under the influence of alcohol,

medicines or drugs of any kind.

5. SNUG FITTING WORK CLOTHES

Your work clothing must be snug, without lose sleeves, rings or

other jewelry, as they may become trapped in moving parts.

Before operating the excavator, clean all grease and mud off your

boots. Always wear the necessary clothes and accessories,

including: helmet, safety gloves, visible clothing, safety boots and

ear defenders.

Wrong!

Wrong!

Right!

Right!

1 SAFETY MEASURES

1 - 3

6. CHECK YOUR EXCAVATOR

Before starting work, walk around and check the excavator

and make sure that there are no persons or obstacles in the

work area.

7. NEVER TAKE ANYTHING FOR

GRANTED

Today, as you start work, do not assume that everything is

OK, only because it was all OK yesterday evening. Before

starting, carefully check the excavator for signs of wear and

defects.

8. MAKE A WORK PLAN

Before starting work, carefully inspect the work area. If

there are any obstacles or hazards, notify all affected

persons of their presence. Avoid overlooking anything that

may cause an accident. Prepare a work plan and

procedures and inform your colleagues accordingly.

Right!

Right!

Right!

Right!

1 SAFETY MEASURES

1 - 4

9. BE CAREFUL OF PUBLIC UTILITY

LINES AND PIPES

Before starting work, inspect the work area. identify all gas,

service, sewer, overhead and underground electrical lines,

and any other obstacles and hazards. The worksite

supervisor is responsible for marking the locations of all

underground utility lines to prevent accidents. If necessary,

ask for the said lines to be closed or transferred.

10. WORK AREA

ALWAYS, before starting work, carefully inspect the work

area and identify any hazards. Do not operate the machine

close to a drop.

Given that the machine is not designed for use in explosive

atmospheres, NEVER operate it inside a tunnel or

explosive area to prevent the risk of explosion. The

machine is not roadworthy, and must be used only on the

worksite; if necessary, it must be moved to other areas by

truck.

11. KEEP YOU REYES OPEN

Keep your eyes open before and during your work and

especially when you slew the tools in crowded areas. In

more complicated situations, we recommend using an

assistant who can supervise the area and give signals; pay

attention to his signals before operating the excavator.

Right!

Right!

Wrong!

Wrong!

1 SAFETY MEASURES

1 - 5

12. MAINTAIN GOOD VENTILATION

Do not use the machine for indoor works.

Take all precautions to vent exhaust gas externally before

starting the engine if working in a hole in the ground, tunnel

or trench. In such a place, the air trends to stagnate.

Breathing exhaust gas is very dangerous. Note that exhaust

gases are fatally poisonous.

In case of excavations or earthworks involving noxious

substances, the user must take all the necessary safety

measures.

13. DO NOT TAMPER WITH THE

ROPS/TOPS

Do not tamper with the rops/tops unless instructed to do so

by the installation manual.

Welding, drilling or cutting the frames can weaken them and

degrade their protection.

The rops/tops cannot be repaired if damaged, but must be

replaced.

1-2 GETTING ON AND OFF THE

MACHINE

1. TAKE CARE WHEN GETTING ON AND

OFF THE MACHINE

When getting on and off the machine, ALWAYS grip the

handles and use the steps.

NEVER grip the control levers when getting on or off the

machine.

NEVER get on or off the machine while it is in motion.

NEVER jump down from the machine.

Never attempt to get onto the machine with your hands full.

Wrong!

Wrong!

1 SAFETY MEASURES

1 - 6

1-3 BEFORE STARTING THE ENGINE

1. TAKE THE FOLLOWING PRECAUTIONS

- Make sure that there are no persons or obstacles in the

work area.

- Put the gear into neutral.

- Make sure the levers are in NEUTRAL before starting the

engine.

- Check the condition of the seat belt and fittings.

- Fasten the seat belt.

- Adjust the seat for your comfort.

1-4 STARTING THE ENGINE

1. MAKE SURE TO:

- ALWAYS start the engine when seated, and following the

procedure given in this manual.

- If a “DO NOT OPERATE” label is on the starter or

controls, do not start the engine or operate the controls.

- NEVER short circuit the starter or battery terminals.

Wrong!

Right!

Right!

Put in neutral

Do not operate

1 SAFETY MEASURES

1 - 7

1-5 BEFORE OPERATING THE MACHINE

1. IMMEDIATELY AFTER STARTING THE

ENGINE

•Check all instruments.

•Make sure the work area is safe.

•Operate all levers to check them.

•Listen for strange noises.

•Check the accelerator lever.

•Check the warning lamps and all safety and signaling

equipment.

•Repair any damaged parts.

•Operate the controls to familiarize yourself with them.

2. PREHEATING

Since all equipment is hydraulically controlled, it is

EXTREMELY IMPORTANT to make sure that the hydraulic

fluid is up to temperature BEFORE starting work. While the

fluid is heating up, the operator must check the operation of

the machine and whether it needs servicing. Remember:

hydraulic equipment is operated by the flow of fluid through

its circuit. If you hear a high pitched grinding noise, this

means that the pump is insufficiently lubricated due to

cavitation, which may be due to the use of too dense or

heavy fluid. UNDER NO CIRCUMSTANCES MAY THE

MACHINE BE OPERATED in this condition; doing so can

seriously damage the pump.

3. CLOSE ALL HATCHES

Make sure to close or secure all hatches and covers before

starting work. Working with the door open is hazardous.

Wrong!

Right!

Right!

Crushing hazard

1 SAFETY MEASURES

1 - 8

1-6 MANEUVERING THE EXCAVATOR

1. ALWAYS WORK IN OBSERVANCE

OF SAFETY REGULATIONS.

Take great care when operating the machine. Operating the

machine jerkily can damage it and reduce its efficiency.

Always observe regulations governing safety in the

workplace.

2. OPERATE THE CONTROL LEVERS

PROPERLY

If the machine is operated irresponsibly or overloaded, its

engine is also loaded beyond its rated capacity. If you are

angry, do not operate the levers angrily. Operating the

machine angrily is hazardous.

3. OBSERVE THE FOLLOW

PRECAUTIONS TO WORK SAFELY

•Do not read.

•Do not drink.

•Do not eat.

•Give your entire attention to the work you are engaged

in. If distracted by anything, it is far better to stop the

machine.

4. OPERATE THE MACHINE FROM A

SEATED POSITION

NEVER operate the machine unless when seated at the

driver’s seat. Operating the machine form any other

position, e.g. standing up at the window or door,

compromises safe operation and can result in accidents.

NEVER get on or off the machine while it is moving.

Wrong!

Wrong!

Wrong!

Wrong!

Table of contents

Other Menzi Muck Excavator manuals