Solarbayer HSK-SLS User manual

© Solarbayer GmbH [02.13]

Solarbayer GmbH 1

Technical descripon

W

e

d

e

v

e

l

o

p

f

o

r

y

o

u

r

f

u

t

u

r

e

PRODUCT INFORMATION

Hygienic straficaon buffer tank HSK‐SLS

Universal heat center for legionella‐safe preparaon of DHW

2Solarbayer GmbH

© Solarbayer GmbH [02.13]

Product informaon HSK‐SLS

Safety regulaons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Brief descripon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Descripon of connecons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Technical specificaons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Technical facts, dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installaon/general informaon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connecon example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Insulaon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installaon of the insulaon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Trouble shoong . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Content

Pictures and drawings in this product informaon are for informaon use only

and do not replace professional planning.

We assume no liability for completeness and accuracy

because of technical changes, typing and prinng errors.

© Solarbayer GmbH [02.13]

Solarbayer GmbH 3

Product informaon HSK‐SLS

Please read the manual carefully to prevent damages due to improper installaon. The installaon

has to be carried out by a specialized company in accordance with the „generally accepted codes of

pracce“ as well as with the valid regulaons and norms. Country‐specific regulaons have to be

regarded. Non‐professional installaon as well as other than the intended use will lead to the

expiraon of warranty.

The following engineering rules have to be parcularly regarded:

DIN 1988

Codes of pracce for drinking water systems

DIN 4751

Safety requirements for heang installaons

DIN 4753

Water heaters and water heang installaons for drinking water and service water;

requirements, marking, equipment and tesng

DIN EN 12975

Thermal solar systems and components

DIN 4807

Expansion vessels

DIN EN 12828

Heang systems in buildings ‐ Design for water‐based heang systems

DIN 18380

Systems for heang and central water heang

DIN 18381

Gas, water and sewage plumbing works inside of buildings

VDI 2035

Prevenon of damage in water heang installaons

DIN 18382

Electric Cable and Wiring Systems Inside Buildings

VDE 0100

Erecon of power installaons

VDE 0105

Operaon of electrical installaons

VDE 0190

Potenal equalizing of electrical installaons

*Before the installaon it has to be tested if the DHW installaon, especially the connecon to the public water supply, is carried out

in accordance with DIN 1988 and if the, stated in part 8, prescribed maintenance had taken place.

The operability of security‐relevant units (e.g. pressure regulator) has to be checked in any case.

Safety regulaons

Product informaon HSK‐SLS

4Solarbayer GmbH

© Solarbayer GmbH [02.13]

Brief descripon

Universal heat center with integrated stainless steel corrugated tube for legionella‐safe preparaon

of DHW, with large dimensioned oval tube heat exchangers. The area of applicaon ranges from

single‐family housesto hotels and industrial buildings.

connecons arranged in 90° angle, possible installaon in the corner

various connecon possibilies

perfect heat straficaon due to the straficaon pipe

flexible foam insulaon WLG 0,039, insulaon thickness approx. 100 mm,

silver PVC jacket, fire protecon classificaon B2

high quality steel

S235JR

large dimensioned solar oval tube hat exchanger, top and boom

legionella‐safe DHW preparaon

stainless steel corrugated hose

1.4404 with DVGW authorizaon

high hot water output

installaon of an electric heang

element possible

Corrosion protecon

The stainless steel DHW exchanger (stainless steel corrugated tube) can be used with all DHW

condions and in every network. The corrosion protecon is given by the stainless steel design.

The internal wall of the heang water tank is not corrosion protected since it is set for the applicaon

in closed heang systems as a buffer tank.

The applicaon of the tank in pressureless heang circuits with Der Einsatz des Speichers in drucklo‐

sen Heizkreisen mit nachlaufendem Frischwasser ist nur zulässig, wenn Pufferspeicher und Holzkessel

miels Systemtrennung vom drucklosen/offenen Teil der Heizungsanlage getrennt ist.

© Solarbayer GmbH [02.13]

Solarbayer GmbH 5

Product informaon HSK‐SLS

Descripon of connecons

de-airing

draining

heating flow line or

boiler flow line wood

heating flow line or

boiler flow line wood

hot water outlet

boiler flow line oil

or heating flow line

heating return line or

boiler return line oil

cold water inlet

heating return line or

boiler return line wood

solar flow line top

solar return line top

boiler flow line oil

or heating flow line

heating return line or

boiler return line oil

solar flow line bottom

solar return line bottom

heating return line or

boiler return line wood AG

solar sensor bottom

solar sensor top

electric heating element

sensor/thermometer

sesnor boiler control

or sensor boiler charging unit

sensor

Aenon:

The heang system has to be filled in accordance with VDI 2035.

Pay aenon to the BDH informaon sheet n° 8.

6Solarbayer GmbH

© Solarbayer GmbH [02.13]

Product informaon HSK‐SLS

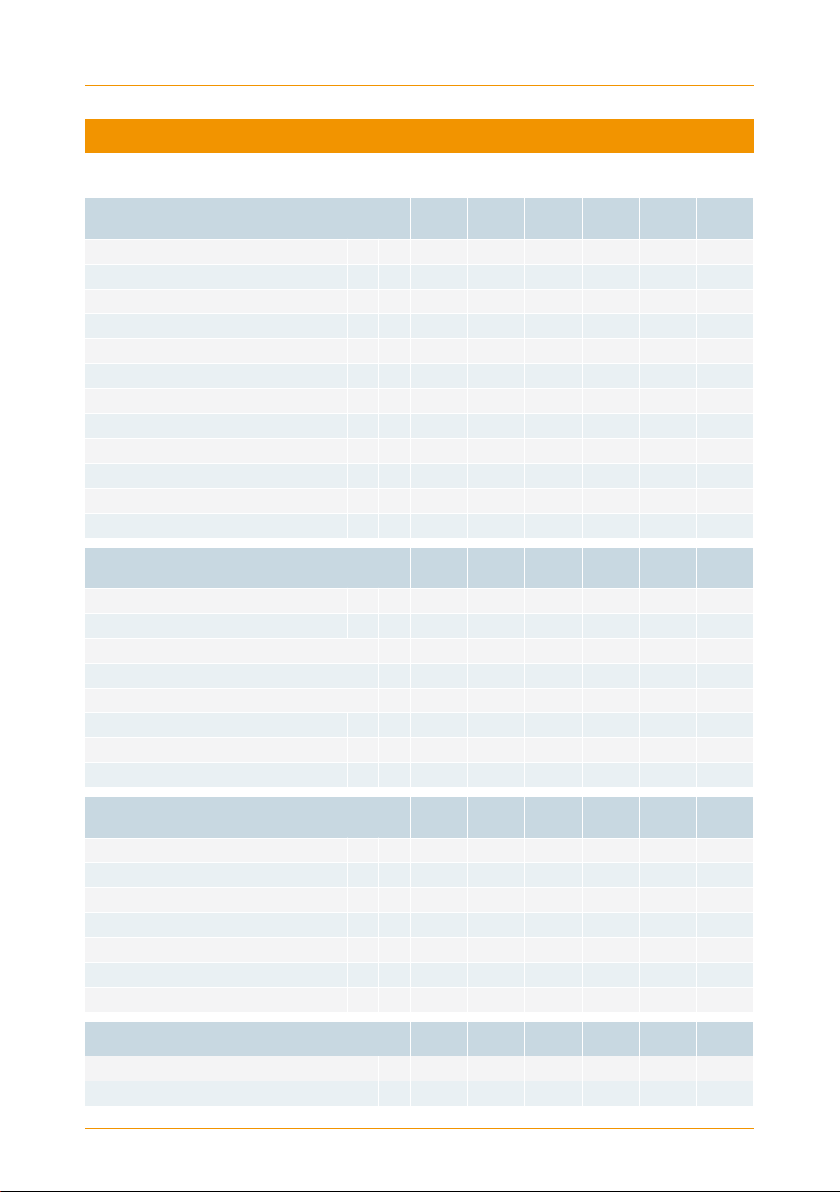

Technical specificaons

Thermotechnical facts 500 800 1000 1250 1500 2200

rate of heat loss in stagnancy according to DIN EN 12976 or DIN ENV 12977‐3

W/K

1,53 2,02 2,22 2,48 2,92 3,38

rate of standby loss ΔT 45°C according DIN 4753‐8

kWh/d

2,22 2,94 3,23 3,61 4,25 4,93

Hygienic straficaon buffer tank HSK‐SLS 500 800 1000 1250 1500 2200

capacity approx. L 500 800 1000 1250 1500 2200

height with insulaon [A] mm 1720 1910 2090 2080 2220 2170

height without insulaon [B] mm 1645 1835 2015 2005 2145 2095

lted height mm 1700 1950 2100 2130 2250 2300

diameter with insulaon [C] mm 850 990 990 1100 1200 1450

diameter without insulaon [D] mm 650 790 790 900 1000 1250

flexible foam insulaon (PVC jacket) mm 100 100 100 100 100 100

weight approx. (without / with heat exchanger) kg 147 193 231 279 287 406

max. operang temperature heang water bar 6 6 6 6 6 6

max. operang pressure heang water °C 95 95 95 95 95 95

internal traficaon system mm 200 200 200 200 200 300

max. size of electric heang element (oponal) kW 4,5 6,0 6,0 6 9 9

specificaon stainless steel DHW heat exchanger 500 800 1000 1250 1500 2200

capacity DHW heat exchanger approx. L 75 96 96 111 111 126

heang surface DHW heat exchanger approx. m² 7,2 9,0 9,0 10,5 10,5 12

connuous output 10/45 at 17 kW, temperature buffer 65°C L/h 480 510 510 522 522 540

connuous output 10/45 at 27 kW, temperature buffer 65°C L/h 685 735 735 750 750 790

connuous output 10/45 at 50 kW, temperature buffer 65°C L/h 1090 1345 1345 1380 1380 1465

stainless steel DHW heat exchanger mm Ø 48 Ø 48 Ø 48 Ø 48 Ø 48 Ø 48

max. operang pressure DHW heat exchanger bar 6 6 6 6 6 6

max. operang temperature DHW heat exchanger °C 95 95 95 95 95 95

specificaon solar heat exchanger 500 800 1000 1250 1500 2200

heang surface solar heat exchanger top m² 1,3 2,0 3,0 3 3,5 4,2

capacity solar heat exchanger top L 6,2 8,0 12,0 12,0 14 16,8

heang surface solar heat exchanger boom m² 2,3 3,0 3,0 3 3 5,5

capacity solar heat exchanger boom L 10,4 12,0 12,0 12,0 12,0 22,0

max. operang pressure solar heat exchanger bar 10 10 10 10 10 10

max. operang temperature solar heat exchanger °C 110 110 110 110 110 110

recommended min. collector surface m² 10 14 17 20 23 31

© Solarbayer GmbH [02.13]

Solarbayer GmbH 7

Product informaon HSK‐SLS

Technical facts, dimensions

2

1

AB

CD

3

4

6

7

8

9

10

13

14

16

17

18

19

20

12

15

21

11

5

Anschlüsse mit Bemaßung 500 800 1000 1250 1500 2200

de‐airing 1½”IG [1] – top top top top top top

sensor ½”IG [2] mm top top top top top top

inlet boiler/heang 1½”IG* [3] mm 1510 1690 1870 1835 1935 1850

inlet boiler/heang 1½”IG* [4] mm 1510 1690 1870 1835 1935 1850

sensor/thermometer ½”IG [5] mm 1420 1590 1770 1735 1835 1845

hot water 1¼”IG [6] mm 1410 1580 1760 1725 1825 1835

inlet solar exchanger top 1”IG [7] mm 1320 1440 1650 1585 1735 1735

sensor solar top ½”IG [8] mm 1220 1290 1370 1405 1435 1445

outlet solar exchanger top 1”IG [9] mm 1120 1160 1270 1165 1235 1295

electric heang element 1½”IG [10] mm 1000 1060 1140 1045 1125 1175

inlet boiler/heang 1½”IG [11] mm 900 930 1100 885 1075 1130

inlet boiler/heang 1½”IG [12] mm 900 930 1100 885 1075 1130

inlet solar exchanger boom 1”IG [13] mm 800 830 990 765 935 1045

outlet boiler/heang 1½”IG [14] mm 670 730 890 665 835 925

outlet boiler/heang 1½”IG [15] mm 670 730 890 665 835 925

sensor/thermometer ½”IG [16] mm 670 730 770 665 835 845

sensor solar boom ½”IG [17] mm 440 470 470 495 535 545

outlet solar exchanger boom 1”IG [18] mm 340 370 370 395 435 445

cold water 1¼”IG [19] mm 240 270 270 295 335 335

outlet boiler/heang 1½CIG* [20] mm 150 170 170 195 235 320

outlet boiler/heang 1½”IG* [21] mm 150 170 170 195 235 320

*from HSK‐SLS 2200 on the connecons are 2” IG (internal thread)

8Solarbayer GmbH

© Solarbayer GmbH [02.13]

Product informaon HSK‐SLS

Locaon

The tank hast to be located in a frost‐protected place. Ice formaon inside the system may lead to the

tank’s destrucon.

The locaon has to have the necessary space for maintenance and repair work, as well as sufficient

load‐bearing capacity of the ground!

Site clearance for dismounng the tank and for transport has to be ensured permanently.

Insulaon

The insulaon has to be mounted before piping begin.

Do not get near the insulaon with fire, brazing flame, welding torch, etc.; fire hazard!

Piping

The tank is to be installed in accordance with the piping diagram [chapter: Descripon of

connecons]. This diagram is only a mounng proposal and does not replace professional planning.

The connecon has to be carried out in accordance with DIN. .

The minimum diameter of the safety valve has to be DN20 (¾").

Aenon has to be paid to possible electro‐chemical reacons when choosing the installaon

material (mixed installaon)! Galvanzied pipe installaons have to be replaced.

With DHW temperatures of more than 60°C it is generally recommended to limit the temperature by

a mixing valve to 60°C!

The connecon components have to be aligned to these temperatures or the temperature has to be

limited by means of a mixing valve!

Operang pressure

The permissible operang pressures according to our technical specificaons [chapter: technical

specificaons] have to be observed. Exceeding the permissible operang pressure may lead to leaka‐

ges and destrucon of the tank!

Pressure‐reducing valve

The installaon of a pressure‐reducing valve is recommended. If the DHW supply is operated with

higher pressure a pressure reducing valve has to be installed.

In order to reduce sounds caused by fluxion inside the building the pipeline pressure should be

adjusted to approx. 3,5 bar.

DHW filter

It is highly recommended to install a DHW filter in the cold water pipeline since floang parcles may

block fings, etc. and may cause corrosion in the pipes.

Installaon / Allgemeine Informaonen

© Solarbayer GmbH [02.13]

Solarbayer GmbH 9

Product informaon HSK‐SLS

Safety devices

The tank has to be equipped with a non‐lockable safety valve. Moreover, an expansion vessel has to

be installed that is dimensioned according to the tank’s capacity. It is to be locked only with a cap

valve.

An expansion vessel for sanitary water has to be installed for the stainless steel heat exchanger.

A safety temperature limiter has to be installed in accordance with heang system regulaons for

scalding protecon means.

Next to the exhaust line of the safety valve, or even beer, on the valve itself, an indicaon plate has

to be installed, saying: :

"Water is leaking from the valve’s pipe for safety reasons during the heating. Do not close!"

Draining/de‐airing

The tank hast to be installed in such a way that it can be drained without demounng it.

While draining, hot water might exit and cause injuries.

The upper socket is provided for de‐airing the tank.

We do not recommend the use of an automac bleeder.

Immersion heater (oponal)

The tank can addionally be equipped with an electric heang element. You have to respect the

regulaons of your local public ulity when installing an immersion heater.

The electric heang elements have to be insulated. It is only with insulaon that the corrosion

protecon is guaranteed.

Electric heang elements with insulaon and integrated temperature control and safety temperature

limiter are oponal available at Solarbayer.

If electric heang elements without insulaon are used, the tank’s warranty expires. .

Inial operaon

Connecons that are not used have to be sealed professionally with plugs.

Thoroughly rinse pipes and tank aer mounng, heang system has to filled with treated water

according to VDI 2035 and bleeded.

Note for installers :

Record the pressure test and the proper filling of the heang system with water in accordance with

VDI 2035 and let it countersign by your customer.

10 Solarbayer GmbH

© Solarbayer GmbH [02.13]

Product informaon HSK‐SLS

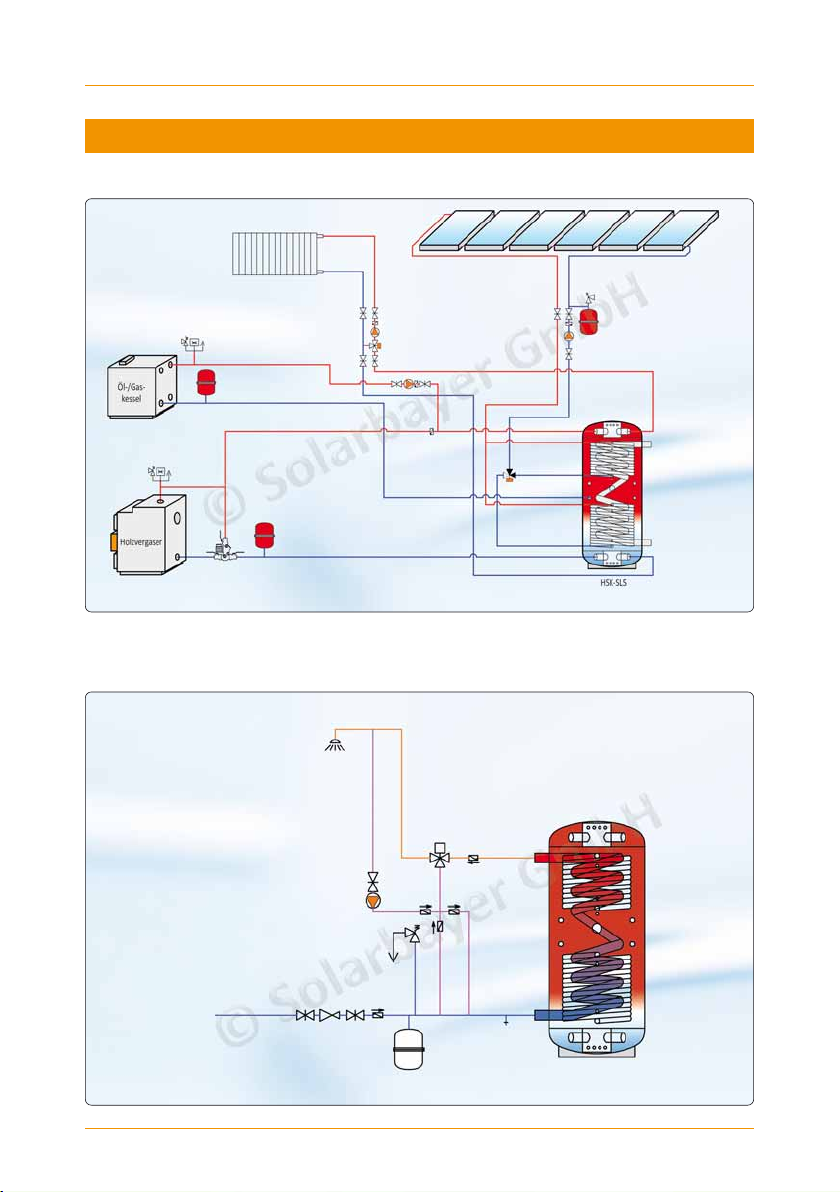

Connecon example

This connecon diagram is only an installaon proposal and does not replace technical planning!This connecon diagram is only an installaon proposal and does not replace technical planning!

Connecon example of

the hot water circulaon

with DHW tank at high

tank temperatures by

heang it up with a solar

system and wood log

boiler.

cold water connecon

according to DIN

© Solarbayer GmbH [02.13]

Solarbayer GmbH 11

Product informaon HSK‐SLS

Insulaon

Inappropriate insulaon of the tank’s boom is

unacceptable.

Tank sockets are available for all popular tank

types up to 1000 Liter. You can increase the

energec efficiency with a perfect boom

insulaon. Especially when renovang old

buildings an addional insulaon at the boom

is recommended. Our tank socket is an easy to

realize alternave for this since it has excellent

insulaon characteriscs.

Our tank sockets are made of galvanized steel

and the rear side is insulated with flexible foam.

75 mm

available in 2 sizes:

Ø 850 mm and 1000 mm

Types of insulaon

Fire protecon insulaon

ISO B1 Standard insulaon B2

flexible foam insulaon 100 mm 100 mm

outer jacket PVC foil 0,55 mm +

5 mm flexible foam

PVC foil 0,8 mm +

5 mm flexible foam

jacket colour grey grey

proof of fire behaviour according to

DIN 4102‐1: 1998‐05 fire classificaon B1 fire classificaon B2

lambda value

(at 10°C ambient temperature) 0,039 W/mK 0,039 W/mK

12 Solarbayer GmbH

© Solarbayer GmbH [02.13]

Product informaon HSK‐SLS

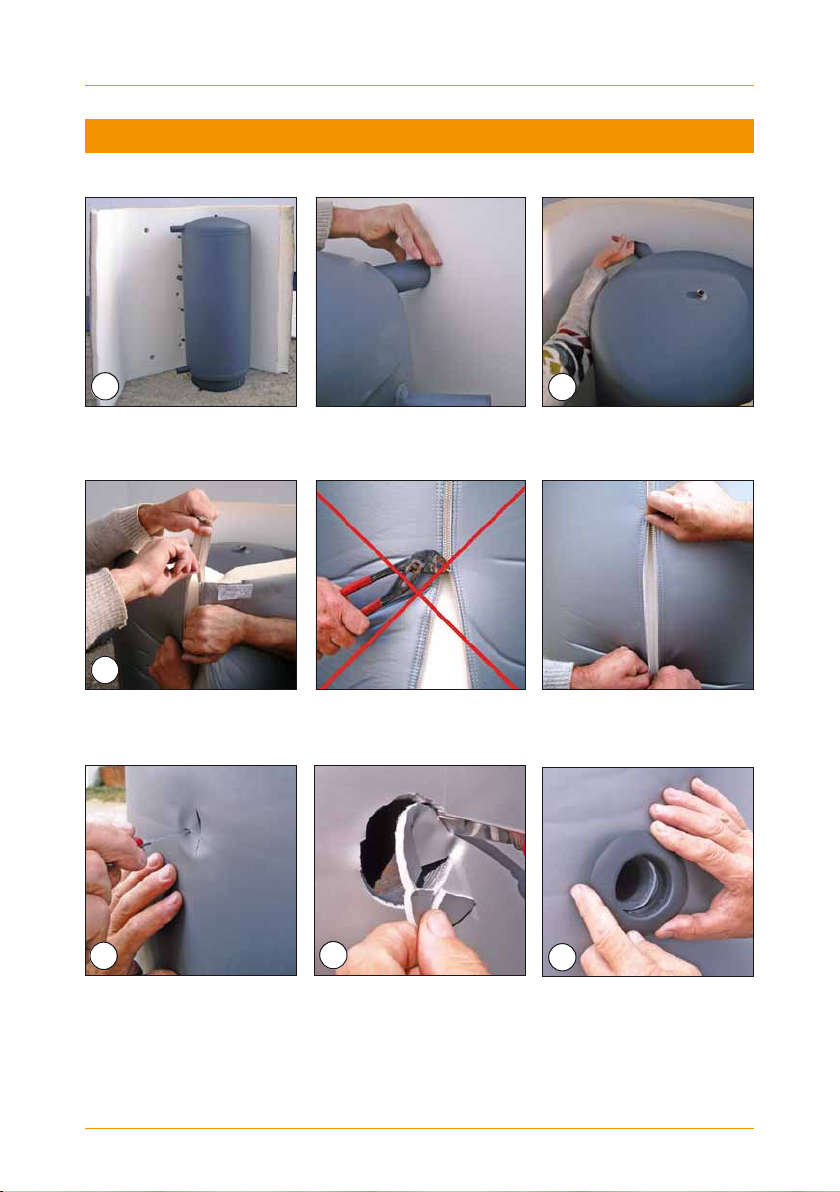

...to boom Put insulaon around the tank and pass the sockets through the pre‐cut

holes (do not remove the foam plugs from the pre‐cut holes that won’t

be used)

Tightly enclose the tank with the

insulaon

3

45

A: Installaon of the fire protecon insulaon ISO B1 (when ordered)

Notes for the installaon of

the fire protecon insulaon

ISO B1:

Only mount the insulaon with a

room temperature of at least 22°C!

Pre‐heat the insulaon in a heated

room and mount in pre‐heat condi‐

on!

The insulaon material and the PVC

jacket are too hard and too short

when mounted in cold condion!

Tilt buffer tank and place boom

insulaon underneath the tank

Pull the insulaon ring for the

tank’s pedestal from top ...

12

Only mount insulaon when warm enough.

Pre‐heat for 24 hrs to at least 22 °C.

!

Put the hexagon socket screws of the stainless steel rail from the le

through the key seats of the right rail and click them into place

(downwards).

© Solarbayer GmbH [02.13]

Solarbayer GmbH 13

Product informaon HSK‐SLS

Carefully cut out the holes

Feel for the sockets that are sll

underneath the PVC jacket

We disclaim any liability for

damages caused by

inappropriate installaon

10

11

6

Put on the collars and push them

onto the sockets

Fasten all hexagon socket screws and check if the insulaon jacket fits

ghtly.

7

9

Pull the black cap on top of the

tank

Put insulaon on top of the tank

(pay aenon to the posion of

the sockets)

8

The tank is now ready to be

connected!

12

The displayed appearance of the tank may differ from yours (number of sockets/dimensions).

14 Solarbayer GmbH

© Solarbayer GmbH [02.13]

Product informaon HSK‐SLS

B: Installaon of the standard insulaon (fire protecon class B2)

Only mount insulaon when pre‐heated.

Pre‐heat the insulaon for at least 24 hrs to at least 22 °C.

Watch out when closing the zipper (danger of tearing the insualon when not warm enough)

Do not use a tong or any other tool.

Adjust sockets to insulaon

12

3

Carefully cut out the holes

Feel for the sockets that are sll

underneath the PVC jacket

5

46

Put on the collars and push them

onto the sockets

The cung out of the holes (thorugh the silver PVC jacket) is done in the same way as with the fire protecon

insulaon ISO‐B1 (see page 13 point 9 to 11)!

© Solarbayer GmbH [02.13]

Solarbayer GmbH 15

Product informaon HSK‐SLS

Trouble shoong

problem possible reason soluon

leakage leaky pipe connecon • seal the connecons

• ghten pipe connecons

heang‐up period too

long

air in the system • bleed the system

heang water temperature set too low with

control unit

• increase temperature seng at the control

unit

scaled heat exchanger surfaces • run system with water treated in accordance

with VDI 2035

no/too small

loading and unloading

of the tank when

heang is required

(in the heang water

circuit)

heang controller not set correctly • set controller

tank temperature too low • check heat sources

(e.g. performance data)

changeover valve defect or installed incorrectly • check funcon

flow‐rate is too low in the heang circuit

• bleed heang circuits

• increase pump performance

• check pipe dimensions, if necessary adjust

them

unwanted tank

cooling

gravity circulaon

in the solar/heang/circulaon circuit • check/install check valve with gravity break

piping insulaon not sufficient • insulate piping/tank connecons

tank insulaon not sufficient • mount Solarbayer tank insulaon

DHW temperature

too low

safety temperature limiter set too low

• increase temperature at the safety

temperature limiter (thermostac DHW

mixing valve)

heang water temperature too low • place tank sensor correctly

• increase tank temperature at the control unit

supplementary heang starts too late

• check parameter of the heang controller

(turn‐on temperature difference)

16 Solarbayer GmbH

© Solarbayer GmbH [02.13]

This manual and the pictures and drawings within

are protected by the copyright of SOLARBAYER GmbH.

Technical changes and errors reserved.

Valid is the most recent version of this handbook which can always be found on our homepage

www.solarbayer.de

This translaon has been provided for informaonal use only.

W

e

d

e

v

e

l

o

p

f

o

r

y

o

u

r

f

u

t

u

r

e

Solarbayer GmbH

Preith, Am Dörrenhof 22

85131 Pollenfeld

Telefon +49(0)8421/93598‐0

Telefax +49(0)8421/93598‐29

www.solarbayer.de

I

Storage systems

I

Fresh water systems

I

Wood log boiler

I

Solar systems

I

Heat pumps

Table of contents

Popular Water Heater manuals by other brands

STIEBEL ELTRON

STIEBEL ELTRON DHE 18 AU Operation and installation

Timberk

Timberk SWH FSL1 30 V instruction manual

Atlantic

Atlantic CHAUFFEO VS 500L Installation and operating manual

HTP

HTP OFT-30 installation manual

Rheem

Rheem RR40-36FV1 Specifications

Webasto

Webasto Thermo Top E installation instructions

Nature's Comfort

Nature's Comfort SM-H60 installation manual

Airxcel

Airxcel Suburban IW60 Operation & maintenance guide

clage

clage BASITRONIC CDX 11-U Installing and operating instructions

PrecisionTemp

PrecisionTemp cIAPMO-T RV-550-EC manual

Nibe

Nibe UKV 200 Kyla User's and installer's manual

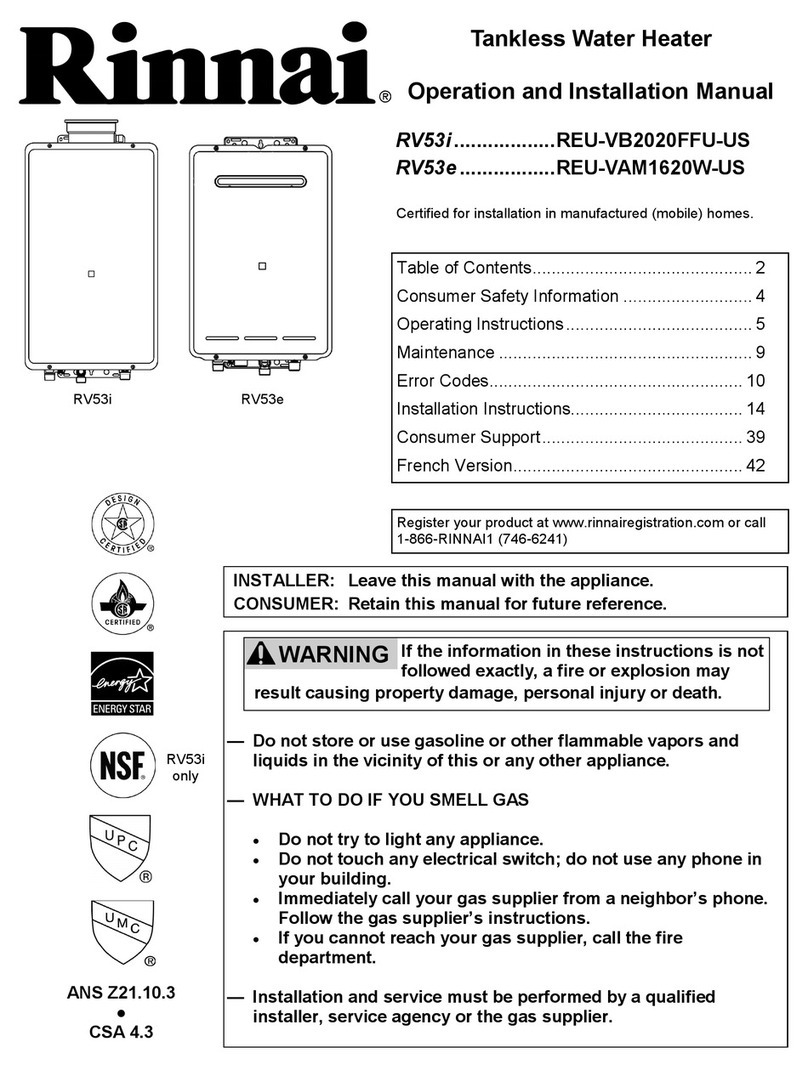

Rinnai

Rinnai RV53I Operation and installation manual