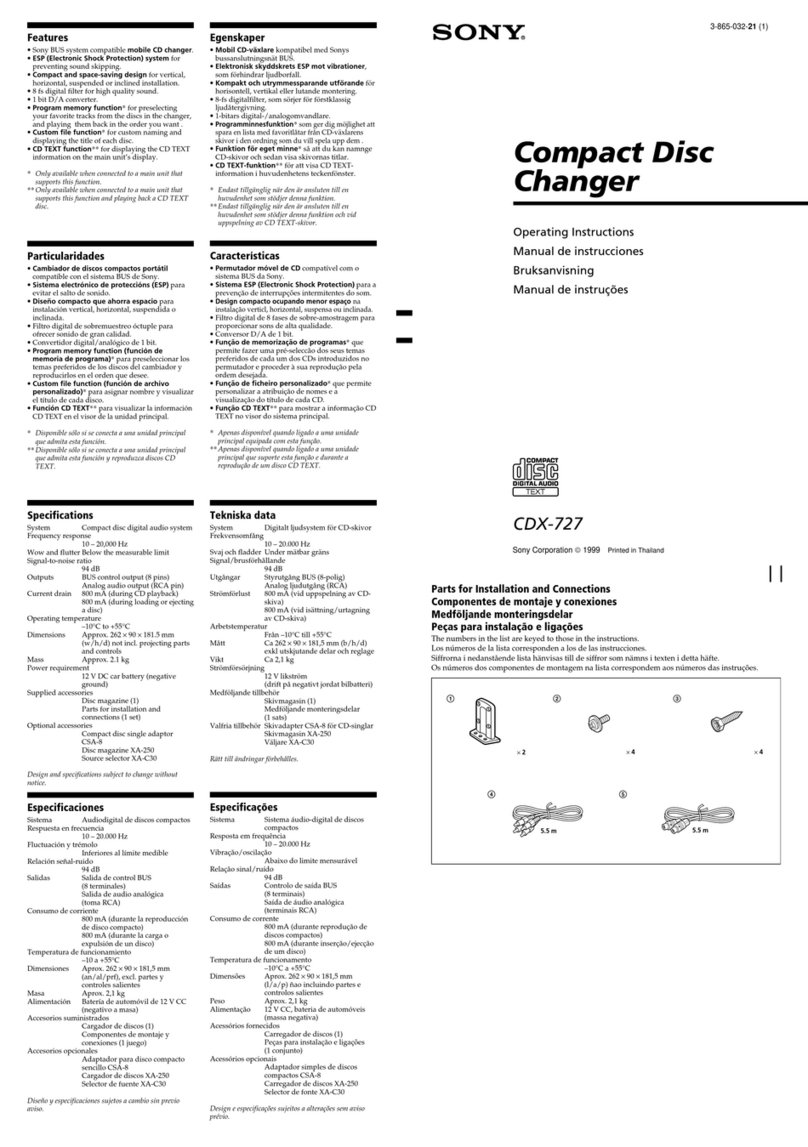

D-99

Power

consumption

2.6

W

OC

Dimensions

Weight

Supplied

accessories

Approx.

130.0

x

31.1

x

142.0

mm

(5'/s

x

1"/s

x

5%/s

in.)

(w/h/d)

not

incl.

Inclined

part

(depth),

projecting

parts

and

controls

Approx.

131.0

x

32.4

x

142.7

mm

(51/4

x

15/6

x

55/e

in.)

(w/h/d)

incl.

projecting

parts

and

controls

Approx.

420

g

(15

0z)

not

incl.

rechargeable

battery

Approx.

500

g

(1

Ib

1

02)

incl.

rechargeable

battery

.

AC

power

adaptor

(1),

Battery

case

(1)

Rechargeable

battery

pack

(1),

Carrying

case

(1)

Connecting

cord

(1)

(stereo

minipiug

+

two

phono

plugs)

Stereo

headphones

(1)

Design

and

specifications

subject

to

change

without

notice.

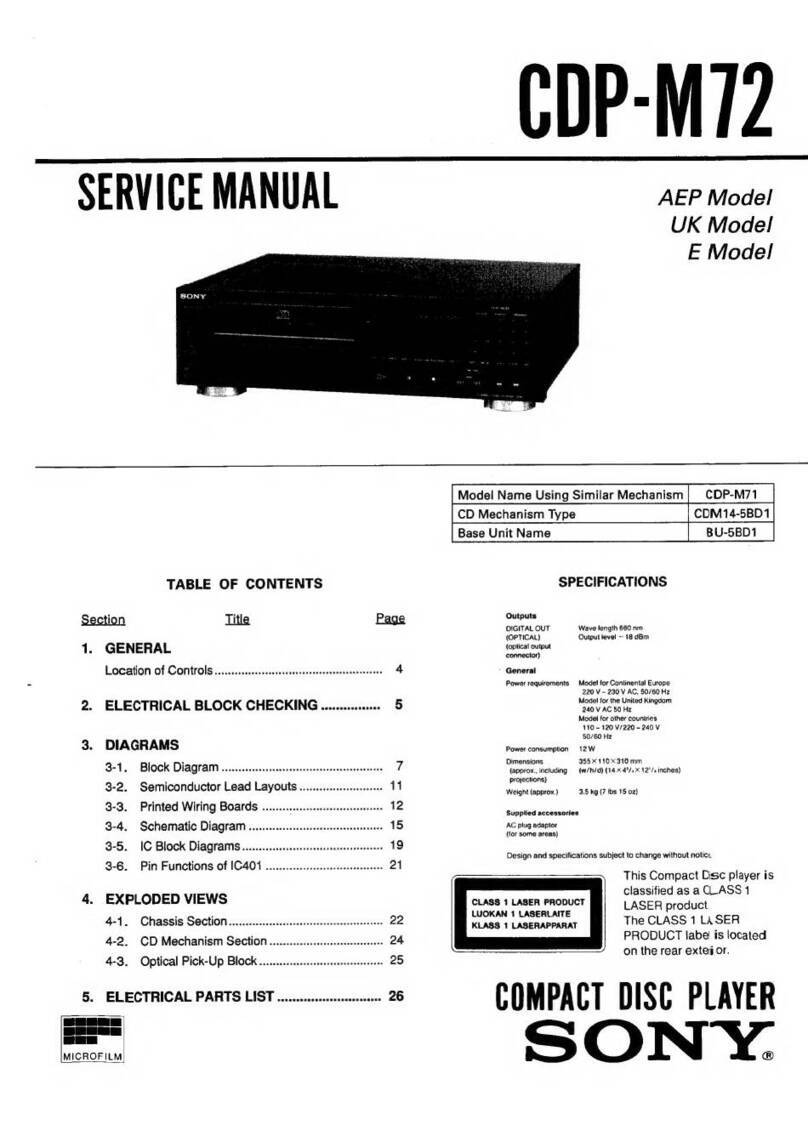

TABLE

OF

CONTENTS

Section

Title

Page

Specifications

POM

ee

mere

e

errr

eee

eee

eee eee

Hee

ee

ene

eee

eeeneeaeeeeHeeseeesereses

1

Ai:

SGP

NER

IN

exhausts

einccuitendinnn

acta

aatraseeeeauccals

2

2

SERVICING

NOTES.

----:-sscccssssccsccscesssccnsecossscevsescenes

3

Befor

Replacing

the

Optical

Block

COOH

EOE

HREOC

HH

EEO

EOOD

3

Note

on

Laser

Diode

Emission

Checkerrrrsrrrrsessersseeseee

4

Laser

Diode

Check

Procedure

OOO

er

ee

eer

eneeeereenreeesereeneees

4

Service

Mode

(service

program)

rere

rrerrrreeererere

rr

Tere

rrr

yy

4

Explanation

of

Terminals

(IC3801

CXD8178Q)-+rreseeerees

5

3.

ELECTRICAL

ADJUSTMENTS

ere

ee

eer

eres

6

4,

DIAGRAMS

4-1,

Block

Diagrams

Cece

e

eee

ew

erro

rer

ne

neene

eee

eeeeeseeeseeeennenee

9

4-2,

PC

Board/Switch/Motor

Layouts

crrrrrereerseeees

11

4-3,

Semiconductor

Lead

Layouts

rerrrsrsesssseseseseeeens

12

4-4,

Printed

Wiring

Boards

Peo

rer

erreverreree

cere

eerreeererene

14

4-5,

Schematic

Diagrams

OEP

ECTeTOEPrErerrererree

ee

er

rer

ee

rr

yy

19

4-6,

Ic

Block

Diagrams

Pomme

ere mee

re

rreeeeerrerereereessseeeeee

22

5.

EXPLODED

VIEWS

Poe eee

ere

eanen

eer

ee

ee

eeeeeeeesereneeeeseeesees

24

6.

ELECTRICAL

PARTS

LIST

Peererre

errr

eee

er

ere

rere

reer

errr

rr

26

SAFETY-RELATED

COMPONENT

WARNING!!

COMPONENTS

IDENTIFIED

BY

MARK

A

OR

DOTTED

LINE

WITH

MARK A\

ON

THE

SCHEMATIC

DIAGRAMS

AND

IN

THE

PARTS

LIST

ARE

CRITICAL

TO

SAFE

OPERATION.

REPLACE

THESE

COMPONENTS

WITH

SONY

PARTS

WHOSE

PART

NUMBERS

APPEAR

AS

SHOWN

IN

THIS

MANUAL

OR

IN

SUPPLEMENTS

PUB-

LISHED

BY

SONY.

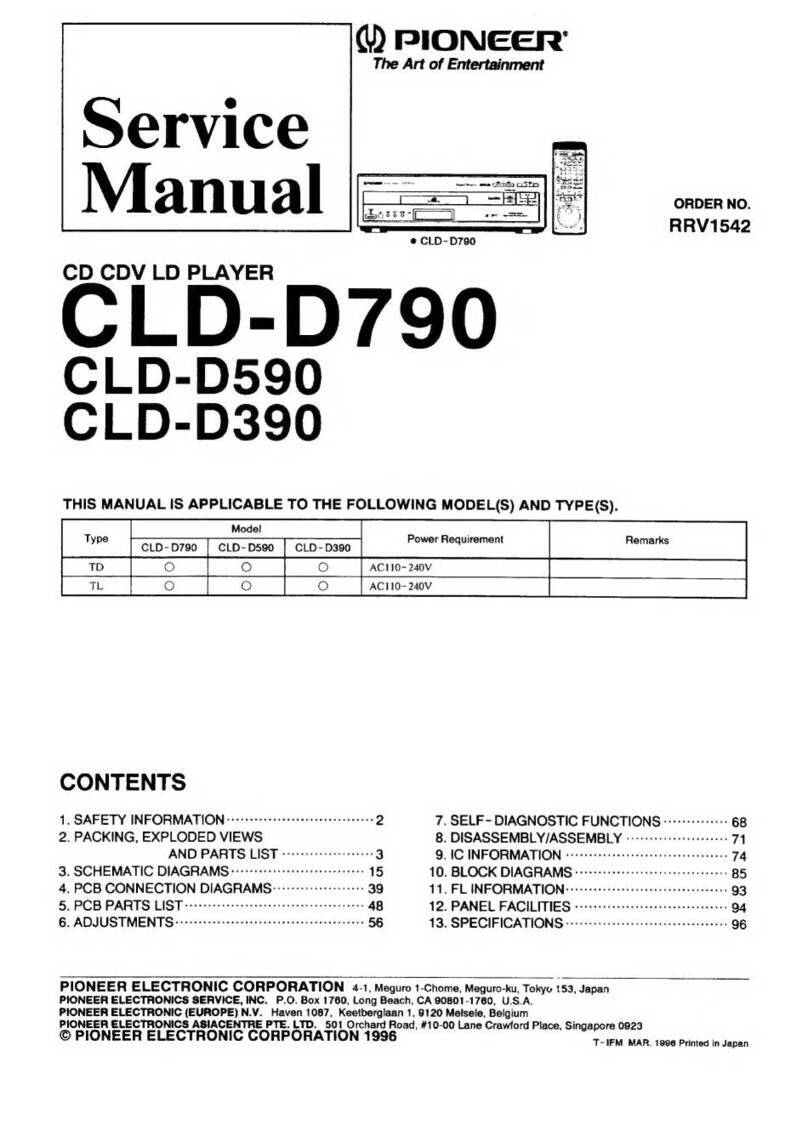

SECTION

1

GENERAL

LOCATION

AND

FUNCTION

OF

CONTROLS

Lens

The

laser

beam

is

emitted

from

this

point

to

pick-up

signal

on

the

disc.

PHONES

(headphones)/REMOTE

jack

Disc

window

Display

window

Normally

the

track

number

and

the

elapsed

playing

time

are

shown.

When

the

power

is

supplied’

through

the

DC

IN

9

V

jack,

the

window

will

light

up.

VOLUME

control

(for

listening

headphones)

ENTER/REMAIN

button

HOLD/RESUME

switch

Slide

this

switch

to

its

rightmost

position.

This

locks

the

buttons

to

prevent

them

from

being

acciden-

tally

pressed

(HOLD

function).

To

resume

disc

play

from

the

point

where

you

last

stopped

the

play,

set

the

switch

to

the

right

or

center

position

(RESUME

function).

KEY

MODE

(AMS*/SEARCH/INDEX)

button

PLAY

MODE

button

*

AMS

is

the

abbreviation

of

Auto

Music

Sensor.

ATTENTION

AU

COMPOSANT

AYANT

RAPPORT

A

LA

SECURITE!

LES

COMPOSANTS

IDENTIFIES

PAR

UNE

MARQUE

/\

SUR

LES

DIAGRAMMES

SCHEMATIQUES

ET

LA

LISTE

DES

PIECES

SONT

CRITIQUES

POUR

LA

SECURITE

DE

FONCTIONNEMENT.

NE

REMPLACER

CES

COM-

POSANTS

QUE

PAR

DES

PIECES

SONY

DONT

LES

NUMEROS

SONT

DONNES

DANS

CE

MANUEL

OU

DANS

LES

SUPPLEMENTS

PUBLIES

PAR

SONY.