SERVICE MANUAL

Sony Corporation

Home Audio Company

Published by Sony Engineering Corporation

AEP Model

UK Model

E Model

COMPACT DISC DECK RECEIVER

9-877-819-01

2004F1678-1

© 2004.06

Ver 1.0 2004.06

SPECIFICATIONS

CX-LEM550

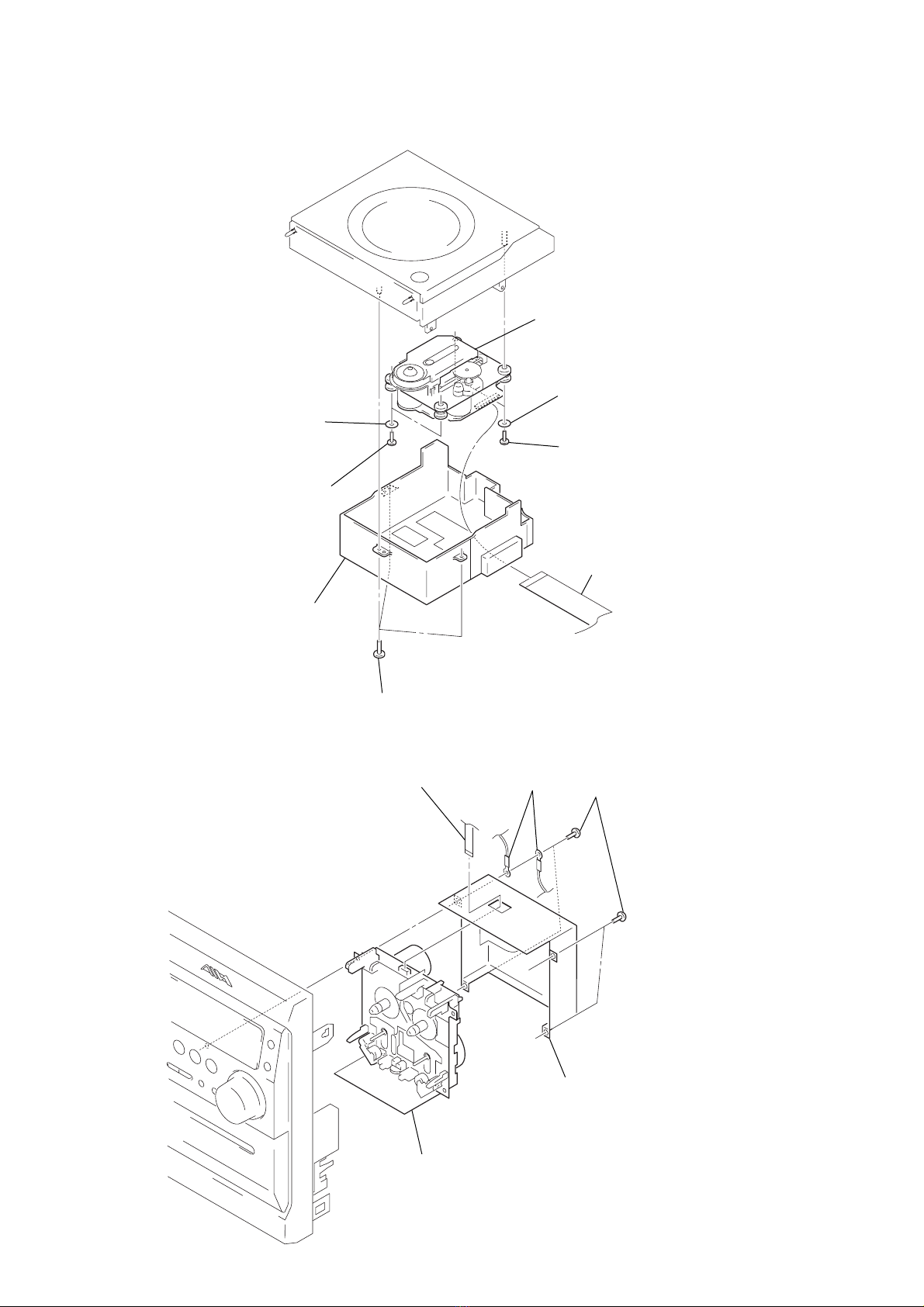

Model Name Using Similar Mechanism HCD-NE5

CD Base Unit Name BU-K7BD81B

Section Optical Pick-up Name KSM-213EDP/C2NP

Tape deck Model Name Using Similar Mechanism HCD-GP5

Section Tape Transport Mechanism Type CMAL1Z240A

CX-LEM550 is the Amplifier, CD player,

TapeDeckandTunersectionin XR-EM550.

— Continued on next page —

Main unit

Amplifier section

European model:

DIN power output (rated): 20 + 20 W

(6 ohms at 1 kHz, DIN)

Continuous RMS power output (reference):

25 + 25 W

(6 ohms at 1 kHz, 10%

THD)

Music power output (reference):

38 + 38 W

Other models:

The following measured at AC 230 V or AC 120 V, 50/

60 Hz

DIN power output (rated): 20 + 20 W

(6 ohms at 1 kHz, DIN)

Continuous RMS power output (reference):

25 + 25 W

(6 ohms at 1 kHz, 10%

THD)

Inputs

MD (phono jacks): Sensitivity 450 mV,

impedance 47 kilohms

Outputs

PHONES: Accepts headphones with

an impedance of 8 ohms or

more

SPEAKER: Accepts impedance of 6 to

16 ohms.

CD player section

Laser Semiconductor laser

(λ=780 nm)

Emission duration:

continuous

Frequency response 20 Hz – 20 kHz

Tape deck section

Recording system 4-track 2-channel, stereo

Frequency response 50 – 13,000 Hz (±3 dB),

using Sony TYPE I

cassettes

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range 87.5 – 108.0 MHz

Antenna FM lead antenna

Antenna terminals 75 ohms unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

European model: 531 – 1,602 kHz

(with the tuning interval

set at 9 kHz)

Other models: 530 – 1,710 kHz

(with the tuning interval

set at 10 kHz)

531 – 1,602 kHz

(with the tuning interval

set at 9 kHz)

Antenna AM loop antenna, external

antenna terminal

Intermediate frequency 450 kHz

General

Power requirements

European model: 230 V AC, 50/60 Hz

Korean model: 220 V AC, 60 Hz

Taiwanese model: 120 V AC, 50/60 Hz

Other models: 110–120 Vor220 – 240V

AC, 50/60 Hz

Adjustable with voltage

selector

Power consumption 67 W

0.3 W (in Power Saving

Mode)