Space-Ray PTS 40 User manual

This manual suits for next models

17

Other Space-Ray Gas Heater manuals

Space-Ray

Space-Ray LRDL25 User manual

Space-Ray

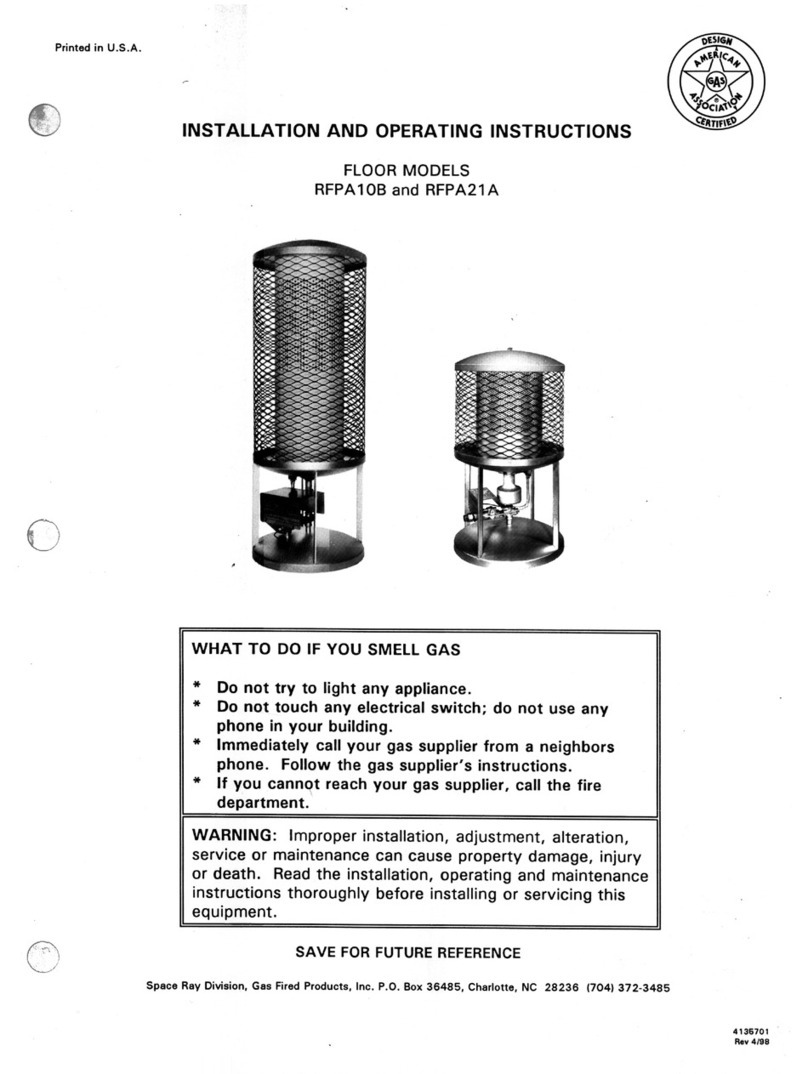

Space-Ray RFPA21A-N6 User manual

Space-Ray

Space-Ray SRB40CR User manual

Space-Ray

Space-Ray CB20-N5 User manual

Space-Ray

Space-Ray RFPA10B User manual

Space-Ray

Space-Ray Space-Ray ETS Series User manual

Space-Ray

Space-Ray SRB40CRE-N2 User manual

Space-Ray

Space-Ray PTS Series User manual

Space-Ray

Space-Ray CB20-N5 User manual

Space-Ray

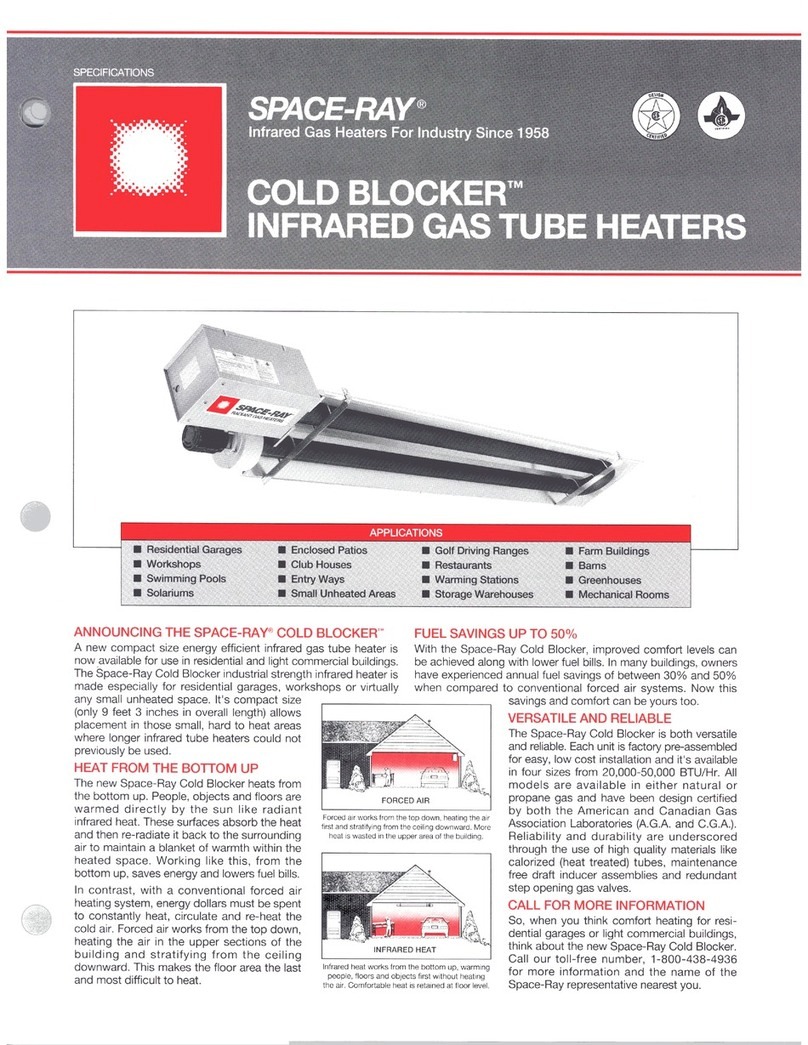

Space-Ray SPACE-RAY Infrared Gas Tube Heaters User manual

Popular Gas Heater manuals by other brands

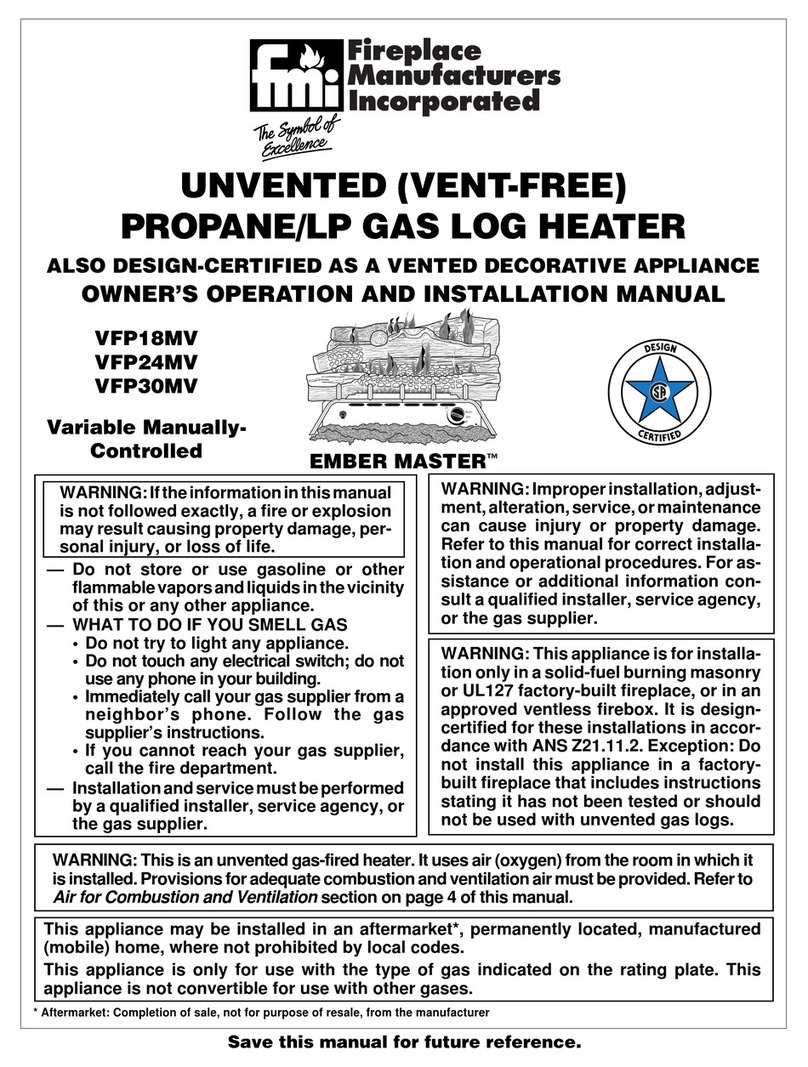

FMI

FMI VFP18MV OWNER'S OPERATION AND INSTALLATION MANUAL

Superior Fireplaces

Superior Fireplaces Superior MNF24ONM Assembly, installation and operation instructions

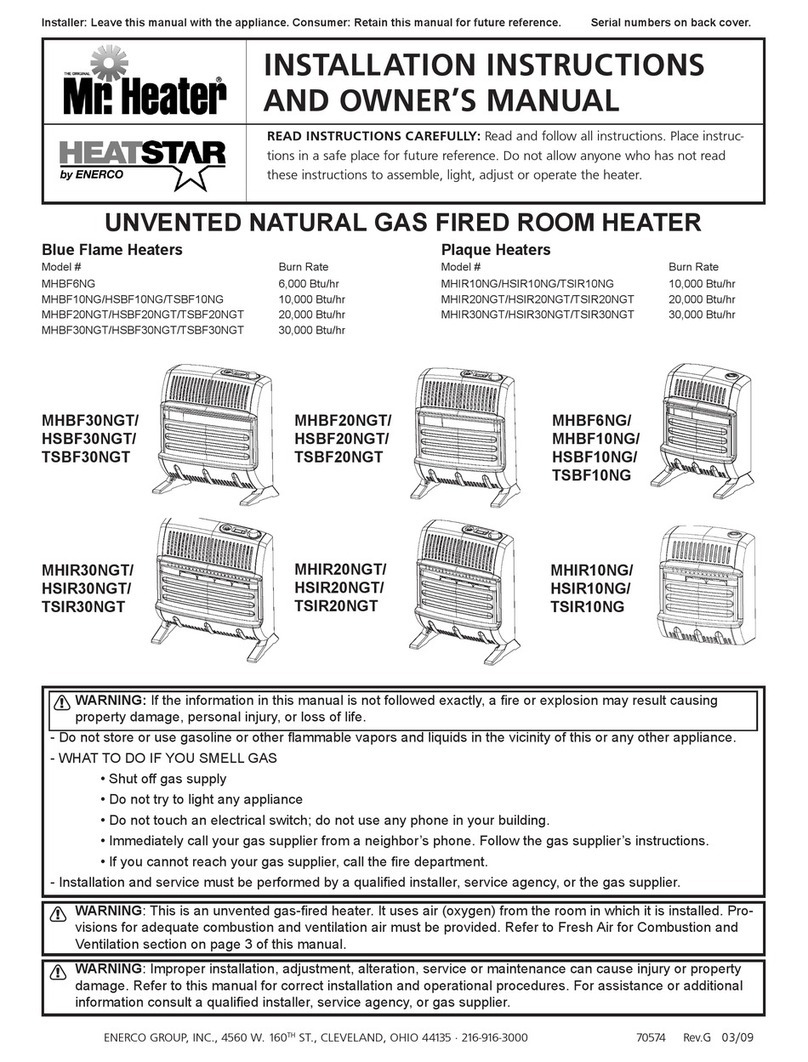

ENERCORP

ENERCORP UNVENTED NATURAL GAS FIRED ROOM HEATER... Installation and owner's manual

Vanguard

Vanguard Gas Log Heater OWNER'S OPERATION AND INSTALLATION MANUAL

MrHeater

MrHeater MH42T Operating instructions and owner's manual

Vanguard

Vanguard VP1600ITB OWNER'S OPERATION AND INSTALLATION MANUAL

MrHeater

MrHeater BIG BUDDY MH188 operating instructions

Real Fyre

Real Fyre G18-24/30-15(M)(P) owner's manual

SunStar

SunStar CK6M-4-NG Installation and owner's guide

Vanguard

Vanguard VN1800D OWNER'S OPERATION AND INSTALLATION MANUAL

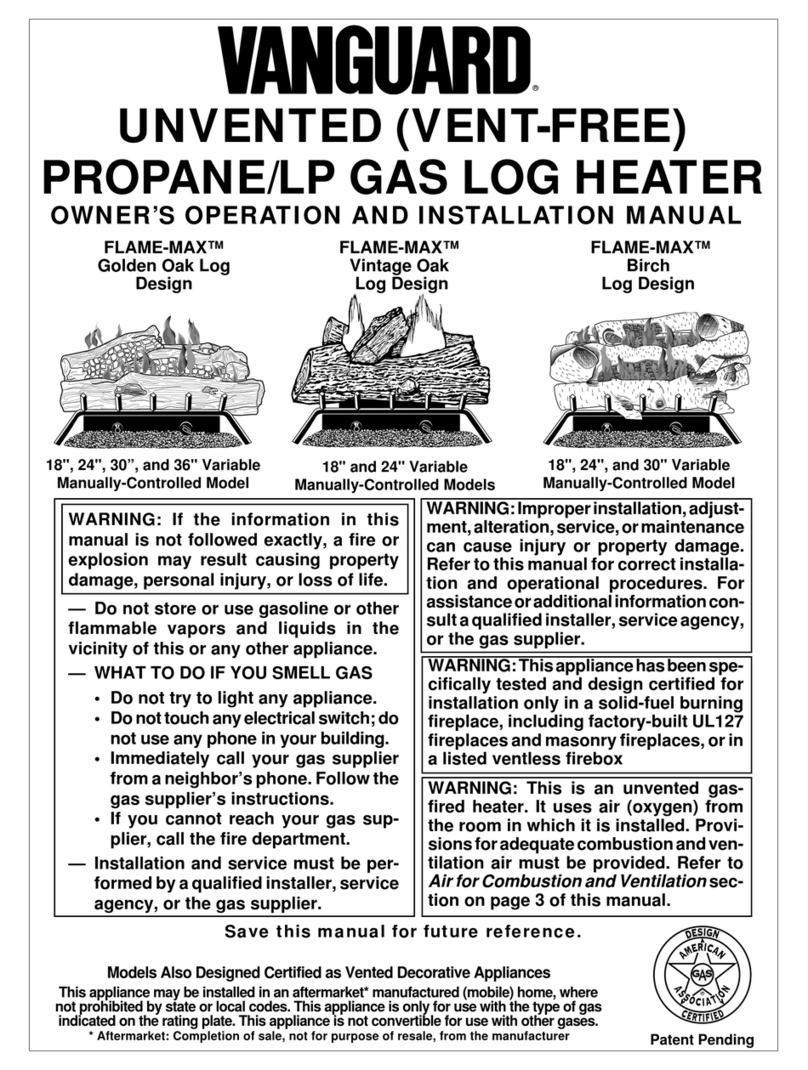

Vanguard

Vanguard FLAME-MAX UNVENTED (VENT-FREE) PROPANE/LP GAS LOG... Operation and installation manual

Vanguard

Vanguard VN1000B OWNER'S OPERATION AND INSTALLATION MANUAL

SunStar

SunStar SC10M-1-NG owner's guide

Vanguard

Vanguard VMH3000TPA OWNER'S OPERATION AND INSTALLATION MANUAL

Kinder

Kinder Rocco KBFL00RN Installation and maintenance instructions

Astria

Astria Blaze&Glow18TN Installation and operation instructions

US Stove Company

US Stove Company HeatFast HF15TT manual

Monessen Hearth

Monessen Hearth PH18 Installation and operating instructions