Space-Ray PTS 40-N7/L7 User manual

Form 43343530

Aug 2012

INSTALLATION AND OPERATION INSTRUCTIONS

OWNER / INSTALLER: For your s fety this m nu l must be c refully nd thoroughly re d nd

understood before inst lling, oper ting or servicing this he ter.

INFRARED RADIANT TUBE HEATER

Two St ge Push Through System (Positive Pressure)

Models:

PTS SERIES:

(40, 50, 75, 100, 125, 150, 175, 200)

–

N

7/L7

PTU SERIES:

(40, 50, 75, 100, 125, 150, 175, 200)

–

N

7

/L

7

!

INSTALLER

:

This m nu l is the property of the owner. Ple se present this m nu l to the

owner when you le ve the job site.

▲WARNING: Improper inst ll tion, djustment, lter tion, service, or m inten nce c n

c use property d m ge, injury or de th. Re d the inst ll tion, oper tion nd m inten nce

instructions thoroughly before inst lling or servicing this equipment.

IF YOU SMELL GAS: FOR YOUR SAFETY

FOR YOUR SAFETYFOR YOUR SAFETY

FOR YOUR SAFETY

!

!!

!

DO NOT

DO NOTDO NOT

DO NOT try to light ny ppli nce.

!

!!

!DO NOT

DO NOTDO NOT

DO NOT touch ny electric l switch; DO NOT

DO NOTDO NOT

DO NOT use ny

telephone in your building.

!

!!

!IMMEDIATELY

IMMEDIATELYIMMEDIATELY

IMMEDIATELY c ll your g s supplier from neighbor's

telephone. Follow the g s supplier's instructions. If you

c nnot re ch your g s supplier, c ll the fire dep rtment.

DO NOT

DO NOT DO NOT

DO NOT store or use g soline or other

store or use g soline or other store or use g soline or other

store or use g soline or other

fl mm ble v pors nd liquids in the vicinity of

fl mm ble v pors nd liquids in the vicinity of fl mm ble v pors nd liquids in the vicinity of

fl mm ble v pors nd liquids in the vicinity of

this or ny other ppli nce.

this or ny other ppli nce.this or ny other ppli nce.

this or ny other ppli nce.

!IMPORTANT:

!IMPORTANT:!IMPORTANT:

!IMPORTANT:

SAVE THIS MANUAL FOR

SAVE THIS MANUAL FOR SAVE THIS MANUAL FOR

SAVE THIS MANUAL FOR FUTURE REFERENCE.

FUTURE REFERENCE.FUTURE REFERENCE.

FUTURE REFERENCE.

SPACE

SPACESPACE

SPACE-

--

-RAY

RAYRAY

RAY

Post Office Box 36485 (28236) • 305 Doggett Street (28203) • Ch rlotte, North C rolin

Phone (704) 372-6391 • F x (704) 332-5843 • www.sp cer y.com • em il: info@sp cer y.com

Form 43343530

Aug 2012 -1-

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

1.0) S fety ................................................................................................................................................... 2

2.0) Inst ller Responsibility ...................................................................................................................... 2

3.0) Gener l Inform tion........................................................................................................................... 2

4.0) Minimum Cle r nces to Combustibles ........................................................................................... 4

5.0) Specific tions...................................................................................................................................... 5

6.0) P cking List ......................................................................................................................................... 5

6.1) Accessory P ck ges .......................................................................................................................... 9

7.0) Typic l L youts – PTS/PTU Series ................................................................................................. 11

7.1) Typic l Assembly L yout – (PTS SHOWN) .................................................................................... 12

8.0) Dimensions – PTS Series ................................................................................................................ 13

8.1) Dimensions – PTU Series ................................................................................................................ 14

8.2) He ter Assembly / Joining of Tube Sections ............................................................................... 15

9.0) Typic l Suspension Methods .......................................................................................................... 17

10.0) Assembly of Tube Sections ............................................................................................................. 18

10.1) Assembly of Extension Section ...................................................................................................... 19

10.2) Inserting Turbul tors ........................................................................................................................ 20

10.3) Adding Body Reflectors ................................................................................................................... 21

11.0) Adding Option l 90º Elbow (PTS Only) ......................................................................................... 22

11.1) Adding Option l Corner Reflector (PTS Only) .............................................................................. 22

11.2) Adding 180º U-Bend (PTU Only) .................................................................................................... 23

11.3) Adding Option l U-Bend Reflector (PTU Only) ............................................................................. 23

12.0) Att ching burner screen – (200M BTU MODELS ONLY) ............................................................. 24

12.1) Att ching Burner Box Assembly..................................................................................................... 25

12.2) Connecting the TISS System .......................................................................................................... 26

13.0) G s Connections nd Regul tions ................................................................................................. 29

14.0) Instructions for Pressure Test G uge Connection ....................................................................... 31

15.0) Electric l Connections ..................................................................................................................... 32

16.0) Venting ............................................................................................................................................... 35

17.0) Air for Combustion ........................................................................................................................... 39

17.1) Direct Outside Air for Combustion ................................................................................................. 39

18.0) Lighting nd Shutdown Instructions .............................................................................................. 41

19.0) Sequence of Oper tion .................................................................................................................... 42

20.0) Control Component Loc tion .......................................................................................................... 43

21.0) Cle ning nd Annu l M inten nce ............................................................................................... 44

22.0) Troubleshooting Guide..................................................................................................................... 45

23.0) Repl cing P rts ................................................................................................................................ 48

23.1) Remov l of M in Burner nd Electrodes ...................................................................................... 48

23.2) Removing G s V lve nd M nifold Assembly ............................................................................. 49

23.3) Air Switch Pressure Check .............................................................................................................. 49

23.4) Ignition System Checks ................................................................................................................... 50

24.0) Inst ll tion D t ............................................................................................................................... 51

25.0) Repl cement P rts Guide ............................................................................................................... 52

26.0) W rnings C rd .................................................................................................................................. 56

This he ter complies with ANSI Z83.20 (current st nd rd) nd CSA 2.34. Copies of the N tion l Fuel G s Code (ANSI

Z223.1-l test edition) re v il ble from the CSA t 8501 E st Ple s nt V lley Ro d, Clevel nd, Ohio 44131 or 55 Sc rsd le

Ro d, Don Mills, Ont rio M3B 2R3. All NFPA codes re v il ble from the N tion l Fire Protection Associ tion, B tterym rch

P rk, Quincy, M ss chusetts 02269.

Form 43343530

-2- Aug 2012

1.0) SAFETY

This he ter is self-cont ined infr red r di nt tube he ter. S fety inform tion required during inst ll tion nd

oper tion of this he ter is provided in this m nu l nd the l bels on the product. The inst ll tion, service nd

m inten nce of this he ter must be performed by contr ctor qu lified in the inst ll tion nd service of g s

fired he ting equipment.

All personnel in cont ct with the he ter must re d nd underst nd ll s fety inform tion, instructions nd l bels

before oper tion. The following symbols will be used in this m nu l to indic te import nt s fety inform tion.

W rning

W rningW rning

W rning instructions must be followed to

prevent or void h z rds which

m y c use serious injury, property d m ge or de th.

C ution

C utionC ution

C ution

instructions must be followed to prevent incorrect oper tion or

inst ll tion of

the he ter which m y c use minor injury or property

d m ge.

2.0) INSTALLER RESPONSIBILITY

The inst ller is responsible for the following:

•

••

•The he ter nd venting, s well s electric l nd g s supplies must be inst lled in ccord nce with these

inst ll tion instructions nd ny pplic ble codes nd regul tions.

•

••

•Every he ter sh ll be loc ted with respect to building construction nd other equipment so s to permit

ccess to the he ter.

•

••

•E ch inst ller must follow the cle r nces to combustible m teri ls for the he ters.

•

••

•Inst ll the he ter so th t the supports nd h ngers re correctly sp ced in ccord nce with these

instructions. The he ter must be supported by m teri ls h ving working lo d limit of t le st 115lbs.

•

••

•Ensure th t the tube integrity s fety system TISS™ supplied is inst lled in ccord nce with these instructions

nd th t the tension is correct.

•

••

•Supply the owner with copy of these Inst ll tion nd Oper tion Instructions.

•

••

•Where unvented he ters re used, gr vity or mech nic l me ns sh ll be provided to supply nd exh ust t

le st 4 CFM per 1,000 Btu/hr input of inst lled he ters.

•

••

•Never use the he ter s support for l dder or other ccess equipment. Do not h ng nything from the

he ter.

•

••

•Supply ll inst ll tion m teri ls necess ry th t re not included with the he ter.

•

••

•Check the n mepl te to m ke sure th t the burner is correct for the g s type in the building nd the

inst ll tion ltitude.

3.0) GENERAL INFORMATION

This he ter is self-cont ined infr red r di nt tube he ter for use in loc tions where fl mm ble g ses or v pors

re not gener lly present ( s defined by OSHA ccept ble limits) nd is intended for the he ting of

nonresidenti l

nonresidenti lnonresidenti l

nonresidenti l sp ces.

For indoor inst ll tion only. Not for use in residenti l dwellings.

For indoor inst ll tion only. Not for use in residenti l dwellings.For indoor inst ll tion only. Not for use in residenti l dwellings.

For indoor inst ll tion only. Not for use in residenti l dwellings.

INSTALLATION REQUIREMENTS

INSTALLATION REQUIREMENTSINSTALLATION REQUIREMENTS

INSTALLATION REQUIREMENTS

The inst ll tion must conform to loc l building codes or in the bsence of loc l codes, with the N tion l Fuel G s

Code ANSI Z223.1/NFPA54 or the N tur l G s nd Prop ne Inst ll tion Code CSA B149.1. He ters sh ll be

inst lled by licensed contr ctor or licensed inst ller. Cle r nces to combustibles s outlined in this m nu l

should lw ys be observed. In re s used for stor ge of combustible m teri ls where they m y be st cked

below the he ter, NFPA54 requires th t the inst ller must post signs th t will “specify the m ximum permissible

st cking height to m int in the required cle r nces from the he ter to combustibles.”

Every he ter sh ll be loc ted with respect to building construction nd other equipment so s to permit ccess

to the he ter. E ch inst ller sh ll use qu lity inst ll tion pr ctices when loc ting the he ter nd must give

consider tion to cle r nces to combustible m teri ls, vehicles p rked below, lights, overhe d doors, stor ge

re s with st cked m teri ls, sprinkler he ds, g s nd electric l lines nd ny other possible obstructions or

h z rds. Consider tion lso must be given to service ccessibility.

Form 43343530

Aug 2012 -3-

The he ter, when inst lled in ircr ft h ng rs nd public g r ges, must be inst lled in ccord nce with

ANSI/NFPA 409-l test edition (St nd rd for Aircr ft H ng rs), ANSI/NFPA 88 -l test edition (St nd rd for

P rking Structures), nd ANSI/NFPA 88b-l test edition (St nd rd for Rep ir G r ges) with the following

cle r nces:

. At le st 10 feet bove the upper surf ces of wings or engine enclosures of the highest ircr ft th t m y be

housed in the h ng r nd t le st 8 feet bove the floor in shops, offices, nd other sections of h ng rs

communic ting with ircr ft stor ge or service re s.

b. At le st 8 feet bove the floor in public g r ges. ▲

▲▲

▲WARNING:

WARNING:WARNING:

WARNING: Minimum cle r nces m rked on the he ter

must be m int ined from vehicles p rked below the he ter.

(FOR CANADA ONLY)

.

Inst ll tion of this ppli nce is to be in ccord nce with l test edition of C

SA

B149.1 (

N tur l G s nd

Prop ne Inst ll tion Code).

b. For inst ll tion in public g r ges or ircr ft h ng rs, the minimum cle r nces from the bottom of the

infr red he ter to the upper surf ce of the highest ircr ft or vehicle sh ll be 50 percent gre ter th n the

certified minimum cle r nce, but the cle r nce sh ll not be less th n 8 feet.

Although these he ters m y be used in m ny pplic tions other th n sp ce he ting (e.g., process he ting),

Sp ce-R y will not recognize the w rr nty for ny use other th n sp ce he ting.

This he ter is for Indoor Inst ll tion nd Covered P tio Inst ll tion only nd c n be used in either Vented or

Unvented mode. The term Unvented ctu lly me ns Indirect Vented. While the products of combustion re

expelled into the building, n tion l codes require ventil tion in the building to dilute these products of

combustion. This ventil tion m y be provided by gr vity or mech nic l me ns.

This he ter is not n explosion proof he ter.

This he ter is not n explosion proof he ter.This he ter is not n explosion proof he ter.

This he ter is not n explosion proof he ter. Where the possibility of exposure to vol tile nd low fl sh point

m teri ls exists, it could result in property d m ge or de th. This he ter must not be inst lled in spr y booth

where the he ter c n oper te during the spr ying process. Consult your loc l fire m rsh l or insur nce comp ny.

PTS Series Only:

PTS Series Only:PTS Series Only:

PTS Series Only: Since str ight tube he ters re lw ys hotter t the control end th n t the flue termin l end,

Since str ight tube he ters re lw ys hotter t the control end th n t the flue termin l end, Since str ight tube he ters re lw ys hotter t the control end th n t the flue termin l end,

Since str ight tube he ters re lw ys hotter t the control end th n t the flue termin l end,

lw ys observe the minimum recommended mounting hei

lw ys observe the minimum recommended mounting heilw ys observe the minimum recommended mounting hei

lw ys observe the minimum recommended mounting heights shown on the specific tion sheets

ghts shown on the specific tion sheetsghts shown on the specific tion sheets

ghts shown on the specific tion sheets nd in Section

5.0) of this m nu l. Use U-tube configur tion inste d of str ight tubes for spot or re he ting (e.g., where

single he ter is utilized for sp ce he ting).

WARM

HOT WARM

WARM

WARM

HOT

High Altitud

High AltitudHigh Altitud

High Altitude:

e:e:

e:

Appli nces re supplied s st nd rd for ltitudes of O to 2,000 feet (0-610 m). High- ltitude r tings re obt ined

by ch nge in the orifice size. When ordered for high ltitude inst ll tions, burners re supplied by the f ctory

re dy for high ltitude inst ll tion. Check the n mepl te for ltitude before proceeding with the inst ll tion. In

C n d the djustment for ltitude is m de in ccord nce with St nd rd CGA 2.17, G s-Fired Appli nces for Use

t High Altitudes.

Form 43343530

-4- Aug 2012

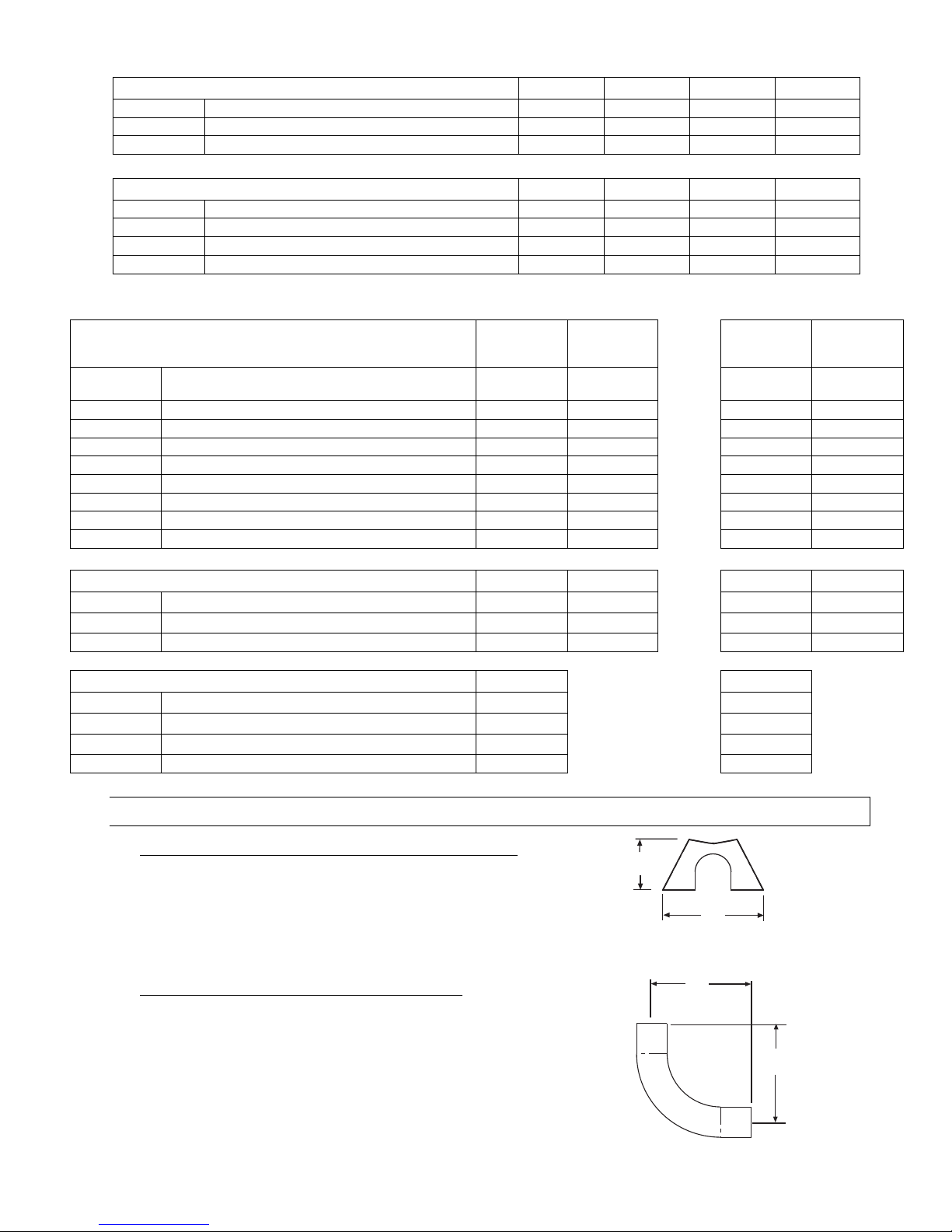

4.0) MINIMUM CLEARANCES TO COMBUSTIBLES

Failure to do so may result in death, serious injury or

property damage.

Combustible material must be located outside the

clearance dimensions listed.

Inst ll the w rnings c rd (ordered sep r tely) nd complete the bl nk sp ces using the cle r nces from

combustibles t ble below. See Section 26 for printed copy of the w rnings c rd.

Minimum cle r nces to combustibles sh ll be me sured from the outer surf ces s shown in the following

di gr m:

End End

Ceiling

Below

Front

Rear

45° Angle (Maximum)

* Ceiling

Below

Side Side

Horizontal

MINIMUM CLEARANCES TO COMBUSTIBLES

MINIMUM CLEARANCES TO COMBUSTIBLESMINIMUM CLEARANCES TO COMBUSTIBLES

MINIMUM CLEARANCES TO COMBUSTIBLES

Model No.

Model No.Model No.

Model No.

Mounted Horizont lly

Mounted Horizont llyMounted Horizont lly

Mounted Horizont lly

Angle Mounted t

Angle Mounted t Angle Mounted t

Angle Mounted t

45º

45º45º

45º

Sides

SidesSides

Sides

Ceiling*

Ceiling*Ceiling*

Ceiling*

Below

BelowBelow

Below

Ends

EndsEnds

Ends

45º Front

45º Front45º Front

45º Front

45º Re r

45º Re r45º Re r

45º Re r

PTS/PTU 40

/25

22

”

6”

52

”

15

”

40

”

12”

PTS/PTU 50

/30

22

”

6”

56

”

15

”

48”

12”

PTS/PTU 75

/50

22

”

6”

60”

15

”

52

”

12”

PTS/PTU 100/65 28” 6” 70” ** 15” 58” 12”

PTS/PTU 125/80 28” 6” 76” ** 20” 66” 12”

PTS/PTU 150

/100

34

”

6”

81

” **

20

”

70

”

12

”

PTS/PTU 175

/110

34

”

6”

86

” **

20

”

75

”

12

”

PTS/PTU 200

/125

42

”

6”

93

” **

20

”

80

”

12

”

* When used indirect vented, minimum cle r nce for CEILING must be: 12” for PTS/PTU 50-75 nd 18” for

PTS/PTU 100-200. If option l corner nd u-bend reflectors re not used, the cle r nce must be 18”.

** M ximum cle r nce below reduces by 50% once you re 25ft. downstre m from the burner box.

▲WARNING:

▲WARNING:▲WARNING:

▲WARNING:

Cert in m teri ls or objects, when stored under the he ter, will be subjected to r di nt he t nd

Cert in m teri ls or objects, when stored under the he ter, will be subjected to r di nt he t nd Cert in m teri ls or objects, when stored under the he ter, will be subjected to r di nt he t nd

Cert in m teri ls or objects, when stored under the he ter, will be subjected to r di nt he t nd

could be seriously d m ged. Observe the Minimum Cle r nces to Combustibles listed in the m nu l nd on the

could be seriously d m ged. Observe the Minimum Cle r nces to Combustibles listed in the m nu l nd on the could be seriously d m ged. Observe the Minimum Cle r nces to Combustibles listed in the m nu l nd on the

could be seriously d m ged. Observe the Minimum Cle r nces to Combustibles listed in the m nu l nd on the

he ter t ll times.

he ter t ll times.he ter t ll times.

he ter t ll times.

NOTE:

NOTE:NOTE:

NOTE:

1.

1. 1.

1. The cle r

The cle rThe cle r

The cle r nces specified bove must be m int ined to combustibles nd other m teri ls th t m y be

nces specified bove must be m int ined to combustibles nd other m teri ls th t m y be nces specified bove must be m int ined to combustibles nd other m teri ls th t m y be

nces specified bove must be m int ined to combustibles nd other m teri ls th t m y be

d m ged by temper tures 90ºF bove mbient temper ture. Cle r nces to combustibles re posted on the

d m ged by temper tures 90ºF bove mbient temper ture. Cle r nces to combustibles re posted on the d m ged by temper tures 90ºF bove mbient temper ture. Cle r nces to combustibles re posted on the

d m ged by temper tures 90ºF bove mbient temper ture. Cle r nces to combustibles re posted on the

burner

burnerburner

burner

box. In re s used for stor ge of combustible m teri ls w

box. In re s used for stor ge of combustible m teri ls wbox. In re s used for stor ge of combustible m teri ls w

box. In re s used for stor ge of combustible m teri ls where they m y be st cked below the he ter,

here they m y be st cked below the he ter, here they m y be st cked below the he ter,

here they m y be st cked below the he ter,

NFPA54 requires th t the inst ller must post signs th t will “specify the m ximum permissible st cking height

NFPA54 requires th t the inst ller must post signs th t will “specify the m ximum permissible st cking height NFPA54 requires th t the inst ller must post signs th t will “specify the m ximum permissible st cking height

NFPA54 requires th t the inst ller must post signs th t will “specify the m ximum permissible st cking height

to m int in the required cle r nces from the he ter to combustibles.” Sp ce

to m int in the required cle r nces from the he ter to combustibles.” Sp ceto m int in the required cle r nces from the he ter to combustibles.” Sp ce

to m int in the required cle r nces from the he ter to combustibles.” Sp ce-

--

-R y recommends posting the

R y recommends posting theR y recommends posting the

R y recommends posting these

se se

se

signs dj cent to the he ter thermost t or other suit ble loc tion th t will provide enh nced visibility.

signs dj cent to the he ter thermost t or other suit ble loc tion th t will provide enh nced visibility.signs dj cent to the he ter thermost t or other suit ble loc tion th t will provide enh nced visibility.

signs dj cent to the he ter thermost t or other suit ble loc tion th t will provide enh nced visibility.

2.

2. 2.

2. The st ted cle r nce to combustibles represents surf ce temper ture of 90 ºF (32 ºC) bove room

The st ted cle r nce to combustibles represents surf ce temper ture of 90 ºF (32 ºC) bove room The st ted cle r nce to combustibles represents surf ce temper ture of 90 ºF (32 ºC) bove room

The st ted cle r nce to combustibles represents surf ce temper ture of 90 ºF (32 ºC) bove room

temper ture. Building m teri ls with low he

temper ture. Building m teri ls with low hetemper ture. Building m teri ls with low he

temper ture. Building m teri ls with low he t toler nce (such s pl stics, vinyle siding, c nv s, tri

t toler nce (such s pl stics, vinyle siding, c nv s, trit toler nce (such s pl stics, vinyle siding, c nv s, tri

t toler nce (such s pl stics, vinyle siding, c nv s, tri-

--

-ply, etc.)

ply, etc.) ply, etc.)

ply, etc.)

m y be subject to degr d tion t lower temper tures. It is the inst ller’s responsibility to ssure th t dj cent

m y be subject to degr d tion t lower temper tures. It is the inst ller’s responsibility to ssure th t dj cent m y be subject to degr d tion t lower temper tures. It is the inst ller’s responsibility to ssure th t dj cent

m y be subject to degr d tion t lower temper tures. It is the inst ller’s responsibility to ssure th t dj cent

m teri ls re protected from degr d tion.

m teri ls re protected from degr d tion.m teri ls re protected from degr d tion.

m teri ls re protected from degr d tion.

Form 43343530

Aug 2012 -5-

5.0) SPECIFICATIONS

Model No.

Model No.Model No.

Model No.

Input

InputInput

Input,

, ,

, Btu/hr

Btu/hrBtu/hr

Btu/hr

Combustion

Combustion Combustion

Combustion

Air Pl te

Air Pl teAir Pl te

Air Pl te

P rt #

P rt #P rt #

P rt #

Orifice Size

Orifice SizeOrifice Size

Orifice Size

Minimum *

Minimum *Minimum *

Minimum *

Mounting Height

Mounting HeightMounting Height

Mounting Height

Turbul tor

Turbul tor Turbul tor

Turbul tor

Qty.

Qty.Qty.

Qty.

High

HighHigh

High Low

LowLow

Low N tur l G s

N tur l G sN tur l G s

N tur l G s

Prop ne G s

Prop ne G sProp ne G s

Prop ne G s

@

@@

@

Horizont l

Horizont lHorizont l

Horizont l

@

@@

@

45º Angle

45º Angle45º Angle

45º Angle

PTS/PTU 40/25 40,000

25,000

#44140061

#32 (0.116)

#49 (0.073)

10 ft. 9 ft. 4

PTS/PTU 50/30 50,000

30,000

#44140064

3.5mm

(0.138)

46 (0.081)

11 ft. 10 ft. 5

PTS/PTU 75/50 75,000

50,000

#44140063

#21 (0.159)

2.5mm

(0.098)

13 ft. 12 ft. 5

PTS/PTU 100/65 100,000

65,000

#44140062

#12 (0.189)

#32 (0.116)

14 ft. 13 ft. 3

PTS/PTU 125/80 125,000

80,000

#44140066

#4 (0.209)

#30 (0.129)

14 ft. 13 ft. 7

PTS/PTU 150/100 150,000

100,000

#44140067

“A” (0.234)

#27 (0.144)

15 ft. 14 ft. 4

PTS/PTU 175/110 175,000

110,000

#44140067

“E” (0.250)

#23 (0.154)

16 ft. 15 ft. 0

PTS/PTU 200/125 200,000

125,000

#44140068

6.9mm

(0.272)

4.1mm

(0.161)

18 ft. 16 ft. 1

* MOUNT HEATERS AS HIGH AS POSSIBLE. Minimums re shown s guideline for hum n comfort nd uniform

energy distribution for complete building he ting pplic tions. Consult your Sp ce-R y represent tive for the

p rticul rs of your inst ll tion requirements.

Type

TypeType

Type

G s

G sG s

G s

G s Pipe

G s PipeG s Pipe

G s Pipe

Connection

Connection Connection

Connection

Tube

TubeTube

Tube

Di meter

Di meterDi meter

Di meter

Flue

FlueFlue

Flue

Connection

ConnectionConnection

Connection1

11

1

Fresh Air

Fresh Air Fresh Air

Fresh Air

Connection

ConnectionConnection

Connection1

11

1

Electric l

Electric lElectric l

Electric l

Supply

SupplySupply

Supply

Current

CurrentCurrent

Current

R ting

R tingR ting

R ting

N tur l

or Prop ne

½” MPT

(M le) 4” 4” Round 4” Round

120 Volt,

60Hz,

1 Ph se 1.74 Amp

1 See Section 16.0) for vent sizes when multiple he ters re connected into common vent

Module Electric l R ting:

Module Electric l R ting:Module Electric l R ting:

Module Electric l R ting:

Ignition System (direct sp rk):

Ignition System (direct sp rk):Ignition System (direct sp rk):

Ignition System (direct sp rk):

Input Power

-

Control: 18

-

30 VAC 50/60 Hz (cl ss 2

tr nsformer)

Input Power-Line: 120 VAC (L1, IND cont cts only)

G s V lve R ting: 2.0 A @ 24 VAC (m x.)

Combustion Blower R ting: 3.0 FLA @ 120 VAC

0.0233 H.P. Motor

Fl me Sensitivity: 0.7 micro mps minimum

15 second tri l for ignition period

15 second pre-purge period

60 second inter-purge period

30 second post-purge period

3 tries for ignition (sep r te fl me sensor).

6.0) PACKING LIST

A.

A.A.

A. PTS/PTU Burner P ck ge

PTS/PTU Burner P ck gePTS/PTU Burner P ck ge

PTS/PTU Burner P ck ge

P rt Description

P rt DescriptionP rt Description

P rt Description

QTY

QTYQTY

QTY

Burner Box Assembly (Refer to the following ch rt for P ck ge P rt N

umbers)

..........................

1

4”ID x 4”Lg Flue Ad pter Coll r (#30504500)

................................

................................

..................

1

F stener Kit

–

Burner Box Att chment/Flue Ad pter Coll r (#42907040)

................................

..

1

Cont ining:

#10 x 1/2” Self

-

Drilling Screws (#02189020)

................................

....................

2

¼

-

20 Locknuts (#02167010)

................................

................................

..............

3

Tube Fl nge G sket

(#42921000)

................................

................................

...........

1

Turbul tor 24” Long (#44152240) *See ch rt bove for required qu ntities.

..............................

*

Inst ll tion & Oper tion Instructions

................................

................................

................................

....

1

Turnbuckle

(#30545040)

................................

................................

................................

.........................

1

G s connector 5/8” OD x 36”

(#30302360)

................................

................................

........................

1

Screen Assembly

–

2

-

5/8” ID x 5

-

1/2” Long (#4415101

0)

200M BTU models only

200M BTU models only200M BTU models only

200M BTU models only

.....................

1

Form 43343530

-6- Aug 2012

BURNER PACKAGE NUMB

BURNER PACKAGE NUMBBURNER PACKAGE NUMB

BURNER PACKAGE NUMBERS

ERSERS

ERS

NATURAL GAS

NATURAL GASNATURAL GAS

NATURAL GAS

PROPANE GAS

PROPANE GASPROPANE GAS

PROPANE GAS

MODEL NO.

MODEL NO. MODEL NO.

MODEL NO.

PART NO.

PART NO.PART NO.

PART NO.

MODEL NO.

MODEL NO. MODEL NO.

MODEL NO.

PART NO.

PART NO.PART NO.

PART NO.

PTS/U 40/25-N7 ................. #44149510 PTS/U 40/25-L7 ................... #44149520

PTS/U 50/30-N7 ................. #44149530 PTS/U 50/30-L7 ................... #44149540

PTS/U 75/50-N7 ................. #44149550 PTS/U 75/50-L7 ................... #44149560

PTS/U 100/65-N7 ............... #44149570 PTS/U 100/65-L7 ................ #44149580

PTS/U 125/80-N7 ............... #44149590 PTS/U 125/80-L7 ................ #44149600

PTS/U 150/100-N7............. #44149610 PTS/U 150/100-L7 .............. #44149620

PTS/U 175/110-N7............. #44149630 PTS/U 175/110-L7 .............. #44149640

PTS/U 200/125-N7............. #44149650 PTS/U 200/125-L7 .............. #44149660

B.

B.B.

B. PTS 40

PTS 40PTS 40

PTS 40-

--

-200 Body P ck ge Descriptions

200 Body P ck ge Descriptions200 Body P ck ge Descriptions

200 Body P ck ge Descriptions

(Package Part Number is indicated on the outside of each corresponding carton.)

System

SystemSystem

Systems

ss

s

1

11

1

0Ft.

0Ft. 0Ft.

0Ft.

System

SystemSystem

System

2

22

2

0Ft.

0Ft. 0Ft.

0Ft.

System

SystemSystem

System

3

33

3

0Ft.

0Ft. 0Ft.

0Ft.

System

SystemSystem

System

4

44

4

0Ft.

0Ft. 0Ft.

0Ft.

System

SystemSystem

System

5

55

5

0Ft.

0Ft. 0Ft.

0Ft.

System

SystemSystem

System

PTS Body P ck ges

PTS Body P ck ges PTS Body P ck ges

PTS Body P ck ges –

––

–

Alu

AluAlu

Aluminized/Hot Rolled or

minized/Hot Rolled orminized/Hot Rolled or

minized/Hot Rolled or

Alumi

AlumiAlumi

Alumi-

--

-Therm/Hot Rolled

Therm/Hot Rolled Therm/Hot Rolled

Therm/Hot Rolled

10 Ft.

10 Ft.10 Ft.

10 Ft.

pkg

pkgpkg

pkg

44134020

4413402044134020

44134020

20 Ft. pkg

20 Ft. pkg20 Ft. pkg

20 Ft. pkg

44135000

4413500044135000

44135000

30 Ft. pkg

30 Ft. pkg30 Ft. pkg

30 Ft. pkg

44136000

4413600044136000

44136000

40 Ft. pkg

40 Ft. pkg 40 Ft. pkg

40 Ft. pkg

44137100

4413710044137100

44137100

50 Ft. pkg

50 Ft. pkg50 Ft. pkg

50 Ft. pkg

44138100

4413810044138100

44138100

P rt #

P rt #P rt #

P rt #

E ch Body P ck ge Includes:

E ch Body P ck ge Includes:E ch Body P ck ge Includes:

E ch Body P ck ge Includes:

Qty.

Qty.Qty.

Qty.

Qty.

Qty.Qty.

Qty.

Qty.

Qty.Qty.

Qty.

Qty.

Qty.Qty.

Qty.

Qty.

Qty.Qty.

Qty.

42912080

1

0 Ft. Tube with 24 Hole Fl nge (Aluminized)

1

1

1

-

-

42912169

10 Ft. Tube with 6 Hole Fl nge (Alumi

-

Therm)

-

-

-

1

1

41932101

10 Ft. Tube less Fl nges (Hot Rolled)

-

1

2

3

4

43319100

Reflector, 9’ 11½”

1

2

3

4

5

30462980

Tube Coupling

-

1

2

3

4

43318

000

Tube H nger/Support Br cket, 13”

1

2

3

4

5

43980010

Wire H nger

1

2

3

4

5

Body F stener Kit (included in body p ck ges)

Body F stener Kit (included in body p ck ges)Body F stener Kit (included in body p ck ges)

Body F stener Kit (included in body p ck ges)

42907280

4290728042907280

42907280

42907190

4290719042907190

42907190

42907200

4290720042907200

42907200

42907210

4290721042907210

42907210

42907220

4290722042907220

42907220

42873000

U

-

Bolt

1

2

3

4

5

02127110

Hex Nut, 5/16

-

18

3

5

6

8

10

02189020

HWHSM Sc

rew, #10

-

16 x ½” TEKS

4

8

10

14

18

System

SystemSystem

System

s

ss

s

60Ft. System

60Ft. System60Ft. System

60Ft. System

70Ft. System

70Ft. System70Ft. System

70Ft. System

PTS Body P ck ges

PTS Body P ck ges PTS Body P ck ges

PTS Body P ck ges –

––

–

Alumi

AlumiAlumi

Alumi-

--

-Therm/Hot Rolled

Therm/Hot RolledTherm/Hot Rolled

Therm/Hot Rolled

40 Ft. Pkg

40 Ft. Pkg40 Ft. Pkg

40 Ft. Pkg

44137100

4413710044137100

44137100

20 Ft. Pkg

20 Ft. Pkg20 Ft. Pkg

20 Ft. Pkg

44135010

4413501044135010

44135010

40 Ft. Pkg.

40 Ft. Pkg.40 Ft. Pkg.

40 Ft. Pkg.

44137100

4413710044137100

44137100

30 Ft. Pkg

30 Ft. Pkg30 Ft. Pkg

30 Ft. Pkg

44136040

4413604044136040

44136040

P rt #

P rt #P rt #

P rt #

E ch Body P ck ge Includes:

E ch Body P ck ge Includes:E ch Body P ck ge Includes:

E ch Body P ck ge Includes:

Qty.

Qty.Qty.

Qty.

Qty.

Qty.Qty.

Qty.

Qty.

Qty.Qty.

Qty.

Qty.

Qty.Qty.

Qty.

42912169

10 Ft. Tube with 6 Hole Fl nge (Alumi

-

Therm)

1

-

1

-

41932101

10 Ft. Tube less Fl nges (Hot Rolled)

3

2

3

3

43319100

Reflector, 9’ 11½”

4

2

4

3

30462980

Tube Coupling

3

2

3

3

43318000

Tube H nger/Support Br cket, 13”

4

2

4

3

43980010

Wire H nger

4

2

4

3

Body F stener Kit (included in body p ck ges)

Body F stener Kit (included in body p ck ges)Body F stener Kit (included in body p ck ges)

Body F stener Kit (included in body p ck ges)

42907210

4290721042907210

42907210

42907190

4290719042907190

42907190

42907210

4290721042907210

42907210

42907200

4290720042907200

42907200

42873000

U-Bolt 4 2 4 3

02127110

Hex Nut, 5/16-18 8 5 8 6

02189020

HWHSM Screw, #10

-

16 x ½” TEKS

14

8

14

10

Form 43343530

Aug 2012 -7-

C.

C.C.

C. PTS 40

PTS 40PTS 40

PTS 40-

--

-200 Series Body P ck ge

200 Series Body P ck ge 200 Series Body P ck ge

200 Series Body P ck ge Descriptions

Descriptions Descriptions

Descriptions –

––

–

ALC Option (Aluminized C lorized)

ALC Option (Aluminized C lorized)ALC Option (Aluminized C lorized)

ALC Option (Aluminized C lorized)

(Package Part Number is indicated on the outside of each corresponding carton.)

System

SystemSystem

Systems

ss

s

1

11

1

0Ft.

0Ft. 0Ft.

0Ft.

System

SystemSystem

System

2

22

2

0Ft.

0Ft. 0Ft.

0Ft.

System

SystemSystem

System

3

33

3

0Ft.

0Ft. 0Ft.

0Ft.

System

SystemSystem

System

4

44

4

0Ft.

0Ft. 0Ft.

0Ft.

System

SystemSystem

System

5

55

5

0Ft.

0Ft. 0Ft.

0Ft.

System

SystemSystem

System

PTS Body P ck ges

PTS Body P ck ges PTS Body P ck ges

PTS Body P ck ges –

––

–

Aluminized/

Aluminized/Aluminized/

Aluminized/

Aluminized

AluminizedAluminized

Aluminized

or

oror

or

Alumi

AlumiAlumi

Alumi-

--

-Therm/

Therm/Therm/

Therm/

Aluminized

AluminizedAluminized

Aluminized

10 Ft.

10 Ft.10 Ft.

10 Ft.

pkg

pkgpkg

pkg

44134020

4413402044134020

44134020

20 Ft. pkg

20 Ft. pkg20 Ft. pkg

20 Ft. pkg

44135020

4413502044135020

44135020

30 Ft. pkg

30 Ft. pkg30 Ft. pkg

30 Ft. pkg

44136020

4413602044136020

44136020

40 Ft. pkg

40 Ft. pkg 40 Ft. pkg

40 Ft. pkg

44137090

4413709044137090

44137090

50 Ft. pkg

50 Ft. pkg50 Ft. pkg

50 Ft. pkg

44138080

4413808044138080

44138080

P rt #

P rt #P rt #

P rt #

E ch Body P ck ge Includes:

E ch Body P ck ge Includes:E ch Body P ck ge Includes:

E ch Body P ck ge Includes:

Qty.

Qty.Qty.

Qty.

Qty.

Qty.Qty.

Qty.

Qty.

Qty.Qty.

Qty.

Qty.

Qty.Qty.

Qty.

Qty.

Qty.Qty.

Qty.

42912080

10 Ft. Tube with 24 Hole Fl

nge (Aluminized)

1

1

1

-

-

42912169

10 Ft. Tube with 6 Hole Fl nge (Alumi

-

Therm)

-

-

-

1

1

41932100

10 Ft. Tube less Fl nges (Aluminized)

-

1

2

3

4

43319100

Reflector, 9’ 11½”

1

2

3

4

5

30462980

Tube Coupling

-

1

2

3

4

43318000

Tube H nger/Support Br

cket, 13”

1

2

3

4

5

43980010

Wire H nger

1

2

3

4

5

Body F stener Kit (included in body p ck ges)

Body F stener Kit (included in body p ck ges)Body F stener Kit (included in body p ck ges)

Body F stener Kit (included in body p ck ges)

42907280

4290728042907280

42907280

42907190

4290719042907190

42907190

42907200

4290720042907200

42907200

42907210

4290721042907210

42907210

42907220

4290722042907220

42907220

42873000

U

-

Bolt

1

2

3

4

5

02127110

Hex Nut, 5/16

-

18

3

5

6

8

10

02189020

HWHSM Screw, #10

-

16 x ½” TEKS

4

8

1

0

14

18

System

SystemSystem

System

s

ss

s

60Ft. System

60Ft. System60Ft. System

60Ft. System

70Ft. System

70Ft. System70Ft. System

70Ft. System

PTS Body P ck ges

PTS Body P ck ges PTS Body P ck ges

PTS Body P ck ges –

––

–

Alumi

AlumiAlumi

Alumi-

--

-Therm/

Therm/Therm/

Therm/

Aluminized

AluminizedAluminized

Aluminized

40 Ft. Pkg

40 Ft. Pkg40 Ft. Pkg

40 Ft. Pkg

44137090

4413709044137090

44137090

20 Ft. Pkg

20 Ft. Pkg20 Ft. Pkg

20 Ft. Pkg

44135030

4413503044135030

44135030

40 Ft. Pkg.

40 Ft. Pkg.40 Ft. Pkg.

40 Ft. Pkg.

44137090

4413709044137090

44137090

30 Ft. Pkg

30 Ft. Pkg30 Ft. Pkg

30 Ft. Pkg

44136050

4413605044136050

44136050

P rt #

P rt #P rt #

P rt #

E ch Body P ck ge Includes:

E ch Body P ck ge Includes:E ch Body P ck ge Includes:

E ch Body P ck ge Includes:

Qty.

Qty.Qty.

Qty.

Qty.

Qty.Qty.

Qty.

Qty.

Qty.Qty.

Qty.

Qty.

Qty.Qty.

Qty.

42912169

10 Ft. Tube with

6 Hole Fl nge (Alumi

-

Therm)

1

-

1

-

4193210

0

10 Ft. Tube less Fl nges (Aluminized)

3

2

3

3

43319100

Reflector, 9’ 11½”

4

2

4

3

30462980

Tube Coupling

3

2

3

3

43318000

Tube H nger/Support Br cket, 13”

4

2

4

3

43980010

Wire H nger

4

2

4

3

Bo

BoBo

Body F stener Kit (included in body p ck ges)

dy F stener Kit (included in body p ck ges)dy F stener Kit (included in body p ck ges)

dy F stener Kit (included in body p ck ges)

42907210

4290721042907210

42907210

42907190

4290719042907190

42907190

42907210

4290721042907210

42907210

42907200

4290720042907200

42907200

42873000

U-Bolt 4 2 4 3

02127110

Hex Nut, 5/16-18 8 5 8 6

02189020

HWHSM Screw, #10

-

16 x ½” TEKS

14

8

14

10

D.

D.D.

D. PTU 40

PTU 40PTU 40

PTU 40-

--

-200 Body P ck ge Descriptions

200 Body P ck ge Descriptions200 Body P ck ge Descriptions

200 Body P ck ge Descriptions

(Package Part Number is indicated on the outside of each corresponding carton.)

System

SystemSystem

Systems

ss

s

2

22

2

0Ft.

0Ft. 0Ft.

0Ft.

System

SystemSystem

System

3

33

3

0Ft.

0Ft. 0Ft.

0Ft.

System

SystemSystem

System

4

44

4

0Ft.

0Ft. 0Ft.

0Ft.

System

SystemSystem

System

5

55

5

0Ft.

0Ft. 0Ft.

0Ft.

System

SystemSystem

System

PT

PTPT

PTU

UU

U

Body P ck ges

Body P ck ges Body P ck ges

Body P ck ges –

––

–

Aluminized/Hot Rolled or

Aluminized/Hot Rolled orAluminized/Hot Rolled or

Aluminized/Hot Rolled or

Alumi

AlumiAlumi

Alumi-

--

-Therm/Hot Rolled

Therm/Hot Rolled Therm/Hot Rolled

Therm/Hot Rolled

20 Ft.

20 Ft.20 Ft.

20 Ft.

pkg

pkgpkg

pkg

44135000

4413500044135000

44135000

30 Ft. pkg

30 Ft. pkg30 Ft. pkg

30 Ft. pkg

44136010

4413601044136010

44136010

40 Ft. pkg

40 Ft. pkg 40 Ft. pkg

40 Ft. pkg

44137100

4413710044137100

44137100

50 Ft. pkg

50 Ft. pkg50 Ft. pkg

50 Ft. pkg

44138110

4413811044138110

44138110

P rt #

P rt #P rt #

P rt #

E ch Body P ck ge Includes:

E ch Body P ck ge Includes:E ch Body P ck ge Includes:

E ch Body P ck ge Includes:

Qty.

Qty.Qty.

Qty.

Qty.

Qty.Qty.

Qty.

Qty.

Qty.Qty.

Qty.

Qty.

Qty.Qty.

Qty.

42912080

10 Ft. Tube with 24 Hole Fl nge (Aluminized)

1

1

-

-

42912169

10 Ft. Tube with 6 Hole Fl nge (Alumi

-

Therm)

-

-

1

1

41932101

10 Ft. Tube le

ss Fl nges (Hot Rolled)

1

1

3

3

41932051

5 Ft. Tube less Fl nges (Hot Rolled)

-

2

-

2

43319100

Reflector, 9’ 11½”

2

2

4

4

43319050

Reflector, 4’ 11½”

-

2

-

2

30462980

Tube Coupling

1

3

3

5

43318000

Tube H nger/Support Br cket, 13”

2

4

4

6

43980010

Wire H nger

2

4

4

6

Form 43343530

-8- Aug 2012

Body F stener Kit (included in body p ck ges)

Body F stener Kit (included in body p ck ges)Body F stener Kit (included in body p ck ges)

Body F stener Kit (included in body p ck ges)

42907190

4290719042907190

42907190

42907210

4290721042907210

42907210

42907210

4290721042907210

42907210

42907221

4290722142907221

42907221

42873000

U

-

Bolt

2

4

4

6

02127110

Hex Nut, 5/16

-

18

5

8

8

1

3

02189020

HWHSM Screw, #10

-

16 x ½” TEKS

8

1

4

14

24

U

UU

U-

--

-Bend P ck ge

Bend P ck geBend P ck ge

Bend P ck ge

43208020

4320802043208020

43208020

43208020

4320802043208020

43208020

43208020

4320802043208020

43208020

43208020

4320802043208020

43208020

42913020

U

-

Bend

1

1

1

1

43318500

31” Tube Support/H nger Br cket

1

1

1

1

30462980

Tube Coupling

1

1

1

1

02189020

HWHSM Screw, #10

-

16 x ½” TEKS

2

2

2

2

System

SystemSystem

System

s

ss

s

60Ft. System

60Ft. System60Ft. System

60Ft. System

70Ft. System

70Ft. System70Ft. System

70Ft. System

PT

PTPT

PTU

UU

U

Body P ck ges

Body P ck ges Body P ck ges

Body P ck ges –

––

–

Alumi

AlumiAlumi

Alumi-

--

-Therm/Hot Rolled

Therm/Hot RolledTherm/Hot Rolled

Therm/Hot Rolled

4

44

40 Ft. Pkg

0 Ft. Pkg0 Ft. Pkg

0 Ft. Pkg

44137

4413744137

4413710

1010

100

00

0

20 Ft. Pkg

20 Ft. Pkg20 Ft. Pkg

20 Ft. Pkg

441350

441350441350

4413501

11

10

00

0

40 Ft. Pkg.

40 Ft. Pkg.40 Ft. Pkg.

40 Ft. Pkg.

44137

4413744137

4413712

1212

120

00

0

30 Ft. Pkg

30 Ft. Pkg30 Ft. Pkg

30 Ft. Pkg

441360

441360441360

4413604

44

40

00

0

P rt #

P rt #P rt #

P rt #

E ch Body P ck ge Includes:

E ch Body P ck ge Includes:E ch Body P ck ge Includes:

E ch Body P ck ge Includes:

Qty.

Qty.Qty.

Qty.

Qty.

Qty.Qty.

Qty.

Qty.

Qty.Qty.

Qty.

Qty.

Qty.Qty.

Qty.

42912169

10 Ft. Tube with 6 Hole Fl nge (Alumi

-

Therm)

1

-

1

-

4193210

1

10 Ft. Tube less Fl nges (

Hot Rolled

)

3

2

2

3

41932051

5 Ft. Tube less Fl nges (Hot Rolled)

-

-

2

-

43319100

Reflector, 9’ 11½”

4

2

3

3

43319050

Reflector, 4’ 11½”

-

-

2

-

30462980

Tube Coupling

3

2

4

3

43318000

Tube H nger/Support Br cket, 13”

4

2

5

3

43980010

Wire H nger

4

2

5

3

Body F stener Kit (included in body p ck ges)

Body F stener Kit (included in body p ck ges)Body F stener Kit (included in body p ck ges)

Body F stener Kit (included in body p ck ges)

42907210

4290721042907210

42907210

42907190

4290719042907190

42907190

429072

429072429072

4290722

22

20

00

0

42907200

4290720042907200

42907200

42873000

U-Bolt 4 2 5 3

02127110

Hex Nut, 5/16-18 8 5 10 6

02189020

HWHSM Screw, #10

-

16 x ½” TEKS

14

8

18

10

U

UU

U-

--

-Bend P ck ge

Bend P ck geBend P ck ge

Bend P ck ge

43208020

4320802043208020

43208020

43208020

4320802043208020

43208020

42913020

U-Bend 1 1

43318500

31” Tube Support/H nger Br cket 1 1

30462980

Tube Coupling 1 1

02189020

HWHSM Screw, #10

-

16 x ½” TEKS

2

2

E.

E.E.

E. PTU 40

PTU 40PTU 40

PTU 40-

--

-200 Series Body P ck ge Descriptions

200 Series Body P ck ge Descriptions 200 Series Body P ck ge Descriptions

200 Series Body P ck ge Descriptions –

––

–

ALC Option (Aluminized C lorized)

ALC Option (Aluminized C lorized)ALC Option (Aluminized C lorized)

ALC Option (Aluminized C lorized)

(Package Part Number is indicated on the outside of each corresponding carton.)

System

SystemSystem

Systems

ss

s

2

22

2

0Ft.

0Ft. 0Ft.

0Ft.

System

SystemSystem

System

3

33

3

0Ft.

0Ft. 0Ft.

0Ft.

System

SystemSystem

System

4

44

4

0Ft.

0Ft. 0Ft.

0Ft.

System

SystemSystem

System

5

55

5

0Ft.

0Ft. 0Ft.

0Ft.

System

SystemSystem

System

PT

PTPT

PTU

UU

U

Body P ck ges

Body P ck ges Body P ck ges

Body P ck ges –

––

–

Aluminized/Aluminized or

Aluminized/Aluminized orAluminized/Aluminized or

Aluminized/Aluminized or

Alumi

AlumiAlumi

Alumi-

--

-Therm/Aluminized

Therm/AluminizedTherm/Aluminized

Therm/Aluminized

20 Ft.

20 Ft.20 Ft.

20 Ft.

pkg

pkgpkg

pkg

44135020

4413502044135020

44135020

30 Ft. pkg

30 Ft. pkg30 Ft. pkg

30 Ft. pkg

44136030

4413603044136030

44136030

40 Ft. p

40 Ft. p40 Ft. p

40 Ft. pkg

kg kg

kg

44137090

4413709044137090

44137090

50 Ft. pkg

50 Ft. pkg50 Ft. pkg

50 Ft. pkg

44138090

4413809044138090

44138090

P rt #

P rt #P rt #

P rt #

E ch Body P ck ge Includes:

E ch Body P ck ge Includes:E ch Body P ck ge Includes:

E ch Body P ck ge Includes:

Qty.

Qty.Qty.

Qty.

Qty.

Qty.Qty.

Qty.

Qty.

Qty.Qty.

Qty.

Qty.

Qty.Qty.

Qty.

42912080

10 Ft. Tube with 24 Hole Fl nge (Aluminized)

1

1

-

-

42912169

10 Ft. Tube with 6 Hole Fl nge (Alumi

-

Therm)

-

-

1

1

41932100

10 Ft. Tube less Fl nges (Alumi

nized)

1

1

3

3

41932050

5 Ft. Tube less Fl nges (Aluminized)

-

2

-

2

43319100

Reflector, 9’ 11½”

2

2

4

4

43319050

Reflector, 4’ 11½”

-

2

-

2

30462980

Tube Coupling

1

3

3

5

43318000

Tube H nger/Support Br cket, 13”

2

4

4

6

43980010

Wire H nger

2

4

4

6

Form 43343530

Aug 2012 -9-

Body F stener Kit (included in body p ck ges)

Body F stener Kit (included in body p ck ges)Body F stener Kit (included in body p ck ges)

Body F stener Kit (included in body p ck ges)

42907190

4290719042907190

42907190

42907210

4290721042907210

42907210

42907210

4290721042907210

42907210

42907221

4290722142907221

42907221

42873000

U

-

Bolt

2

4

4

6

02127110

Hex Nut, 5/16

-

18

5

8

8

1

3

02189020

HWHSM Screw, #10

-

16 x ½” TEKS

8

1

4

14

24

U

UU

U-

--

-Bend P ck ge

Bend P ck geBend P ck ge

Bend P ck ge

43208020

4320802043208020

43208020

43208020

4320802043208020

43208020

43208020

4320802043208020

43208020

4320802

43208024320802

43208020

00

0

42913020

U

-

Bend

1

1

1

1

43318500

31” Tube Support/H nger Br cket

1

1

1

1

30462980

Tube Coupling

1

1

1

1

02189020

HWHSM Screw, #10

-

16 x ½” TEKS

2

2

2

2

60Ft. System

60Ft. System60Ft. System

60Ft. System

70Ft. System

70Ft. System70Ft. System

70Ft. System

PT

PTPT

PTU

UU

U

Body P

Body PBody P

Body P ck ges

ck ges ck ges

ck ges –

––

–

Alumi

AlumiAlumi

Alumi-

--

-Therm/Aluminized

Therm/AluminizedTherm/Aluminized

Therm/Aluminized

40 Ft. Pkg

40 Ft. Pkg40 Ft. Pkg

40 Ft. Pkg

44137

4413744137

4413709

0909

090

00

0

20 F

20 F20 F

20 Ft. Pkg

t. Pkgt. Pkg

t. Pkg

441350

441350441350

4413503

33

30

00

0

40 Ft. Pkg.

40 Ft. Pkg.40 Ft. Pkg.

40 Ft. Pkg.

441371

441371441371

4413711

11

10

00

0

30 Ft. Pkg

30 Ft. Pkg30 Ft. Pkg

30 Ft. Pkg

441360

441360441360

4413605

55

50

00

0

P rt #

P rt #P rt #

P rt #

E ch Body P ck ge Includes:

E ch Body P ck ge Includes:E ch Body P ck ge Includes:

E ch Body P ck ge Includes:

Qty.

Qty.Qty.

Qty.

Qty.

Qty.Qty.

Qty.

Qty.

Qty.Qty.

Qty.

Qty.

Qty.Qty.

Qty.

42912169

10 Ft. Tube with 6 Hole Fl nge (Alumi

-

Therm)

1

-

1

-

4193210

0

10 Ft. Tube less Fl nges (

Aluminized

)

3

2

2

3

4193205

0

5 Ft.

Tube less Fl nges (

Aluminized

)

-

-

2

-

43319100

Reflector, 9’ 11½”

4

2

3

3

43319050

Reflector, 4’ 11½”

-

-

2

-

30462980

Tube Coupling

3

2

4

3

43318000

Tube H nger/Support Br cket, 13”

4

2

5

3

43980010

Wire H nger

4

2

5

3

Body F stener Kit (i

Body F stener Kit (iBody F stener Kit (i

Body F stener Kit (included in body p ck ges)

ncluded in body p ck ges)ncluded in body p ck ges)

ncluded in body p ck ges)

42907210

4290721042907210

42907210

42907190

4290719042907190

42907190

429072

429072429072

4290722

22

20

00

0

42907200

4290720042907200

42907200

42873000

U-Bolt 4 2 5 3

02127110

Hex Nut, 5/16-18 8 5 10 6

02189020

HWHSM Screw, #10

-

16 x ½” TEKS

14

8

18

10

U

UU

U-

--

-Bend P ck ge

Bend P ck geBend P ck ge

Bend P ck ge

43208020

4320802043208020

43208020

43208020

4320802043208020

43208020

42913020

U-Bend 1 1

43318500

31” Tube Support/H nger Br cket 1 1

30462980

Tube Coupling 1 1

02189020

HWHSM Screw, #10

-

16 x ½” TEKS

2

2

6.1) ACCESSORY PACKAGES

A.

A.A.

A.

End Reflector Accessory P ck ge, P rt #43341010

End Reflector Accessory P ck ge, P rt #43341010End Reflector Accessory P ck ge, P rt #43341010

End Reflector Accessory P ck ge, P rt #43341010

(1 pkg. per PTS Series or 2 pkgs. per PTU Series)

Contains:

End Reflector, #43320000……QTY–2

Speed Clips, #02266010……QTY–8

6

(15cm)

12

(30cm)

END REFLECTOR

B.

B.B.

B.

Elbow Accessory P ck ge, P rt #43208010

Elbow Accessory P ck ge, P rt #43208010Elbow Accessory P ck ge, P rt #43208010

Elbow Accessory P ck ge, P rt #43208010

( ption for PTS Series nly)

Contains:

Elbow, #43175000……QTY–1

#10-16 x ½ Self-Drilling Screws, #02189020……QTY–2

Tube Coupling, #30462980……QTY–1

13

(33cm)

13

(33cm)

Form 43343530

-10- Aug 2012

C.

C.C.

C.

Corner Reflect

Corner ReflectCorner Reflect

Corner Reflect

or Accessory P ck ge, P rt #43342000

or Accessory P ck ge, P rt #43342000or Accessory P ck ge, P rt #43342000

or Accessory P ck ge, P rt #43342000

( ption for PTS Series nly)

Contains:

Corner Reflector Assembly, #43345000……QTY–1

Speed Clips, #02266010……QTY–4

24

(61cm)

24

(61cm)

D.

D.D.

D.

U

UU

U

-

--

-

Bend P ck ge, P rt #43208020

Bend P ck ge, P rt #43208020Bend P ck ge, P rt #43208020

Bend P ck ge, P rt #43208020

( ption for PTU Series nly)

Contains:

U-Bend, #42913020……QTY–1

#10-16 x ½ Self-Drilling Screws, #02189020……QTY–2

Tube Coupling, #30462980……QTY–1

31” Tube Support/H nger Br cket, #43318500……QTY–1

18

(46cm)

E.

E.E.

E.

U

UU

U

-

--

-

Bend Reflector P ck ge, P rt #43488000

Bend Reflector P ck ge, P rt #43488000Bend Reflector P ck ge, P rt #43488000

Bend Reflector P ck ge, P rt #43488000

( ption for PTU Series nly)

Contains:

U-Bend Reflector, #43490000……QTY–1

U-Bend End Reflector, #43490050……QTY–1

Speed Clips, #02266010……QTY–11

#10-16 x ½ Self-Drilling Screws, #02189020……QTY–4

Inst ll tion Form, #43489000……QTY-1

30 3/4 (78cm)

Length = 24 (61cm)

F.

F.F.

F.

31” H nger/Tube Support, P rt #43318500

31” H nger/Tube Support, P rt #4331850031” H nger/Tube Support, P rt #43318500

31” H nger/Tube Support, P rt #43318500

( ption for Angle Mounting of PTU Series)

18

(46cm)

Tube Centers

31

(79cm)

G.

G.G.

G.

Exh ust Hood P ck

Exh ust Hood P ckExh ust Hood P ck

Exh ust Hood P ck

ge, P rt #42924000

ge, P rt #42924000ge, P rt #42924000

ge, P rt #42924000

Contains:

Exh ust Hood Assembly, #42925540……QTY–1

#8-18 x ½ Self-Drilling Screws, #02189030……QTY–2

4 (10cm)

7 1/2

(19cm)

3 3/4 (10cm)

3 1/2 (9cm)

6

(15cm)

Bird

Screen

Side View Front View

H.

H.H.

H.

Rel y

Rel yRel y

Rel y

P ck ge, P rt #4

P ck ge, P rt #4P ck ge, P rt #4

P ck ge, P rt #4

41950

4195041950

41950

00

0000

00

Contains:

Rel y Bo rd, #30740000……QTY–1

ABS Enclosure, #30709059……QTY–

Mounting Pl te, #30709058 QTY-1

W ter Tight Connectors, #30635010 QTY-2

#6-32x5/8” Screws, #02242030 QTY-2

Form 43343530

Aug 2012 -11-

7.0) TYPICAL LAYOUTS – PTS/PTU SERIES

Burner Box

Flue Termination

10 FT. Body Section

30 FT.

SYSTEM

40 FT.

SYSTEM

20 FT.

SYSTEM

50 FT.

SYSTEM

60 FT.

SYSTEM

70 FT.

SYSTEM

10FT.

SYSTEM

5 FT. Body Section

90 Deg. Elbow

180 Deg. U-Bend

LEGEND

MODEL

MODELMODEL

MODEL

EMITTER LENGTH

EMITTER LENGTHEMITTER LENGTH

EMITTER LENGTH

MODEL

MODELMODEL

MODEL

BODY LENGTH

BODY LENGTHBODY LENGTH

BODY LENGTH

Min.

Min.Min.

Min.

M x.

M x.M x.

M x.

Min.

Min.Min.

Min.

M x.

M x.M x.

M x.

PTS 40

/25

10 Ft.

20 Ft.

PTU 40

/25

10 Ft.

10 Ft.

PTS 50

/

30

20 Ft

4

0 Ft.

PTU 50

/30

10 Ft.

20

Ft.

PTS 75

/50

20 Ft.

4

0 Ft.

PTU 75

/50

10 Ft.

20

Ft

PTS 100

/65

30 Ft.

5

0 Ft.

PTU 100

/65

15 Ft.

25

Ft.

PTS 125

/80

30 Ft

6

0 Ft.

PTU 125

/80

15 Ft.

30

Ft.

PTS 150

/100

40 Ft.

60 Ft.

PTU 150

/100

20 Ft.

30 Ft.

PTS 175

/110

5

0 Ft.

70 Ft.

PTU 175

/110

25 Ft.

35 Ft.

PTS 200

/125

50 Ft.

70 Ft.

PTU 200

/125

25 Ft.

35 Ft.

NOTES:

NOTES:NOTES:

NOTES:

1. In ll configur tions, the control unit must be connected directly to either ) the 24-hole fl nge of the 10 ft.

luminized steel st rting body section (for 10 ft., 20 ft., nd 30 ft. systems) or b) the 6-hole fl nge of the 10

ft. lumi-therm steel st rting body section (for 40 ft., 50 ft., 60 ft., nd 70 ft. systems).

2. Joining of two 90º elbows directly together to form “Z” sh pe IS NOT permitted.

3. PTS/U 175/110 - 40 ft length v il ble for speci l pplic tions.

4. 5 Ft. Body P ck ges m y be utilized on ny of these he ters to yield he ter lengths from 15 ft. to 70 ft.

5. Any configur tion of components not shown in the illustr tions m y be used except s noted in 1 nd 2

bove.

Form 43343530

-12- Aug 2012

7.1) TYPICAL ASSEMBLY LAYOUT – (PTS SHOWN)

Failure to do so may result in death, serious injury, property damage or illness

from Carbon Monoxide poisoning.

The heater must be assembled with the correct number of turbulator sections

and tube length for the rated heat input.

The turbulator must be installed in the last tube section as shown.

POISONOUS GAS AND SOOT HAZARD

60 FT. SYSTEM

50 FT. SYSTEM

20 FT. SYSTEM

30 FT. SYSTEM

40 FT. SYSTEM

LEGEND

Burner Box 10ft Aluminized Tube 24

Hole Flange

or

10ft Alumi-Therm Tube

6 Hole Flange

Coupling 10ft Aluminized or HRS

Tube model dependent

2ft Aluminized

Steel

Turbulator

sections

70 FT. SYSTEM

10 FT. SYSTEM

2ft Stainless

Steel

Turbulator

sections

Stainless Steel Turbulator

closest to burner PTS / U

40/25 only.

Model

PTS/U 40/25

PTS/U 50/30

PTS/U 75/50

PTS/U 100/65

PTS/U 125/80

PTS/U 150/100

PTS/U 175/110

PTS/U 200/125

2 Ft. Turbulator

Sections

4

5

5

3

7

4

0

1

Form 43343530

Aug 2012 -13-

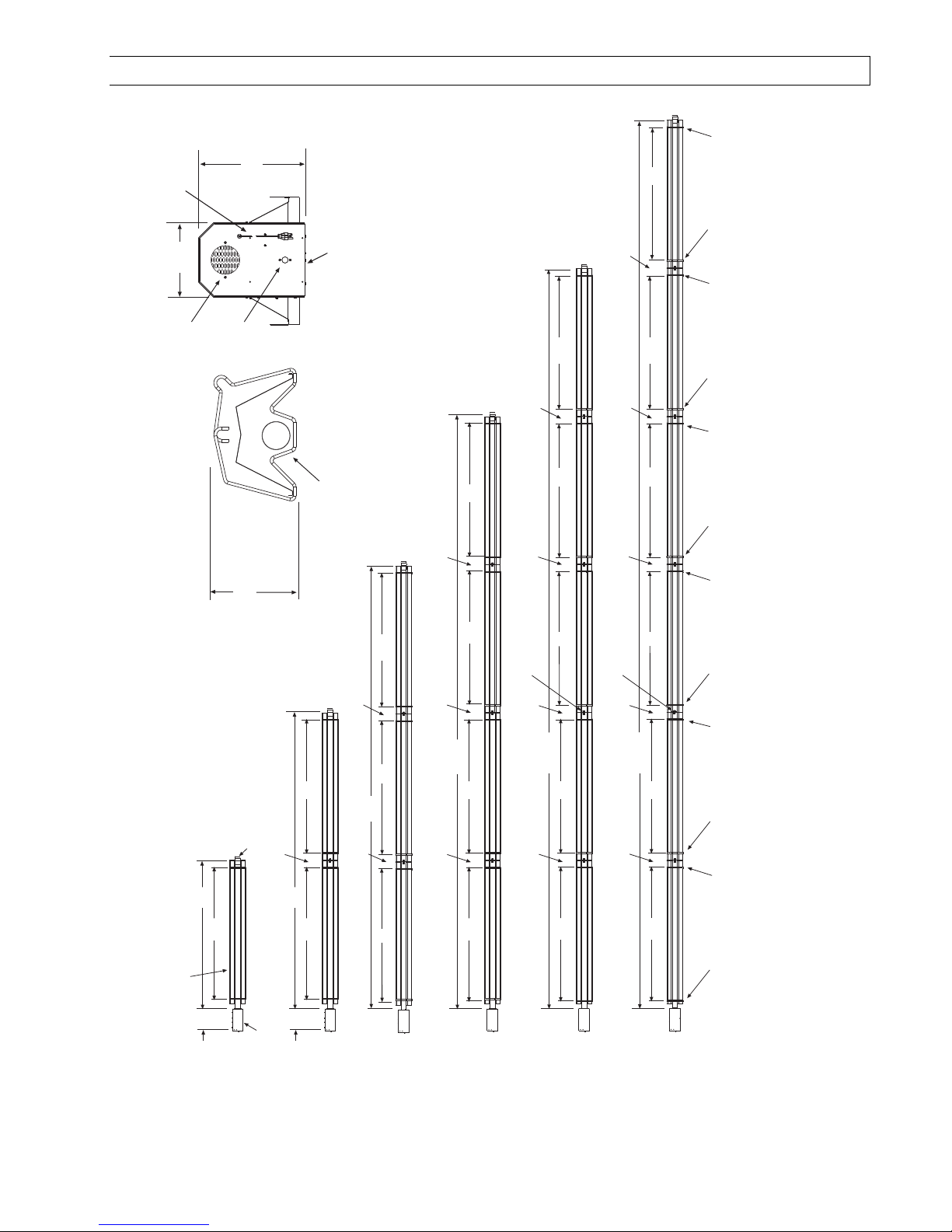

8.0) DIMENSIONS – PTS SERIES

Typic l Dimensions Up to 60 Ft. Shown.

Burner

Box

13 Tube Support/

Hanger Bracket

Wire Hanger

4 Tube Coupling

(typical)

Bottom View

Wire Hanger

Wire Hanger 13 Tube Support/

Hanger Bracket

13 Tube Support/

Hanger Bracket

108

(274cm)

720

(1829cm)

108

(274cm)

108

(274cm) 108

(274cm)

108

(274cm)

12

(30cm)

12

(30cm) 12

(30cm)

Wire Hanger

Wire Hanger 13 Tube Support/

Hanger Bracket

13 Tube Support/

Hanger Bracket Wire Hanger

13 Tube Support/

Hanger Bracket

108

(274cm)

12

(30cm)

12

(30cm)

4 Tube Coupling

(typical)

Bottom View

108

(274cm)

600

(1524cm)

108

(274cm)

108

(274cm) 108

(274cm)

108

(274cm)

12

(30cm)

12

(30cm) 12

(30cm)

12

(30cm)

108

(274cm)

Models:

PTS 40/25 - 75/50

14

(36cm) 108

(274cm)

240

(610cm)

12

(30cm)

108

(274cm)

480

(1219cm)

108

(274cm)

12

(30cm)

108

(274cm)

108

(274cm)

12

(30cm)

Models:

PTS 50/30 - 125/80

360

(914cm)

108

(274cm)

12

(30cm)

12

(30cm)

108

(274cm)

108

(274cm)

Flue

Terminal

10 FT Tube

Assembly

(typical)

Models:

PTS 40/25

14

(36cm) 108

(274cm)

120

(305cm)

10

(25cm)

14-1/2

(37cm)

Fresh Air

Inlet

1/2 MPT Gas

Connection

9-1/4

(24cm)

End View

Flue Terminal Burner

Box

120VAC

Power Supply Cord

Models:

PTS 50/30 - 150/100

Models:

PTS 100/65 - 200/125

Models:

PTS 125/80 - 200/125

Form 43343530

-14- Aug 2012

8.1) DIMENSIONS – PTU SERIES

Typic l Dimensions Up to 50 Ft. Shown.

Models:

PTU 40/25 - 75/50

Models:

PTU 50/30 - 125/80

Models:

PTU 50/30 - 175/110

Models:

PTU 100/65 - 200/125

300

(762cm)

108

(274cm)

12

(30cm)

12

(30cm)

Bottom View

Wire Hangers

(typical)

108

(274cm)

12

(30cm)

240

(610cm) 108

(274cm)

180

(457cm) 108

(274cm)

12

(30cm)

48

(122cm)

5 FT Tube

Assembly

14

(36cm)

120

(305cm)

108

(274cm)

Burner

Box

Flue

Terminal

10 FT Tube

Assembly

(typical)

15

(38cm)

108

(274cm)

48

(122cm)

31 Tube Support/

Hanger Brackets

(typical at control end)

Shipped with

U-Bend Package

Wire Hangers

(typical)

U-Bend

13 Tube Support/

Hanger Brackets

(typical)

4 Tube Coupling

(typical)

13 Tube Support/

Hanger Brackets

(typical)

6

(16cm)

Flue Terminal 18 (46cm)

31 (79cm)

End View

Burner

Box

U-Bend

31 Tube Support/

Hanger Bracket

10

(25cm)

14-1/2

(37cm)

Fresh Air

Inlet

1/2 MPT Gas

Connection

120VAC

Power Supply Cord

Form 43343530

Aug 2012 -15-

8.2) HEATER ASSEMBLY / JOINING OF TUBE SECTIONS

Typical Assembly Overview

(

PTS

40FT Shown)

4"OD x 10Ft.

Tube

See section

7

for required tubes.

Tube Support Bracket

U-Bolt Clamp &

5/16" Hex Nuts

Mounting

Flange

24 Hole for Aluminized Steel Tubes

6 Hole for Alumi-Therm Steel Tubes

Wire Hanger

Gasket

Burner

Box

Flue

Terminal

5 hanging points to be used for suspension for a typical 40ft

long system. There must be two hanging points on the first

tube and one on each of the other tubes

Maximum 6 distance

from control box to the

tube support/hanger

bracket.

8 - 9 ¼

8 - 10

8 - 10

Not More

Than 10

#10 Self-Drill Screws

(Typical all tube supports,

tube couplings and flue

terminal.)

Typical

Overlap

Turbulator

(See specifications

section 5 for required

quantities.)

Tube Coupling

(Typical each tube joint

.

)

Burner Box

Suspension

Chain

3

(

burner

box to reflector)

2

overlap

1

overlap

1

overlap

Form 43343530

-16- Aug 2012

Typical Assembly Overview

(PTU 40FT Shown)

Wire Hanger

Flue

Terminal

#10 Self-Drill Screws

(Typical all tube supports,

tube couplings and flue

terminal.)

4"OD x 10Ft. Tube

See section 7

for required tubes.

13 Tube Support Brk.

with U-Bolt Clamp

& 5/16" Hex Nuts

Mounting Flange

24 Hole for Aluminized Steel Tubes

6 Hole for Alumi-Therm Steel Tubes

Gasket

Burner Box

Typical

Overlap

U-Bend

Tube Coupling

(Typical each tube joint.)

Reflector

31 Tube Support Brk.

with U-Bolt Clamp

& 5/16" Hex Nuts

8 - 10

6 hanging points to be used for suspension for a typical

40ft long system. There must be two hanging points

on the first tube and one on each of the other tubes

Maximum 6 distance

from burner box to the

tube support/hanger

bracket.

8 - 9 ¼

#10 Self-Drill

Screws

(2 each)

Turbulator

(See specifications

section 5 for required

quantities.)

Burner Box

Suspension

Chain

Form 43343530

Aug 2012 -17-

9.0) TYPICAL SUSPENSION METHODS

Burner must be secured to the mounting flange with nuts.

All materials used to suspend the heater must have a minimum working load

of 115 lbs.

All S Hooks must be crimped closed.

Never use the heater to support a ladder or other access equipment.

Failure to do so may result in death, serious injury or property damage.

SUSPENSION HAZARD

V rious me ns of suspending the he ter c n be used. See the following dr wings for typic l ex mples.

1. Use only noncombustible m teri ls for suspending h ngers nd br ckets.

2. A minimum No. 2 ch in with working lo d limit of 115 lbs. is required.

3. Turnbuckles c n be used with ch ins to llow leveling of the he ter. All “S” hooks nd eye bolts must be

m nu lly crimped closed by the inst ller.

4. When using rigid me ns for he ter suspension (rod, fl t b r, etc.) provide sufficient lengths or swing joints to

compens te for exp nsion. See Figures b nd c.

5. He ters subject to vibr tion must be provided with vibr tion isol ting h ngers.

6. He ters must not be supported by g s or electric supply lines nd must be suspended from perm nent

structure with dequ te lo d c p city.

Sp ce-R y recommends th t the body sections be suspended using ch ins with turnbuckles. This will llow

slight djustments fter ssembly nd he ter exp nsion/ contr ction during oper tion.

If “tr peze” method is used for tube support/h nger br ckets (shown below), the minimum ch in length for the

two connecting ch ins is 36” to minimize ny vibr tion th t might be gener ted by the burner box. If these

ch ins must be less th n 36”, then do not use the tr peze method nd, inste d, use individu l ch ins on e ch

tube support/h nger br cket.

Eyebolt

Turnbuckle

Minimum

No. 2 Chain

Eyebolt

c.

Threaded

Rod

Turnbuckle

Eyebolt

b.

3/16 x 1

wideFlat Bar

Minimum

No. 2 Chain

a.

S-Hook crimped

closed (typical)

Wire Hanger

Wire

Hanger

36 (91cm) Minimum

Tube Support/

Hanger Bracket

d.

Failure to install the burner box suspension

chain vertically will void the manufacturers

warranty.

Burner Box Suspension

Eye bolt

Turnbuckle

Form 43343530

-18- Aug 2012

10.0) ASSEMBLY OF TUBE SECTIONS

Sheet metal parts, particularly reflectors and vent have sharp

edges. Always use gloves when handling.

Failure to do so may result in death, serious injury or property

damage.

CUT HAZARD

During field ssembly of the he ter body sections, the recommended procedure is s follows:

1. Before h nging he ter sections, first determine the ctu l l yout of the system (see Sections 7.0) & 8.0) for

det ils). Consider tion must lso be t ken for flue pipe, fresh ir ducting, g s piping, cle r nces to

combustibles, etc. before h nging he ter. Typic l suspension methods re shown in Section 9.0).

2. H ng e ch tube section individu lly. DO NOT tt ch the he ter tube sections together on the ground nd

ttempt to h ng the entire system.

3. In ll configur tions, the burner box must be connected directly to either ) the 24-hole fl nge of the 10 ft.

luminized steel st rting body section (for 10 ft., 20 ft., nd 30 ft. systems) or b) the 6-hole fl nge of the 10

ft. lumi-therm steel st rting body section (for 40 ft., 50 ft., 60 ft., nd 70 ft. systems.

4. Assemble tube support/h nger br cket 4” from the end of the he t exch nger tube h ving the mounting

fl nge. Align the tube such th t the welded se m is f cing down tow rd the ground.

F

FF

F ilure to ssemble the tube with the se m f cin