SPX Hankinson HHE Series User manual

HHE, HHL, HHS SERIES

Pressure-Swing Desiccant Type Compressed Air Dryers with AccuShift™ Switching Valves

FORM NO.: 3162258 REVISION: 03/2014 READ AND UNDERSTAND THIS MANUAL PRIOR TO OPERATING OR SERVICING THIS PRODUCT.

INSTRUCTION MANUAL

MODELS

RATED

FLOW

REFER

AS

MODELS

HHE

SERIES

w/ Timer

Controller

HHL

SERIES

w/ Level 1

Controller

HHS

SERIES

w/ Level 2

Controller

HHE-40

HHE-60

HHE-90

HHL-40

HHL-60

HHL-90

HHS-40

HHS-60

HHS-90

40 SCFM

60 SCFM

90 SCFM

40

60

90

HHE-115

HHE-165

HHE-260

HHL-115

HHL-165

HHL-260

HHS-115

HHS-165

HHS-260

115 SCFM

165 SCFM

260 SCFM

115

165

260

HHE-370

HHE-450

HHE-590

HHL-370

HHL-450

HHL-590

HHS-370

HHS-450

HHS-590

370 SCFM

450 SCFM

590 SCFM

370

450

590

HHE-750

HHE-930

HHE-1130

HHL-750

HHL-930

HHL-1130

HHS-750

HHS-930

HHS-1130

750 SCFM

930 SCFM

1130 SCFM

750

930

1130

HHE-1350

HHE-1550

HHE-2100

HHL-1350

HHL-1550

HHL-2100

HHS-1350

HHS-1550

HHS-2100

1350 SCFM

1550 SCFM

2100 SCFM

1350

1550

2100

HHE-3000

HHE-4100

HHE-5400

HHL-3000

HHL-4100

HHL-5400

HHS-3000

HHS-4100

HHS-5400

3000 SCFM

4100 SCFM

5400 SCFM

3000

4100

5400

Contents

1. GENERAL SAFETY INFORMATION................................ 1

2. RECEIVING, MOVING, UNPACKING .............................. 1

3. DESCRIPTION ................................................................. 2

4. INSTALLATION................................................................. 7

5. CONTROLLERS – GENERAL.......................................... 15

6. CONTROLLER – TIMER BASED..................................... 17

7. CONTROLLER – LEVEL 1............................................... 20

8. CONTROLLER – LEVEL 2............................................... 31

9. OPERATION..................................................................... 48

10. MAINTENANCE ............................................................... 54

11. TROUBLESHOOTING ..................................................... 55

12. REPLACEMENT PARTS .................................................. 56

13. NOTES ............................................................................. 64

WARRANTY ............................................................................. 65

— 1 —

2. RECEIVING, MOVING, UNPACKING

2.1 Receiving:

•This shipment has been thoroughly checked, packed and

inspected before leaving our plant.

•It was received in good condition by the carrier and was so

acknowledged.

•Check for visible loss or damage. If this shipment shows evidence

of loss or damage at time of delivery to you, insist that the carrier’s

agent make a notation of this loss or damage on the delivery

receipt.

2.2 Moving:

CAUTION: Use lifting lugs or forklift. Do not lift equipment

by piping.

2.3 Unpacking:

•Check for concealed loss or damage. When a shipment has been

delivered to you in apparent good order, but concealed damage

is found upon unpacking, notify the carrier immediately and insist

that his agent inspects the shipment.

•Fifteen days from receipt of shipment is the maximum time limit

for requesting such inspection.

•Concealed damage claims are not our responsibility as our terms

are F.O.B. point of shipment.

1. GENERAL SAFETY INFORMATION

1.1 Pressurized Devices

•This equipment is a pressure-containing device.

•Do not exceed maximum operating pressure as shown on the

equipment serial number tag.

•Verify that equipment is fully de-pressurized before performing

service or maintenance functions.

1.2 Electrical:

•This equipment requires electricity to operate.

•Install equipment in compliance with national and local electrical

codes.

•Standard equipment is supplied with NEMA 4,4X electrical

enclosures and is not intended for installation in hazardous

environments.

•Disconnect power supply to equipment when performing any

electrical service work.

1.3 Breathing Air:

•Air treated by this equipment may not be suitable for breathing

without further purication.

•Refer to OSHA standard 1910.134 for the requirements for

breathing quality air.

1.4 Noise:

CAUTION: Do not operate dryer without mufflers

installed.

1.5 High Velocity Air:

CAUTION: Do not stand near mufflers during tower

depressurization.

— 2 —

3. DESCRIPTION

3.1 Dryer Function

• Dual tower regenerative desiccant dryers are an economical

and reliable way to dry compressed air to dew points below the

freezing point of water (dew points as low as -100°F (-73.3°C)

[0.2 ppmV @ 100 psig, 6.9 barg] are possible) or reduce the

moisture content of compressed air when used in critical process

applications.

• These dryers continuously dry compressed air by using two

identical towers, each containing a desiccant bed. While one

tower is on-stream drying, the other tower is off-stream being

regenerated (reactivated, i.e., dried out). The towers are

alternated on- and off-stream so that dry desiccant is always in

contact with the wet compressed air. In this way a continuous

supply of dry air downstream of the dryer is possible.

• Desiccant dryers lower the dew point of compressed air by

adsorbing the water vapor present in the compressed air onto

the surface of the desiccant. Desiccant is a highly porous solid

containing extensive surface area.

• Adsorption occurs until the partial pressure of the water vapor

in the air and that on the surface of the desiccant come into

equilibrium. As adsorption occurs, heat is released (referred to

as the heat of adsorption) and is stored in the bed for use during

regeneration.

• Desiccant is regenerated by driving off (desorbing) the water

collected on its surface. Pressure-swing (also called heatless or

heater-less because no outside heat is added) dryers regenerate

by expanding a portion (approximately 14 -15% at 100 psig,

6.9 barg) of the dried air to atmospheric pressure. This “swing in

pressure” causes the expanded air to become very dry (have a

very low vapor pressure). This very dry air (called purge air) plus

the stored heat of adsorption allows the moisture to desorb from

the desiccant. The purge air then carries the desorbed water out

of the dryer.

3.2 Automatic Purge Saving System

Featured with the Level 2 Controller, the Automatic Purge Saving

System is designed to save energy (purge air) when pressure-swing

dryers are operated at reduced loads.

The Purge Saving System operates by monitoring the changes

in temperature within the desiccant beds. These changes in

temperature are the result of heat (thermal energy) that is released

when a bed is on-line drying (heat of adsorption), and the heat

that is used when a bed is off-line being regenerated (heat of

desorption). The magnitude of these changes in temperature is an

indirect measure of the water vapor content in the air being dried.

This information is used to determine the time a tower stays on line

during the drying cycle.

— 3 —

3.3 Description of Operation – Dryer

3.3.1 Models 40 to 3000 w/ Shuttle Valve

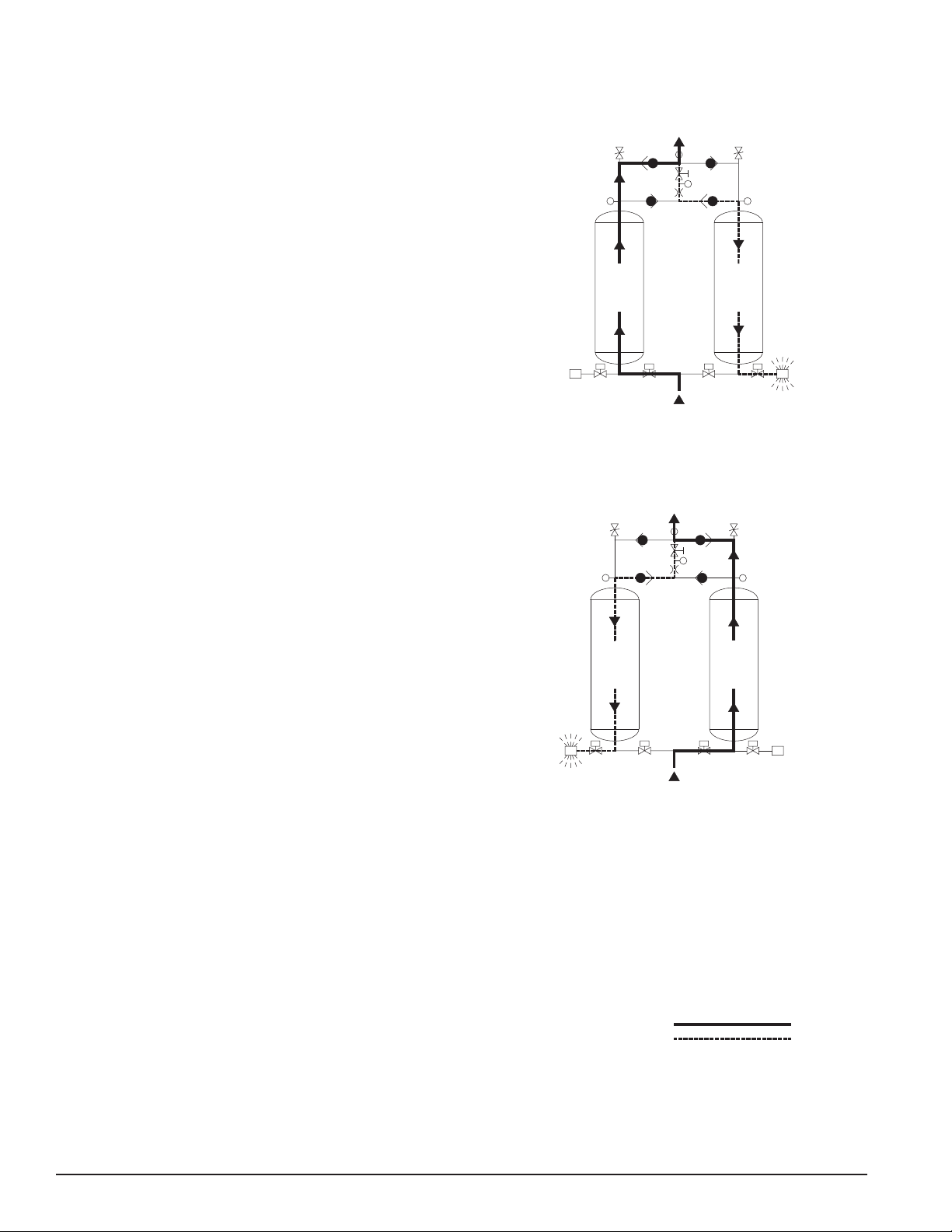

(Refer to Fig. 3-1a.) Compressed air ows through inlet shuttle valve (3)

to tower (4A) where the air is dried. After the air is dried it ows through

outlet shuttle valve (5) and then to the dryer outlet. A portion of the dry

air, the purge stream, branches off from the main air stream prior to

the outlet. The purge stream ow rate is controlled by the adjustable

purge rate valve (6) and the two purge orices (7).

The purge ow, which has been throttled to near atmospheric pressure,

is directed to tower (4B). As the purge ow passes over the desiccant

in tower (4B), it removes the water vapor, which was deposited there

while the tower was on-line drying. The purge air then passes through

purge and repressurization valve (9B) (normally closed) and purge

mufer (10B) to the atmosphere.

After regeneration, purge and repressurization valve (9B) (normally

closed) closes allowing tower (4B) to repressurize slowly. Adequate

repressurization time is allowed so that tower (4B) is fully repressurized

before tower switchover. After a controlled time period, purge and

repressurization valve (9A) (normally closed) then opens. This causes

the inlet and outlet shuttle valves to shift, directing the air ow through

tower (4B).

(Refer to Fig. 3-1b.) Tower (4B) is now drying the main air stream

while tower (4A) is being regenerated by the purge air stream. The

operation of the purge and repressurization (normally closed) valves is

sequenced by the control system located in the electrical enclosure.

8. Safety Valve

9. Purge and Repres-

surization Valves

10. Purge Mufflers

11. Moisture Indicator

A Left Tower Suffix

B Right Tower Suffix

TOWER 4B REGENERATING

4B

TOWER

Purge Stream

Process Stream

1. Tower Pressure Gauges

2. Purge Pressure Gauge

3. Inlet Shuttle Valve

4. Desiccant Drying Towers

5. Outlet Shuttle Valve

6. Adjustable Purge Rate Valve

7. Purge Orifices

9A

FIGURE 3-1a

TOWER 4A DRYING

INLET

TOWER

4A

1

762

OUTLET

5

8

9B

10B

1

7

9A

TOWER 4B DRYING

TOWER

4A

INLET

FIGURE 3-1b

TOWER 4A REGENERATING

1

76

1

8

27

9B

4B

TOWER

10A

10B10A

11

5

11

OUTLET

3

3

— 4 —

3.3.2 Models 4100 to 5400 w/ Check Valves

(Refer to Fig. 3-2a.) Compressed air ows through inlet switching

valve (3A) (normally open) to tower (4A) where the air is dried. After

the air is dried it ows through outlet check valve (5A) and then to

the dryer outlet. A portion of the dry air, the purge stream, branches

off from the main air stream prior to the outlet. The purge stream ow

rate is controlled by the adjustable purge rate valve (6) and the single

purge orice (7).

The purge ow, which has been throttled to near atmospheric pressure,

is directed through purge check valve (5D) to tower (4B). As the purge

ow passes over the desiccant in tower (4B), it removes the water

vapor which was deposited while the tower was on-line drying. The

purge air then passes through purge and repressurization valve (9B)

(normally closed) and purge mufer (10B) to the atmosphere.

After regeneration, purge and repressurization valve (9B) (normally

closed) closes allowing tower (4B) to re-pressurize slowly. Adequate

repressurization time is allowed so that tower (4B) is fully re-

pressurized before switchover. After a controlled time period, air

inlet switching valve (3B) (normally open) opens and inlet-switching

valve (3A) (normally open) closes, purge and repressurization

valve (9A) (normally closed) then opens.

(Refer to Fig. 3-2b.) Tower (4B) is now drying the main air stream while

tower (4A) is being regenerated by the purge air stream. The operation

of the inlet switching (normally open) and purge and repressurization

(normally closed) valves is sequenced by the control system located

in the electrical enclosure.

7

INLET

OUTLET

TOWER

4A

3A9A

5C

1

8

7

62

3B 9B

TOWER

4B

5A 5B

5D

8

1

1. Tower Pressure Gauges

2. Purge Pressure Gauge

3. Inlet Switching Valves

4. Desiccant Drying Towers

5. Check Valves

6. Adjustable Purge Rate Valve

7. Purge Orifice

8. Safety Valves

9. Purge and Repres-

surization Valves

10. Purge Mufflers

11. Moisture Indicator

A & C Left Tower Suffixes

B & D Right Tower Suffixes

Process Stream

Purge Stream

INLET

OUTLET

4A

10A

9A 3A

TOWER

8

1

6

4B

3B 9B

TOWER

2

8

1

5C 5D

FIGURE 3-2a

TOWER 4A DRYING

TOWER 4B REGENERATING

FIGURE 3-2b

TOWER 4B DRYING

TOWER 4A REGENERATING

11

5A 11 5B

10B

10

A1

0B

— 5 —

3.3.3 Models 40 to 450 (High Pressure Option)

(Refer to Fig. 3-3a.) Compressed air ows through inlet switching

valve (3A) (normally open) to tower (4A) where the air is dried. After

the air is dried it ows through shuttle valve (5) and then to the dryer

outlet. A portion of the dry air, the purge stream, branches off from

the main air stream prior to the outlet. The purge stream ow rate is

controlled by the adjustable purge rate valve (6) and the two purge

orices (7).

The purge ow, which has been throttled to near atmospheric pressure,

is directed to tower (4B). As the purge ow passes over the desiccant

in tower (4B), it removes the water vapor which was deposited while

the tower was on-line drying. The purge air then passes through

purge and repressurization valve (9B) (normally closed) and purge

mufer (10B) to the atmosphere.

After regeneration, purge and repressurization valve (9B) (normally

closed) closes allowing tower (4B) to re-pressurize slowly. Adequate

repressurization time is allowed so that tower (4B) is fully re-

pressurized before switchover. After a controlled time period, air

inlet switching valve (3B) (normally open) opens and inlet-switching

valve (3A) (normally open) closes, purge and repressurization

valve (9A) (normally closed) then opens.

(Refer to Fig. 3-3b.) Tower (4B) is now drying the main air stream while

tower (4A) is being regenerated by the purge air stream. The operation

of the inlet switching (normally open) and purge and repressurization

(normally closed) valves is sequenced by the control system located

in the electrical enclosure.

8. Safety Valve

9. Purge and Repres-

surization Valves

10. Purge Mufflers

11. Moisture Indicator

A Left Tower Suffix

B Right Tower Suffix

4B

TOWER

Purge Stream

Process Stream

1. Tower Pressure Gauges

2. Purge Pressure Gauge

3. Inlet Switching Valves

4. Desiccant Drying Towers

5. Shuttle Valve

6. Adjustable Purge Rate Valve

7. Purge Orifices

9A

3A

INLET

TOWER

4A

1

762

8

9B

3B

10B

1

7

9A

TOWER

4A

INLET

FIGURE 3-3b

TOWER 4A REGENERATING

TOWER 4B DRYING

3A 3B

1

76

1

8

27

9B

4B

TOWER

10A

10B10A

5

11

OUTLET

OUTLET

11 5

FIGURE 3-3a

TOWER 4A DRYING

TOWER 4B REGENERATING

— 6 —

3.4 Automatic Purge Saving System

(Refer to Figure 3-4a for Models 40 through 3000 and Figure 3-4b for

Models 4100 through 5400.)

Assume tower A is on-line drying while tower B has just gone off-line

to be regenerated. At the beginning of tower B’s regeneration cycle a

thermistor temperature measurement is made at position B1. After the

tower has been regenerated, another measurement is made at B1. The

drop in temperature sensed during regeneration is an indirect measure

of the water vapor content of the inlet air. The Automatic Purge Saving

System’s microprocessor then uses this information to calculate an

allowable temperature rise in the bed during the drying cycle.

When tower B goes back on-line, a temperature probe at position B2

measures the initial bed temperature at this point and then monitors

the bed until the calculated temperature rise occurs. The temperature

rise occurs as heat of adsorption is released during the drying process.

The time for the temperature rise to occur depends on ow rate. At

100% ow the temperature rise takes 5 minutes, at 50% ow it takes

10 minutes.

NOTE: If after 30 minutes, the bed temperature has not risen to the

calculated value, the dryer will automatically switch towers.

When the calculated temperature rise is reached, the towers switch

with tower A now drying and tower B being regenerated. Tower B

regenerates for 3.9 minutes, re-pressurizes, and remains idle until it

is called upon for the next drying cycle.

1. Tower Pressure Gauges

2. Purge Pressure Gauge

3. Inlet Shuttle or Switching

Valves

4. Desiccant Drying Towers

5. Shuttle or Check Valve(s)

6. Adjustable Purge Rate Valve

7. Purge Orifice(s)

Purge Stream

Process Stream

8. Safety Valve(s)

9. Purge and Repres-

surization Valves

10. Purge Mufflers

11. Moisture Indicator

A & C Left Tower Suffix(es)

B & D Right Tower Suffix(es)

11

OUTLET

INLET

4A

10A

9A 3A

TOWER

8

1

5A

5C

6

7

4B

3B 9B

10B

TOWER

5B

25D

8

1

FIGURE 3-4b

Models 4100 through 5400

TOWER 4A DRYING

TOWER 4B REGENERATING

A2

A1 B1

B2

4A 4B

TOWER 4A DRYING

TOWER 4B REGENERATING

10A

9A

FIGURE 3-4a 10B

INLET

9B

7

1

TOWER

1

26

8

7

TOWER

Models 40 through 3000

A1

A2

B1

B2

OUTLET

11 5

3

— 7 —

4. INSTALLATION

4.1 Location in the compressed air system

NOTE: The air compressor should be adequately sized to handle

air system demands as well as purge loss. Failure to take this into

account could result in overloading air compressors and/or insufcient

air supply downstream. It is desirable to install the dryer where the

compressed air is at the lowest possible temperature (downstream of

aftercoolers) and the highest possible pressure (upstream of pressure

reducing valves) without exceeding the maximum operating pressure

of the equipment. (Refer to Figure 4-1)

4.1.4 Heatless Pressure-Swing Desiccant Air Dryer

4.1.5 Afterlter(s) –

To ensure downstream air purity (prevent desiccant dust from

traveling downstream) adequate ltration downstream of the dryer

is required.

• First Afterlter - Particulate Removal -Typically 1-micron ltration

is specied although ner ltration is available.

• Second Afterlter - Oil Vapor Adsorption -This lter is used to

remove oil vapor and its subsequent taste and odor and to protect

down-stream components from solid particles 0.01 micron and

larger.

NOTE: By-pass lines and isolation valves are recommended so

that maintenance work can be performed without shutting off the air

supply.

4.1.1 Aftercooler/Separator –

Compressed air entering dryer must be cooled to a temperature of

140°F (60°C) or lower. Use of an aftercooler and condensate separator

may be necessary to reduce inlet air temperature to an acceptable

level.

NOTE: Installation of a refrigerated dryer ahead of a pressure-swing

desiccant dryer does not increase desiccant dryer capacity or reduce

purge ow requirements.

4.1.2 Receiver(s) –

Air receivers dampen pulsations from the compressor discharge line

and can eliminate some of the condensed moisture that is carried over

from the aftercooler and separator. They also provide a reservoir of

stored air for response to system demands in excess of compressor

capacity. Size and location of receivers in the compressed air system

need to be considered carefully. Flows must not exceed the adjusted

maximum inlet capacity of the desiccant air dryer.

4.1.3 Prelter(s) –

Adequate ltration is required upstream of the dryer in order to

protect the desiccant bed from contamination. The following ltration,

equipped with automatic condensate drains, is recommended:

• First Prelter - Particulate/Gross Liquid Removal - On heavily

contaminated systems, a gross contaminant lter to remove solids

and high inlet liquid concentrations should be used.

•Second Prefilter - Oil Aerosol Removal - On systems with

lubricated compressors, an oil removal filter to remove oil

aerosols and protect the desiccant beds from oil contamination

is required.

4.2 Physical Location

The dryer must be installed with suitable overhead protection

as well as clearance to change desiccant. Sufficient clearance

around the periphery of the dryer should be provided to allow

maintenance personnel access to all areas for routine inspections

and adjustments.

4.3 Minimum & Maximum Operating Conditions

The compressed air supply to the dryer inlet should be checked

periodically to ensure that dryer design specifications are not

exceeded. Normally the compressor installation includes intercoolers,

aftercoolers, separators, receivers, or similar equipment, which

adequately pretreat the compressed air supply in order to avoid

excessively high air temperatures and liquid slugging of downstream

equipment.

4.4 Maximum Operating Pressure (MOP):

•150 psig (10.3 barg) is standard.

•250 psig (17.2 barg) is optional.

Refer to Dryer Serial Number Tag.

WARNING - Do not operate the dryer at pressures above the

maximum operating pressure shown on the serial number tag.

NOTE: Consult factory for applications requiring higher maximum

operating pressures.

Compressor AftercoolerSeparator Receiver Prefilters Afterfilters ReceiverDesiccant Dryer

Figure 4-1

Figure 4-1

— 8 —

Figure 4-2

40-450 SCFM General Arrangement

(continued on next page)

WARNING:Disconnectthemain power

supplybeforeremovingthiscove r.

CENTERLINE OF CUSTOMER

INLET/OUTLET CONNECTIONS

M

(MAX)

D

E

C

B

J

LIFTING LUG

DESICCANT FILL PORT

LEFT CHAMBER

PRESSURE GAUGE

MOISTURE INDICATOR

RIGHT CHAMBER

PRESSURE GAUGE

CONTROL ENCLOSURE

DESICCANT DRAIN PORT

G

H

P

AIR OUTLET

7/8”X 1 1/4” SLOT (TYP 4 PLCS)

[22mm] [32mm]

A

L

(MAX)

F

N

(MAX)

P

AIR INLET

TOP VIEW

FRONT VIEW RIGHT SIDE VIEW

RIGHT CHAMBER REMOVED FOR CLARITY

REAR VIEW

ASME PRESSURE

RELIEF VALVE

OUTLET SHUTTLE

VALVE ASSY

PILOT AIR FILTER

PURGE PRESSURE GAUGE

& REGULATOR

PURGE ADJUSTING VALVE

ASME CODE TAG

INLET SHUTTLE

VALVE ASSY

PURGE EXHAUST

VALVE

PURGE EXHAUST

MUFFLER

— 9 —

Figure 4-2

40-450 SCFM General Arrangement

(continued from previous page)

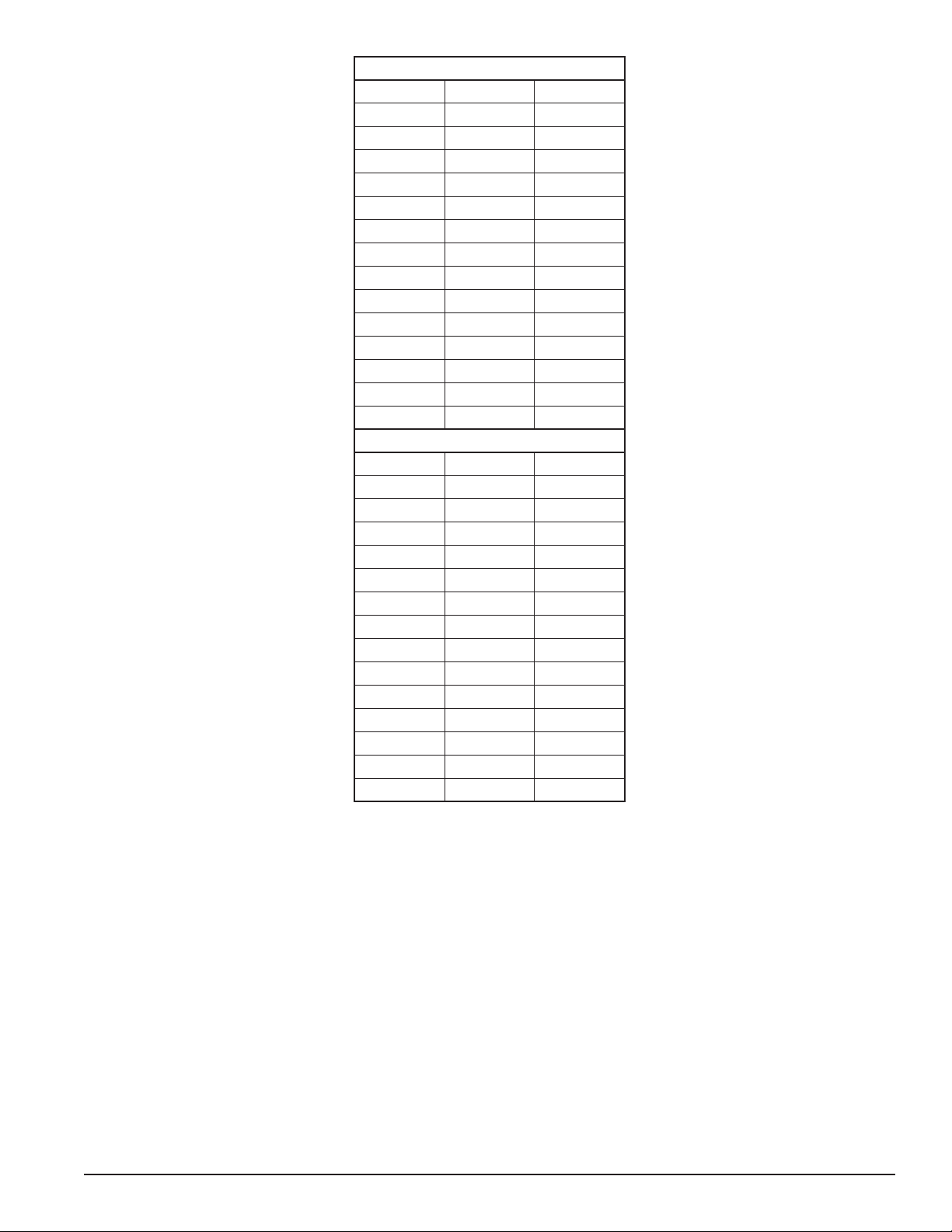

DIMENSIONS IN INCHES

MODEL 40 60 90 115 165 260 370 450

A27.5/8 27.5/8 27.5/8 38.3/8 38.3/8 41.3/8 49.3/8 49.3/8

B13.13/16 13.13/16 13.13/16 19.13/16 19.13/16 20.11/16 24.11/16 24.11/16

C1.1/4 1.1/4 1.1/4 1.1/4 1.1/4 1.1/4 1.1/4 1.1/4

D29.1/2 29.1/2 29.1/2 35.1/2 35.1/2 35.1/2 35.1/2 35.1/2

E14.3/4 14.3/4 14.3/4 17.3/4 17.3/4 17.3/4 17.3/4 17.3/4

F2.13/16 2.13/16 2.13/16 2.13/16 2.13/16 3.1/4 3.1/4 3.1/4

G14 14 14 15 15 15 16 16

H39 54 71 45 45 63 53 61

J1.3/4 1.3/4 1.3/4 1.3/4 1.3/4 2.3/4 2.3/4 2.3/4

L35 35 37 50 50 51 58 58

M35 35 35 41 41 41 42 42

N49 64 81 57 57 75 65 73

P1 NPT 1 NPT 1 NPT 1 NPT 1 NPT 2 NPT 2 NPT 2 NPT

WT/LBS 365 445 575 685 685 1010 1215 1350

DIMENSIONS IN MILLIMETERS

MODEL 40 60 90 115 165 260 370 450

A702 702 702 975 975 1051 1254 1254

B351 351 351 487 487 525 627 627

C32 32 32 32 32 32 32 32

D749 749 749 902 902 902 902 902

E375 375 375 451 451 451 451 451

F71 71 71 71 71 83 83 83

G356 356 356 381 381 381 406 406

H991 1372 1803 1143 1143 1600 1346 1549

J44 44 44 44 44 70 70 70

L889 889 948 1264 1264 1305 1470 1470

M889 889 889 1041 1041 1041 1062 1062

N1235 1616 2047 1437 1437 1894 1658 1861

P1 NPT 1 NPT 1 NPT 1 NPT 1 NPT 2 NPT 2 NPT 2 NPT

WT/KGS 166 202 261 311 311 458 551 612

NOTE: Dimensions and weights are for reference only. Request certied drawings for construction purposes.

— 10 —

Figure 4-3

590-3000 SCFM General Arrangement

(continued on next page)

WARNING:Disconnectthemainpower

supplybeforeremovingthiscover.

P

AIR OUTLET

F

H

PURGE

EXHAUST

MUFFLER

ASME CODE TAG

PILOT AIR

FILTER

P

AIR INLET

ASME PRESSURE

RELIEF VALVE

DESICCANT DRAIN PORT

L

(MAX)

N

(MAX)

CONTROL

ENCLOSURE

RIGHT CHAMBER

PRESSURE GAUGE

PURGE PRESSURE GAUGE

MOISTURE INDICATOR

DESICCANT FILL PORT

7/8”X 1-1/4” SLOT (TYP 4 PLACES)

[22mm] [32mm]

A

B

LEFT CHAMBER

PRESSURE GAUGE

LIFTING LUG

PURGE PRESSURE

ADJUSTMENT VALVE

CENTERLINE OF CUSTOMER

INLET/OUTLET CONNECTIONS

M

(MAX)

D

E

C

G

TOP VIEW

FRONT VIEW RIGHT SIDE VIEW

(Models 590 through 1350)

RIGHT CHAMBER REMOVED FOR CLARITY

REAR VIEW

F

H

P

AIR INLET

G

BOTTOM RIGHT SIDE VIEW

(Models 1550, 2100 and 3000)

RIGHT CHAMBER REMOVED FOR CLARITY

— 11 —

Figure 4-3

590-3000 SCFM General Arrangement

(continued from previous page)

DIMENSIONS IN INCHES

MODEL 590 750 930 1130 1350 1550 2100 3000

A46.3/4 47.9/16 52.11/16 56.7/16 57.5/16 63.1/8 69.13/16 73.3/8

B23.3/8 23.13/16 26.5/16 28.1/4 28.11/16 31.9/16 34.7/8 36.11/16

C1.1/4 1.1/4 1.1/4 1.1/4 1.1/4 1.1/4 1.1/4 1.1/4

D45.1/2 45.1/2 53.1/2 53.1/2 53.1/2 53.1/2 53.1/2 59.1/2

E22.3/4 22.3/4 26.3/4 26.3/4 26.3/4 26.3/4 26.3/4 29.3/4

F3.1/4 3.1/4 3.1/4 5.1/8 5.1/8 5.9/16 5.9/16 5.9/16

G9.3/16 9.11/16 11.7/16 11 11 5.1/4 6.3/16 8.1/2

H97.5/16 100.13/16 105.9/16 107.1/8 112.1/8 109.1/2 111.5/16 117.3/8

L55 57 63 66 68 74 82 86

M51 51 59 59 59 59 59 67

N104 107 112 115 120 117 119 125

P2 NPT 2 NPT 2 NPT 3 FLANGE 3 FLANGE 4 FLANGE 4 FLANGE 4 FLANGE

WT/LBS 1473 2134 2414 2875 3722 4167 4417 9010

DIMENSIONS IN MILLIMETERS

MODEL 590 750 930 1130 1350 1550 2100 3000

A1187 1208 1338 1434 1456 1604 1773 1864

B594 604 669 717 728 802 886 932

C32 32 32 32 32 32 32 32

D1156 1156 1359 1359 1359 1359 1359 1511

E578 578 679 679 679 679 679 756

F83 83 83 130 130 141 141 141

G234 247 291 279 279 133 157 216

H2472 2561 2681 2721 2848 2781 2827 2981

L1387 1438 1603 1673 1724 1876 2080 2172

M1295 1295 1499 1499 1499 1499 1499 1693

N2631 2720 2841 2924 3051 2980 3026 3180

P2 NPT 2 NPT 2 NPT 3 FLANGE 3 FLANGE 4 FLANGE 4 FLANGE 4 FLANGE

WT/KGS 668 968 1095 1304 1688 1890 2004 4087

NOTE: Dimensions and weights are for reference only. Request certied drawings for construction purposes.

— 12 —

Figure 4-4

4100-5400 SCFM General Arrangement

(continued on next page)

FLOW FLOW

FLOW FLOW

FLOW FLOW

FLOW FLOW

M

(MAX)

D

E

CB

A

L

(MAX)

7/8”X 1-1/4” SLOT (TYP 4 PLACES)

[22mm] [32mm]

ASME PRESSURE

RELIEF VALVE

CENTERLINE OF CUSTOMER

INLET/OUTLET CONNECTIONS

LIFTING LUG

PURGE PRESSURE

ADJUSTMENT VALVE

LEFT CHAMBER

PRESSURE GAUGE

DESICCANT FILL PORT

MOISTURE INDICATOR

PURGE PRESSURE GAUGE

RIGHT CHAMBER

PRESSURE GAUGE

CONTROL

ENCLOSURE

PURGE EXHAUST MUFFLER

DESICCANT DRAIN PORT

N

OVERALL

LENGTH

J

G

P

AIR INLET

H

PILOT AIR FILTER

FP

AIR OUTLET

TOP VIEW

FRONT VIEW RIGHT SIDE VIEW

RIGHT CHAMBER REMOVED FOR CLARITY

REAR VIEW

— 13 —

Figure 4-4

4100-5400 SCFM General Arrangement

(continued from previous page)

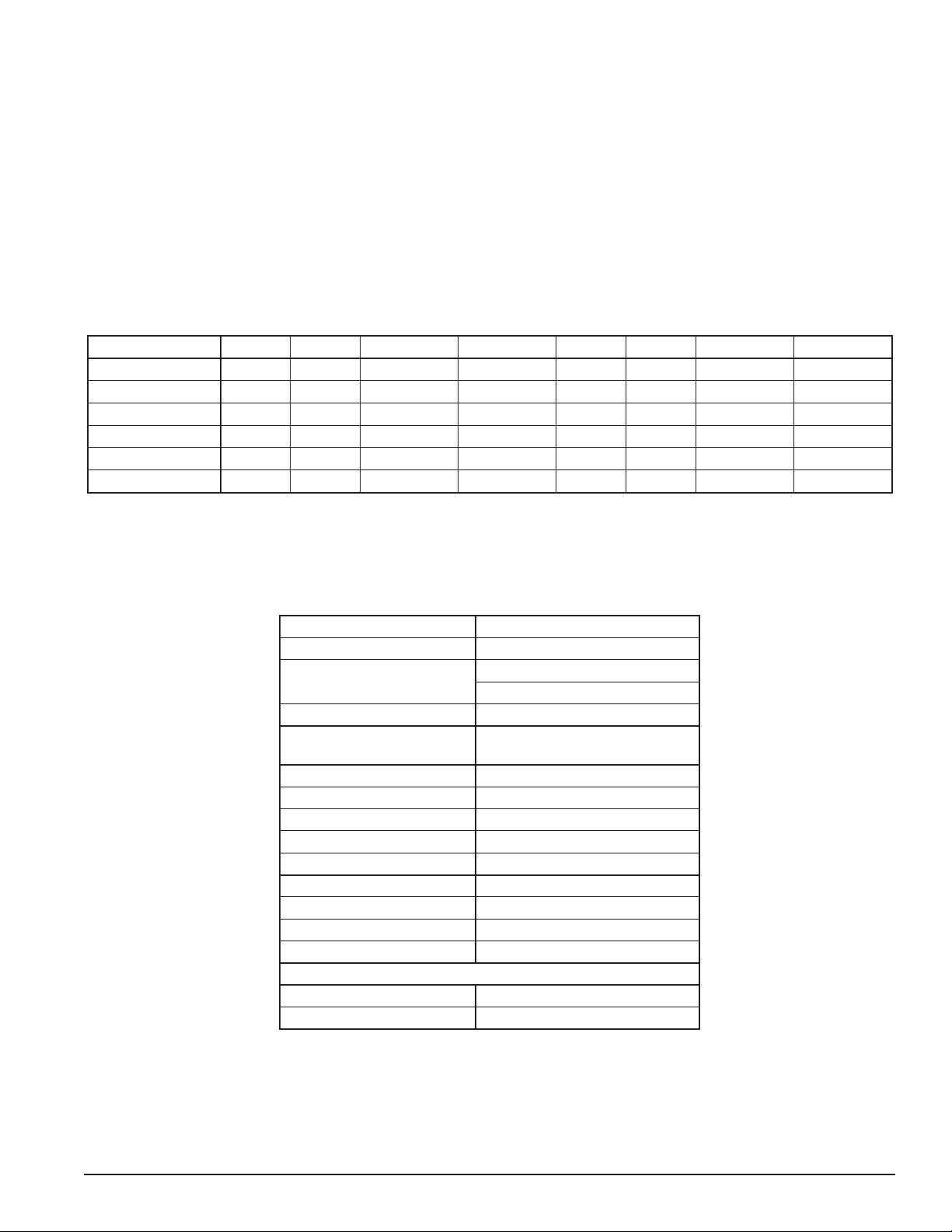

DIMENSIONS IN INCHES

MODEL 4100 5400

A82.7/8 93.3/8

B41.7/16 46.11/16

C1.1/4 1.1/4

D59.1/2 63.1/2

E29.3/4 31.3/4

F33.3/16 35.7/8

G13.13/16 19.7/16

H115.13/16 116.3/16

J36.3/16 38.7/8

L100 105

M88 89

N124 124

P6 FLANGE 6 FLANGE

WT/LBS 9900 12000

DIMENSIONS IN MILLIMETERS

MODEL 4100 5400

A2106 2372

B1053 1186

C32 32

D1511 1613

E756 806

F843 911

G351 494

H2942 2951

J919 988

L2537 2667

M2227 2253

N3158 3158

P6 FLANGE 6 FLANGE

WT/KGS 4500 5445

NOTE: Dimensions and weights are for reference only. Request certied drawings for construction purposes.

— 14 —

4.5 Minimum Operating Pressures:

4.5.1 For 150 psig (10.3 barg) MOP models -

•60 psig (4.1 barg) is the minimum operating pressure for dryers

operated on ISO classes 1, 2, 3, and 4.

4.5.2 For 250 psig (17.2 barg) MOP models -

•120 psig (8.3 barg) is the minimum operating pressure for dryers

operated on ISO classes 1, 2, 3, and 4.

Refer to Dryer Serial Number Tag.

WARNING - Do not operate the dryer at pressures below the

minimum operating pressure shown on the serial number tag.

NOTE: Consult factory for applications requiring lower minimum

operating pressures.

4.6 Maximum Compressed Air Temperature at Dryer

Inlet:

•140°F (60°C) for all models.

4.7 Ambient Temperatures:

4.7.1 Minimum Ambient Temperature

•Standard units: 35°F (2°C)

•Units with optional low ambient package: -20°F ( -29°C)

4.7.2 Maximum Ambient Temperature

•120°F (49°C)

NOTE: If dryer is installed in ambients below 35°F (2°C), low ambient

protection requiring heat tracing and insulation of the prelter bowls,

auto drains and/or sumps, and lower piping with inlet switching and

purge/repressurization valves is necessary to prevent condensate

from freezing. If installing heat tracing, observe electrical class code

requirements for type of duty specied. Purge mufers and their relief

mechanisms must be kept clear from snow and ice buildup that could

prevent proper discharge of compressed air.

4.8 Mounting

Install dryer on a level pad. Holes are provided in the dryer base

members for oor anchors.

NOTE: Floor anchors must be used if area is subject to vibration.

4.9 Piping

Inlet and Outlet connections

Observe locations of inlet and outlet connections as shown in Figures

4-2, 4-3 or 4-4 and connect inlet and outlet piping as indicated.

NOTE: All piping must be supported so as not to bear on the dryers

or lters.

4.10 Isolation Valves

If isolation or bypass valves are installed, care must be used to

ensure that equipment is pressurized slowly. This is particularly true if

isolation valves are placed before and after pre and afterlters where

rapid pressurization could cause excessive pressure drop across

lter elements.

NOTE: When quarter-turn valves (e.g. ball or buttery valves) are

used for isolation of pressure components, care should be taken to

open or close valves slowly.

4.11 Electrical Connections

Refer to the appropriate controller sections for detailed information

on connections, ratings, and operation of the Level 1 or Level 2

Controller.

NOTE: Refer to the dryer serial number tag for allowable voltages,

frequency and power rating.

4.12 Provisions for Purge Exhaust

•Purge exhaust must be routed through the factory supplied

mufers or piped to a remote location.

• Purge mufers - If shipped separately, install purge exhaust

mufers in the locations shown in Figures 4-2, 4-3 or 4-4.

• If purge exhaust is piped to a mufer located in a remote location,

choose a combination of diameters, lengths, and turns that limits

the additional pressure drop to 1 psid or less.

WARNING - Do not operate dryer without installed mufflers.

Exhausting compressed air directly to atmosphere will result in

noise levels above OSHA permissible levels and rapidly expanding

gas could potentially cause harm to persons or property.

4.13 Initial Desiccant Charge

The dryer is shipped complete with desiccant and is ready to operate

after piping and electrical connections are made and controller settings

are established.

4.14 Icon Identication

P

P

P

Left Tower

Pressure Gauge

Right Tower

Pressure Gauge

Air Outlet

Air Inlet

Purge

Pressure Gauge

Electrical

Inlet

— 15 —

5. CONTROLLERS – GENERAL

5.1 Overview

The solid-state dryer controller is located in a polycarbonate, NEMA

Class 4/4X, IP66 rated electrical enclosure mounted to a center panel

located between the two desiccant towers. Controls are available in

three functional levels. The Timer Controller offers a xed-time cycle

that provides a dew point corresponding to ISO compressed air quality

class 2. Both the Level 1 and Level 2 controls offer four xed-time

cycles that provide dew points corresponding to ISO compressed air

quality classes 1 through 4. A key difference between the Level 1 and

Level 2 controls is the way in which they address energy savings. When

inlet ow is less than the adjusted rated capacity of the dryer, average

purge air requirements are reduced. This reduction can translate to

energy savings at the air compressor.

The Level 1 Controller offers 8 selectable xed-cycle Energy (purge)

Saver modes (0% to 70% in 10 % increments) to reduce purge time

to match the load on the dryer.

Level 2 Controllers feature the Automatic Purge Saving System

(APSS) as described in Sections 3.2 and 3.4. When Level 2 Controllers

are operated in demand rather than xed cycle modes, the APSS

automatically adjusts to dryer loading and extends drying time when

possible. Average purge use is thus automatically reduced.

A feature-by-feature comparison of each controller can be found in

Table 5-1.

Table 5-1

Feature Comparison

(continued on next page)

Desiccant Dryer Controllers Timer

Controller

Level 1

Fixed Cycle Only

Level 2

Fixed Cycle

and APSS

Category Feature

General

AC Input Voltage: 100-240 VAC, 50-60 Hz (See NOTE 1) •

AC Input Voltage: 85-264 VAC, 47-63 Hz (See NOTE 1) • •

DC Input Voltage: 11.5-28 VDC (See NOTE 1) • •

Auxiliary power terminals (See NOTE 2) • •

Solenoid valve coil voltage 12 VDC 12 VDC 12 VDC

NEMA 4/4X, IP 66 electrical enclosure rating •••

Soft on/off switch with two power recovery modes (See NOTE 3) • •

Tower status LEDs (amber=drying) •

Tower status LEDs (green=drying, amber=regenerating) • •

Process valve status LEDs (on=valve open, off=valve closed) • •

Operating mode LEDs (see next category for number of modes) •

Alarm LED (red) • •

Voltage-free alarm contacts, 5A rating • •

Alarm reset switch (mounted on front panel) • •

Service reminder LEDs (See NOTE 4) • •

Vacuum fluorescent text display •

Operating Modes

(See NOTE 5 and

NOTE 7)

60-150 or 120-250 psig MOP (selectable via jumper on circuit board) • •

ISO Class 1 (-100°F/-73°C PDP) - fixed cycle (4 minute) • •

ISO Class 2 (-40°F/-40°C PDP) - fixed cycle (10 minute) •••

ISO Class 3 (-4°F/-20°C PDP) - fixed cycle (16 minute) • •

ISO Class 4 (+38°F/+3°C PDP) - fixed cycle (24 minute) • •

Fixed Cycle Energy (purge) Saver (See NOTE 6) •

Manual Cycle (test mode) • •

ISO Class 2 (-40°F/-40°C PDP) - demand cycle •

ISO Class 3 (-4°F/-20°C PDP) - demand cycle •

ISO Class 4 (+38°F/+3°C PDP) - demand cycle •

Digital I/O

Controlled shutdown and restart (upon user supplied contact closure) • •

Tower pressure switches (2) • •

High Humidity Alarm Optional

Filter monitor alarm (1 or 2 filters) Optional

Electric drain alarm (1 or 2 filters) Optional

Electric drain test (1 or 2 filters) Optional

Analog I/O

(12 bit accuracy) Thermistors (4) •

Communication RS232 communication port • •

— 16 —

Table 5-1 (continued from previous page)

NOTEs:

1. The Timer Controller will accept AC (Alternating Current) input power. The Level 1 and Level 2 Controllers will accept either AC

(Alternating Current) or DC (Direct Current) input power.

2. (Level 1 & Level 2 Controllers) The auxiliary power terminals are in parallel with the input power terminals (i.e., there are two common

terminals for each input power connection point, L, N, and PE. The auxiliary power terminals provide a connection point for another device

that operates on the same voltage as the Desiccant Dryer Controller.

3. (Level 1 & Level 2 Controllers) The controller has two power recovery modes. For Level 1 the selection is made using a jumper on the

circuit board. For Level 2 the selection is made using the switches on the front panel. In one mode, the controller remembers its state (on

or off) prior to a power interruption and returns to that state when power is restored. In the other mode, the controller always returns to the

off state when power is restored after an interruption.

4. (Level 1 & Level 2 Controllers) The service reminder LEDs indicate that it is time to perform preventive maintenance on the (a) lters

and drains, (b) valves, or (c) desiccant. The user selects between Normal and Severe service intervals. For Level 1 the selection is made

using a jumper on the circuit board. For Level 2 the selection is made using the switches on the front panel.

5. (Level 1 & Level 2 Controllers) For Level 1 and Level 2, the operating mode (with exception of the MOP) is selected via switches on the

front panel.

6. (Level 1 Controllers) The Level 1 Energy (purge) Saver feature has eight settings, 0% to 70% in 10% increments. Energy Saver setting

= 100% – (percentage of adjusted allowable inlet ow). (e.g. if the maximum adjusted allowable inlet ow to a dryer was 1000 SCFM, but

the actual ow to the inlet was only 300 SCFM, then the Energy Saving setting would be 100%-((300/1000)*100%)=70%. At 300 SCFM,

only 30% of the dryer capacity is being utilized. Average purge requirements and the related energy needed to compress that purge air can

be reduced by 70%.) The selection is made using a switch on the front panel.

7. PDP - Pressure Dew Point

MOP - Maximum Operating Pressure

— 17 —

6. CONTROLLER – TIMER BASED

This section provides connection, adjustment and operational

information for the Timer Based – Fixed Cycle Controller. Similar

information for the Level 1 – Fixed Cycle Controller and Level 2

Controller featuring the APSS, Automatic Purge Saving System, can

be found in Sections 7 and 8 respectively.

6.1 Reference Figures – Timer Based Controller

•Figure 6-1, Front Panel Overlay – Timer Controller

•Figure 6-2, Point-to-Point Diagram – Timer Controller

6.2 Connections – Timer Based Controller

See Figure 6-2, Point-to-Point Diagram for the location and function of

the various cable and cord connectors that are provided on the bottom

of the Timer Based enclosure.

6.2.1 Connections - Input Power

6.2.1.1 VAC Input Power Connections

Single-phase, alternating current (AC) input power connection of 100-

240 VAC / 1 ph / 50-60 Hz. can be made at terminals mounted within

the control enclosure. See reference gures for proper polarity.

Program Step 1 2 3 4 5 6 7 8

Left tower status drying drying drying drying regen regen regen regen

Right tower status regen regen regen regen drying drying drying drying

Left purge solenoid off off off off off off on off

Right purge solenoid off off on off off off off off

Left purge valve closed closed closed closed closed closed open closed

Right purge valve closed closed open closed closed closed closed closed

Table 6-1

Cycle Sequence Steps –Timer Based Controller

Dryer MOP 60 - 150 psig (4.1 - 10.3 barg)

ISO Class 2

Dew Point -40°C

-40°F

Cycle Time (minutes) 10

Time Time from start of cycle

(minutes:seconds)

t0 00:00

t1 00:02

t2 00:06

t3 04:12

t4 05:00

t5 05:02

t6 05:06

t7 09:12

t8 10:00

Reference Data

Purge time (min:sec) 04:12

Repress. time (min:sec) 00:48

Table 6-2

Fixed Cycle Timing –Timer Based Controller

— 18 —

Figure 6-1

Front Panel Overlay –Timer Based Controller

(NOTE: Figure is representative of Models 40 through 3000.)

WARNING: Disconnect the main power

supply before removing this cover.

Power ON Light

Left Tower

DRYING Light

Right Tower

DRYING Light

This manual suits for next models

56

Table of contents

Other SPX Dryer manuals