SPX JEMACO HXK Series User manual

1

ٻ

ٻ

Installation, Operation and

Maintenance Manual

HXK SERIES

REFRIGERATED AIR DRYERS

Models

HX76K ~ HX601K

This instruction manual must be read by everyone

Who installs or works with this equipment

GDSTP-24280-MAN-0002_P2

A

D-1010-011, 021, 031

Goodnal STP ST041 Site Services (Jemaco HXK Series Refrigerated Air Dryers HX76K to HX601K Installation

Q-Pulse Id VM409

Active 29/10/2013

Page 1 of 24

2

Table Of Contents

INTRODUCTION …………………………………………………………………………………

SAFETY ……………………………………………………………………………………………

Safety Instructions ……………………………………………………………………………

Data Plate ……………………………………………………………………………………..

RECEIVING AND INSPECTION ………………………………………………………………...

INSTALLATION ……………………………………………………………………………………

Ambient Air Temperature ……………………………………………………………………

Location and Clearance ……………………………………………………………….…….

System Arrangement ………………………………………………………………………..

Piping and Connections ……………………………………………………………………..

Drains ………………………………………………………………………………………….

Electrical Connections (see Figure 3) ………………………………………………………

HOW IT WORKS ……………………………………………………………………………….…

Airflow (see Figure 4) …………………………………………………………………………

Refrigeration System …………………………………………………………………………

Color Indicator ……………………………………………………………………………………

Dryer Control Board (DCB) …………………………………………………………………..

Electronic Drain Valve Adjustment ………………………………………………………….

START-UP ………………………………………………………………………………………….

SHUTDOWN ……………………………………………………………………………………….

MAINTENANCE …………………………………………………………………………………...

General ………………………………………………………………………………………...

Daily ……………………………………………………………………………………………

Monthly ………………………………………………………………………………….…….

Returns to Manufacturer ……………………………………………………………….…….

Electronic Drain Valve Disassembly and Servicing ………………………………………

FIELD SERVICE GUIDE ………………………………………………………………………….

Data Table……………………………………………………………………………….…….

Drawings………………………………………………………………………………….…….

REPLACEMENT PARTS …………………………………………………………………………

3

3

4

4

4

5

5

5

5

6

6

6

7

7

7

7

8

9

10

11

12

12

12

12

12

12

14

16

18

21

Goodnal STP ST041 Site Services (Jemaco HXK Series Refrigerated Air Dryers HX76K to HX601K Installation

Q-Pulse Id VM409

Active 29/10/2013

Page 2 of 24

3

INTRODUCTION

The dryers use mechanical refrigeration to dry compressed air. See Table 4 for rated

capacity and other dryer specifications.

To ensure continuous good performance and safe operation, everyone who installs, uses

or maintains the dryer must read and carefully follow the instructions in this manual.

SAFETY

The dryers are designed and built with safety as a prime consideration; industry-

accepted safety factors have been used in the design. Each dryer is checked at the factory

for safety and operation. All necessary adjustments are made before shipment.

Follow the maintenance schedules outlined in this manual for good performance and safe

operation. Maintenance should be done only by qualified personnel with proper tools.

Carefully read the following safety rules before proceeding with installation, operation or

maintenance. The rules are essential to ensure safe dryer operation. Failure to follow

these rules void the warranty or result in dryer damage or personal injury.

1. Do not install or try to repair a dryer that has been damaged in shipment.

See Receiving and Inspection for instructions.

2. Compressed air and electricity have the potential to cause personal injury or

equipment damage. Before doing any work in the dryer, be sure the electrical supply

has been locked and tagged and the internal pressure of the dryer has been vented to

the atmosphere.

3. Do not operate the dryer at pressures or temperatures above the maximum conditions

shown on the data plate.

4. Always supply electrical power that complies with the voltage shown on the data plate.

5. Do not readjust the dryer without factory authorization.

6. Work on the refrigeration system must be done only by a competent refrigeration

mechanic.

7. Use only manufacturer’s genuine replacement parts. The manufacturer bears no

responsibility for hazards caused by the use of unauthorized parts.

Goodnal STP ST041 Site Services (Jemaco HXK Series Refrigerated Air Dryers HX76K to HX601K Installation

Q-Pulse Id VM409

Active 29/10/2013

Page 3 of 24

4

Safety Instructions

Safety instructions in this manual are boldfaced for emphasis. The signal words DANGER,

WARNING and CAUTION are used to indicate hazard seriousness levels as follows:

DANGER ------- Immediate hazard which WILL result in severe injury or death.

WARNING ------- Hazard or unsafe practice which COULD result in severe injury

or death.

CAUTION ------- Hazard or unsafe practice which COULD result in minor injury or

in product or property damage.

Data Plate

The dryer data plate contains identification information. If the data plate is missing or

damaged, contact your local distributor and request a replacement.

RECEIVING AND INSPECTION

Inspect the dryer closely when it is received. Record any indication of damage on the

delivery receipt, especially if the dryer will not be immediately uncrated. Obtain the de-

livery person's signed agreement to recorded damages to facilitate future insurance claims.

Since the dryer is shipped F.O.B. Factory, the manufacturer's responsibility for the

shipment ceases when the carrier signs the bill of lading.

If goods are received short or in damaged condition, notify the carrier and insist on a

notation of the loss or damage across the face of the freight bill. Otherwise no claim can

be enforced against the carrier.

If concealed loss or damage is discovered, notify your carrier at once and request an

inspection. This is absolutely necessary. Unless you do this, the carrier will not consider

any claim for loss or damage. The carrier will make an inspection and may grant a

concealed damage notation. If you give the carrier a clear receipt for the goods that have

been damaged or lost in transit, you do so at your own risk and expense.

The manufacturer is willing to assist you in collecting claims for loss or damage.

Willingness does not make the manufacturer responsible for collecting claims or replac-

ing material. Claim filing and processing is your responsibility.

Goodnal STP ST041 Site Services (Jemaco HXK Series Refrigerated Air Dryers HX76K to HX601K Installation

Q-Pulse Id VM409

Active 29/10/2013

Page 4 of 24

5

INSTALLATION

Ambient Air Temperature

Locate the dryer indoors where the ambient air temperature will be between 4ഒand

43ഒ. Intermittent operation at ambient temperatures up to 43ഒwill not damage the

dryer but may result in a higher dew point or dryer shutdown due to high refrigerant

discharge pressure (see Field Service Guide).

Do not operate air-cooled dryers at ambient air temperatures below 4ഒ. Such operation

may result in low suction pressure, causing freeze-up.

Location and Clearance

Mount the dryer on a level base and bolt down if the base vibrates. If the dryer is air

cooled, install it in a clean, well-ventilated area to reduce fouling of the condenser coils

with dirt and dust. Allow 6inches clearance on the sides and the front of the dryer for

cooling airflow on air-cooled dryers and for service access on air-cooled dryers.

System Arrangement

Liquid water adversely affects dryer performance. To prevent "slugging" the dryer with

liquid water, locate the dryer downstream of an aftercooler and a mechanical separator.

Install drain valves to discharge condensate that collects in these areas.

If the airflow is relatively constant and will not cause short term overloading of the

dryer, it is recommended that the dryer be located downstream of the receiver tank. If the

nature of the application is such that the air demand regularly exceeds the dryer flow

rating, it is recommended that the dryer be located upstream of the receiver.

For safety and convenience, install inlet and outlet shutoff valves and depressurization

valves at the locations indicated. These valves allow the dryer to be isolated and

depressurized for servicing. Bypass piping may be installed around the dryer for

uninterrupted airflow when the dryer is serviced. If the compressed air operation cannot

tolerate undried air for short periods, install a second dryer in the bypass line.

Compressed air systems commonly require filters to remove compressor oils, particulates,

condensed liquids and other contaminants. When an oil-removal filter is used, install the

Goodnal STP ST041 Site Services (Jemaco HXK Series Refrigerated Air Dryers HX76K to HX601K Installation

Q-Pulse Id VM409

Active 29/10/2013

Page 5 of 24

6

filter downstream of the dryer. At this location, the life of the replaceable filter element is

prolonged since some of the entrained oil is removed by the dryer and drained through the

separator.

Piping and Connections

Piping must be furnished by the user unless otherwise specified. Connections and fit-

tings must be rated for the maximum operating pressure given on the dryer data plate

and must be in accordance with applicable codes. Support all piping ; do not allow the

weight of any piping to stress the dryer or filters. Inlet and outlet shutoff valves and a

valved bypass are recommended. Piping should be at least the size of the inlet and out-

let connections to minimize pressure drop in the air system. See Table 3 for dryer inlet

and outlet connections.

Drains

Condensate must be drained from the dryer to prevent its reentrainment. The dryers are

equipped with automatic drain valves and internal drain hoses up to the drain connections

on the dryer cabinets. The user must install a discharge line from the drain connection

and run it to a waste disposal collection system that meets applicable regulations. Pipe or

copper tubing inch or larger is recommended for condensate discharge lines. Install

the drain lines so that condensate can be seen as it drains.

Electrical Connections (See Figure 3)

The dryers are constructed according to NEMA Type 1 electrical standards. Field wiring

must comply with local and national fire, safety and electrical codes. Installation must be in

accordance with the National Electrical Code. Confirm that your line voltage is the same

as the voltage listed on the dryer data plate. Refer to Figure 3 for electrical schematics.

CAUTION

Operation of dryers with improper line voltage constitutes abuse and could

affect the dryer warranty.

Goodnal STP ST041 Site Services (Jemaco HXK Series Refrigerated Air Dryers HX76K to HX601K Installation

Q-Pulse Id VM409

Active 29/10/2013

Page 6 of 24

7

HOW IT WORKS

Airflow (see Figure 4)

The dryers use refrigeration cooling to condense entrained moisture out of the air stream.

Warm saturated air enters the air-to-air heat exchanger where it is cooled by outgoing cold

air. The inlet air is further cooled in the refrigeration chiller. The cold, dry air is reheated by

incoming warm air as it passes back through the air-to-air heat exchanger. Using the

outgoing air to pre-cool the inlet air condenses up to 65 percent of the moisture out of the

inlet air before it reaches the chiller. Pre-cooling the inlet air reduces the heat load on the

refrigerant compressor, permitting the use of a smaller refrigerant compressor.

Refrigeration System

The refrigeration system is designed and fabricated in accordance with recognized com-

mercial/industrial practices. It consists of a compressor and the controls, safety inter-

locks and associated equipment necessary for safe performance.

All models use the constant pressure expansion valve. The constant pressure expansion

valve modulates the refrigerant flow in response to changes in the refrigerant pressure.

The constant expansion valve is adjusted at the factory; operation is fully automatic.

Color Indicator (HX76K~151K)

Figure 1. Color Indicator

The dryers (HX76K~151K) are equipped with a color indicator which indicates dryer

conditions as follows:

It is normal for the indicator color to be in the red zone when the dryer is first turned on

and then move to the green zone when the dryer reaches its normal operating

temperature. If this indicator is in the red zone during normal operation, turn the dryer off

to avoid compressor damage. Refer to the Field Service Guide, for additional information,

or call your local distributor.

Goodnal STP ST041 Site Services (Jemaco HXK Series Refrigerated Air Dryers HX76K to HX601K Installation

Q-Pulse Id VM409

Active 29/10/2013

Page 7 of 24

8

ELECTRONIC DRAIN VALVE

The dryers(HX76K~151K) are equipped with an electronic drain valve that automatically

discharges condensate from the dryer. The drain valve and its controls are accessible from

the left side of the dryer. The electronic drain valve has two indicators and a test button to

help verify operation. Pushing the test button causes the drain port to click open. If either

indicator fails to turn on at the proper time, refer to the maintenance section of this manual.

Drain valve operation is controlled by an electronic timer. The drain opening can be set

from 0.5 sec to 10 sec. The drain cycle can be set from 0.5 min to 45 min.

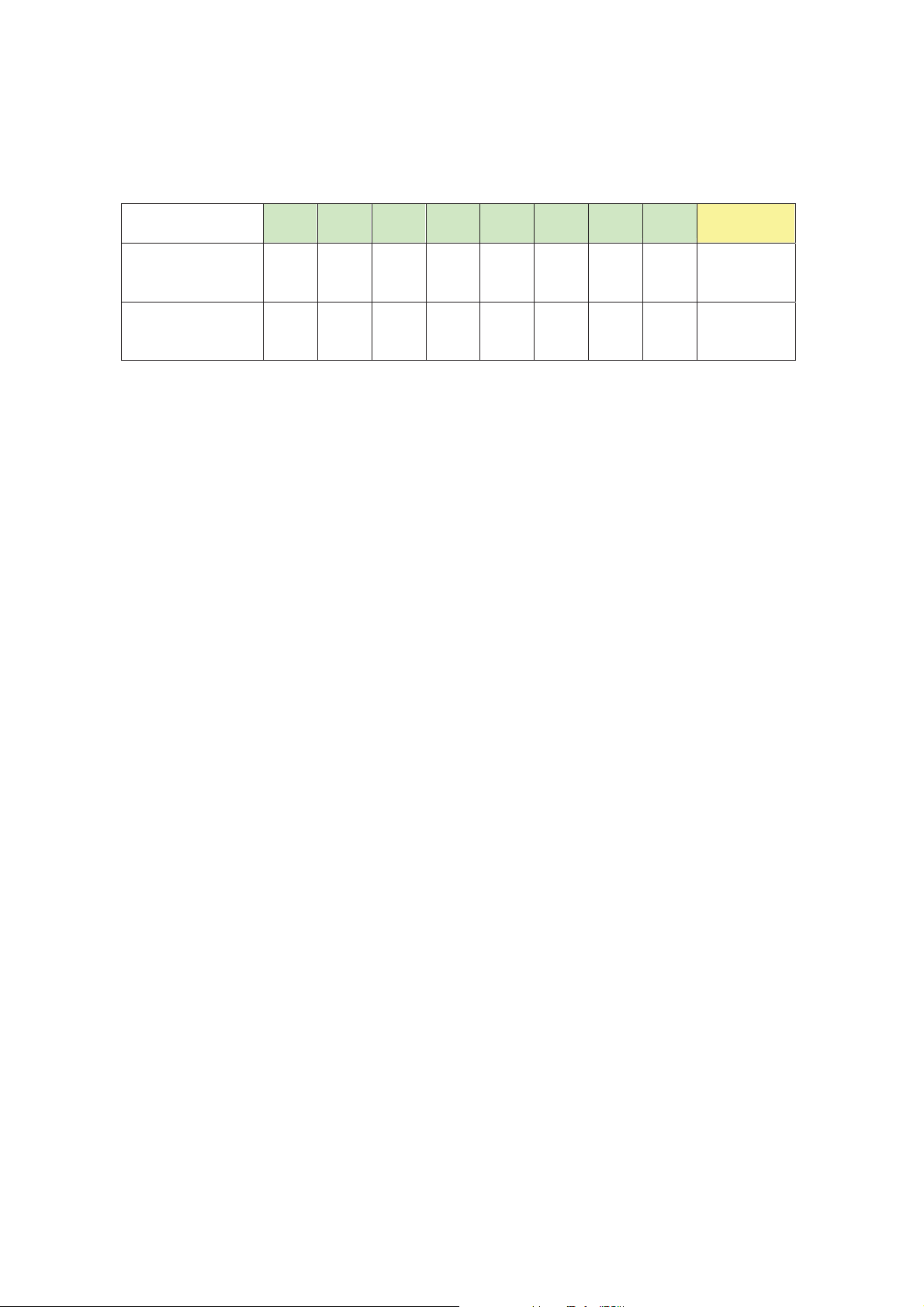

DCB, Digital Control Board (HX201K~601K)

G

The dryers(HX201K~601K) are equipped with LED type dew point indicator.

G

G

G

G

GGGGGGGGGGGGGGGGGG

G

hGGGGGGGiGGGGG

G

GjGGG

GGG

kG G G G G

GGGGGG

GGGlGGGGGGGGGGGGG

GG

Gm

G

G

GGG

G

nG G G G G oG

Figure 2. Digital Control Board

G

GA : On/off Switch

B : Switch Legend

C : Power On Light, On Time Setting Mode

D : Compressor On Light, Off Time Setting Mode

E : Dewpoint Temperature Indicator

F : Selection Button

G : Enter Button (Drain Test Button)

H : Drain On LightG

G

G

G

G

DCB has LED type dew point indicators and electronic drain valve operation time adjusting,

When the dryer is normal running, the green LED will light on. The red indicator light

indicating a need for dryer operating condition checking. If all LEDs light on, the sensor for

dew point monitor is malfunction. The automatic drain valve controls allow the period of

drain opening to the set from 0.5 sec to 9 sec and drain valve closed time to be set from

0.5 min to 15 min. When the “G” button(drain test button) is pushed, the “H” LED is on and

the drain port clicks open with a cleaning audible sound.

Goodnal STP ST041 Site Services (Jemaco HXK Series Refrigerated Air Dryers HX76K to HX601K Installation

Q-Pulse Id VM409

Active 29/10/2013

Page 8 of 24

9

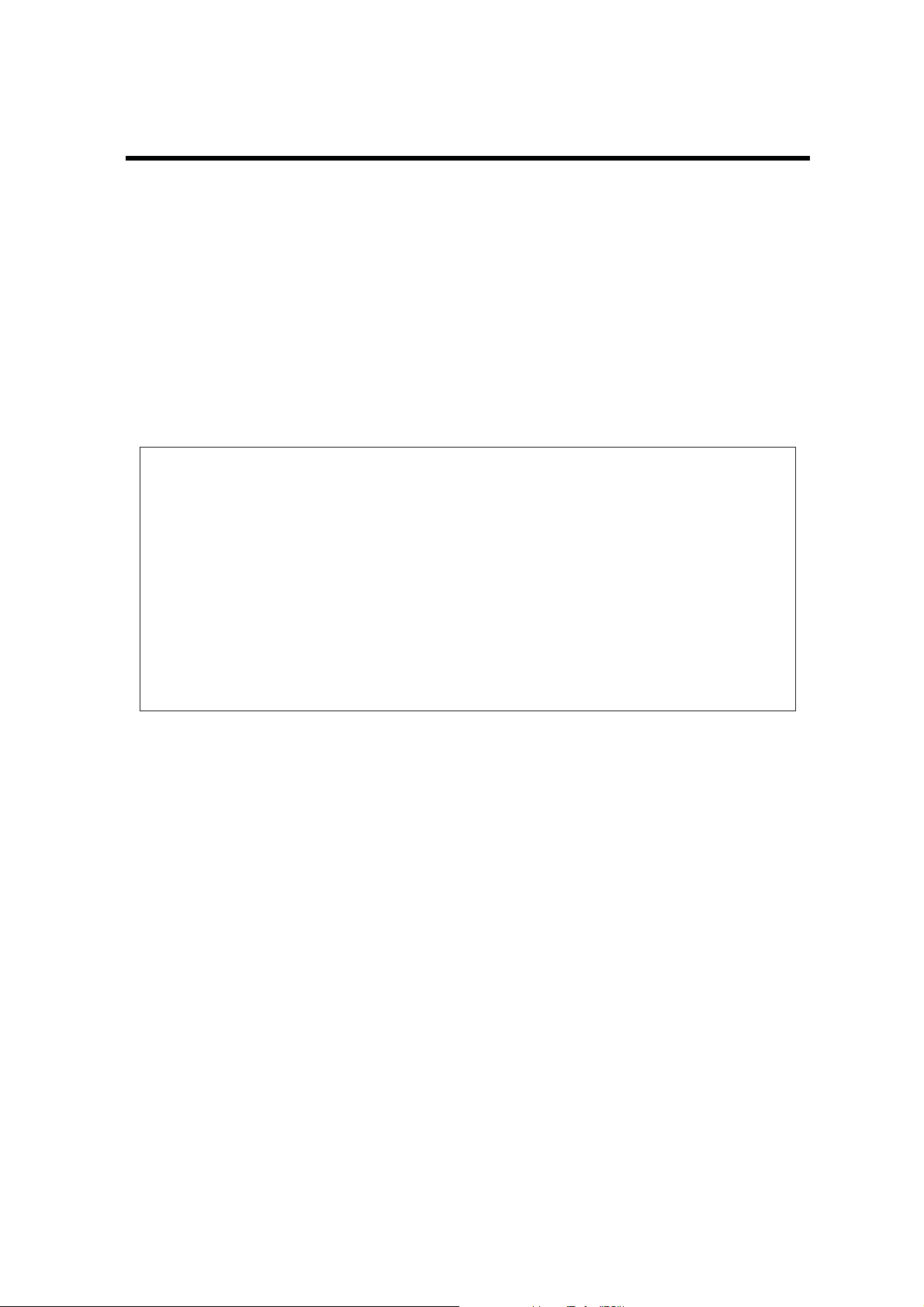

AUTOMATIC DRAIN VALVE SETTING

"E" LAMP 1st 2nd 3rd 4th 5th 6th 7th 8th 9th

ON TIME

(SEC) 0.5 1 2 3 4 5 7 9

Continuous

(Drain Trap

Option)

OFF TIME

(MIN) 0.5 1 2 3 5 7 9 10 15

1. Press the “F” and “G” buttons at the same time for 3 seconds, the “C” LED will start to

flash, and the illuminated LED on the “E”(Dew Point Temperature Indicator) LED will

identify the factory setting for “On Time”. (See table)

2. Press and release the “F” button to sequence from left to right until reaching your

selection. The “Red” LED is not used.

3. To store the On time and set the Off time, press the “G” button and set as step 2.

4. Exiting the Program will cause the Timer Drain to discharge and begin a new cycle.

Note: Failure to perform step 3 within 10 seconds of completing step 2 will cause the unit

to revert back to the previous setting.

* Operating check points

Check the following on a periodic basis:

A. Green power on light is illuminated.

B. Dewpoint indicator is in green area.

C. Condensate is discharging from drain.

Electronic Drain Valve Adjustment

To minimize air losses, the drain valve control time should be adjusted to open the drain

port just long enough to discharge accumulated condensate. Set the drain valve operating

time so that only air discharges at the end of the open period. Recommended initial

settings are a 1 to 2-second drain opening and 30 seconds drain closed time (cycle). If

liquid discharges as the port is closing, set the timer for a shorter cycle or a longer opening.

Goodnal STP ST041 Site Services (Jemaco HXK Series Refrigerated Air Dryers HX76K to HX601K Installation

Q-Pulse Id VM409

Active 29/10/2013

Page 9 of 24

10

START-UP

Follow the procedure below to start your dryer. Failure to follow the prescribed start-up

procedure will invalidate the warranty. If problems arise during start-up, call your dis-

tributor.

1. Turn the dryer ON/OFF switch to OFF.

2. Turn on the main electrical power to the dryer.

3. Don’t turn the power switch to ON directly! Refer to the below.

To start dryer :

1. Turn the power switch to ON. The refrigerant compressor will turn on.

2. Confirm that condensate is discharging from the drain valve.

3. Check drain valve timing. See Electronic Drain Valve section for drain valve adjust-

ment procedure.

4. Check that the main electrical supply voltage matches the voltage specified on the

dryer data plate.

5. Check proper connection and support of compressed air lines to the dryer; check

bypass valve system, if installed.

6. Ensure adequate ventilation for air-cooled dryers.

7. Confirm that the inlet air temperature, pressure and airflow to the to the dryer meet the

specified requirements (see Table 4 & 5)

8. confirm that the condensate lines from the drain valve discharge into a collection tank

or an environmentally-approved disposal system.

9. If the refrigerant Suction Pressure Gauge is out of range, refer to the Field Service

Guide for information or contact your local distributor.

The dryer is designed to run continuously. Let the dryer run even when the demand for

compressed air is interrupted; the dryer will not freeze up.

IMPORTANT

Energize dryer for 4 hours before refrigeration compressor is started! Never use the

disconnect switch to shutdown the dryer for an extended period of time (except for

repair). Failure to follow these instructions may result in a non-warrantable compressor

failure.

Goodnal STP ST041 Site Services (Jemaco HXK Series Refrigerated Air Dryers HX76K to HX601K Installation

Q-Pulse Id VM409

Active 29/10/2013

Page 10 of 24

11

SHUTDOWN

When the dryer must be shut down for maintenance or other reasons, use the following

procedures.

If electrical repairs must be made :

1. Turn off the power switch.

2. Disconnect the main power supply.

3. Lock out and tag the power supply in accordance with OSHA requirements.

DANGER

Portions of the control circuit remain energized when the power switch is in the OFF

position. Disconnect supply power to the dryer before performing maintenance on the

electrical system.

Dismantling or working on any component of the compressed air system under

pressure may cause equipment failure and serious personal injury.

Before dismantling any part of the dryer or compressed air system, completely

vent the internal pressure to the atmosphere.

If mechanical repairs must be made, vent the internal pressure of the dryer to atmospheric

pressure. After the refrigerant compressor become cool, restart the dryer according to

the start-up instructions.

Goodnal STP ST041 Site Services (Jemaco HXK Series Refrigerated Air Dryers HX76K to HX601K Installation

Q-Pulse Id VM409

Active 29/10/2013

Page 11 of 24

12

MAINTENANCE

The dryers require little maintenance for satisfactory operation. Good performance can be

expected if the following routine maintenance steps are taken.

DANGER

Dismantling or working on any component of the compressed air system under

pressure may cause equipment failure and serious personal injury. Before dis-

mantling any part of the dryer or compressed air system, completely vent the

internal pressure to the atmosphere.

General

For continued good performance of your refrigerated dryer, all refrigeration system

maintenance should be performed by a competent refrigeration mechanic. Before correc-

tive maintenance is done during the warranty period, call your local distributor and

proceed according to instructions.

Daily

Check the operation of the electronic drain valve at least once during each 8-hour shift.

See the Field Service Guide for remedies to drain valve malfunctions. See the

ELECTRONIC DRAIN VALVE section for drain valve adjustment.

Monthly

For air-cooled condensers, it is recommended to inspect the condenser coils monthly. If

necessary, remove dirt or other particles with compressed air from an OSHA-

approved air nozzle that limits its discharge pressure to 2.1 kgf/cm².

Returns to Manufacturer

If the dryer or a component of the dryer must be returned to the manufacturer, first call

your local distributor for a return authorization number and shipping address. Your

distributor will inform you whether the dryer or only a component must be returned. Mark

the package with the return authorization number and ship freight prepaid as directed by

your local distributor.

Electronic Drain Valve Disassembly and Servicing

The valve body is mounted on the frame bottom; a hose connects the valve body to the

Goodnal STP ST041 Site Services (Jemaco HXK Series Refrigerated Air Dryers HX76K to HX601K Installation

Q-Pulse Id VM409

Active 29/10/2013

Page 12 of 24

13

heat exchanger vessel.

CAUTION

Do not disassemble drain valve timer or attempt to repair electrical parts.

Replace timer if defective.

The drain valve discharges condensate through a full-port drain opening. The valve body

may need to be cleaned under conditions of gross particulate contamination.

To disassemble the drain valve body for cleaning and other maintenance :

1. Turn power switch off.

2. Disconnect main power supply to dryer.

3. Lock out and tag power supply in accordance with OSHA requirements.

WARNING

If power supply is not disconnected before disassembly, serious personal injury

and valve damage may result.

4. Remove hoses that connect the drain valve to the drain valve strainer.

5. Remove screw and washer from front of the drain valve.

6. Remove the power supply connector and gasket(with the timer assembly if attached)

from the solenoid coil housing. Do not damage or lose the gasket.

7. Remove coil fixing nut and spring washer from top of solenoid coil housing.

8. Lift solenoid coil housing off solenoid core in valve body.

9. Unscrew solenoid core from valve body.

Once the drain valve is disassembled, the following maintenance can be performed.

1. Inspect internal parts of valve body; clean or replace as required.

2. Remove debris from valve body.

3. Wipe solenoid core components with a clean cloth or blow out debris with com-

pressed air from an OSHA-approved air nozzle that limits its discharge pressure to

2.1 kgf/cm².

4. Check that the inside part assembly is clear and solenoid coil moves freely in housing

5. If timer is attached to valve body, check electrical continuity across timer assembly.

To reassemble the drain valve, reverse the sequence of the preceding steps. After the

drain valve is reassembled, connect the main power supply to the dryer.

When the dryer is returned to service, check the drain valve for air or condensate leaks;

tighten connections as required to correct leaks. Check the drain cycle; adjust the timer

according to the procedure in the drain valve adjustment section.

Goodnal STP ST041 Site Services (Jemaco HXK Series Refrigerated Air Dryers HX76K to HX601K Installation

Q-Pulse Id VM409

Active 29/10/2013

Page 13 of 24

14

FIELD SERVICE GUIDE

Problems most frequently encountered with refrigerated dryers are water downstream of

the dryer and excessive pressure drop. Most causes can be identified and remedied by

following this guide.

DANGER

Closed refrigeration systems are potentially dangerous. Work on the refrigeration

system must be done only by a competent licensed refrigeration mechanic.

Do not release fluorocarbon refrigerants to the atmosphere. Do not discharge

liquid refrigerants into floor drains. Refrigerant vapors may accumulate in low

places. Inhalation of high concentrations may be fatal.

Do not smoke while working on the refrigeration system or when a refrigerant leak is

suspected. Burning materials may decompose refrigerants, forming toxic gas or acids

that may cause serious injury and property damage.

The refrigerant valves are adjusted at the factory with the refrigerant system operating

and no airflow through the dryer. While the dryer is operating, the suction pressure may

fluctuate slowly with changes in the refrigeration load. To determine the suction

pressure, see the Refrigerant Suction Pressure Gauge mounted on the front panel.

Goodnal STP ST041 Site Services (Jemaco HXK Series Refrigerated Air Dryers HX76K to HX601K Installation

Q-Pulse Id VM409

Active 29/10/2013

Page 14 of 24

15

FIELD SERVICE GUIDE

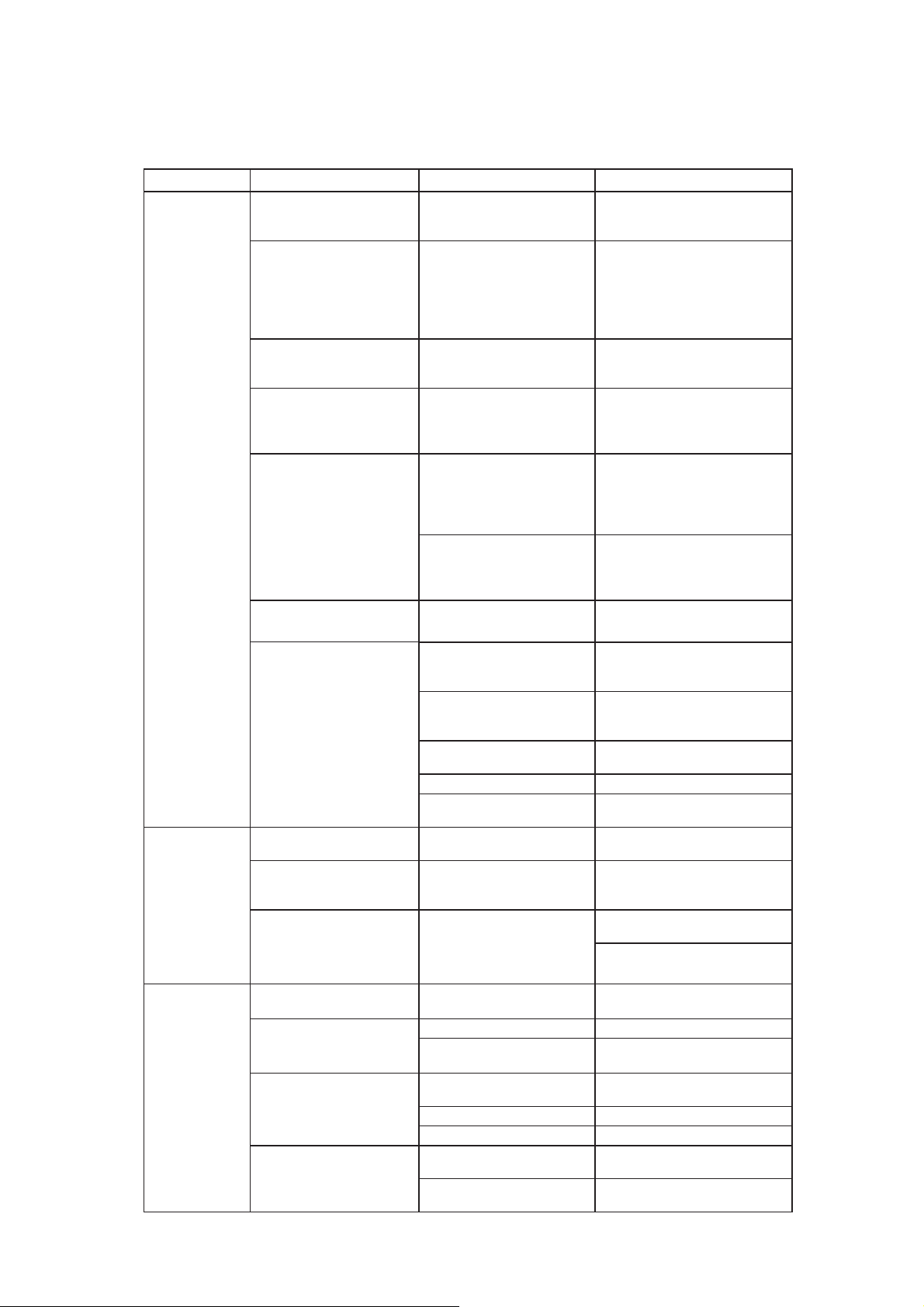

PROBLEM SYMPTOM POSSIBLE CAUSE REMEDY

Water

downstream

of dryer.

No discharge from

automatic drain valves

(ADV).

ADV failure or accumula-

tion of dirt in drain valve

strainer.

Dismantle drain valve:

clean, repair or replace.

See maintenance section.

Inlet air temperature is

too high. Aftercooler malfunction.

Check aftercooler discharge

temperature. Reduce tem-

perature to 49ഒmax.;

reduce airflow if tempera-

ture is above 35ഒ.

Liquid water entering

dryer. Aftercooler drain valve

malfunction.

Dismantle aftercooler drain

valve ; clean, repair or

replace.

Excessive airflow

(may also cause high

pressure drop). Dryer improperly sized.

Check airflow and dryer

capacity(see Table 4).

Reduce airflow or resize

and replace dryer.

Compressor cuts out

on internal overload.

Inadequate ventilation of

refrigerant compressor.

Ensure adequate ventilation

of the condensing unit (see

Clearance). Motor will

restart automatically when

compressor is cool.

Leak in refrigeration

system.

Locate leak, repair and re-

charge. Motor will restart

automatically when

compressor is cool.

Compressor windings

read open or shorted. Compressor burned out. Have a refrigeration

mechanic check and replace.

The red LED light on

Inlet air temperature too

high.

Reduce aftercooler discharge

temperature to design con-

ditions(see Table 5).

Excessive airflow. Check airflow and system

capacity. Reduce airflow or

resize and replace system.

Condenser fouled or

clogged. Clean or replace condenser.

Fan motor inoperative. Replace fan motor.

High ambient temperature. Ventilate area.

See Table 5

High pressure

drop across

dryer.

Inlet air temperature

is too low. Low ambient temperature. Consult your local

distributor.

Excessive airflow(may

also cause water

downstream of dryer). Dryer improperly sized. Check airflow and dryer

capacity. Reduce airflow or

resize and replace dryer.

Dryer icing up. -

Adjust operating conditions

to meet sizing conditions.

Adjust Expansion valve to

raise suction pressure

No condensate

from automatic

drain valve

(ADV)

Valve venting. But no

condensate from valve. Accumulation of dirt in

valve strainer. Dismantle valve strainer.

Strainer clean or replace.

Valve continuously

venting.

Clogged valve orifice. Replace valve.

Short in electrical

component. Check and replace connector

or DCB assembly.

Valve not cycling. No electrical power. Check and correct power

supply and connections.

DCB malfunction. Replace DCB assembly.

Solenoid coil malfunction. Replace solenoid coil.

No response when test

button is pushed.

No electrical power. Check and correct power

supply and connections.

Burn out fuse Check solenoid coil and wiring

cable and replace fuse.

Goodnal STP ST041 Site Services (Jemaco HXK Series Refrigerated Air Dryers HX76K to HX601K Installation

Q-Pulse Id VM409

Active 29/10/2013

Page 15 of 24

16

PROBLEM SYMPTOM POSSIBLE CAUSE REMEDY

Dew Point

indicator

malfunction All LED indicator light on Sensor malfunction Replace sensor assembly

Color indicator

out of green

zone

Indicator in red zone

Inlet air temperature too

high

Reduce aftercooler discharge

temperature to design

conditions (see Table 1).

Excessive airflow Check airflow and system

capacity. Reduce airflow or

resize and replace system.

Condenser fouled or

Clogged Clean or replace condenser.

High ambient temp. Ventilate area.

Improper adjustment of

Expansion valve.

Remove cap from the exp.

valve and turn the screw until

the indicator is in the green

zone.

Indicator in blow zone Improper adjustment of

Expansion valve Adjust the exp. valve until the

indicator is in the green zone.

Table 1

SUCTION PRESSURE

REFRIGERANT WITHOUT AIRFLOW WITH AIRFLOW

R-134a (HX76K/101K) 2.2s0.1 bar 2.6s0.5 bar

R-407C (HX151K~601K) 4.2s0.1 bar 4.8s0.7 bar

Do not adjust refrigerant valves without factory authorization. Adjustments must be made

only with no airflow into the dryer.

CAUTION

Do not introduce mineral oils into the refrigeration system of the dryers.

Servicing equipment should contain NO TRACE OF MINERAL OILS.

Table 2

REFRIGERANT PRESSURE SWITCH SETTINGS

MODEL Fan Pressure Switch Setting

ON OFF

HX76K ~101K 12 ·1 bar 7 ·1 bar

HX151K~601K 21 ·1 bar 15 ·1 bar

MODEL High Pressure Switch Setting

Cut-out Cut-in

HX76K~101K 21 ·1 bar Manual Reset

Goodnal STP ST041 Site Services (Jemaco HXK Series Refrigerated Air Dryers HX76K to HX601K Installation

Q-Pulse Id VM409

Active 29/10/2013

Page 16 of 24

17

HX151K~601K 28 ·1 bar Manual Reset

Table 3

DIMENSIONS AND CONNECTION SIZES

MODEL

DIMENSIONS

( mm ) INLET-OUTLET

CONNECTIONS

(PT, Male, inch)

HWD

HX76K / 101K 601 363 861 1

HX151K 601 363 921 1

HX201K / 251K 761 443 971 2

HX351K / 426K 811 493 1151 2

HX500K 811 493 1251 2

HX601K 811 543 1321 2 1/2

Table 4

DRYER SPECIFICATIONS

MODEL

RATED

CAPACITYa

(N

/min)

POWER

SUPPLY

(V / PH/Hz)

WEIGHT

(kg)

INPUT

POWER

(kW)

REFRIGERANT

TYPEb

HX76K 2.50 230/1/50 50 0.58 R134a

HX101K 3.00 230/1/50 53 0.60 R134a

HX151K 4.92 230/1/50 58 0.87 R-407C

HX201K 6.67 230/1/50 78 1.39 R-407C

HX251K 8.00 230/1/50 85 1.58 R-407C

HX351K 10.08 230/1/50 100 2.06 R-407C

HX426K 13.33 230/1/50 112 2.61 R-407C

HX500K 15.00 230/1/50 134 2.82 R-407C

HX601K 18.02 380~420/3/50 152 3.40 R-407C

aRating conditions are 35inlet temperature, 7barg inlet pressure, 100% inlet relative humidity, 25ambient temperature

@ 50Hz.

bRefer to dryer data plate for refrigerant charge.

Table 5

DRYER OPERATING CONDITIONS

MODEL NO.

Maximum

Inlet Air

Pressure

Minimum

Inlet Air

Pressure

Maximum

Inlet Air

Temperature

Minimum

Inlet Air

Temperature

Maximum

Ambient Air

Temperature

Minimum

Ambient Air

Temperature

All models 16barg 3barg 494434

Note : Continuous operation in the above maximum and minimum operating conditions is not allowable.

Goodnal STP ST041 Site Services (Jemaco HXK Series Refrigerated Air Dryers HX76K to HX601K Installation

Q-Pulse Id VM409

Active 29/10/2013

Page 17 of 24

18

Goodnal STP ST041 Site Services (Jemaco HXK Series Refrigerated Air Dryers HX76K to HX601K Installation

Q-Pulse Id VM409

Active 29/10/2013

Page 18 of 24

19

Drawings

G

lGzG

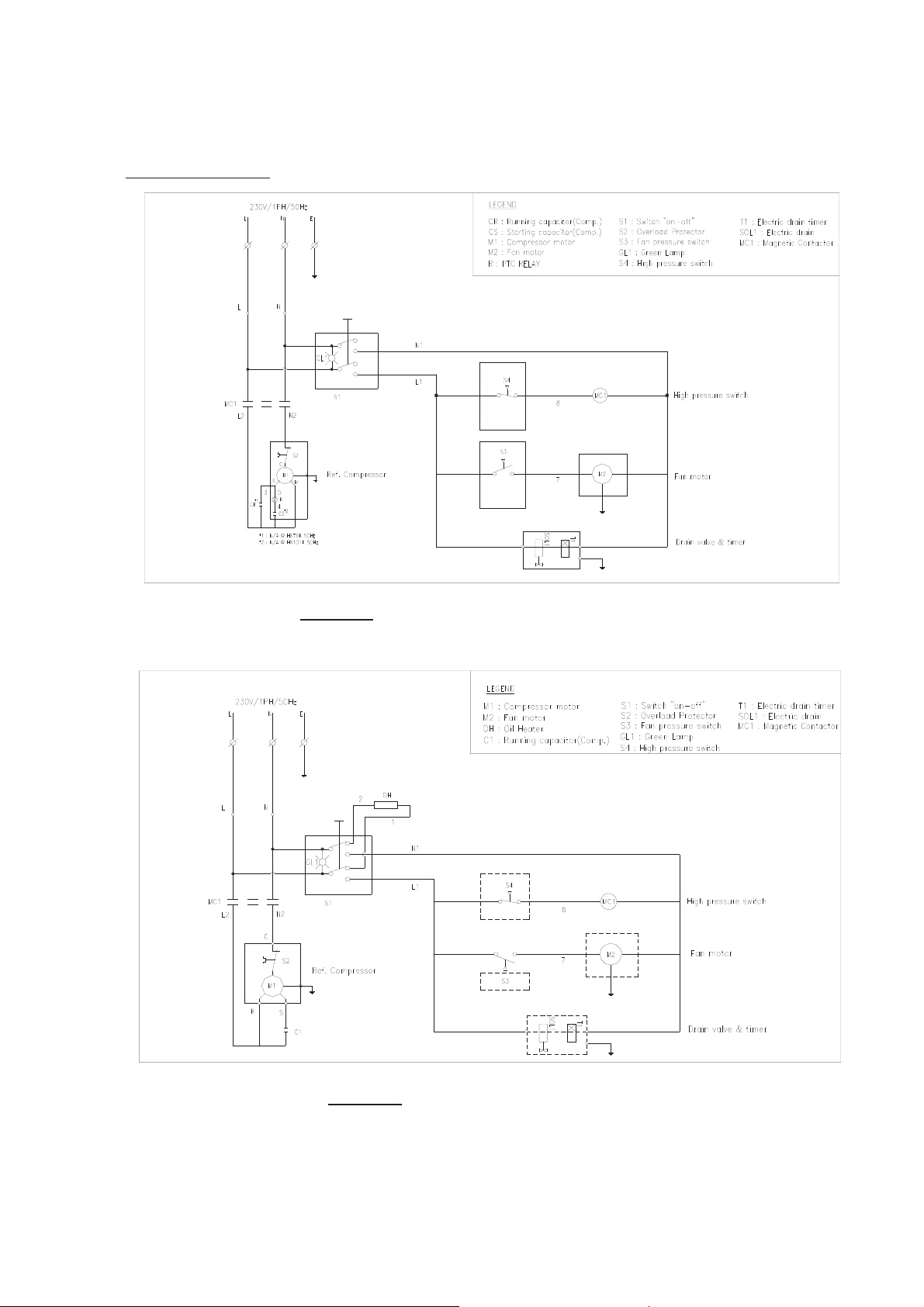

Figure 3.a Electric Schematic – HX76K / HX101KG

G

G

Figure 3.b Electric Schematic – HX151K

G

G

G

G

G

G

Goodnal STP ST041 Site Services (Jemaco HXK Series Refrigerated Air Dryers HX76K to HX601K Installation

Q-Pulse Id VM409

Active 29/10/2013

Page 19 of 24

20

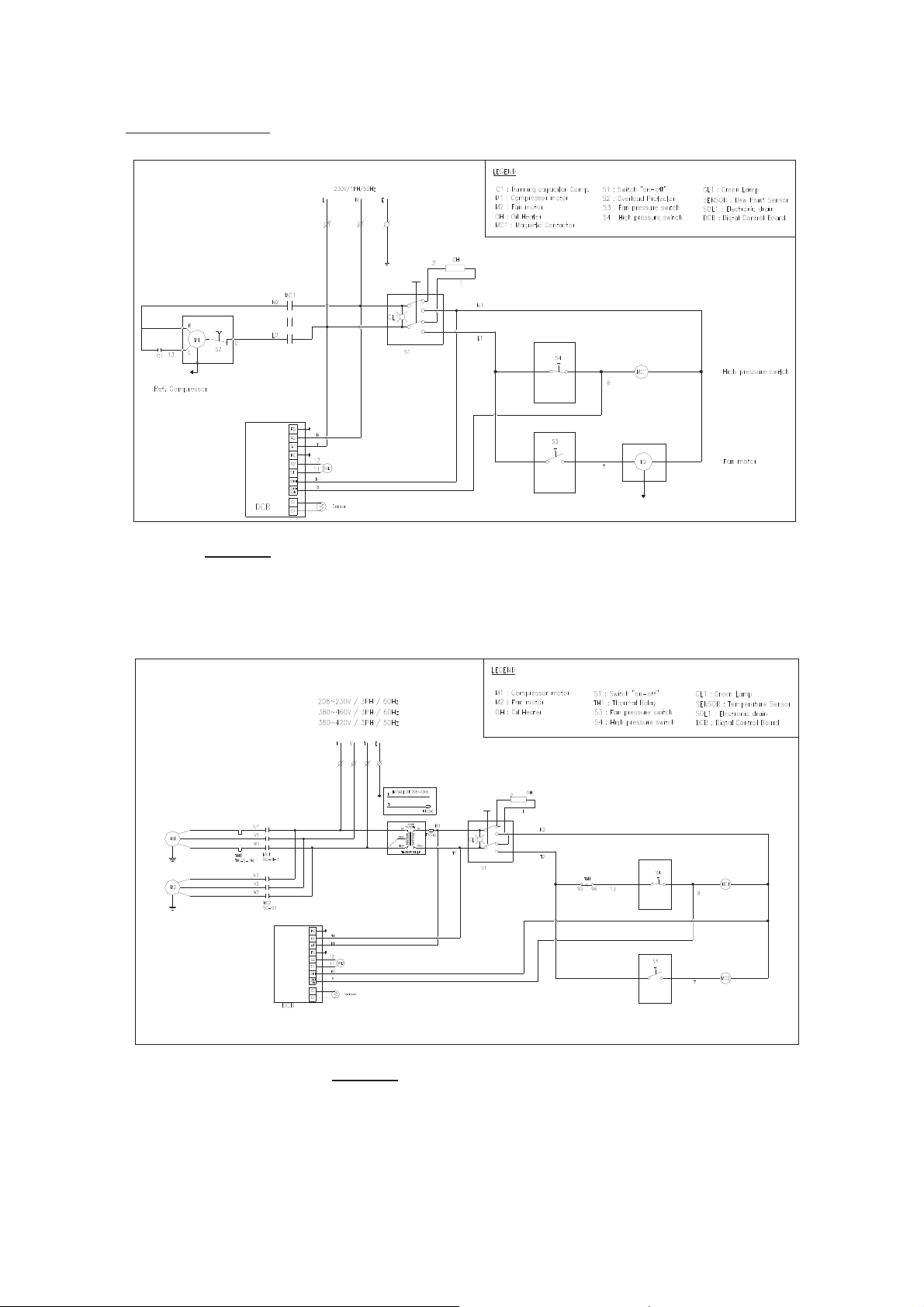

lGzG

G

Figure 3.c Electric Schematic - HX201K / HX251K / HX351K / HX426K / HX500KG

G

Figure 3.e Electric Schematic – HX601K

G

G

G

G

G

G

G

Goodnal STP ST041 Site Services (Jemaco HXK Series Refrigerated Air Dryers HX76K to HX601K Installation

Q-Pulse Id VM409

Active 29/10/2013

Page 20 of 24

This manual suits for next models

8

Table of contents

Other SPX Dryer manuals

Popular Dryer manuals by other brands

LG

LG SteamDryer LSDG389VS owner's manual

Whirlpool

Whirlpool LE5805XP Use and care guide

Alliance Laundry Systems

Alliance Laundry Systems ADG41F1 installation instructions

Beko

Beko DCU 9330 Installation & operating instructions and drying guidance

Miele

Miele TKR 650 WP operating instructions

Samsung

Samsung DV419AE series user manual

Bosch

Bosch WTA74201IN Installation and operating instructions

GE

GE DuraDrum GTDX200GM Dimensions and installation information

Asko

Asko TL751 XXL Training program

Whirlpool

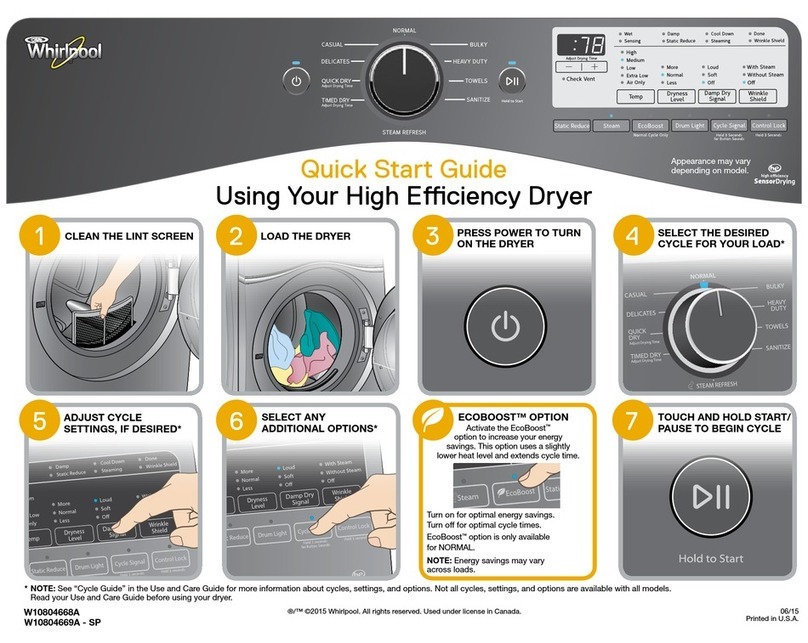

Whirlpool W10804668A quick start guide

Siemens

Siemens WQ45G2AFDN User manual and installation instructions

Whirlpool

Whirlpool LE5721XS Use & care guide