Staber Industries HXW2304 User manual

STABER CLOTHES WASHER

Operator’s Manual

Installation/Operation/Maintenance/Parts

Part Number 818235

Printed in USA

HXW2304

HXW2305

HXW2404

HXW2405

HXW2504

HXW2505

We are pleased that you have selected a Staber clothes washer as one of

your appliances. Your clothes will be washed using a tumble action inner

tub. Please register your new Staber washer on our Internet web site,

www.staber.com.

An average of sixteen gallons of water per cycle moves through your clothes

to clean them, therefore less water and detergent is used than in agitator

washers. Your clothes spin at approximately 700-750 RPM during the spin

cycle, removing most of the water to reduce drying time.

You will receive many years of service with the durable stainless steel inner

and outer tubs. You will enjoy economic, environmental, and energy

savings. All parts of the Staber washer are completely recyclable.

To get the best performance from this clothes washer, operate and maintain

it according to the instructions in this manual.

Note the importance of safety. You and anyone else using or maintaining

this clothes washer are strongly urged to read this manual, especially all the

safety instructions.

WARNING and CAUTION, used with the triangular safety alert symbol,

highlight safety messages. Always read and understand these messages

because they relate to personal injury and your safety.

IMPORTANT messages refer to mechanical information and the possibility

of damaging a part or parts of the clothes washer.

NOTE identifies general information worthy of special attention.

3

4

5

6

8

9

13

15

FORWARD

CONTENTS

Important Safety Instructions

Warranty

Installation Instructions

Benefits and Washing Instructions for the Staber Washer

Operation

Maintenance

Troubleshooting Guide

Parts

2

3

Model, Series and Serial numbers are used to identify your new Staber

clothes washer. These numbers should always be referred to when

consulting the Customer Assistance Center concerning service, parts, or

other information you may require.

For your convenience and ready reference, enter Model, Series, and Serial

numbers below.

This safety alert symbol means CAUTION or WARNING – “personal safety instruction.” Read and

understand the instruction because it has to do with safety. Failure to comply with the instruction

may result in personal injury.

Improper use or maintenance of clothes washer can result in injury. To reduce potential for

injury, comply with the following safety instructions.

WARNING –To reduce the risk of fire, electric shock, or injury to persons when using this appliance,

follow basic precautions, including the following:

1Read all instructions before using the appliance.

2Do not wash articles that have been previously cleaned in, washed in, soaked in, or

spotted with gasoline, dry-cleaning solvents, or other flammable or explosive substances

as they give off vapors that could ignite or explode.

3Do not add gasoline, dry cleaning solvents, or other flammable or explosive substances

to the wash water. These substances give off vapors that could ignite or explode.

4Under certain conditions, hydrogen gas may be produced in a hot water system that has

not been used for two weeks or more. HYDROGEN GAS IS EXPLOSIVE If the hot water

system has not been used for such a period, before using this washing machine, turn on all

hot water faucets and let the water flow from each for several minutes. This will release any

accumulated hydrogen gas. Since the gas is flammable, do not smoke or use an open

flame during this time.

5Do not let children play on or around the appliance. Close supervision is necessary when

the appliance is used near children.

6Before the appliance is removed from service or discarded, remove the top lid assembly.

7Do not reach into the appliance if the clothes basket is moving.

8Do not install or store this appliance where it will be exposed to the weather.

9Do not tamper with any controls.

10Do not repair or replace any part of the appliance or attempt any servicing until contacting

customer service, unless specifically recommended in the user-maintenance instructions

or in published user-repair instructions that you understand and have the skills to carry out.

Model number.

Series number.

Serial number.

PRODUCT IDENTIFICATION

IMPORTANT SAFETY INSTRUCTIONS

4

This appliance must be grounded. In the event of malfunction or breakdown,

grounding will reduce the risk of electric shock by providing a path of least

resistance for electric current. This appliance is equipped with a cord having

an equipment grounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly installed and grounded

in accordance with all local codes and ordinances .

WARNING – Improper connection of the equipment grounding conductor

can result in the risk of electric shock. Check with a qualified electrician or

service person if you are in doubt as to whether the appliance is properly

grounded. Do not modify the plug provided with the appliance. If it will not

fit the outlet, have a proper outlet installed by a qualified electrician.

STABER INDUSTRIES DOES NOT ASSUME ANY RESPONSIBILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so this exclusion may not apply to you.

This warranty gives you specific legal rights and you may have other rights which may vary from state to state.

If you need service, first see the "Troubleshooting Guide" section of the Operator's manual. After checking the "Troubleshooting Guide",

additional help can be found by calling our Customer Assistance Center telephone number 1-614-548-0098.

All warranty parts must be returned to the factory freight prepaid.

IMPORTANT GROUNDING INSTRUCTIONS

Length of warranty

ONE YEAR FULL WARRANTY

FROM DATE OF PURCHASE

FIVE YEAR LIMITED WARRANTY

ONE YEAR FULL PLUS SECOND THROUGH

FIFTH YEAR LIMITED

FROM DATE OF PURCHASE

TWENTY-FIVE YEAR LIMITED WARRANTY

FROM DATE OF PURCHASE

Staber Industries will pay for:

Replacement parts and/or repair labor with

prior written authorization to correct

defects in materials or workmanship.

Replacement parts for the Bearing Assembly

& Suspension System if defective in materials

or workmanship.

Replacement parts for the outer tub

module if the tub develops a water leak

caused by rust through as a result of

defective materials or workmanship.

Staber Industries will not pay for:

AService calls to:

1Correct the installation of the

washer.

2Instruct you how to use the

washer.

3Correct wiring, correct

plumbing or replace house

fuses.

BLabor charges when washer is used in

other than normal home use.

CLabor charges for other than normal

grid power usage.

DDamage resulting from accident,

alteration, misuse, abuse,

improper installation or

installation not in accordance

with local electrical and

plumbing codes.

EAny labor costs during the

limited warranty.

FShipping charges for warranty parts or

labor for units operated

outside the Continental United States.

GPickup and delivery. This product

is designed to be repaired in

the home.

HRepairs to parts or systems

caused by unauthorized

modifications made to the

appliance.

WARRANTY

5

CAUTION: Use great care when loading, unloading or working around

clothes basket with top lid raised. DO NOT allow any items to fall between

inner and outer tubs. If this should occur DO NOT START WASHER. The

item must be removed from the tub or damage to the clothes basket or

water system may occur. If the item cannot be removed by rotating the

clothes basket, we recommend removing the item though the sump hose.

Refer to maintenance procedures for details.

Uncrate clothes washer using care not to scratch or damage surface of washer.

IMPORTANT: When lifting or moving clothes washer, always do so from

left and/or right side of washer. Lifting or moving from the front or back

may damage clothes washer.

Lift clothes washer straight up off bottom of shipping container and

remove styrofoam shipping block. Unpack clothes basket and accessories.

NOTE: We recommend that all shipping materials be either retained for

later use in moving the clothes washer or recycled through a local solid

waste management agency.

The water fill hoses are pre-attached to the water inlet valve on the rear of

the washer and should not be removed during installation.

Place clothes washer in position taking care to move clothes washer by

moving only from either side.

Level clothes washer side-to-side and front-to-back. DO NOT level washer

with front higher than back, damage to internal parts can result.

Place a bubble level on top of clothes washer with lid open. Loosen

locknuts on leveling legs and level washer. Keep leveling legs as close to

washer frame as possible.There should be an equal amount of weight on

all four legs.

After washer is level, secure legs by rotating locknuts up against washer

frame. Locate the four foot pads and install one on each leveling leg.

Recheck level of clothes washer and adjust as necessary.

Remove all but the lowest drain hose shipping ties from back of washer.

Form a 'gooseneck' in free end of hose, place end in standpipe and secure.

Attach free end of each fill hose to appropriate water supply, top hose to

hot water supply and bottom hose to cold water supply. Turn water on

and check for leaks.

Plug power supply cord into grounded 120V60Hz electrical receptacle only.

WARNING: Do not use adapter plug, extension cord, or remove

grounding prong from power supply cord. Do not modify plug provided

with this clothes washer. If it will not fit a properly grounded outlet, have a

properly grounded outlet installed by a qualified electrician. Electrical

current can cause fire and serious bodily harm.

INSTALLATION

Grounding type

wall receptacle

6

1Washes more clothes per load than a traditional agitator washer

and saves on drying time with superior moisture extraction.

2. Gentle wash action ensures less wear and tear on clothes (clothes last longer).

3. Conserves water, energy, and money spent on laundry products.

TO WASH CLOTHES, FOLLOW THESE SIMPLE INSTRUCTIONS

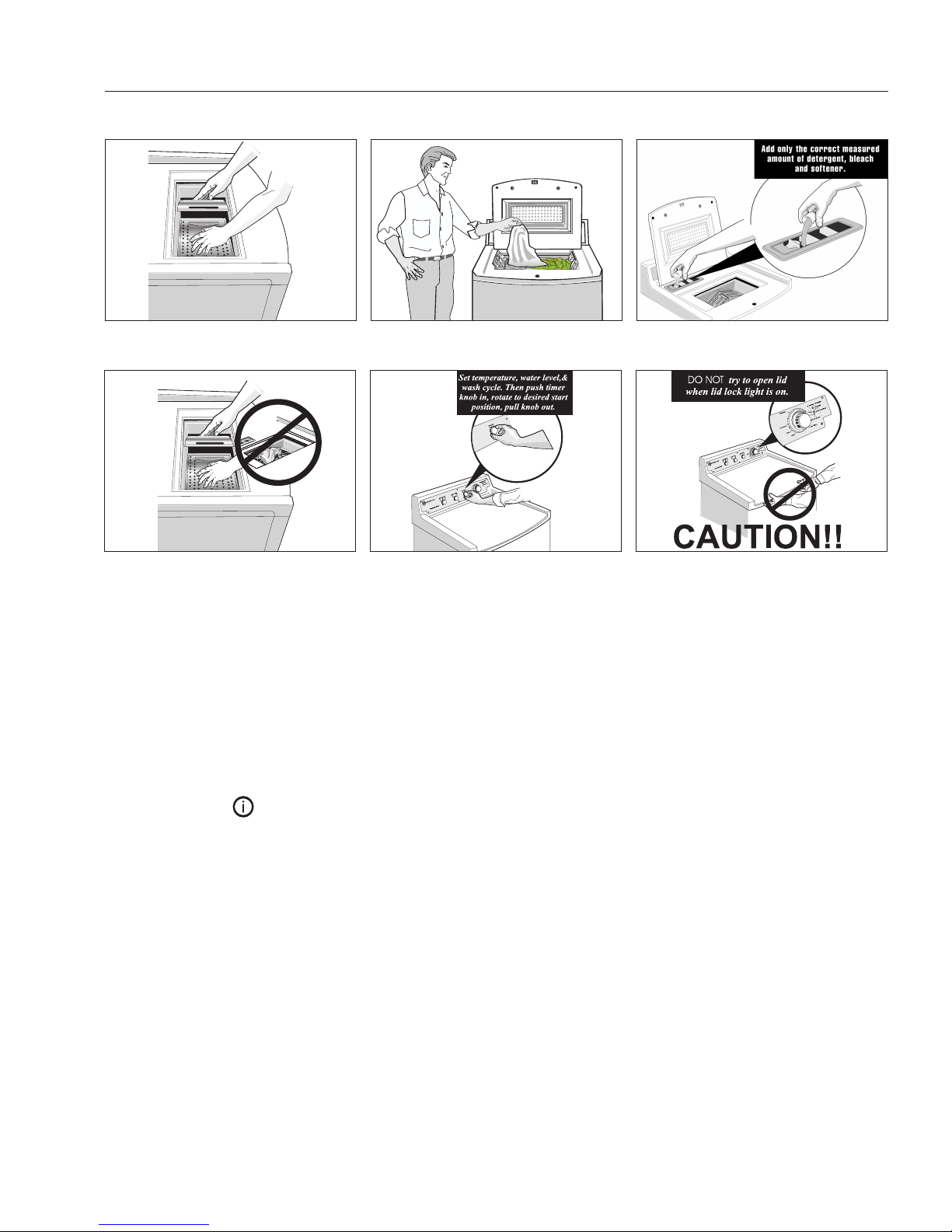

STEP 1 After raising top outer lid, open access doors to clothes basket. Using

both hands, one on each door, firmly depress safety latch on left

door to release latching hook; slowly allow the doors to spring open.

STEP 2 Load tub with clothes--tub can be lightly packed without affecting

wash performance.

STEP 3 Add measured amount of detergent/bleach/softener as follows:

IMPORTANT: Use an average of only one ounce of detergent,

bleach, or fabric softener. Using more detergent than

recommended decreases the cleaning effectiveness, can cause

suds or water to overflow and may damage the washer. If using a

water softener, less detergent may be required.

PREWASH CYCLE

Pour 1 OUNCE each, of low sudsing detergent, bleach (if

desired) and fabric softener (if desired) into designated reservoirs,

adding up to one additional OUNCE of detergent to the reservoir

marked "pre-wash."

NORMAL WASH CYCLE

Pour 1 OUNCE each, of low sudsing detergent, bleach (if

desired), and fabric softener (if desired) into designated reservoirs.

If using powdered detergent, pour NOT MORE THAN

2 OUNCES over clothes.

STEP 4 Using both hands, close inner access doors ensuring that left door

“latching hook” securely engages right side “louver”. Close top lid.

STEP 5 Set temperature, water level, and wash cycle selection switches.

Push timer knob in, rotate to desired start position, pull timer knob

out. The red light will come on to indicate power to the washer

and agitation will start. The green “lid locked” light only lights

during spin portions of the cycle. To gain access to clothes after

washer has started to agitate, wait for washer to stop agitating,

then open lid. If the lid is opened while washer is agitating the

loading doors may not be at the top.

Caution –DO NOT attempt to raise the top lid when the lid locked

lamp is lit. To gain access to clothes tub after washer has started to

spin, push timer knob in. Lid locked lamp will go out within two

minutes and top lid may then be opened.

BENEFITS OF STABER WASHER

7

STEP 4 STEP 5 CAUTION

FOUR THINGS THAT AFFECT THE CLEANLINESS OF YOUR CLOTHES

1. The amount of Agitation: Equipped with a patented inner and outer tub,

the Staber washer is designed to increase the agitation rate

allowing for minimal use of chemicals, heat and time per wash load.

2. The amount of Detergent used: The increased agitation performance

eliminates the need for excess detergent, leaving your clothes smelling

less like perfume and more like natural woven fabrics.

Note: Using too much detergent will cause oversudsing and create a

'whiteout' condition. This prevents all agitation and will cause poor wash

performance. Using more detergent does not mean cleaner clothes!

3. The amount of Heat used: Use hot water for white loads and use warm

or cold water for other colors. The wash temperature can be increased

to allow for more energy to break down the unwanted particles on your

clothes.

4. The amount of Time washed: By using the pre-wash cycle with

detergent, the Staber washer allows for more time to break down

unwanted dirt particles, getting your clothes cleaner in one wash load.

The Staber washer is designed to eliminate the need to increase

the above mentioned items while ensuring the maximum cleaning per

wash cycle.

STEP 1 STEP 2 STEP 3

8

CONTROLS

Temperature Controls temperature of wash water only. Clothes washer is

designed to use cold water for rinses.

Water level Controls amount of water entering clothes washer during

each fill. Use High setting for all normal loads containing a fully or loosely

packed tub. Use Low setting for loads containing only a few garments.

Wash cycle Controls agitation speed, agitation duty cycle and spin speed.

Use Normal setting for most fabrics; it has the fastest spin speed. Perm

and Delicate settings have the slower spin speeds. Use Perm setting for

cottons and blends with a No-Iron fabric. Use Delicate setting for delicate

and knit items.

Timer Controls selection of pre-wash cycle and length of wash cycle.

Power lamp ON indicates that power is being applied to electronics to

start clothes washer.

Lid locked lamp ON indicates that lid lock has locked and spin cycle can

begin. OFF indicates that lid lock has released and top lid may be safely

opened. DO NOT attempt to open lid while this lamp is ON.

LIQUID DISPENSING SYSTEM

All holding reservoirs will retain a maximum of 2 ounces of liquid solution.

Flow through reservoir serves as a funnel to dispense a pre-measured

amount of low sudsing liquid detergent or bleach into wash tub without

pouring solution directly onto clothes in tub.

Recommended amount of low sudsing liquid detergent, bleach, or fabric

softener to use for normal wash loads is 1 ounce. For Low water level

setting, use 1/2 ounce.

Use a water-like concentration liquid fabric softener. Using a thick

concentrate softener can clog reservoir outlet. If clogging occurs, flush

reservoir with clean water.

OPERATION

PRESSHERE

LEFT HAND HERE

RIGHTHAND HERE

BLEACH

SOFTENER

USEBOTH HANDSTO OPEN&CLOSETUB

USE LIQUIDONLY

DETERGENT

DISPENSER

9

MAINTENANCE PROCEDURES

REMOVE FRONT PANEL

1Disconnect the appliance from the power source.

2Remove the four 5/16 headed screws located at the bottom of the front panel.

3After the screws have been removed, grasp the panel on both sides

and pull forward.

Allow the panel to drop free of the top assembly and set aside.

INSTALL FRONT PANEL

1Locate left and right side of front panel over guide pins on cabinet.

2While applying upward pressure, use a 5/16 nut driver and screw the

four 5/16 headed screws back in the bottom of the front panel.

HOW TO RAISE TOP ASSEMBLY

1Remove front panel.

2Remove the two 5/16-headed screws located at the upper left and

right corner of the edge of the cabinet. These two screws will allow

access to the interior of the machine. Set these two screws aside

separate from the other four screws because they may be different on

your machine.

3Lift up on the front of the top until the two front clips have cleared the

edge of the cabinet. Note: Secure the lid to the top panel with a piece

of tape or some other means. Once the top is raised vertically, the lid

might open and fall backwards. This could damage the lid or cause it

to become detached from the top.

4Pull the plastic top assembly towards you an inch to free up the

hinges on the back. Then lift the top until you can gain access to the

rear wall of the cabinet. Note: Again, secure the top so it will remain

open while you are working in this area. If the top is not secured, it

could fall closed while you are working in this area.

ACCESSING THE MOTOR CONTROL BOARD

1First unplug the machine from its power source.

2Remove front panel

3Raise top assembly

4The motor control board is now accessible. The location of the board

is on the rear upper right corner of the cabinet.

10

REPLACE DRIVE BELT

1Remove the front panel as directed under "REMOVE FRONT PANEL".

2Remove belt and inspect pulleys for wear and tightness.

3Install new belt on pulleys, check belt tension and adjust as necessary.

Install front panel on clothes washer as directed under "INSTALL

FRONT PANEL" and plug power cord into electrical receptacle.

REPLACE PUMP

1Remove the front panel as directed under "REMOVE FRONT PANEL".

2Remove sump and drain hoses from pump (with pliers) using a pan to

catch any trapped water.

3Remove wires from pump.

4Remove two bolts from pump and remove pump from clothes

washer.

5Install wires on new pump, install pump on clothes washer, reconnect

sump and drain hoses on pump and reinstall front panel as directed

under "INSTALL FRONT PANEL". Plug power cord into electrical

receptacle.

REPLACE DRIVE MOTOR

1Remove the front panel as directed under "REMOVE FRONT PANEL".

2Remove belt adjustment bolt and drive belt from motor.

3Remove clip and washer from pivot shaft. Slide shaft to rear far enough

to allow motor to come off shaft.

4Note position of wiring plugs on motor and remove plugs from motor.

5Install wiring plugs on new motor as noted, position motor on shaft, slide

shaft into position and secure with washer and clip. Install drive belt

adjustment bolt on motor. Install drive belt, adjust belt tension and

tighten adjustment bolt. Install front panel on clothes washer as directed

under "INSTALL FRONT PANEL" and plug power cord into electrical receptacle.

REPLACE TIMER

1Disconnect the appliance from the power source.

2Remove the six screws that hold the control panel to the top.

3Allow the control panel to slide down, pull the top of the control panel out

and lift up.

4Lay the control panel face down on the top while removing the timer.

5To release the setting knob pull out on the black shaft extending through the

timer. Pull off indicator dial.

6Remove the timer wire harness connection. Lift up locking tap and pull out

on the harness until the connector is free from the timer.

7Note the position of the timer. The replacement will be reinstalled in the

same position.

8Remove the 5/16 headed screw that holds the timer to the control panel.

9Lift up on timer locking tap labeled "1" and slide the complete timer to

the left and remove. Install the new timer in reverse sequence.

10 Install timer mounting screw.

11 Reinstall the wire connection. Once the timer connection is fully seated,

you will hear a slight click. This indicates that the locking tab is locked.

12 Replace the timer indicator dial. There is a flat on the inside of the

indicator that will match the flat on the timer plastic shaft. This will

align the indicator dial on the timer.

13 Install knob on timer and push black shaft extending through timer

until flush with rear of timer housing.

Replpump R1

PUMP

SUMP HOSE

DRAIN HOSE

11

14 Reinstall control panel to housing. Insert bottom of control panel into

housing first. Then slide the panel into place and secure with six

philips head screws.

NOTE: Do not over tighten the screws or you will strip the holes and

the screws will not hold.

15 Plug machine into the 120 vac power supply.

REPLACE TEMPERATURE, WATER LEVEL AND WASH CYCLE SWITCHES

1Disconnect the appliance from the power source.

2Remove the six screws that hold the control panel to the top.

3Allow the control panel to slide down, pull the top of the control panel

out and lift up.

4Lay the control panel face down on the top.

5Pull knob off switch to be replaced. Unscrew attaching nut from

switch and remove switch from front control panel. Note on a piece of

paper, position and color of electrical wires on switch. Remove wires

from switch.

6Install wires on new switch as noted. Install switch on control panel

using nut. Reinstall control panel by reversing procedures above.

Install knob on switch and plug in power cord.

12

REPLACE PRESSURE SWITCH

1Disconnect the appliance from the power source.

2Remove the six philips head screws that hold the control panel to the top.

3Allow the control panel to slide down, pull the top of the control panel

out and lift up.

4Lay the control panel face down on the top.

5Pull up on the pressure switch that is fastened to the bottom of the

control housing.

6Remove the connectors from the switch.

7To install a new switch, reverse the above procedures.

8Plug power cord into electrical receptacle.

REPLACE WATER VALVE

1Disconnect the appliance from the power source.

2Shut off the hot and cold water supply.

3Remove the six screws that hold the control panel to the top.

4Allow the control panel to slide down, pull the top of the control panel

out and lift up.

5Lay the control panel face down on the top.

6Using a 5/16 nut driver, remove the water valve hold down nut

located between the two electrical coils on the valve. Lift the water

valve from the control panel.

7Note on a piece of paper, position and color of electrical wires on the

water valve. Remove the wires from the valve.

8Remove the two inlet hoses from the water valve.

9Remove the outlet hose from the water valve.

10 Install a the new water valve on the clothes washer by reversing the

above procedures.

11 Turn on both water supplies. Check for water leaks.

12 Plug the power cord into electrical receptacle.

REPLACE LID LOCK SWITCH

1Remove the front panel as directed under "REMOVE FRONT PANEL".

2Remove two screws from lid lock switch bracket and remove switch

from clothes washer.

3Note on a piece of paper, position of wiring plug on switch. Remove

plug from switch.

4Install plug on new switch as noted and install switch on clothes

washer. Reinstall front cover as directed under "INSTALL FRONT PANEL"

and plug power cord into electrical receptacle.

13

PROBLEM

Power On light does not illuminate when

timer knob is pulled out.

Lid locked light does not illuminate during

spin cycle.

Water does not enter the clothes washer.

Water flows continuously.

Washer does not agitate.

CAUSE

Clothes washer not plugged in.

Electrical outlet does not have AC power.

Light is burned out.

Lid is not fully closed.

Microprocessor did not properly boot up.

Lid lock assembly has failed.

Motor control circuit board defective.

Water on circuit board.

Polarity is incorrect at receptacle.

Low voltage on inverter system

Light has burned out

Water supply turned off.

Screens in water inlet valve are plugged.

Water valve has failed.

Pressure switch has failed.

Water level switch has failed.

Water level switch hung up between high

and low.

Drain hose is not in stand pipe.

Pressure switch has failed.

Water level switch has failed.

Pressure switch tube is disconnected from

pressure switch.

Plugged pressure switch tube.

Motor control board has failed.

Motor has failed.

Drive belt has broken or come off the pulley.

J1 connector on motor control board is not

making contact.

Washer plugged into “Green Plug.”

Poor connection on timer plug.

CORRECTIVE ACTION

Plug power cord into properly grounded

receptacle.

Check fuse or circuit breaker.

Replace light.

Close lid completely.

Reset microprocessor, unplug machine for a

minimum of 30 seconds and plug back in.

Replace lid lock assembly.

Check inputs to circuit board.

Dry board.

Call electrician and correct.

Take inverter out of sleep mode and reset

microprocessor, unplug machine for a

minimum of 30 seconds and plug back in.

Replace light.

Turn water on.

Clean screens.

Replace water valve.

Replace pressure switch.

Replace water level switch.

Move switch to correct position.

Place hose in stand pipe and secure.

Replace pressure switch.

Replace water level switch.

Connect pressure tube.

Remove obstruction.

Check fuse on circuit board.

Replace motor.

Replace belt or reinstall drive belt.

Reset connector on board.

Do not use. Remove from circuit.

Reseat connector.

TROUBLESHOOTING

14 TROUBLESHOOTING

PROBLEM

Water does not drain from clothes washer.

Washer does not spin

Washer walks across floor.

Washer spins with a full tub of water.

Water leaks from washer.

Timer does not advance in prewash, wash

or rinse cycles.

CAUSE

Obstruction in sump area of outer tub.

Obstruction in sump hose.

Obstruction in pump.

Obstruction in drain hose or stand pipe.

Pump has failed.

Stand pipe higher than seven feet.

Poor connection on timer plug.

Motor control circuit has failed.

Pressure switch has failed.

Drive belt has broken or come off the pulley.

Motor has failed.

Out of balance switch has tripped.

Program selector switch has failed.

Pump did not pump out water.

Shipping block under motor not removed.

Washer not level.

Weight of washer not evenly distributed on

all four leveling legs.

Out of balance switch out of adjustment.

Defective control board.

Reverse polarity at receptacle.

Defective pressure switch.

Over sudsing of wash load.

Rubber skirt not in correct position.

Defective hose from water valve to soap

dispenser.

Defective drain hose.

Sump hose hanger not on

Not enough water.

CORRECTIVE ACTION

Remove obstruction.

Remove obstruction.

Remove pump and clear obstruction.

Remove obstruction.

Replace pump.

Shorten stand pipe.

Reseat connector.

Check circuit breaker on back of machine.

If showing white is has popped out and will

push gently- do not force.

Replace pressure switch.

Replace belt or reinstall drive belt.

Replace motor.

Wash a larger load.

Replace program selector switch.

Remove obstruction from pump.

Remove shipping block.

Level washer.

Adjust leveling legs properly.

Adjust out of balance switch.

Replace control board.

Call electrician and correct.

Change pressure switch.

Reduce amount of detergent. Do not use

Ultra products.

Reseat skirt into outer bezel.

Replace hose.

Replace drain hose and install in correct position.

Reinstall sump hose hanger

Check water supply.

Check inlet screens at water valve.

Replace water valve.

15

PARTS

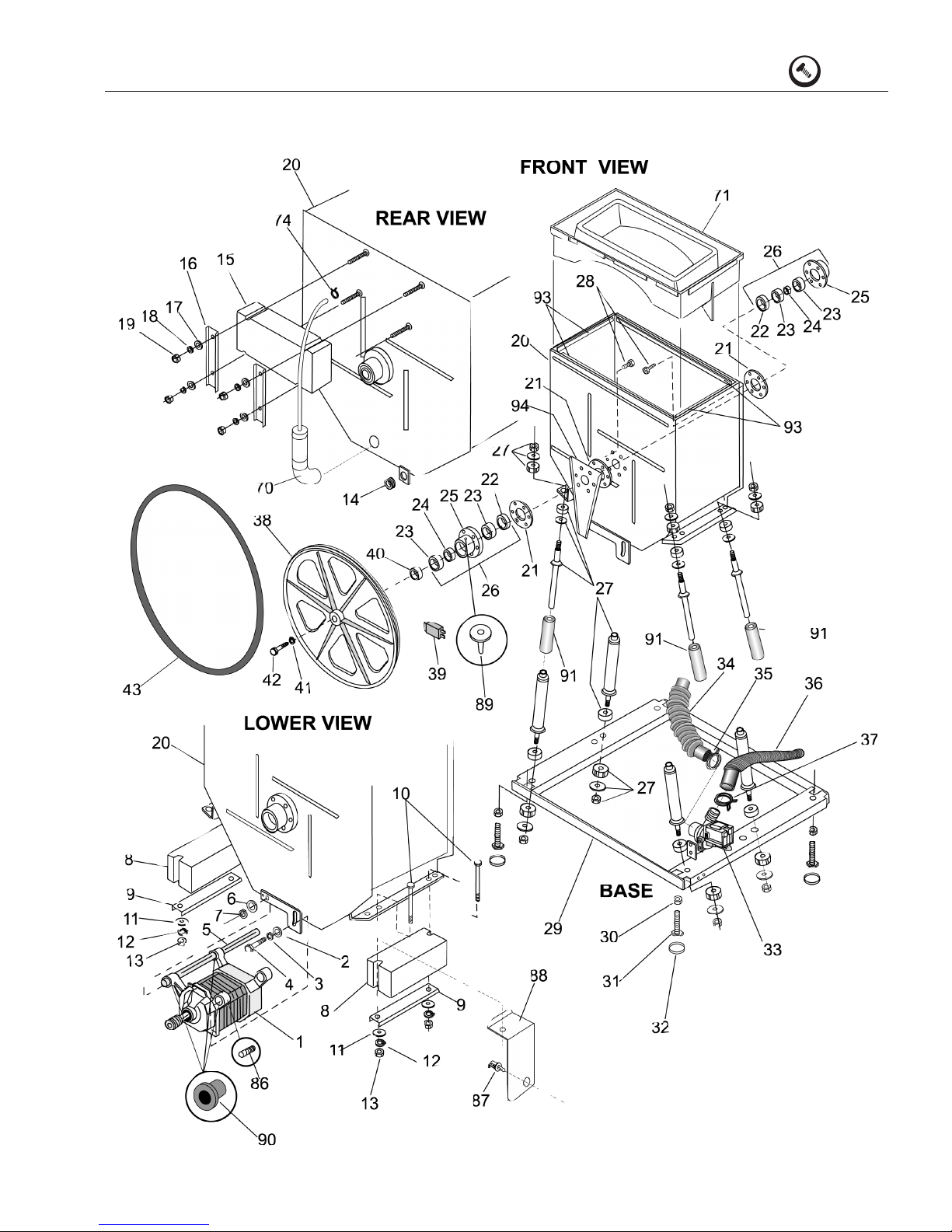

ITEM PART NUMBER DESCRIPTION QUANTITY

75 813271M Wiring Harness 1

76 813226 Motor Controller 1

77 813203 Lid Lock 1

78 814201 Pump 1

79 814237 Water Valve 1

80 813215 Pressure Switch 1

81 813209 Switch - Temperature 1

82 813223 Switch - Water Level 1

83 813211 Switch - Program Selector (Wash Cycle) 1

84 813267 Timer 1

1

85 813213 Indicator Light - Red 1

813214 Indicator Light - Green 1

86 813245 Circuit Breaker 10 AMP 1

16

ITEM PART NUMBER DESCRIPTION QUANTITY

1813217 Motor 1

2818225 Flat Washer 5/16 1

3818265 Lock Washer 5/16 1

4818229 Bolt 5/16-18 x 3/4 1

5817216 Shaft, Motor Pivot 1

6817222 Spacer 2

7818219 Retaining Ring 2

8817219 Weight - Side 2

9817305 Bracket 2

10 818261 Bolt 5/16-18 x 4 4

11 818225 Flat Washer 5/16 4

12 818265 Lock Washer 5/16 4

13 818263 Nut 5/16-18 4

14 817220 Motor Pivot Shaft Bushing 1

15 817217 Weight - Rear 1

16 817307 Bracket 2

17 818225 Flat Washer 5/16 4

18 818265 Lock Washer 5/16 4

19 818263 Nut 5/16-18 4

20 817101 Tub - Outer 1

21 811203 Gasket 3

22 811201 Seal 2

23 812201 Bearing 4

24 817249 Spacer 2

25 817239M Hub 2

26 817105 Hub Assembly 2

27 817253 Strut Assembly 4

28 818201 Bolt 1/4-20 x 5/8 S.S. 12

29 817111 Base Frame 1

30 818227 Nut 3/8-16 4

31 817265 Leveling Leg 4

32 817267 Foot Pad 4

33 814201 Pump 1

34 814213 Sump Hose 1

35 814217 Hose Clamp 1

36 814215 Drain Hose 1

37 814221 Hose Clamp 1

38 817135 Pulley 1

39 813225 Proximity Switch 1

40 817249 Spacer 1

41 818285 Lock Washer 1/4 2

42 818349 Bolt 1/4-20 x 5/8 with hole 2

43 817293 Belt 1

70 817139 Hose - Pressure Switch 1

71 817298 Bezel 1

74 814227 Pressure Switch Hose Clamp 1

86 817214 Adjustment Stud 1

87 813265 Balance Switch 1

88 817357 Balance Switch Bracket 1

89 818343 Hole Plug-Yellow 1

90 818231 Leg Grommet (Motor) 3

91 817163 Assembly, Suspension Cover 4

93 811209 Foam Tape 1/8" x 1/2"

94 817335 Outer Tub Brace 1

PARTS

17

PARTS

18 PARTS

ITEM PART NUMBER DESCRIPTION QUANTITY

44 817271 Cabinet 1

45 817115 Front Panel 1

46 818217 Screw 4

47 817291 Locking Pin 1

48 817289 Lid 1

49 817103 Inner Tub Assembly 1

50 817107 Drive Shaft Assembly 1

51 818201 Bolt 1/4-20 x 5/8 S.S. 8

52 817109 Support Shaft Assembly 1

53 813221 Power Cord 1

54 817279 Top 1

55 817314 Control Panel 1

56 818241 Screw 6

57 817381 Panel Overlay - HXW2304, HXW2305 1

58 818353 Small White Knob 3

818363 Small Black Knob 3

59 818357 White Indicator Dial 1

818367 Black Indicator Dial 1

60 818355 Large White Knob 1

818365 Large Black Knob 1

61 814237 Water Valve 1

62 994201 Hose Clamp 2

63 814251 Hose - Valve to Soap Dispenser 1

65 817365 Soap Dispenser Body 1

66 814241 Valve Dispenser 1

67 817370 Soap Dispenser Siphon 1

817366 Soap Dispenser Deflector 1

68 814205 Water Supply Hose 2

69 814225 Hose Washer 4

72 817299 Skirt 1

73 813203 Lid Lock Switch 1

75 817323 Lid Lock Switch Bracket 1

76 817321 Bracket, Top Hold Down 2

77 817351 Flange Cover 2

78 811217 O-Ring 2

79 817225 Hinge Pin 2

79A 817229 Spring 4

80 817153 Door Hook Assembly 1

81 817233 Door Louver 1

82 818373 Screw 6

83 817367 Dispenser Bezel (Soap) 1

84 811221 Gasket Soap Dispenser 1

85 818257 Lid Bumper 2

86 818213 Locator Drive Rivet 2

88 813245 Circuit Breaker- 10 Amp 1

89 813247 6" Wire Lead 2

19

PARTS

Staber Industries, Inc.

4800 Homer Ohio Lane

Groveport, Ohio 43125

614.548.0098 phone

www.staber.com

Product information and specifications are shown herein as of the time of printing.

Staber Industries, Inc. reserves the right to change product specifications, designs

and standard equipment without notice and without incurring obligation.

Other manuals for HXW2304

1

This manual suits for next models

5

Table of contents

Other Staber Industries Washer manuals