Star 1-9NRL User manual

1

SPECIALTY

DISPENSER

MODEL

1-9NRL

Installation and

Operation

Instructions

2M-Z0476 Rev. G 3/1/07

1-9NRL

22

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

Using any part other than genuine Star factory supplied parts relieves the

manufacturer of all liability.

Star reserves the right to change specifications and product design without

notice. Such revisions do not entitle the buyer to corresponding changes,

improvements, additions or replacements for previously purchased

equipment.

Due to periodic changes in designs, methods, procedures, policies and

regulations, the specifications contained in this sheet are subject to change

without notice. While Star Manufacturing exercises good faith efforts to provide

information that is accurate, we are not responsible for errors or omissions

in information provided or conclusions reached as a result of using the

specifications. By using the information provided, the user assumes all risks in

connection with such use.

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance. Please record the model

number, serial number, voltage and purchase date in the area below and have it ready when you call to

ensure a faster service.

SAFETY SYMBOL

Model No.

Serial No.

Voltage

Purchase Date

Business 8:00 am to 4:30 p.m. Central Standard Time

Hours:

Telephone: (800) 807-9054 Local (314) 781-2777

Fax: (800) 396-2677 Local (314) 781-2714

E-mail [email protected]

Website: www.star-mfg.com

The Star Service Help Desk

Authorized Service Agent

Reference the listing provided with the unit

or

for an updated listing go to:

Website: www.star-mfg.com

E-mail [email protected]

Telephone: (800) 807-9054 Local (314) 781-2777

Mailing Address: Star Manufacturing International Inc.

10 Sunnen Drive

St. Louis, MO 63143

U.S.A

3

CAUTION

This equipment is designed and sold for commercial use only by personnel trained and

experienced in its operation and is not sold for consumer use in and around the home nor

for use directly by the general public in food service locations.

Before using your new equipment, read and understand all the instructions & labels

associated with the unit prior to putting it into operation. Make sure all people associated

with its use understand the units operation & safety before they use the unit.

All shipping containers should be checked for freight damage both visible and concealed.

This unit has been tested and carefully packaged to insure delivery of your unit in perfect

condition. If equipment is received in damaged condition, either apparent or concealed, a

claim must be made with the delivering carrier.

Concealed damage or loss - if damage or loss is not apparent until after equipment is

unpacked, a request for inspection of concealed damage must be made with carrier within

15 days. Be certain to retain all contents plus external and internal packaging materials for

inspection. The carrier will make an inspection and will supply necessary claim forms.

GENERAL OPERATING PROCEDURES

Follow these simple instructions for the setup and operation of your new dispenser.

1. Lift the unit out of its shipping container and remove all tapes and packing materials. Do

not discard carton until the dispenser is completely assembled and working.

2. Ensure the magnetic impeller and wire agitator are installed by lifting the lid and looking

down into the bowl. The word "TOP" should be visible on the magnetic impeller.

NOTE: Supplied with your new Star dispenser are two (2) wire agitator

assemblies.

3. Add liquid to be heated/dispensed. If working with a powder, mix with water prior to pouring

into bowl. For best results, use hot liquid when mixing with powder. This improves mixing

and greatly reduces time to reach serving temperature. Do not place powders directly into

bowl. Mix first.

4. Plug unit into 115V AC outlet.

WARNING

DO NOT CONNECT TO DIRECT CURRENT (DC).

5. Turn the switch on the front right side of the unit to ON position. This controls the indicator

light, heating element, and motor. Power is indicated by the switch light.

6. The recessed area below the spigot is intended for use as a drip tray.

7. Your new Star dispenser is equipped with a worry-free, preset thermostat that maintains

product serving temperatures around 165° F, which is desirable in most applications.

Should your application require a different temperature for serving, please contact one of

our service representatives at 1-800-264-7827.

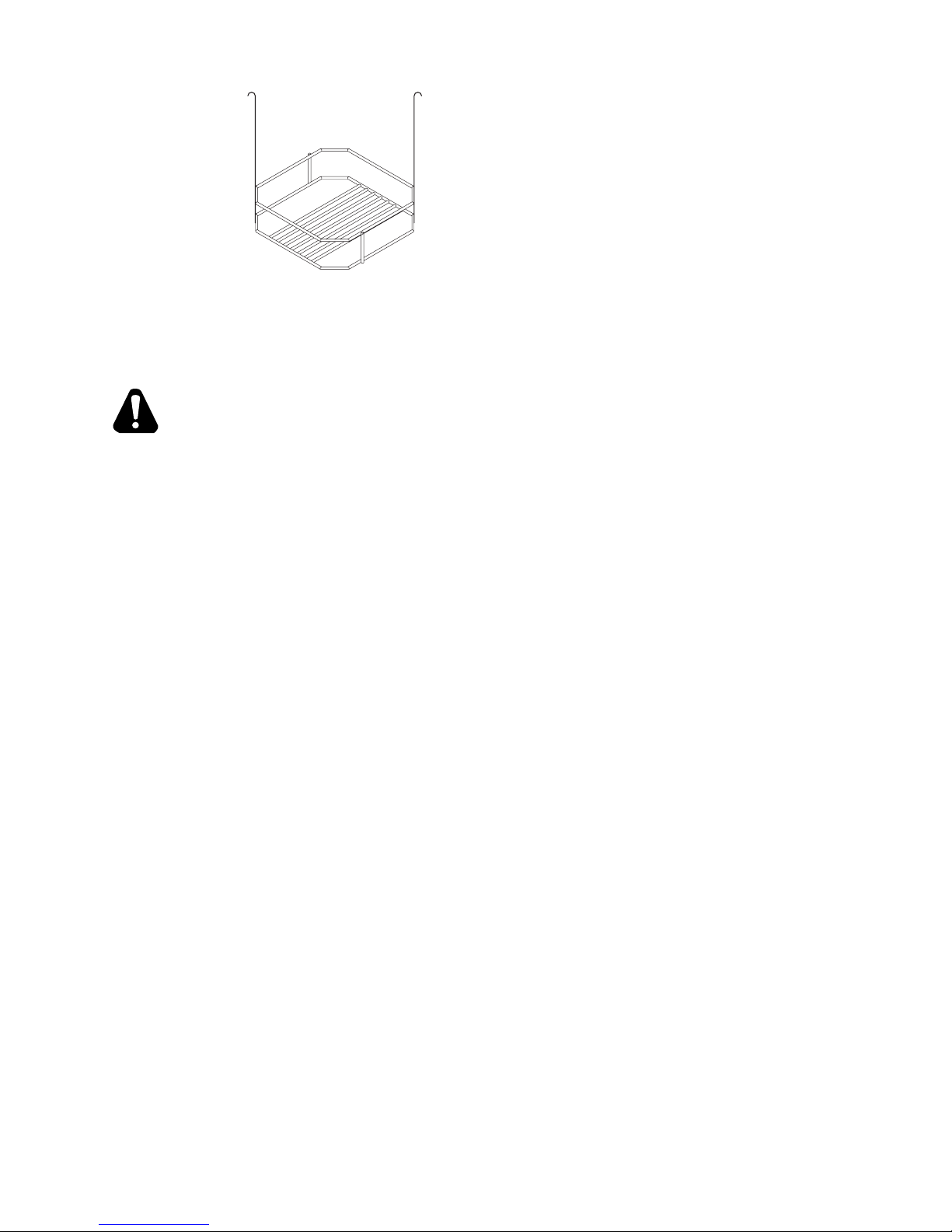

8. Also provided with your new dispenser is a suspension basket. See figure below.

4

DISPENSER CLEANING INSTRUCTIONS

1. For best results and customer satisfaction, thoroughly clean dispenser daily.

CAUTION

TURN UNIT OFF AND UNPLUG PRIOR TO CLEANING.

2. Remove contents of the bowl before lifting and cleaning. Product removed from the bowl

may be placed in a suitable container for overnight refrigerated storage.

3. Allow unit to cool, lift the cover, and remove the grate and impeller.

4. Remove the front of the unit by pulling on both sides at the top with your fingers. Release

the latch to loosen the bowl from the element band and swing the clamp to the left.

5. Raise the bowl until the faucet shank touches the top of the frame, then tilt the bowl forward

and upward until the faucet shank clears the unit.

6. Clean and dry the inset bowl, replacing it in the unit by reversing operations of

step 5. Tighten the latch for the heating element.

7. Reinstall the impeller such that the word "TOP" is again visible, then reinstall the metal

grate.

MAINTENANCE AND REPAIRS

Contact the factory, a service representative, or a local service company for service or required

maintenance.

This basket is for use when placing solids in the

dispenser prior to melting. The basket can also be

used to store spices or other flavorings not directly

placed in the liquid.

5

Cleaning & Sanitizing Instructions

Proper cleaning and sanitizing of the faucet on your tea machine is necessary to delivery great tasting fresh brewed

iced tea. SPB and SPBH faucets do not require tools for servicing, cleaning, or sanitizing. Simplified construction

means fewer parts to wear out or replace.

To prevent bacterial growth, follow step by step sequence and refer to the diagram below. When ordering

replacement parts, be sure to specify our model number. The chart below shows common replacement parts.

CLEANING & SANITIZING

STEP 1:

Remove the entire upper assembly by

unscrewing the bonnet (A).

STEP 2:

•Pull seat cup (B) to remove from

stem. Inspect for wear or hardening

and replace if necessary.

•Cleanall parts, including faucet body,

in hot soapy water.

•Sanitize with a chlorine (50 PPM),

iodine (14 PPM) or quaternary am-

monium compound (100 PPM).

•Rinse with clear hot water.

STEP 3:

Snap seat cup over stem end by apply-

ing direct pressure.

STEP 4:

Screwupperassemblybackontobody.

HAND TIGHTEN ONLY!

NOTE:

To dismantle the entire upper assem-

bly, carefully pull handle from stem

while applying pressure to seat cup.

Remove spring, stem and seat cup.

Reassemble in reverse.

Tomlinson manufactures this same

valvefor most major tea brewer manu-

facturers whose names may appear

on the handle.

IMPORTANT: To prevent bacterial growth and protect tea flavor, clean and sanitize tea

brewing and storage equipment at least ONCE A DAY according to manufacturer's directions.

Upper Assembly

A

B

NSF

Table of contents

Popular Beverage Dispenser manuals by other brands

CDS AUTOMATEN

CDS AUTOMATEN ML-16C2-C user manual

Siemens

Siemens GA 3000 OPERATING & SERVICE MANUAL

Bunn

Bunn IMIX Service & repair manual

Fizz Creations

Fizz Creations Slush Puppie Instructions for use

Cornelius

Cornelius IntelliCarb Cold Beverage Dispenser Training manual

TAPRITE

TAPRITE Rattler II Instructional manual