Startco SE-701 User manual

SE-701 MANUAL

GROUND-FAULT MONITOR

DECEMBER 19, 2000

REVISION 4

Copyright © 2000 by Startco Engineering Ltd.

All rights reserved.

Publication: SE-701-M

Document: S95-C701-00000

Printed in Canada.

Blank Page

Startco Engineering Ltd. Page i

SE-701 Ground-Fault Monitor Rev. 4

Pub. SE-701-M, December 19, 2000.

TABLE OF CONTENTS

PAGE

Table of Contents...................................................................i

List of Figures ........................................................................i

1. General......................................................................1

2. Operation..................................................................1

2.1 Configuration-Switch Settings...................................1

2.1.1 Relay Operating Mode ...................................1

2.1.2 Inhibit..............................................................1

2.1.3 CT Verification...............................................1

2.1.4 Filter Selection................................................1

2.1.5 Autoreset.........................................................1

2.2 Front-Panel Controls..................................................1

2.2.1 Ground-Fault Trip Level ................................1

2.2.2 Ground-Fault Trip Time.................................1

2.2.3 Reset ...............................................................1

2.2.4 Test .................................................................3

2.3 Front-Panel Indication ...............................................3

2.3.1 Power ..............................................................3

2.3.2 Ground-Fault Trip ..........................................3

2.3.3 Inhibit..............................................................3

2.4 Analog Output ...........................................................3

3. Installation................................................................3

4. Technical Specifications..........................................3

5. Ordering Information .............................................5

LIST OF FIGURES

FIGURE PAGE

1 SE-701 Outline and Mounting Details...................... 2

2 Typical Connection Diagram.................................... 4

3 EFCT-1 Outline and Mounting Details .................... 6

4 EFCT-2 Outline and Mounting Details .................... 7

5 PMA-55 Panel-Mount Adapter................................. 8

DISCLAIMER

Specifications are subject to change without notice. Startco

Engineering Ltd. is not liable for contingent or

consequential damages, or for expenses sustained as a result

of incorrect application, incorrect adjustment, or a

malfunction.

Blank Page

Startco Engineering Ltd. Page 1

SE-701 Ground-Fault Monitor Rev. 4

Pub. SE-701-M, December 19, 2000.

1. GENERAL

The SE-701 is a microprocessor-based ground-fault

monitor for resistance-grounded and solidly grounded

systems. Its output relay can operate in the fail-safe or non-

fail-safe mode for undervoltage or shunt-trip applications,

and the output contacts are isolated for use in independent

control circuits. Additional features include LED and

fluorescent-flag trip indication, autoreset or latching trips

with front-panel and remote reset, self test, 0 to 5-V analog

output, inputs for standard and sensitive ground-fault

current transformers, CT verification for sensitive current

transformers, digital selector switches, switch-selectable

algorithms for fixed-frequency or variable-frequency

applications, and an inhibit that can be enabled to prevent

the output relay from operating during a high-current

ground fault.

Ground-fault current is sensed by a standard CT with a

1-A or 5-A secondary, or by a sensitive CT with a 5-A-

primary rating (EFCT-1 or EFCT-2). The trip level of the

ground-fault circuit is digital-switch selectable in 1%

increments from 1% to 99% of the CT-primary rating. Trip

time is digital-switch selectable with 10 settings from 0.05

to 2.5 s.

2. OPERATION

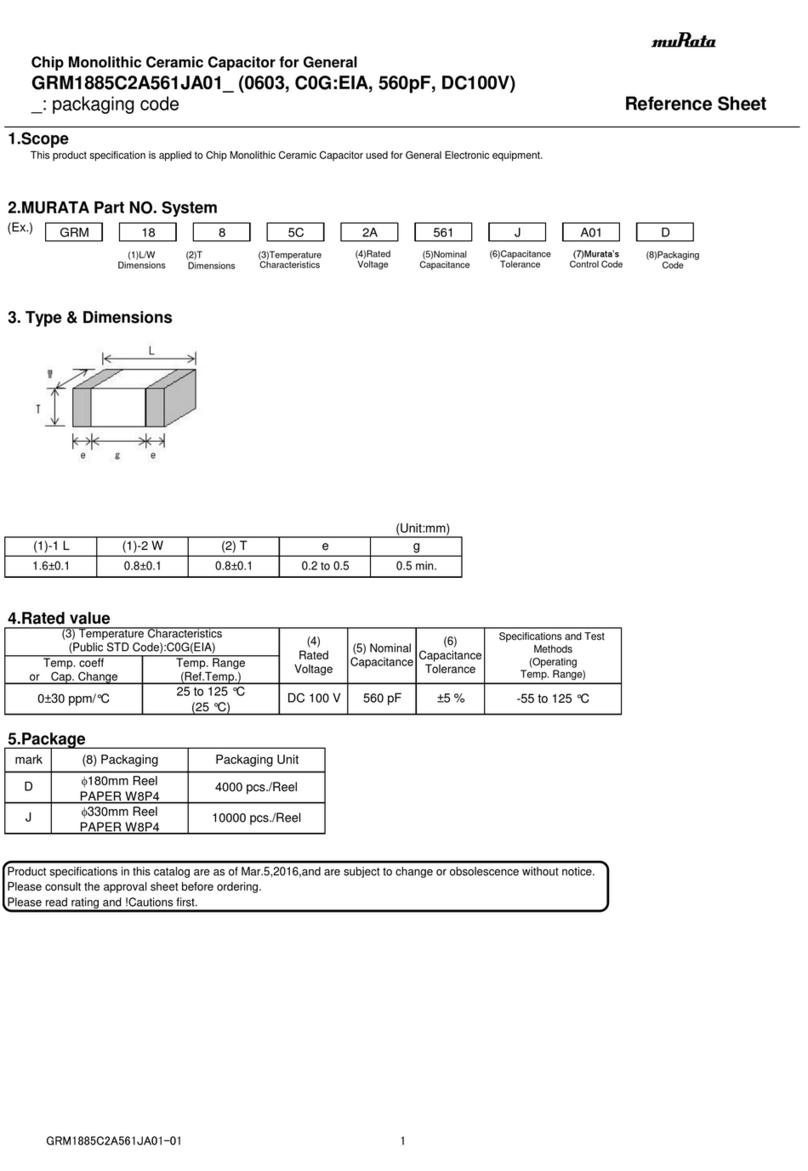

2.1 CONFIGURATION-SWITCH SETTINGS (See Fig. 1)

2.1.1 RELAY OPERATING MODE

The SE-701 has one output relay with isolated normally

open and normally closed contacts. Switch 1 is used to set

the operating mode of the output relay. In the fail-safe

mode, the output relay energizes when the ground-fault

circuit is not tripped. In the non-fail-safe mode, the output

relay energizes when a ground-fault trip occurs.

2.1.2 INHIBIT

Switch 2 is used to select Class I or Class II operation. In

the INHIBIT OFF position, high-current inhibit is off for

Class I operation. In the INHIBIT ON position, high-

current inhibit is on for Class II operation. If high-current

inhibit is on and ground-fault current escalates above eleven

times the CT-primary rating before the ground-fault circuit

trips, the output relay will not operate until ground-fault

current falls below eight times the CT-primary rating. This

feature allows the overcurrent protection to operate in

applications where the ground-fault current can be larger

than the interrupting capacity of the device tripped by the

SE-701.

2.1.3 CT VERIFICATION

Switch 3 is used to enable CT verification with the

EFCT-1 or EFCT-2. In the CT VERIFY ON position, a

trip will occur if the CT is disconnected. The red LED will

flash to indicate a trip initiated by a CT fault. Switch 3 must

be in the CT VERIFY OFF position when a 5-A- or 1-A-

secondary CT is used.

2.1.4 FILTER SELECTION

Switch 4 is used to select the filtering algorithm for a

fixed-frequency (50/60 Hz) or variable-frequency

application. The fixed-frequency algorithm allows lower

trip levels to be used by rejecting harmonics that can cause

nuisance tripping. The variable-frequency setting should be

used if the CT is located on the load side of a variable-

frequency drive.

2.1.5 AUTORESET

Switch 5 is used to select autoreset or latching trips. See

2.2.3.

2.2 FRONT-PANEL CONTROLS

2.2.1 GROUND-FAULT TRIP LEVEL

The % CT PRIMARY selector switches are used to set

the ground-fault trip level as a percentage of the CT-primary

rating. Protection against arcing ground faults in a solidly

grounded system requires a ground-fault CT that will not

saturate below the operating value of the overcurrent

protection. For reliable ground-fault detection, the ground-

fault trip level must be substantially below the prospective

ground-fault current. To avoid sympathetic tripping, the

trip level must be above the charging current of the largest

feeder; and to eliminate nuisance tripping, surge current

must not saturate the CT. See Startco Technical

Information 11.1 available at www.startco.ca.

2.2.2 GROUND-FAULT TRIP TIME

The TIME (s) selector switch is used to set the ground-

fault trip time for coordination with upstream and

downstream ground-fault devices. Coordination requires

the same trip level for all ground-fault devices in a system

and the trip time to progressively increase upstream. The

amount of equipment removed from the system will be a

minimum if the first ground-fault device to operate is the

one immediately upstream from the fault.

2.2.3 RESET

The reset circuit responds only to a momentary closure so

that a jammed or shorted switch will not prevent a trip. The

front-panel RESET switch is inoperative when the remote-

reset terminals (6 and 7) are shorted.

Startco Engineering Ltd. Page 2

SE-701 Ground-Fault Monitor Rev. 4

Pub. SE-701-M, December 19, 2000.

FIGURE 1. SE-701 Outline and Mounting Details.

Startco Engineering Ltd. Page 3

SE-701 Ground-Fault Monitor Rev. 4

Pub. SE-701-M, December 19, 2000.

If Switch 5 is in the LATCHING position, a trip remains

latched until the RESET switch is pressed, the remote-reset

terminals are momentarily shorted, or the supply voltage is

cycled. Cycling the supply voltage will not reset (black) the

fluorescent flag.

If Switch 5 is in the AUTORESET position, a trip will

reset when the fault is removed. The fluorescent flag will

not reset until the RESET switch is pressed or the remote-

reset terminals are momentarily shorted. Cycling the supply

voltage will not reset the fluorescent flag unless the remote-

reset terminals are shorted.

If Switch 5 is in the AUTORESET position and the

remote-reset terminals are shorted, operation is the same as

for older SE-701’s with the A1 or A2 option.

2.2.4 TEST

The TEST switch is used to test the ground-fault circuit,

the indication, and the output relay. When the TEST switch

is pressed for one second; the circuit will trip, trip indication

will come on, and the output relay will operate. If high-

current inhibit has been selected, the inhibit indicator will

come on.

2.3 FRONT-PANEL INDICATION

2.3.1 POWER

The green LED labeled PWR indicates presence of the

supply voltage.

2.3.2 GROUND-FAULT TRIP

The red LED and the fluorescent flag, labeled TRIP,

indicate a trip. A solid red LED indicates a ground-fault

trip and a flashing LED indicates a trip initiated by a CT

fault.

2.3.3 INHIBIT

The yellow LED labeled INHB indicates that output-

relay operation was inhibited during a high-current ground

fault. Inhibit indication is reset when the ground-fault trip is

reset. Inhibit operation and indication will not respond if

Switch 2 is in the INHIBIT OFF position.

2.4 ANALOG OUTPUT

The non-isolated, 0 to 5-V analog output indicates

ground-fault current sensed by the ground-fault CT. The

output is 5 V at 100% of the CT-primary rating.

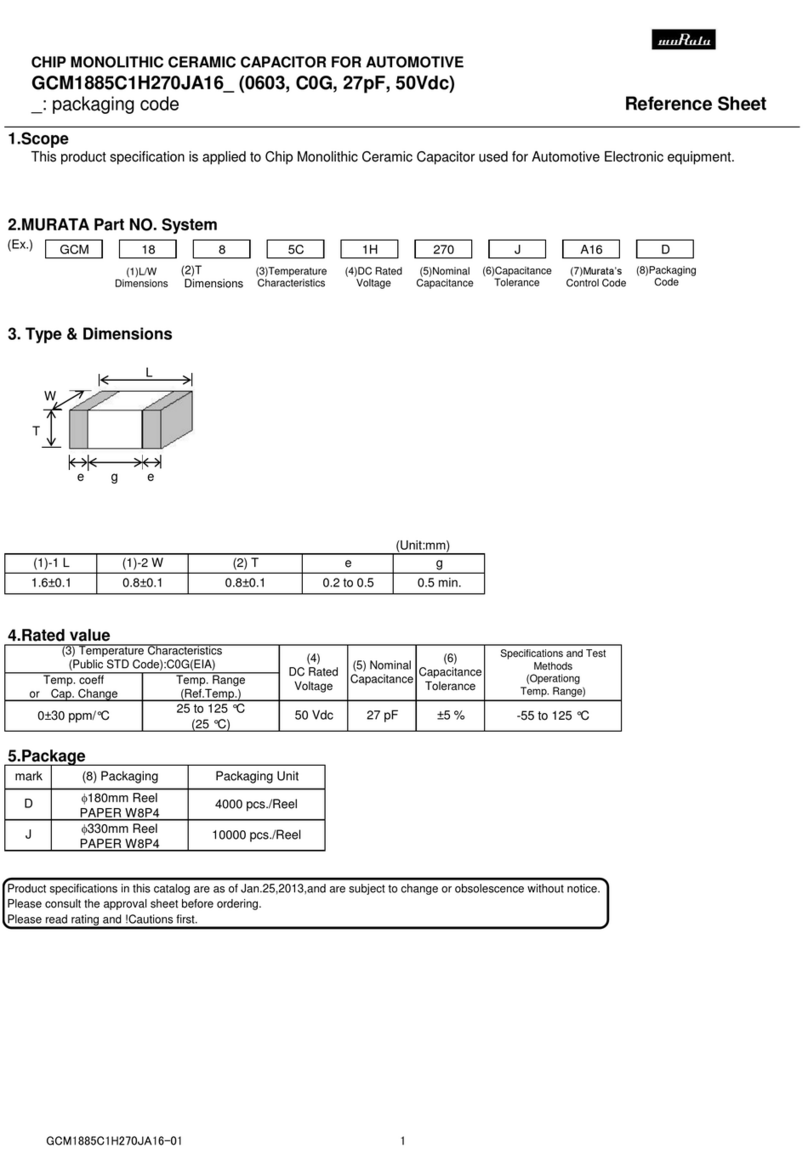

3. INSTALLATION

Pass the phase conductors through the CT window as

shown in Fig. 2 (for 4-wire and single-phase systems, also

pass the neutral conductor through the CT window). Do not

pass ground conductors through the CT window. In

applications that require shields or drain wires to pass

through the CT window, return them through the CT

window before connecting them to ground. If a ground-

fault CT with a 5-A secondary is used, connect it to

terminals 2 and 3 (terminals 1 and 3 with a 1-A secondary)

and ground terminal 3. If the EFCT-1 or EFCT-2 is used,

connect it to terminals 4 and 5, connect the shield to

terminal 5, and ground terminal 5. Remove the connection

to terminal 9 for dielectric-strength testing—all inputs and

outputs have ANSI/IEEE C37.90 surge-protection circuits

that conduct above 300 Vac.

4. TECHNICAL SPECIFICATIONS

Supply:

01 Option..............................120 Vac (+15%, -40%),

50/60 Hz, 2.5 VA

02 Option..............................240 Vac (+15%, -40%),

50/60 Hz, 2.5 VA

03 Option..............................24 Vac (+15%, -40%),

50/60 Hz, 2.5 VA

0S Option ............................. 120 or 240 Vac (+15%,

-40%), 50/60 Hz, 2.5 VA

0U Option............................. 55 to 275 Vac, 50/60 Hz,

3.5 VA

75 to 275 Vdc, 2.0 W (1)

0D Option.............................9 to 36 Vdc, 3.0 W (1)

0T Option .............................30 to 70 Vdc, 3.0 W (1)

(1) CSA Certification pending.

Dimensions:

Height...................................75 mm (3.0")

Width....................................55 mm (2.2")

Depth....................................115 mm (4.5")

Shipping Weight..........................0.45 kg (1 lb.)

Trip-Level Range.........................1% to 99% CT-Primary

Rating in 1% increments

(50 mA to 4.95 A with

EFCT-1 or EFCT-2)

Trip-Time Settings....................... 0.05, 0.10, 0.20, 0.30,

0.40, 0.50, 1.0, 1.5, 2.0,

and 2.5 s

Accuracies:

Trip Level.............................+1%, -5% of trip level for

settings ≥10%.

+0.1%, -0.5% of full scale

for settings ≤9%.

Trip Time .............................+15 ms, -25 ms

Startco Engineering Ltd. Page 4

SE-701 Ground-Fault Monitor Rev. 4

Pub. SE-701-M, December 19, 2000.

FIGURE 2. Typical Connection Diagram.

Startco Engineering Ltd. Page 5

SE-701 Ground-Fault Monitor Rev. 4

Pub. SE-701-M, December 19, 2000.

Inhibit:

Off........................................ Class I

On ........................................ Class II

Level............................. 11 x CT-Primary Rating

Input:

Algorithms ........................... DFT Digital or Peak

Digital Filter......................... 50 to 60 Hz, Bandpass

CT ........................................ 1-A or 5-A Secondary

Rating, EFCT-1,

or EFCT-2

Thermal Withstand:

Continuous ................... 5 x CT-Secondary Rating

1-Second....................... 80 x CT-Secondary

Rating

Burden ................................. < 0.01 Ωfor 5-A input

< 0.05 Ωfor 1-A input

Operating Mode .......................... Latching or Autoreset

Analog Output:

Range ................................... 0 to 5 V, 5 V = 100%

Output Impedance ............... 220 Ω

Reset............................................ Front-Panel Switch and

Remote, N.O. Contact

Functional Test............................ Front-Panel Switch

Output Relay:

Contact Rating .................... 8 A Resistive,

250 Vac/30 Vdc

Contact Configuration ........ Isolated N.O. and N.C.

Operating Mode................... Fail-Safe or Non-Fail-Safe

Supplemental Contact Ratings:

Make/Carry 0.2 s ................20 A

Carry Continuous................8 A

Break:

dc .................................30 W Resistive,

15 W Inductive

(L/R = 0.4 s)

ac................................. 2000 VA Resistive

1400 VA Inductive

(PF = 0.4)

Subject to maximums of 8 A and 250 V (ac or dc).

Environment:

Operating Temperature ........-40°C to 60°C

Storage Temperature............-55°C to 80°C

Humidity...............................85% Non-Condensing

Surge Withstand ..........................ANSI/IEEE 37.90.1-1989

(Oscillatory and Fast

Transient)

Certification .................................CSA NRTL/C

(Canada & USA)

5. ORDERING INFORMATION

SE-701-0 — 1 120-Vac Supply

2 240-Vac Supply

3 24-Vac Supply

S 120- or 240-Vac Supply

U Universal ac/dc Supply

D 9- to 36-Vdc Supply

T 30- to 70-Vdc Supply

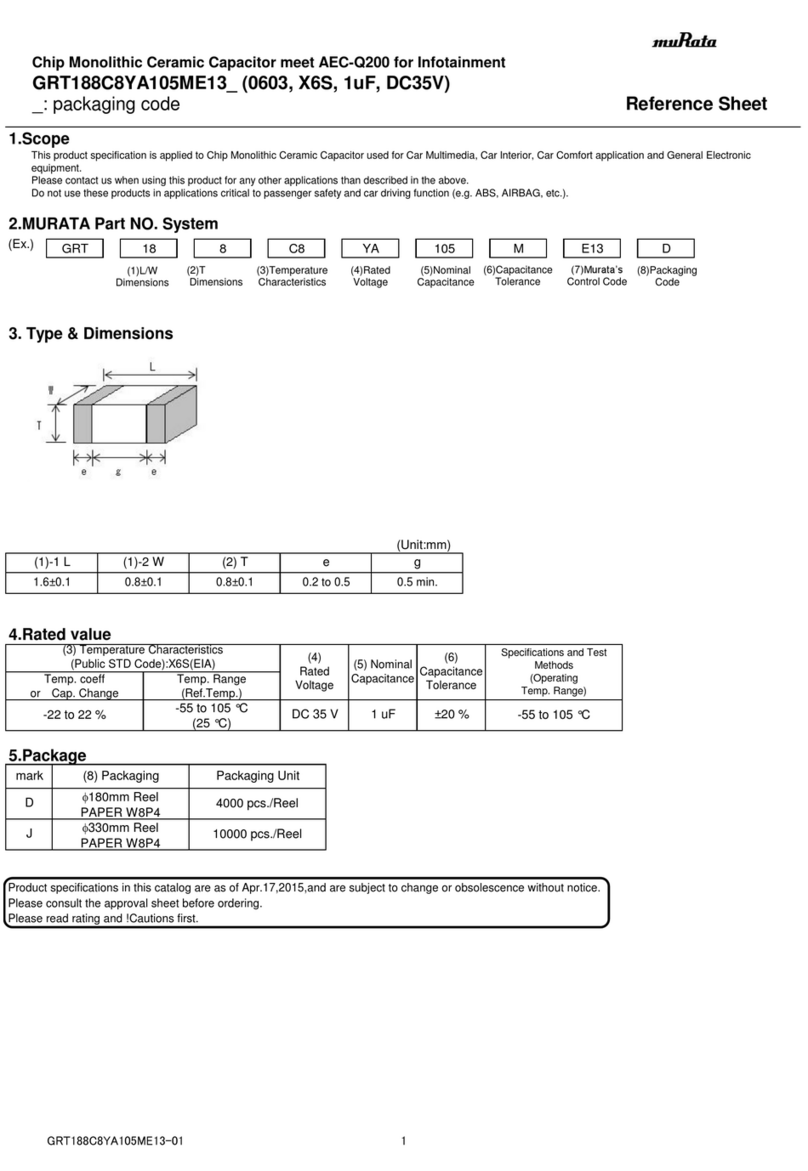

EFCT-1 ............Sensitive Ground-Fault CT, 5-A Primary

Rating, 82-mm (3.2") Window

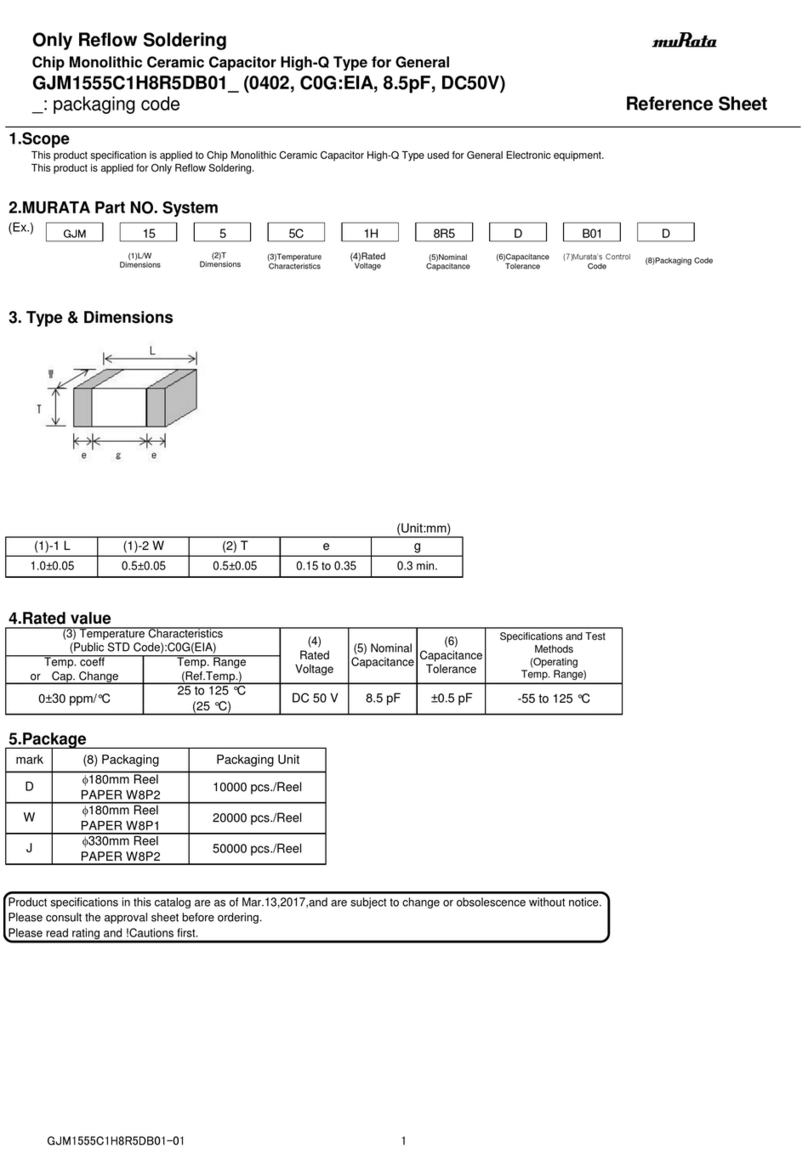

EFCT-2 ............Sensitive Ground-Fault CT, 5-A Primary

Rating, 155-mm (6.1”) Window

EFCT-1FC .......Flux Conditioner, 70 mm (2.7”) Window

EFCT-2FC .......Flux Conditioner, 139 mm (5.5”) Window

PMA-55 ...........Panel-Mount Adapter

SE-EFVC.........Voltage Clamp

Consult factory for custom mounting adapters.

LR 53428

NRTL /C

Startco Engineering Ltd. Page 6

SE-701 Ground-Fault Monitor Rev. 4

Pub. SE-701-M, December 19, 2000.

FIGURE 3. EFCT-1 Outline and Mounting Details.

Startco Engineering Ltd. Page 7

SE-701 Ground-Fault Monitor Rev. 4

Pub. SE-701-M, December 19, 2000.

FIGURE 4. EFCT-2 Outline and Mounting Details.

Startco Engineering Ltd. Page 8

SE-701 Ground-Fault Monitor Rev. 2

Pub. SE-701-M, December 19, 2000.

FIGURE 5. PMA-55 Panel-Mount Adapter.

Other manuals for SE-701

2

Table of contents

Popular Industrial Electrical manuals by other brands

Lindorm, Inc.

Lindorm, Inc. SediMeter SM3 manual

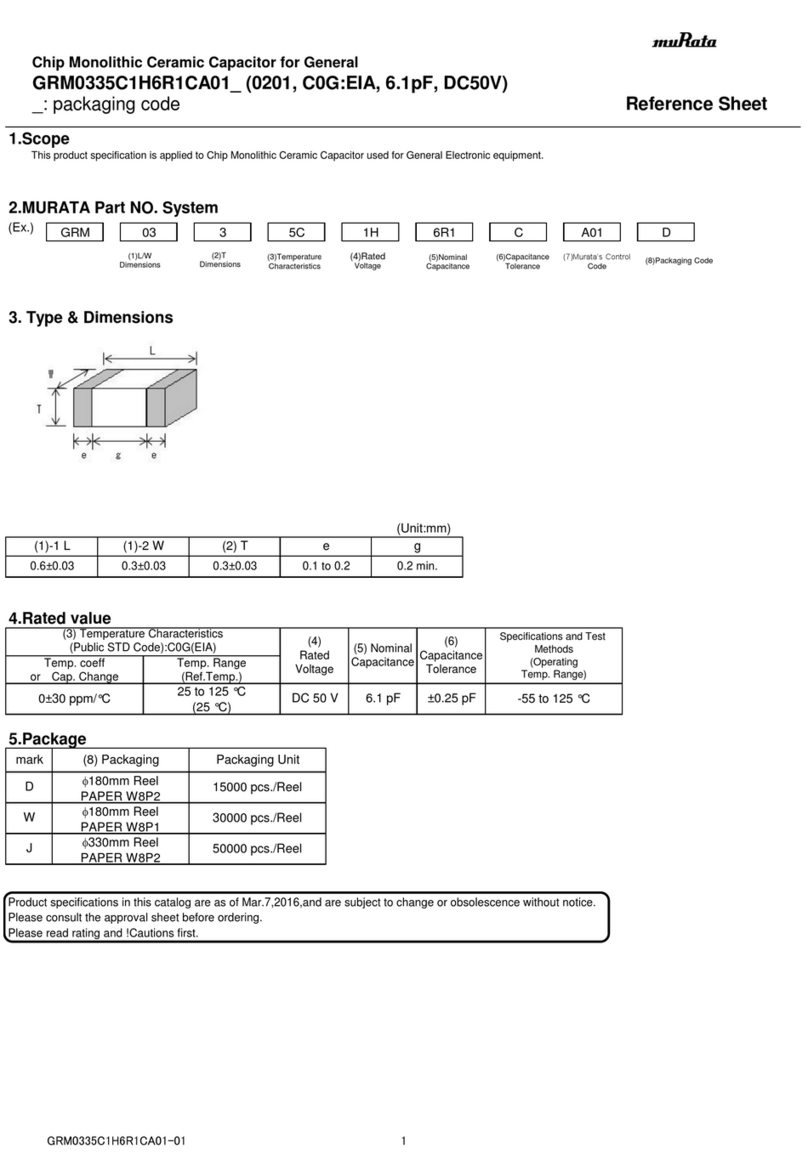

Murata

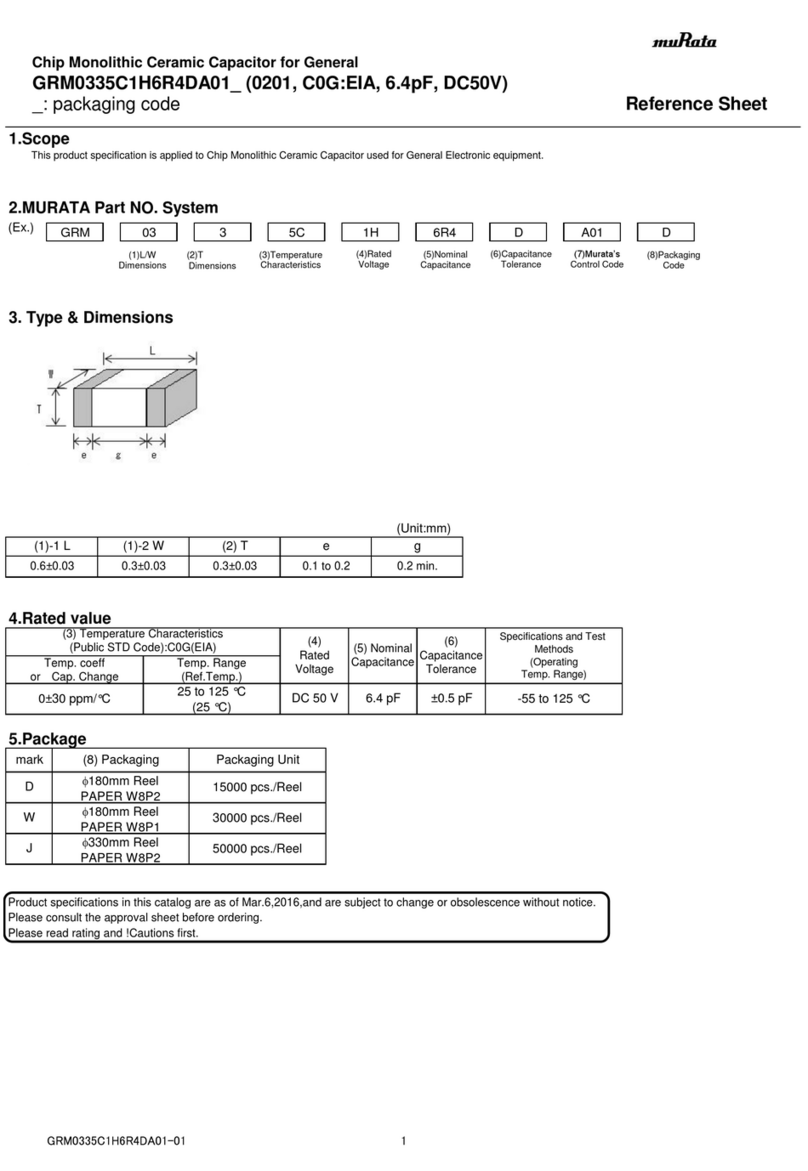

Murata GRM0335C1H6R1CA01 Series Reference sheet

Murata

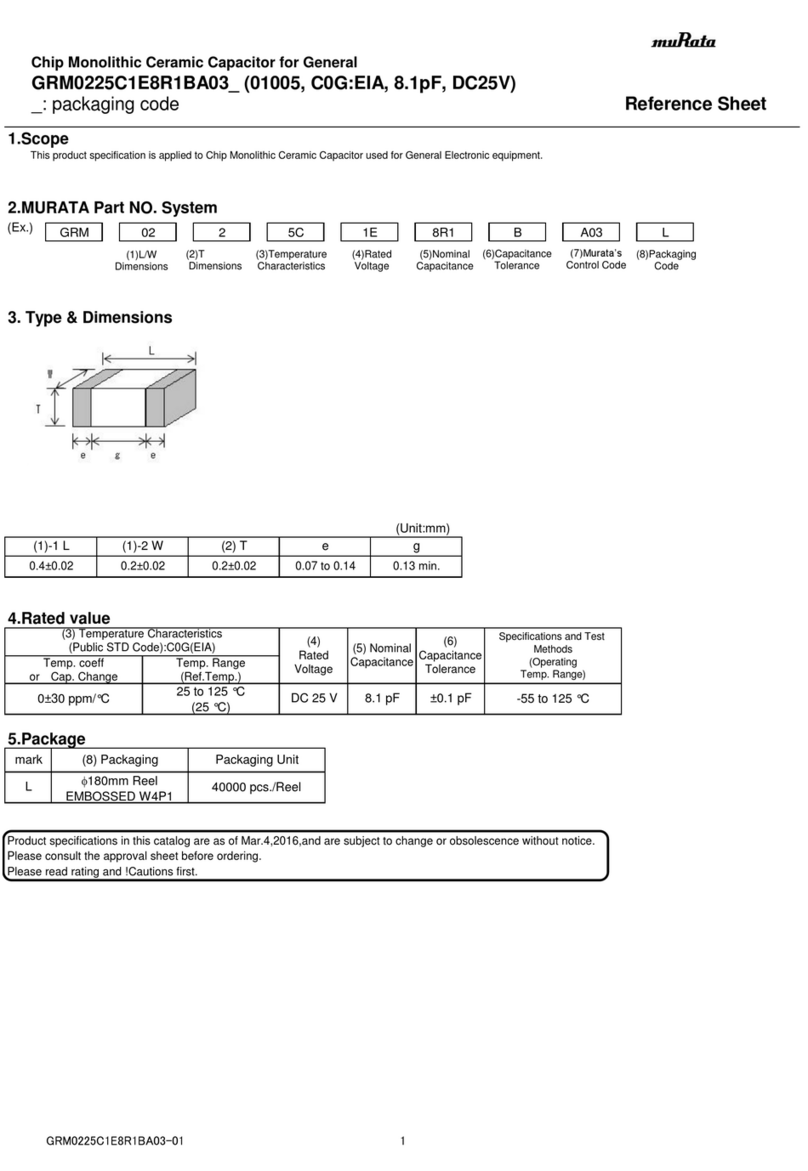

Murata GRM0225C1E8R1BA03 Series Reference sheet

Siemens

Siemens 3TM operating instructions

Lucent Technologies

Lucent Technologies Lineage 2000 ECS Battery Plant product manual

Murata

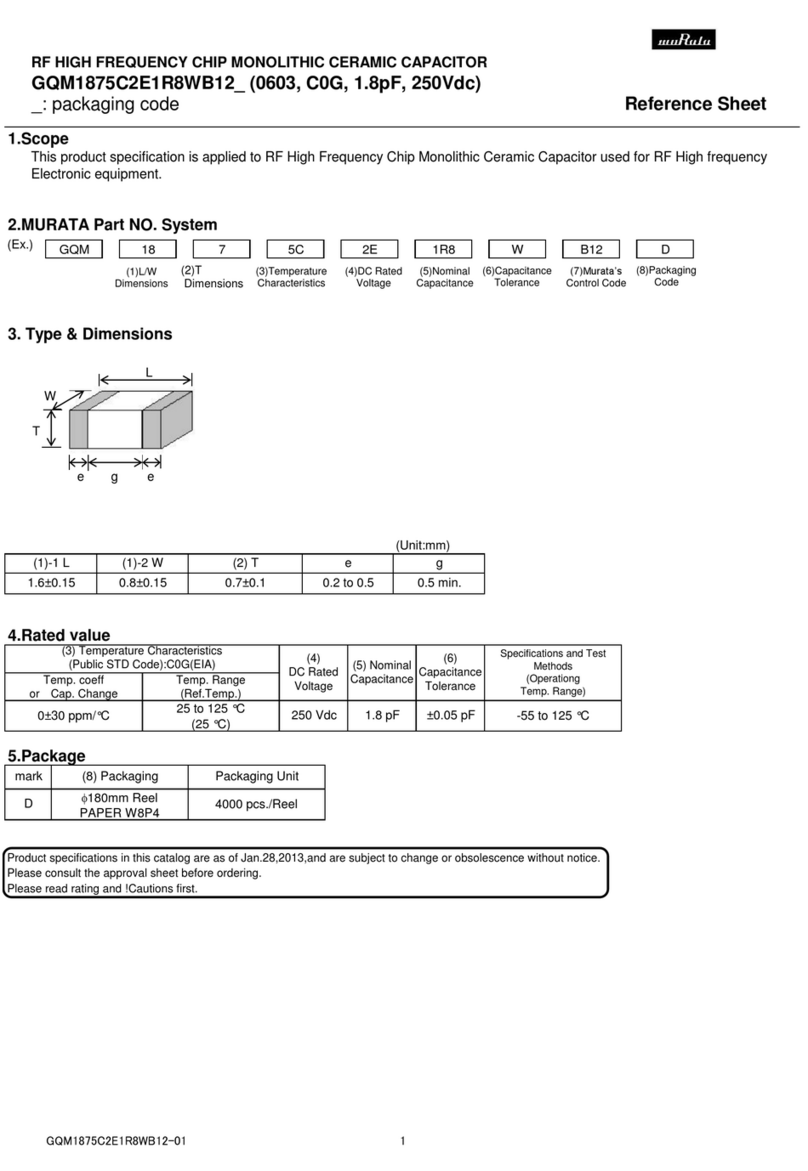

Murata GQM1875C2E1R8WB12 Series Reference sheet