D2543-01-02 CN5219 SEM1000 Web User Guide

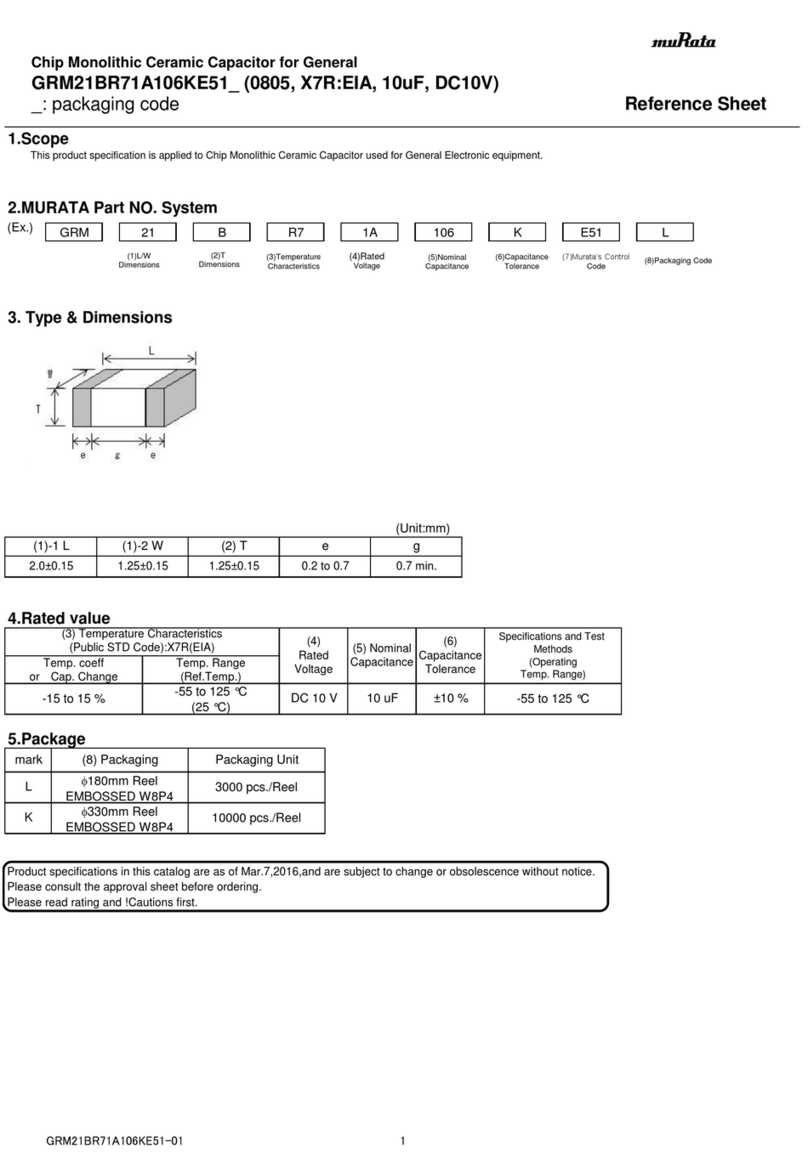

The SEM1000 isolator is designed to be series connected into a new or existing (4 to 20) mA current

loop and provide an isolated (4 to 20) mA signal capable of driving into 300 R. The output is powered

from the input loop.

Type Current input 2 wire loop powered

Range (4 to 20) mA (30 mA maximum)

Protection Reverse connection

Voltage Drop 5.5 V + O/P V Drop (O/P V Drop = O/P load x 0.02)

Max Loop Supply 35 V

Type (4 to 20) mA source (Powered from input)

Load (0 to 300) Ω(Open circuit limits at approximately 15 V)

Isolation 500 VAC (flash tested @ 1 kV) (Isolation method, opto-

coupler/transformer)

Electrical Safety BS EN61010-1 Pollution Degree 2; Installation CAT II; CLASS I

Ambient (0 to 70) ºC; (10 to 95) % RH non condensing

Accuracy 0.05 % full range output

Stability 0.01 % / ºC

Response Time Less than 100 ms to reach 63 % of final value.

EMC Compliant with BS EN50081-1, BS EN50082-1

Connection Captive clamp screws

Cable Size Maximum 4 mm² solid/2.5 mm² stranded

Case Material Grey Polyamide

Flammability To UL94-VO VDE 0304 Part 3, Level IIIA

Dimensions (60 x 60 x 12.5) mm (67.5 mm above rail)

Mounting Snap on "Top Hat" rail (DIN EN 50022-35)

Adjustments Zero and Span Adjustment

Page 1

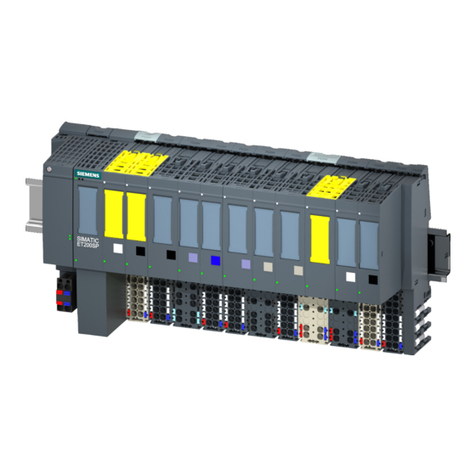

This unit must be housed within a suitable enclosure that will provide protection from the external

environment, ensuring that the stated temperature and humidity operating ranges are not exceeded. It

is good practice to mount the unit away from sources of electrical noise, such as switch gear and

transformers. The unit enclosure is designed to snap fit onto a standard "Top Hat" DIN rail. To

remove from rail, apply pressure at the bottom face at the back upwards towards the rail to release

the spring clip and tip away from the top. The unit may be mounted in any orientation and stacked

side by side along the rail.

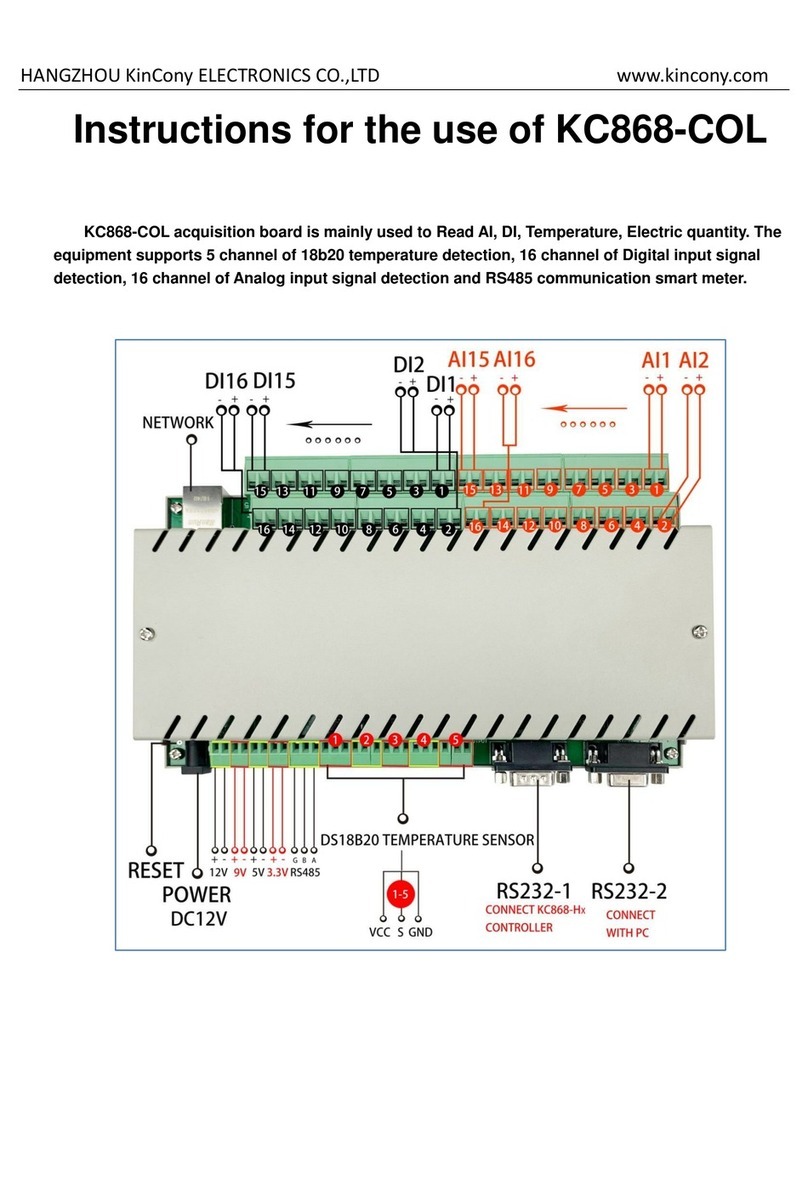

Connections to the isolator are made via screw terminals. Wire protector plates are provided inside

each terminal. To maintain CE compliance twisted pair (screened) cables are recommended. It is also

good practice to ensure that all (4 to 20) mA loops are grounded at a single point in the loop. Before

installation, care must be taken to ensure enough voltage is available in the loop to drive the total loop

load. Refer to the specifications listed for the voltage drop. In the case of the SEM1000 the additional

voltage drop of the load connected in the isolated circuit, will be added to the loop drop of the isolator,

for example a SEM1000 isolator driving into a 250 Ωload will have a total loop drop of 10.5 V

maximum.

Refer to the SEM1000 series data sheet for further information on applications of this series of

isolators. Please note the isolation provided by this device is only suitable for providing isolation

between two process signals and therefore must not be used to provide isolation from hazardous

voltages, such as mains supplies.

Figure 1

Page 2