Stevens Ricci Triplane Manual

Wing Span: 11.6 inches | Wing Area: 78 square inches | Average Flying Weight: 1.75 ounces

Build Instructions - Version 1.12 (revised 08.20.2015)

WARRANTY

Stevens AeroModel guarantees this kit to be free from defects in both material and workmanship at the

date of purchase. This warranty does not cover any component parts damaged by use or modification.

In no case shall Stevens AeroModel’s liability exceed the original cost of the purchased kit. Further,

Stevens AeroModel reserves the right to change or modify this warranty without notice.

LIABILITY RELEASE

In that Stevens AeroModel has no control over the final assembly or material used for final assembly,

no liability shall be assumed nor accepted for any damage resulting from use by the user. By the act of

using the user-assembled product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated with the use of this product, the buyer is

advised to return this kit immediately in new and unused condition to the place of purchase.

THIS PRODUCT IS NOT INTENDED FOR CHILDREN 12 YEARS OF AGE OR YOUNGER.

WARNING: This product may contain chemicals known to the state of California to cause cancer

and/or birth defects or other reproductive harm.

PRODUCT SUPPORT

This product has been engineered to function properly and perform as advertised, with the suggested

power system and supporting electronics as outlined within this product manual. Product support

cannot be provided, nor can Stevens AeroModel assist in determining the suitability or use of

electronics, hardware, or power systems not explicitly recommended by Stevens AeroModel.

For product assembly support, replacement parts, hardware, and electronics to complete this model,

please contact Stevens AeroModel at www.stevensaero.com.

Stevens AeroModel

26405 Judge Orr Rd., Colorado Springs, CO 80808 USA

719-387-4187 www.stevensaero.com

Build Instructions

1919 Ricci Triplane UM - Build Instructions © 2015 Stevens AeroModel, all rights reserved.!Page 2

Ricci Triplane UM - Kit Inventory

☐Laser-cut wood, 10 sheets (See Sheet Wood Inventory, page 5)

☐Illustrated Build Instructions

☐Detail Set, 3 sheets, 11 in. x 17 in.

Taped to back of wood brick:

☐1 Landing gear, wire, .032 in. x 12 in.

☐2 Pushrods, wire, .015 in. x 12 in.

Hardware Bag:

☐1 Heat shrink tube, 1 1/2 in. x 1/16 in. (5012)

☐1 Part F7, 1/16 in. plywood (*)

☐1 Delrin receiver clip (5013)

☐1 Windscreen, acetate (*)

☐2 Neo-Magnets, 1/8 in. x 1/16 in. (4013)

☐2 Parts Wa, 3/32 in. balsa wheel centers (*)

☐2 Tires, O-ring #218 (5020)

☐2 Wheel bearings, aluminum tube, 1/16 in. x 1/4 in. (2010)

1919 Ricci Triplane – Background

There is not a lot of information available on this quirky little design. What attracted us to it as a potential

model design was a wonderful line drawing that we had stashed away in our future projects file. A search

of the internet yielded some additional information including a few photos.

Lifelong Italian aviation enthusiasts, brothers Umberto and Ettore Ricci, started their aviation careers with

rigid hot-air airship models and free flight gliders, designed and built in their youth. They went on to

design huge flying boats, and a series of small aircraft, conceived as flying motorcycles. The Ricci

Triplane is one of these designs. The 10-foot, 7-inch wing span aircraft, was powered by a six-cylinder

Anzani engine that could propel the plane through the sky at approximately 78 miles per hour. The lovely

little triplane was built for a competition of small light aircraft, held in 1919, it came in behind a few other

competitors, including the little Breda Pensuti Triplane.

Although The Ricci Triplane is largely forgotten today, it can still take to the skies – in model form at least.

The Stevens AeroModel Ricci Triplane UM features a modern kit design that builds trouble-free and

quickly, thanks to modern design processes, pioneered by Stevens AeroModel.

Build Instructions

1919 Ricci Triplane UM - Build Instructions © 2015 Stevens AeroModel, all rights reserved.!Page 3

Suggested Items to Complete this Model

Many of the suggested items listed below are available at your local hobby shop. For your convenience,

Stevens AeroModel stocks all the power system components and most of the building supplies required

to complete this kit. If you have difficulties sourcing any of these items locally, please visit our website,

stevensaero.com to purchase the items necessary to complete your model.

Required Electronics

☐RC transmitter with at least 3 channels

☐Receiver/ESC/Servo brick (PKZ3352 or PKZUA1152)*

☐Motor/Gearbox (PKZ3624)

☐Propeller, 130mm x 70mm (EFL9051)

☐LiPo battery, 130 - 160 mAh 3.7V

*SPMAR6400 may be used with computer radio.

Covering Film Requirements

While any high-quality covering film may be used to finish this model, superior results will be achieved by

using genuine AeroLITE brand covering film, available exclusively from Stevens AeroModel. The lower

working temperature and light weight of AeroLITE are especially desirable for this type of model.

AeroLITE is one-third the weight of typical model covering films, and will present a significant weight

savings when applied to this model.

☐2 - PatchPakTM AeroLITE (Antique Cream and Black - or Dark Green)

Sealing Bare Wood

While not required, it is suggested that a high-quality clear lacquer be used to protect and seal any

unfinished wood. One single light coat of clear lacquer should be sufficient to protect the model from

moisture, without adding significantly to the model’s final flying weight.

Many parts of this model may be colored using a lacquer-based spray paint. Listed below are some of

the products we have used on our models. Please feel free to use whatever products you prefer.

☐DEFT clear lacquer-based sealant (available at most hardware stores)

☐Design Master Color Tool, lacquer-based spray paint (available at most arts and crafts stores)

Build Instructions

1919 Ricci Triplane UM - Build Instructions © 2015 Stevens AeroModel, all rights reserved.!Page 4

Required Building Supplies and Tools

☐CA glue, medium, 1/4 oz (PAAPT04)

☐CA glue, thin, 1/4 oz (PAAPT10)

☐CA glue applicator tips (PAAPT21)

☐CA glue accelerator (PAAPT15)

☐Hobby knife with supply of #11 blades

☐Sanding block with 120 and 240 grit paper

Building Supplies and Tools

☐Covering iron and heat gun

☐Needle nose pliers, small

☐Clear tape, 1/2 in. (DUB916)

☐Velcro for mounting battery (PKZ1039)

☐Masking tape (low-tack blue painter’s tape)

☐AeroLITETM covering film

Optional Building Supplies and Tools

☐Balsa filler (HCAR3401)

☐Modeling clay (ballast)

☐CA glue de-bonder (PAAPT16)

☐Required Building Supplies

☐

☐Clear lacquer-based sealant (DEFT)

☐Lacquer-based spray paint (Design

Master®)

Sheet Wood Inventory (1 of 1)

Build Instructions

1919 Ricci Triplane UM - Build Instructions © 2015 Stevens AeroModel, all rights reserved.!Page 5

Builder’s Notes

Build Instructions

1919 Ricci Triplane UM - Build Instructions © 2015 Stevens AeroModel, all rights reserved.!Page 6

General Assembly Instructions

Thank you for purchasing the Ricci Triplane UM from Stevens AeroModel.

This model has been developed and manufactured using state-of-the-art CAD/CAM systems. Our kits

feature a unique, interlocking construction process, that when compared to traditional building methods,

saves countless hours of measuring, cutting, sanding, and fitting. We are certain that you’ll find our kit to

offer a truly exceptional build experience.

As this kit is recommended for the novice model builder and pilot, we invite beginners who have

purchased this kit to seek the help of an experienced builder and pilot. If at any time during the assembly

of this kit, should you run across a term or technique that is foreign to you, please contact our staff with

your questions.

IMPORTANT!

Please READ and RE-READ these build instructions along with any other included documentation before

starting your build and/or contacting our staff for builder support.

Pre-Sanding

DO NOT SKIP THIS STEP. Before removing any parts from the laser-cut sheet wood, use a sanding

block loaded with 120 - 240 grit sandpaper and lightly sand the backside of each wood sheet. This step

removes any residue produced as a result of the laser cutting process. We have found that most stock

wood sizes run several thousandths of an inch oversized. This step also slightly reduces the thickness of

each sheet of wood. Leave all parts in the sheet wood until required for assembly.

Protecting Your Work Surface

Use the poly tube that this kit was shipped in as a nonstick barrier between your work surface and the

product assembly.

Bonding the Assembly

This product’s tabs and notches interlock like a 3D puzzle. We strongly suggest that when fitting parts,

you “dry fit” (use no glue) the parts together first. It is advised to work 1 - 2 steps ahead in the

instructions, using this dry-fit technique. This allows the opportunity to inspect the fit and location of

assembled components, and shows the benefits of our construction technique. As each successive part

is added, it contributes to pulling the entire assembly square. Once you arrive at the end of a major

assembly sequence, square your work on a flat work surface, and bond the dry fit joints with glue. Using

the dry-fit process, you’ll be able to recover from a minor build mistake, and will ultimately end up with a

square-and-true assembly.

Unless otherwise noted in the instructions, we find it easier to “tack glue” parts (temporarily bonding parts

in assemblies, using a small dot of glue). When using medium CA glue, apply with a fine-tip CA glue

applicator. Never bond painted or covered assemblies with thin CA, as it can destroy the finish of a

beautifully prepared model.

Never Force the Fit!

This is a precision laser-cut kit. Our lasers cut to within 5 thousandths of an inch in accuracy. Yet the

wood stock supplied to us by the mill may vary in thickness by up to 20 thousandths. This variance in the

wood stock can cause some tabs and notches to fit very tightly. With this in mind, consider lightly sanding

or lightly pinching a tight-fitting tab, rather than forcing the parts together. You will break fewer parts in

assembly, and end up with a square-and-true airframe.

Manual Updates

Please check our website for updates to these instructions before starting the build. To obtain downloads

and updates for this model aircraft kit, please visit the product page at stevensaero.com

Build Instructions

1919 Ricci Triplane UM - Build Instructions © 2015 Stevens AeroModel, all rights reserved.!Page 7

Fuselage

Fuselage parts are designated with the letter “F” followed by a number. Parts have been numbered so

that the fuselage assembly follows a sequential order: F1 to F30.

Note: When initially bonding parts, use a single, small drop of medium CA glue applied sparingly with a

CA glue applicator tip to “tack glue” the part in place. Should you commit an error in assembly, it will be

easier to recover from the mistake and remove or correct the part in error, if you do not soak the assembly

with glue after each step! This method of assembly will allow our interlocking design to do its job.

As each successive part is installed within the fuselage, it will help pull the entire structure square and

true. When a major assembly is completed, revisit all joints and bond completely. Do not use excessive

amounts of glue, as this only adds weight to the model.

1. Central Crutch - Receiver Tray: Lay F1 (sheet 06/10, 1/20 in. balsa) on the work surface

with the side etched “Top” facing up. Locate the nylon receiver clip in the hardware bag,

and fit F2 and F3 (sheet 10/10, 1/32 in. ply) to the receiver clip to create the receiver tray.

Fit the complete receiver tray to F1. Orient the receiver tray so that the long arm on the clip

is toward the front of F1. Bond with CA.

2. Motor Mount: Lay F4 (sheet 10/10, 1/32 in. ply) on the work surface with the side etched

“Top” facing up. Fit F5 and F6 (sheet 10/10, 1/32 in. ply) to the slots at the front of F4.

Bond with medium CA.

3. Fit the completed motor mount to the front of F1. Orient the motor mount so that F4 is

underneath F1. Bond with medium CA.

4. Formers: Slide former F7 (hardware bag, 1/16 in. ply) onto the front of the motor mount

until it engages the tabs at the front of F1. Bond with CA.

5. Fit and “tack glue” former F8 (sheet 10/10, 1/32 in. ply) to the slots, in front of the

receiver tray.

6. Fit and “tack glue” former F9 (sheet 06/10, 1/20 in. balsa) to the rear of F1. Orient the “Top”

marking on F9 so that it is on the same side of F1 as the receiver tray and F8.

7. Fit a 1/8 in. x 1/16 in. Neo-Magnet (hardware bag) to the hole at the rear of part F10 (sheet

08/10, 1/16 in. balsa). Bond with CA.

8. Fit and “tack glue” F10 to the notches in F9, and to the tabs at the top of F8. Use medium

CA, to ensure that no glue fills the perforations on the crosspiece at the front of F10.

Build Instructions

1919 Ricci Triplane UM - Build Instructions © 2015 Stevens AeroModel, all rights reserved.!Page 8

□

□

□

□

□

□

□

□

Build Instructions

1919 Ricci Triplane UM - Build Instructions © 2015 Stevens AeroModel, all rights reserved.!Page 9

Step 1

Step 2

Step 3

Step 4 Step 8

Step 7

Step 6

Step 5

F1

F6

Bond

F7

Top

F10

F10

F9

Top

F8

F2

F3

Front

Long

Arm

F5

F4 Etched

Side Up!

Bond

F1

Receiver Tray

Receiver Tray

1/8 in.

Neo-Magnet

No glue on

perforations!

Fuselage (continued)

9. Fuselage Sides - Fit and bond F11a and F11b (sheet 04/10, 1/20 in. balsa) to create the

left fuselage side. Fit and bond F12a to F12b (sheet 04/10, 1/20 in. balsa) to create the

right fuselage side.

10. Fit and “tack glue” the F11 assembly to the left side of the central crutch. Fit and “tack glue”

the F12 assembly to the right side of the central crutch. Square the assembly on a flat

surface and “final bond” all parts of the central crutch and the fuselage sides with CA.

Do not bond the rear of the fuselage at this time.

11. Remove the crosspiece at the front of F10.

12. Landing Gear Pocket - Turn the fuselage assembly upside down. Slide F13 (sheet 10/10,

1/32 in. ply) into the angled notches along the bottom of the fuselage sides, and into the two

corresponding slots in F1. The notches in the fuselage are oversized to accommodate the

other parts of the landing gear pocket. F13 goes to the front portion of these notches.

13. Slide F14 (sheet 10/10, 1/32 in. ply) into the same slots in the fuselage sides, immediately

behind F13.

14. Slide F15 (sheet 10/10, 1/32 in. ply) into the same slots in the fuselage sides, immediately

behind F14, and into the single slot in F1. Ensure that all three parts are fully seated, then

wick CA around the edges of both sides of the landing gear pocket. Make sure that no

glue enters the landing gear pocket.

15. Rear Fuselage - Turn the assembly right side up. Fit and bond crosspiece F16 (sheet

02/10, 1/20 in. balsa) to the notches along the top of the fuselage sides behind former F9.

16. Fit former F17 (sheet 02/10, 1/20 in. balsa) to the slots in the fuselage sides behind F16.

Ensure that F17 is installed with the “Top” marking at the top of the fuselage.

Build Instructions

1919 Ricci Triplane UM - Build Instructions © 2015 Stevens AeroModel, all rights reserved.!Page 10

□

□

□

□

□

□

□

□

Build Instructions

1919 Ricci Triplane UM - Build Instructions © 2015 Stevens AeroModel, all rights reserved.!Page 11

Step 9

Step 10

Step 11

Step 12 Step 16

Step 15

Step 14

Step 13

F11a

Bottom View

Bottom View

Bottom View

F11

F12

Remove

Crosspiece

F13

F17

Top

F16

F15

F14

F11b

Fuselage (continued)

17. Fit the rear deck, part F18 (sheet 02/10, 1/20 in. balsa) to the top of the fuselage, slightly

overlapping F16. View the fuselage assembly from the rear, and make sure that the

fuselage is not twisted. When satisfied that it is straight, “final bond” F17 and F18 to F16,

and to the fuselage sides with CA. Pull the rear of the fuselage together, bond with CA.

18. Fuselage Bottom - Fit and bond together parts F19a through F19d (sheet 06/10, 1/20 in.

balsa) to create the fuselage bottom.

19. Turn the fuselage upside down. Fit the F19 assembly to the bottom of the fuselage sides,

landing gear pocket, and to formers F9 and F17. Check to ensure that the fuselage is still

straight, then bond the fuselage bottom with CA. Ensure that no glue enters the landing

gear pocket.

20. Fit and bond the forward fuselage bottom, part F20 (sheet 06/10, 1/20 in. balsa) to the

fuselage sides, and to the front of the landing gear pocket, part F13 and former F7.

21. Cowl - In order, slide F21, F22, and F23 (sheet 09/10, 3/16 in. balsa) onto the front of the

motor mount and against former F7. Make sure that the etched side of F23 faces forward.

“Tack glue” the laminations together with medium CA. Do not bond the cowl to the

fuselage or motor mount at this time.

22. Carefully remove the cowl and lay it on the work surface with F23 facing up. Center part

F24 (sheet 09/10,3/16 in. balsa) within the etched circle on the front of F23. “Tack glue” in

place. Next, wick CA between all laminations to bond the cowl assembly together.

23. Use a sanding block or stick, to sand the cowl. Match the contours shown on the Fuselage

Side View drawing on Detail Sheet 1 of 2. Set the cowl aside until required in the Covering

and Painting steps in this manual.

Build Instructions

1919 Ricci Triplane UM - Build Instructions © 2015 Stevens AeroModel, all rights reserved.!Page 12

□

□

□

□

□

□

□

Build Instructions

1919 Ricci Triplane UM - Build Instructions © 2015 Stevens AeroModel, all rights reserved.!Page 13

Step 17

Step 18

Step 19

Step 20 Step 23

Step 22 Cont.

Step 22

Step 21

F18

Bottom View

Bottom View

F19a

F20

F19

F23

F24

Etched

Line

F19b

F19c

F19d

F22 F21

Fuselage (continued)

24. Nose Sheeting - Fit and bond former F25 (sheet 06/10, 1/20 in. balsa) to the angled

notches in the top of the fuselage sides, immediately in front of F10.

25. Fit and bond F26 (sheet 04/10, 1/20 in. balsa) to the tabs on formers F7 and F25.

Orient F26 so that the slightly curved edge rests on F7.

26. Fit and bond F27 (sheet 04/10, 1/20 in. balsa) to each side of F26. Engage the tab at the

bottom rear of F27 with the small notch in the fuselage side.

27. Cockpit - Fit part F28 (sheet 08/10, 1/16 in. balsa) on top of F10 in the cockpit area. Bond

F28 around the outer edges only with medium CA. Make sure that no glue gets into the

perforations at each end of the crosspiece at the front of F28. Do not apply glue around

the inner edges of F28.

28. Carefully remove the crosspiece at the front of F28.

29. Turtle Deck - Fit and bond F29 to the tab at the top of former F9, and to the front of F18.

30. Fit and bond one F30 to each side of F29 and to the fuselage sides.

31. Hatch - Lay H1 on the work surface with the side etched “Bottom” facing up. Press a 1/8 in.

x 1/16 in. Neo-Magnet into the hole at the rear of H1. Check the polarity of the magnet, so

that it attracts the magnet in F10 when H1 is placed within the cockpit with the side etched

“Bottom” facing down. Bond the magnet to H1 with CA.

Build Instructions

1919 Ricci Triplane UM - Build Instructions © 2015 Stevens AeroModel, all rights reserved.!Page 14

□

□

□

□

□

□

□

□

Build Instructions

1919 Ricci Triplane UM - Build Instructions © 2015 Stevens AeroModel, all rights reserved.!Page 15

Step 24

Step 25

Step 26

Step 27 Step 31

Step 30

Step 29

Step 28

F25

F26

F27

F28

Remove

Crosspiece

F29

F30

1/8 in.

Neo-Magnet

Curved

Edge

Tab/Notch

No glue in

perforations!

F29

F18

H1 - Etched

Side Up!

Fuselage (continued)

32. Align part H2 (sheet 10/10, 1/32 in. ply) within the etched outline at the other end of H1.

Bond with CA.

33. Turn the hatch right side up – with H2 underneath. Fit the pilot figure P (sheet 02/10, 1/20

in. balsa) to the slot at the rear of H1. Make sure that the pilot is facing forward! Bond with

CA. Lay the completed hatch assembly aside until required in the Covering and Painting

steps in this manual.

Tail Surfaces

34. Vertical Stabilizer and Rudder - Locate V and R1 (sheet 07/10, 1/20 in. balsa). Lightly

sand them to remove the burn residue left over from the laser cutting process.

35. Align the leading edge of the rudder R1 with the edge of the work surface. Orient R1 so

that the left side of the rudder faces up. Use a sanding block or stick to sand a 45-degree

bevel along the left side of the leading edge of R1.

36. Horizontal Stabilizer and Elevator - Locate parts H and E2 (sheet 07/10,1/20 in. balsa),

and E1 (sheet 10/10, 1/32 in. ply). Lightly sand the parts to remove the burn residue from

the laser cutting process. Set part H aside. Build the elevator assembly by fitting and

bonding together parts E1, and both E2s.

37. Align the leading edge of the elevator with the edge of the work surface, and sand a 45-

degree bevel all along the leading edge. This bevelled side will now be referred to as the

bottom of the elevator.

Set the completed tail surfaces aside until required in the Covering and Painting steps in

this manual.

Wings

38. Upper Wing - Fit two ribs UW2 (sheet 05/10, 1/20 in. balsa) to the upper spar UW1 (sheet

10/10, 1/32 in. ply).

39. Lay the upper wing sheeting UW3 (sheet 01/10, 1/20 in. balsa) on the work surface with the

etched side facing up. Fit the tabs at the rear of ribs UW2 into the slots at the center rear of

UW3. Bond only the rear of the ribs to UW3 with CA.

Build Instructions

1919 Ricci Triplane UM - Build Instructions © 2015 Stevens AeroModel, all rights reserved.!Page 16

□

□

□

□

□

□

□

□

Build Instructions

1919 Ricci Triplane UM - Build Instructions © 2015 Stevens AeroModel, all rights reserved.!Page 17

Step 32

Step 33

Step 34

Step 35 Step 39

Step 38

Step 37

Step 36

H2

Bottom View

P

H2 Underneath!

V

45 deg.

UW3

UW1

E1

Etched

Line

H1

H1

Top

R1

Top View

Top View

Left

Right

45 deg.

Bottom

Top

E2

E2

UW2

UW2

Etched

Side Up!

Bond

Bottom View

Wings (continued)

40. Fit the rear of ribs UW4 and UW5 (sheet 05/10, 1/20 in. balsa) to the notches and slots

along the rear of the left and right ends of the wing panel. Fit the tips of the spar into the

slots in ribs UW4, but do not bond. Refer to the plan on Detail Sheet 2 of 2 for the correct

location of each rib. Bond the rear of the ribs to UW3 with CA.

41. Turn the assembly over on the work surface. Wrap UW3 over the top of the ribs. Fit the

tabs at the front of each rib into the corresponding slots in UW3. Bond the ribs at each tab

location with CA. Remove the wing from the work surface, and carefully examine each rib.

Close any gaps and “final bond” the ribs to UW3. Bond the spar to UW3 and to ribs UW1

and UW4.

42. Fit and bond the outer wing trailing edges UW6 to the trailing edge of each wing tip, and to

ribs UW4 and UW5.

43. Middle Wing - Lay one MW1 (sheet 02/10, 1/20 in. balsa) on the work surface, with the

etched side facing up. Fit the tabs at the rear of ribs MW2, MW3, and MW4 (sheet 05/10,

1/20 in. balsa) to the slots along the rear of MW1. Refer to the plan on Detail Sheet 2 of 2

for the correct location of each rib. Bond the rear of each rib to MW1 with CA.

44. Turn the wing over and wrap MW1 over the top of the ribs. Fit the tabs at the front of the

ribs into the corresponding slots in MW1. Bond the ribs at each tab with CA. Remove the

wing from the work surface and examine each rib. Close any gaps and “final bond” all the

ribs to MW1.

45. Fit and bond the outer trailing edge, part MW5 (sheet 02/10, 1/20 in. balsa) to the trailing

edge of the wing tip and to ribs MW3 and MW4

Repeat steps 43 through 45 to build the other wing panel. Build a mirror image of the

first wing panel!

46. Lower Wing - Center Section: Lay two ribs LW1a (sheet 05/10, 1/20 in. balsa) on the work

surface with the etched sides facing up. Position LW1b and LW1c (sheet 03/10, 1/20 in.

balsa) over the front and rear of each rib. Align the rear of LW1b and the front of LW1c with

the etched lines on LW1a. Bond with CA.

47. Fit the completed ribs to the lower spar, part LW2 (sheet 10/10, 1/32 in. ply).

Orient LW1a so that it is on the inside, and LW1b and LW1c are on the outside.

Build Instructions

1919 Ricci Triplane UM - Build Instructions © 2015 Stevens AeroModel, all rights reserved.!Page 18

□

□

□□

□□

□

□

□□

□

Build Instructions

1919 Ricci Triplane UM - Build Instructions © 2015 Stevens AeroModel, all rights reserved.!Page 19

Step 40

Step 41

Step 42

Step 43 Step 47

Step 46

Step 45

Step 44

UW4

Bottom View

Bottom View

UW6

MW1

MW5

LW1a

LW2

UW5

Bond

Bond

MW4

MW3

MW2

Bond

LW1b LW1c

LW1c

LW1c

LW1a

Wings (continued)

48. Locate the lower wing center sheeting LW3 (sheet 03/10, 1/20 in. balsa) and fit the notches

at the rear of each side to the tabs at the rear of ribs LW1a. Bond the tabs to LW3 with CA.

Wrap the wing center section sheeting over the ribs. Bond with CA.

49. Lower Wing - Outer Panels: Lay LW4 (sheet 03/10, 1/20 in. balsa) on the work surface

with the etched side facing up. Fit the tabs at the rear of ribs LW5 and LW6 (sheet 05/10,

1/20 in. balsa) to the slots along the rear of LW4. Refer to the plan on Detail Sheet 2 of 2

for the correct location of each rib. Bond the rear of each rib to LW4 with CA.

50. Turn the wing over and wrap LW4 over the top of the ribs. Fit the tabs at the front of the ribs

into the corresponding slots in LW4. Bond the ribs at each tab with CA. Remove the wing

from the work surface and examine each rib. Close any gaps and “final bond” the entire rib

to LW4.

51. Fit and bond the outer trailing edge, part LW7 (sheet 03/10, 1/20 in. balsa) to the trailing

edge of the wing tip and to ribs LW5 and LW6.

Repeat steps 49 through 51 to build the other lower wing panel. Build a mirror image of

the first wing panel!

52. Fit the wing panels to the center section. Insert the tip of the spar into the slots in rib LW5.

Rest the root of the wing panel on LW1b and LW1c, align the leading and trailing edges

carefully.

53. Bond LW1b and the spar to the lower wing assembly LW4.

54. Turn the wing over, and close any gaps between the wing panel and the center section.

Bond with CA.

Landing Gear Struts

55. Make two sets of landing gear struts. Use medium CA to bond LG1 to LG2 (sheet 10/10,

1/32 in. ply).

Build Instructions

1919 Ricci Triplane UM - Build Instructions © 2015 Stevens AeroModel, all rights reserved.!Page 20

□

□

□

□

□

□

□

□

Table of contents

Popular Toy manuals by other brands

RIOT PLANES

RIOT PLANES Sea Monkey Building instructions

Eduard

Eduard P-39Q/N interior quick start guide

Trix

Trix Minitrix 66322 instructions

Mega Construx

Mega Construx Call of Duty Dragonfire Drone Strike manual

PIKO digital

PIKO digital SmartControllight startset manual

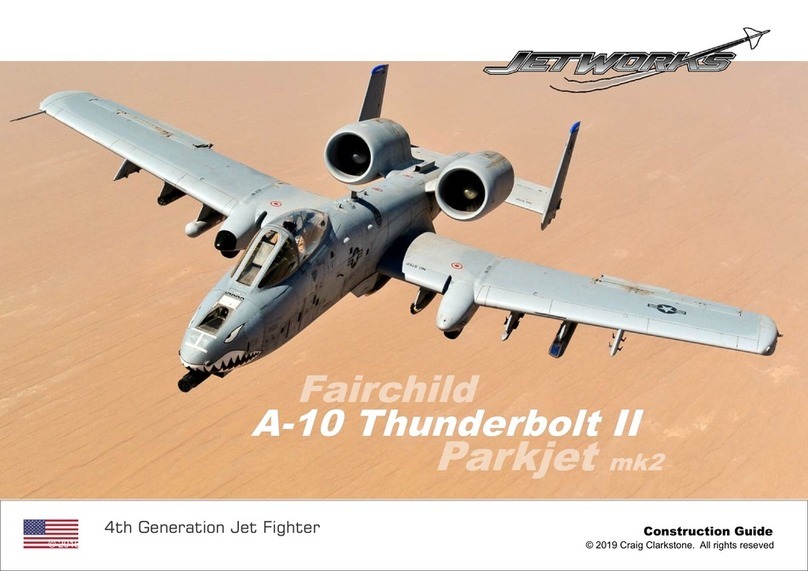

Jetworks

Jetworks Fairchild A-10 Thunderbolt II Parkjet mk2 Construction guide