Stewart MacDonald Bluegrass Resomaster User manual

Resonator Guitar Kit

Assembly Instructions

www.stewmac.com

page 1

Getting started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Assembling the body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Gluing the sides to the neck block and tail block. . . . . . . . . . . . . . . . 3

Making the inner-body form and waist clamp . . . . . . . . . . . . . . . . . . 4

Installing the kerfed lining (“kerfing”) . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installing the top. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Sanding the back kerfing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installing the soundwell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installing the back. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Routing for binding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installing the binding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Assembling the neck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installing the truss rod. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Shaping the fingerboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Inlaying the fingerboard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installing side dots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Fretting the fingerboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Installing the fingerboard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Installing the peghead overlay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Fitting the tuning machines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Final assembly and setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Fitting the cone. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Truing the spider’s “legs”. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Installing the saddle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installing the nut. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Spacing the strings at the saddle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Setting the string height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Install the remaining strings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Cut the saddle notches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Tune to pitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Install the fingerboard mounting screws . . . . . . . . . . . . . . . . . . . . . . 24

Burnish the saddle slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Installing the cover plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Finishing with a traditional sunburst. . . . . . . . . . . . . . . . . . . . . 26

Do’s and don’ts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Sanding the body. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Filling fret ends and sanding the neck. . . . . . . . . . . . . . . . . . . . . . . . . 27

Making hangers and masking the neck and body. . . . . . . . . . . . . . 27

Staining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Applying a wash coat sealer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Filling the wood grain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Sunbursting the body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Lacquer spraying schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Wet-sanding and rubbing out the finish. . . . . . . . . . . . . . . . . . . . . . . 30

Appendix 1: Neck-fitting details . . . . . . . . . . . . . . . . . . . . . . . . . 31

The “cheeks” of the neck heel set the neck angle . . . . . . . . . . . . . . . 31

Neck adjustment: side-to-side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Neck adjustment: tilt the neck back . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Neck adjustment: tilt the neck up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Understanding neck angle geometry . . . . . . . . . . . . . . . . . . . . . . . . . 33

Appendix 2: Intonation check (optional). . . . . . . . . . . . . . . . . . 34

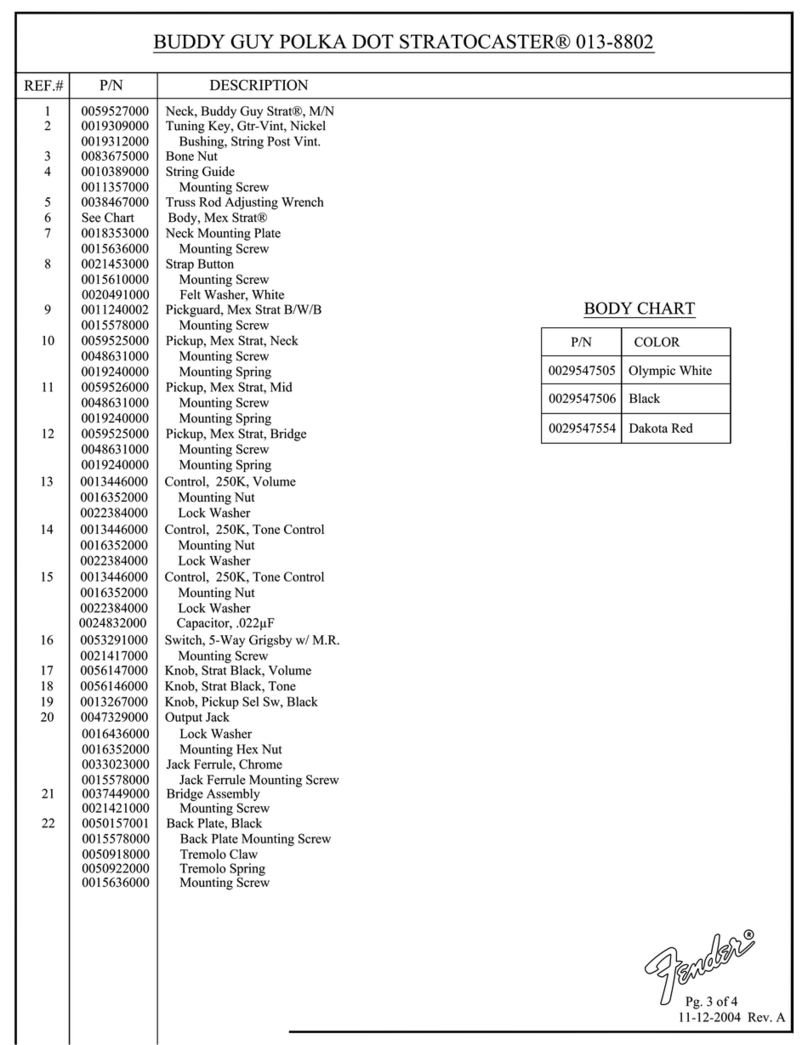

Table of Contents

Welcome to guitar building! You’re about to build a great

square-neck resonator guitar — the instrument that puts the

blues in bluegrass!

We designed this kit with the small shop builder and a mod-

est tool budget in mind. For power tools, we used a small

laminate router and an electric hand drill. With the exception

of a few specialty guitarmaking tools, such as several nut-

slotting files, we used standard woodshop hand tools. These

included a chisel, rasp, half-round bastard file, small razor saw,

a sharp knife, a couple of rulers, and a long straightedge. Of

course, we used some clamps (8 cam clamps, 24 spool

clamps and 50 clothespins), but that’s all.

Please read these instructions before building your guitar. It’s

important for you to “dry run” the fitting, gluing, clamping

and finishing operations before trying them for real. Also, it’s

very important to acclimate the wood to your building envi-

ronment. The ideal temperature is 70-80° Fahrenheit, with a

controlled relative humidity of 45-50%. The kit wood should

be laid out and allowed to “equalize” for one week in your

shop. Flip the wood daily to minimize excessive warping.

Depending upon your location and the season, you may

need to humidify or dehumidify your shop to maintain the

desired relative humidity. It’s a good idea to use a ther-

mometer/hygrometer to monitor your shop’s climate (our

Digital Hygrometer is accurate and inexpensive). If you’re

unable to control the relative humidity in your shop, we dis-

courage building the guitar during the transition from dry to

wet seasons, or vice versa. The radical change in humidity

can cause serious complications from cracks or warping.

Neck assembly and body assembly are two separate process-

es. So, you can work on the neck while glue is drying on the

body, and vice versa.

Use a flat workboard approximately 24" x 36" x 3/4" for keep-

ing the body flat during assembly. Plywood is your best bet,

and Baltic birch is an ideal choice. We used a flat basswood

drafting board.

Be safe when using tools, glues, and chemicals. Wear

eye protection and gloves when needed, and always

use proper ventilation.

Getting started

© 2003 Stewart-MacDonald

page 2

page 3

Determine the center of the neck block and tail block and

draw centerlines in pencil on their outer faces (their gluing

surfaces) and on the tops and bottoms of the blocks.

Place the bent sides on the flat workboard to approximate

the shape of your guitar. The top of your guitar will be facing

down (either edge of the sides can be used as top or back).

One at a time, glue the sides to the neck and tail block. No

trimming to length is necessary; simply butt the ends tightly

together on the centerlines penciled on the blocks.

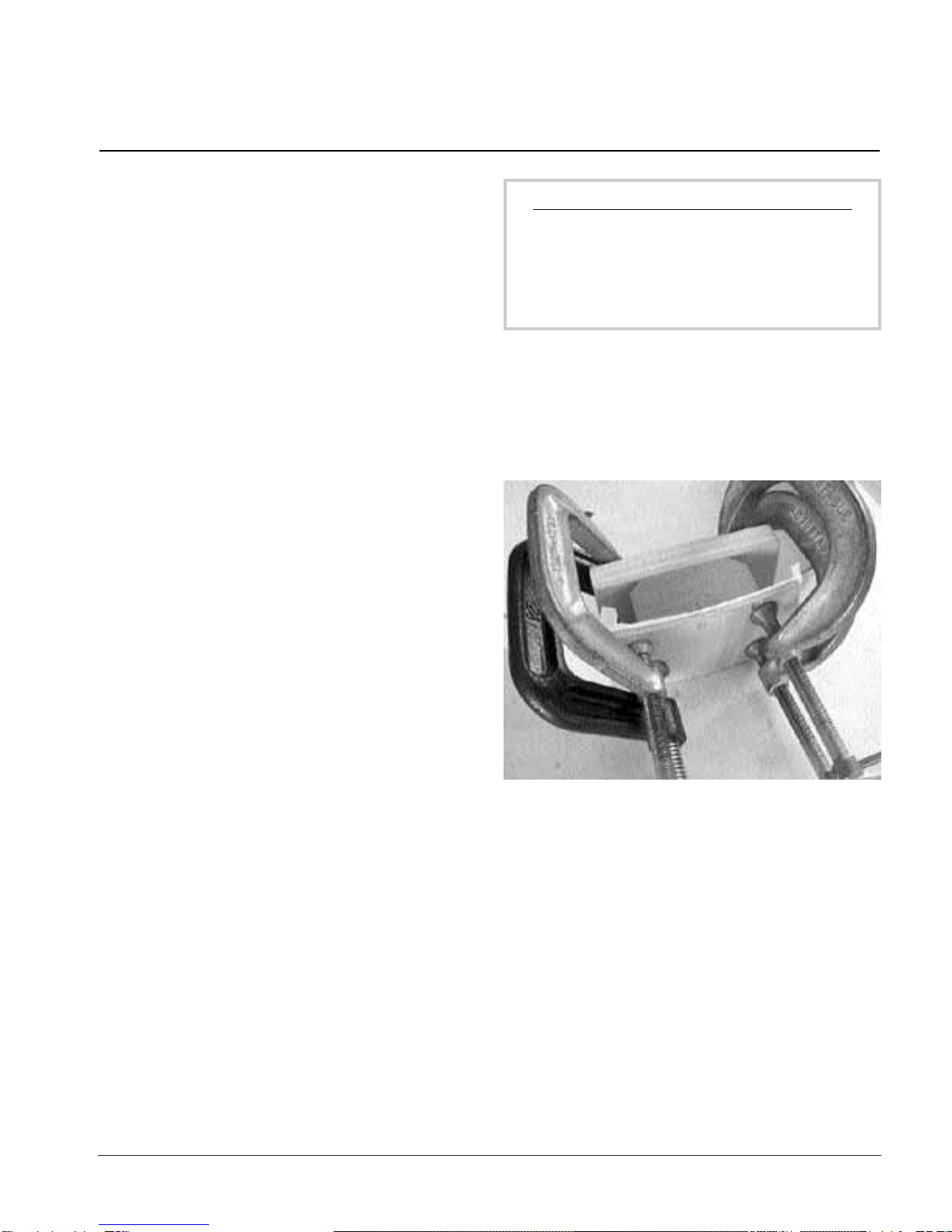

Throughout these instructions we will use clamping“cauls”to

protect the wood from clamp marks, and to apply even pres-

sure over a glue joint. The outer (gluing) surface of the neck

block is flat, so use a flat caul when you clamp it. However,

the tail block is radiused. The simplest clamping caul for

squeezing the sides against the radiused tail block is a scrap

of 1/4" plywood or wall paneling as the outer curved caul,

and a scrap wood caul on the backside of the tail block.

The neck block and tail block have beveled corners on their

inner sides. The inner backing caul at the tail block should be

wider than the block itself so the clamps put pressure where

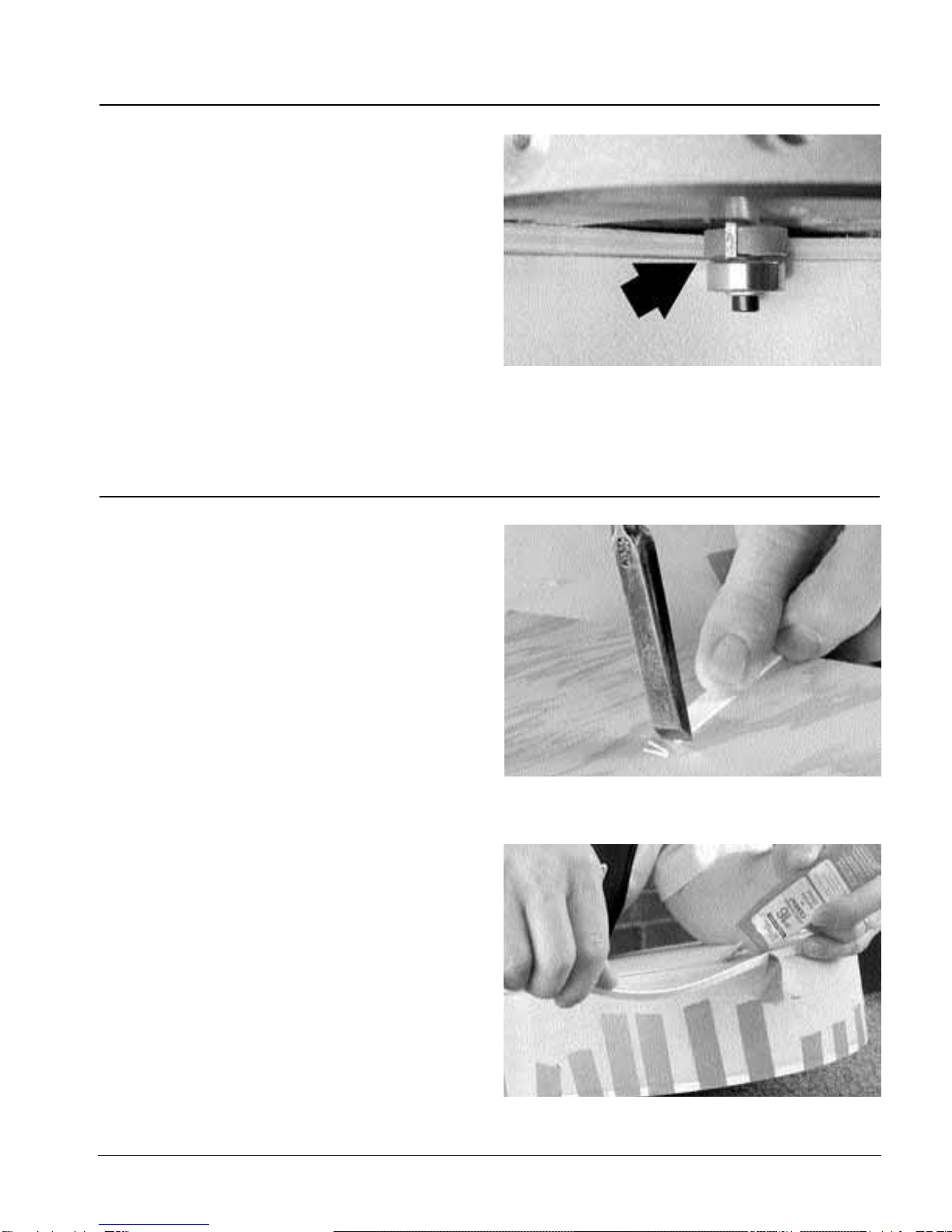

it’s needed to pull the sides into the curve (1). The 1/4" outer

caul, being longer than the block, flexes and forms the sides

to the block. A layer of wax paper between the sides and the

caul will keep them from being glued together accidentally.

During gluing, the neck block and tail-block should rest flat

on the work surface, and flush with the face down top edge

of the sides. A weighted block of wood laid across the sides

helps keep them flat on the table during gluing.

TIP: Use a glue brush

Applying glue with a brush eliminates most of the

glue squeeze-out because the brush spreads just

the right amount of glue. We use are flux brushes,

inexpensive hardware store items used in plumb-

ing. Or, you can spread the glue with your finger!

After the neck and tail blocks are installed and the glue has

dried, use a 9/32" drill bit to drill through the sides to open

up the neck block’s bolt holes. Clamp a piece of scrap wood

over the sides before drilling to minimize tear-out as the bit

breaks through the fragile side wood.

Assembling the body

Gluing the sides to the neck block and tail block

1. The simplest clamping caul for squeezing the sides against the

radiused tail block is a scrap of 1/4" plywood or wall paneling as the

outer curved caul, and a wooden caul on the backside of the tail

block.

Install the waist clamp from the backside of the guitar. (Later,

after the top’s installed, you’ll switch the waist clamp to the

top side). When sliding the waist clamp on, hold the guitar

sides tight against the cardboard form to avoid cracking the

sides. If the fit is too tight, remove small amounts from each

side of the U-shape until the waist clamp slides snugly onto

the waist, but not so tightly that it’s hard to remove.

page 4

The two pieces of heavyweight cardboard supplied with the

kit are for creating a guitarmaking form to support the body

during the early stages of building.

Using the paper pattern, cut two matching pieces in the

shape of the guitar body. Cut carefully on the lines of the pat-

tern, leaving no extra cardboard outside the lines.

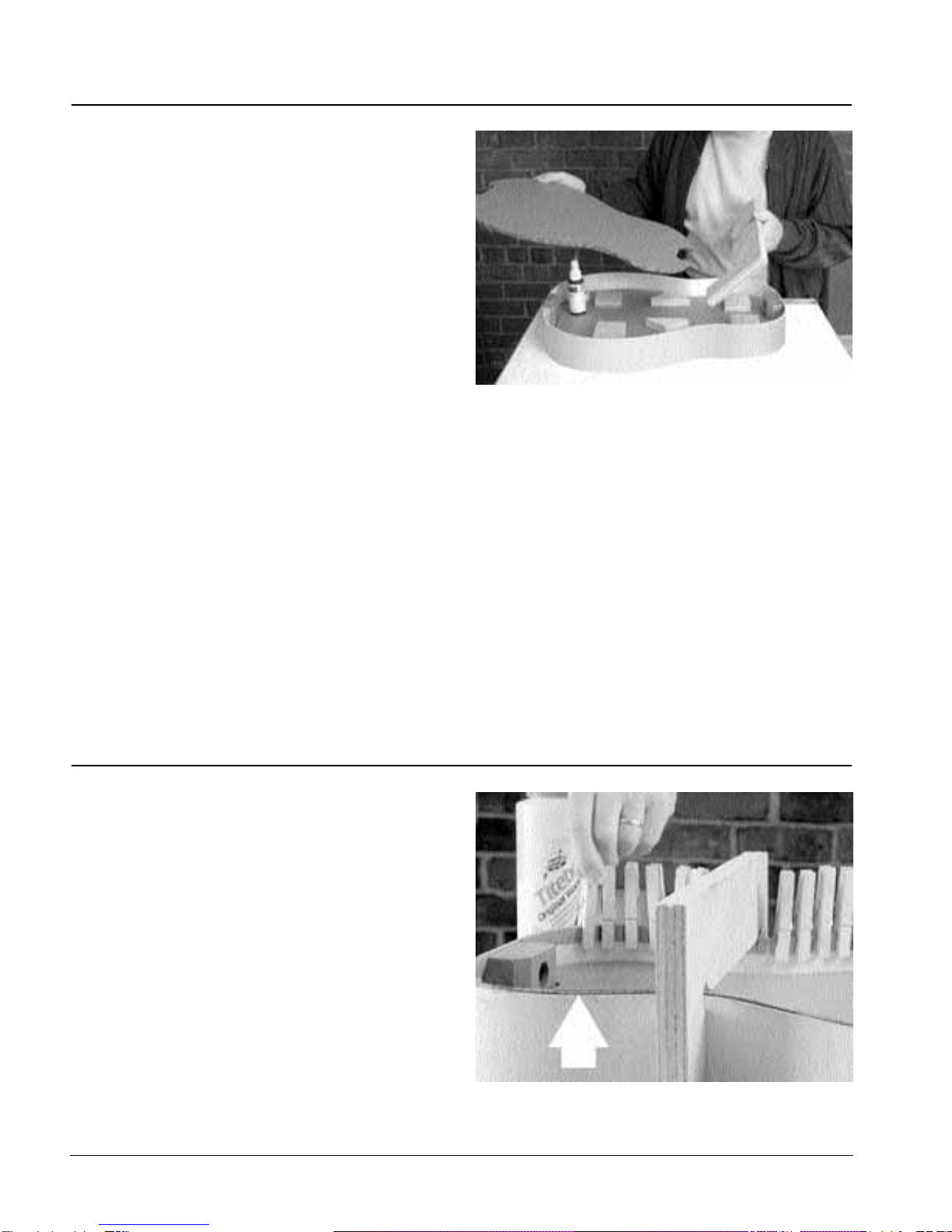

Build the cardboard form inside the guitar body. First, place

two scraps of 3/4" plywood onto the work surface inside the

guitar. This will lift the cardboard form up to make room for

the kerfed linings, which will be installed later. Lay the first

cardboard piece onto the 3/4" plywood inside the guitar

body.

Next, glue several 3/4" thick blocks of scrap wood onto the

cardboard, and then glue the second piece of cardboard

onto them. Now the two cardboard forms are fastened

together with blocks of wood between them, creating a

three-dimensional form for supporting the guitar sides (2).

Now use the paper pattern to make the U-shaped “waist

clamp” from 3/4" plywood. The purpose of the waist clamp is

to hold the guitar’s waist tight to the inner cardboard mold,

maintaining a constant shape until the back is glued on.

Use a file to smoothly round the two inner edges of the waist

clamp. Square edges wouldn’t slide over the tight curve of

the guitar sides at the waist, and they could crack the wood.

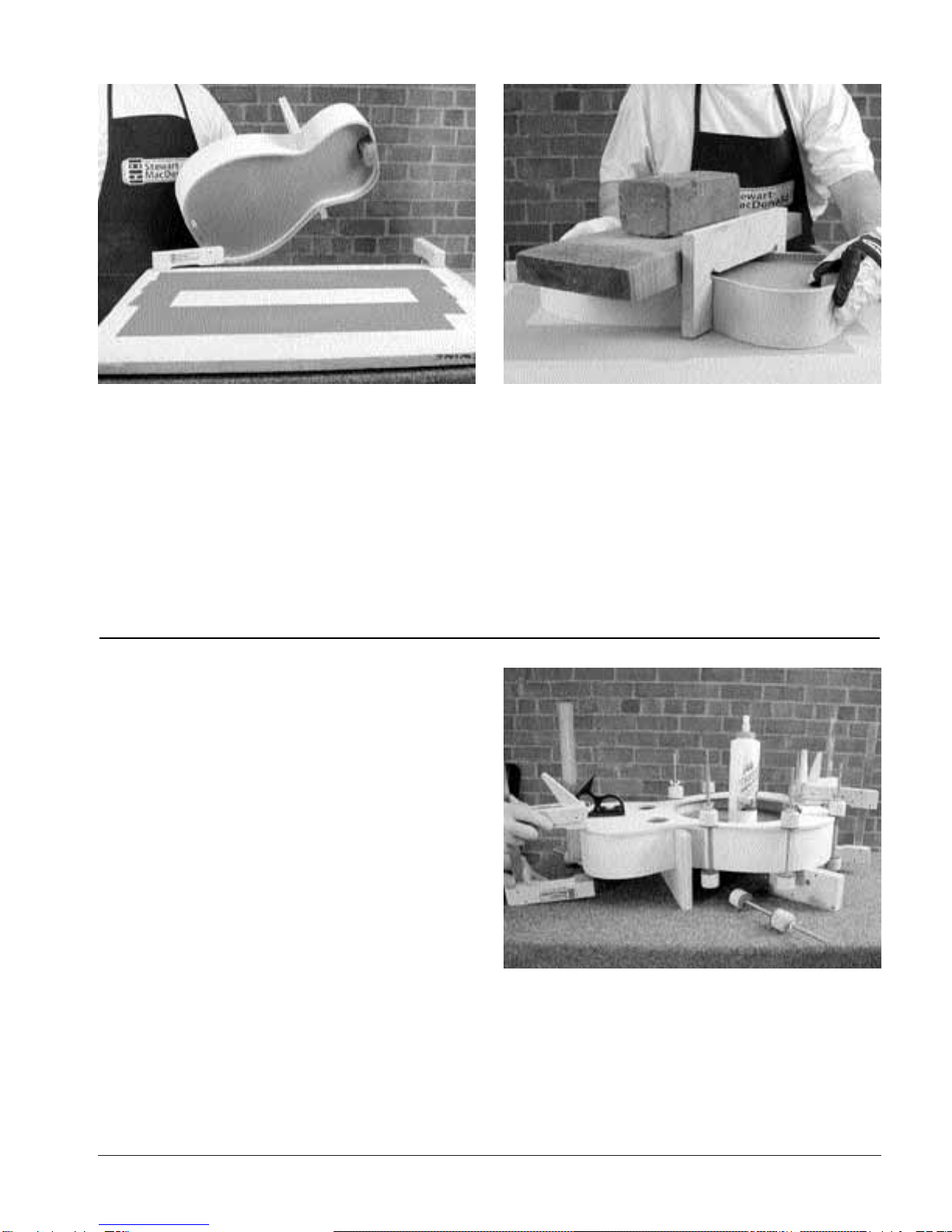

With Titebond glue, and clothespins as clamps, install the

kerfing on the top and back. The kerfing should start at the

inner edge of the neck block and run to the inner edge of the

tail block. Leave the kerfing raised slightly, approximately

1/64", above the side’s edges, both top and back (3). This

guarantees that the kerfing will be flush with the top edge of

the sides after sanding (as described next), and makes up for

any possible misalignment during gluing. In guitar building

it’s safest to err slightly on the high side — you can always

remove wood, but it’s hard to put it back! Let the glue dry at

least 4 hours.

Installing the kerfed lining (“kerfing”)

2. The two cardboard forms are fastened together with blocks of

wood between them, creating a three-dimensional form for sup-

porting the guitar sides.

Making the inner-body form and waist clamp

3. The kerfing is installed with 1/64" exposure above the side's

edges.

page 5

Apply adhesive-backed 80-grit sandpaper (or non-stick sand-

paper and double-stick tape) to an area of the workboard as

shown in the picture (4). Don’t cover the entire board, just a

large enough area so that the kerfing and sides contact the

sandpaper as you move the side assembly, face down, in

small circles to level the kerfed lining. Mark the gluing sur-

5. Try using a weighted board placed across the top side of the rim

for uniform downward pressure.

Choose the best looking surface of the guitar top as the out-

side surface. There two small centering holes at each end of

the guitar top. Center a long straightedge on these holes,

and lightly pencil an erasable centerline on the top.

Next, glue on the top. The most important thing you must do

is to line up the front (machined) edge of the top with the

sides at the neck block. The top and sides must be flush

there. This alignment locates the soundwell, and with it,

accurate intonation. There should not be ANY top overhang

in this area! (If, by accident, you glue on the top so that it

overhangs the sides at the neck block read “Appendix 2:

Intonation Check” at the end of these instructions before

continuing.)

With the waist clamp still installed from the rear, line up the

top’s centerline with the centerlines you drew on the neck

and tail blocks. Start clamping in the waist area, within sever-

al inches of either side of the waist clamp, using spool clamps

to gently hold the top in place (6). Clamp the tail block, using

two cam clamps or bar clamps and a caul to spread the

clamp pressure. Next, clamp the neck block. Use an accurate

square to be sure that the neck block is square to the top as

you clamp. Use the same type of clamps and caul that you

Installing the top

4. Apply adhesive-backed 80-grit sandpaper (or non-stick sandpa-

per and double-stick tape) to an area of the workboard.

faces of the sides, kerfing, neck block, and tail block all the

way around with a pencil. Check your sanding progress

often; when the sandpaper begins to remove the pencil

marks around the entire top, the kerfed lining will be level

with the sides. Try using a weighted board placed across the

top side of the rim for uniform downward pressure (5).

6. Start clamping in the waist area, for several inches to either side

of the waist clamp, using spool clamps to gently hold the top in

place.

page 6

used on the tail block. Follow with spool clamps spaced

evenly around the sides. With spool clamps close on either

side of the waist clamp, you should have good glue squeeze-

out at the waist. Leave the waist clamp in place, and let the

glue dry at least 5 hours.

TIP: Spool clamps

Spool clamps can be made using 8" all thread rods,

wing nuts, drilled wooden spools and cork or

leather lining pads. They’re also available in our

catalog.

Remove the waist clamp temporarily to make room for a

router. With the top glued on, notice that the sides have

gained great stability, even with the waist clamp removed.

Use a flush-cutting ball-bearing router bit to remove the top

overhang in the waist clamp area (any slight burnish marks

left by the ball-bearing will sand off easily). Later, after the

back is glued on, you’ll remove the rest of the top overhang.

For now, the top overhang will match the back overhang,

making it easier to align the spool clamps.

Since you need to remove the cardboard inner form before

you can install the soundwell, sand the back kerfing now

while the body is still relatively rigid.

Re-install the waist clamp from the top side. Place the guitar

on the sandpaper workboard with the back side down. Sand

the back kerfing flush just as you did the top, until the sand-

paper just “kisses” the penciled edge of the sides.

Sanding the back kerfing

The edges of the soundwell connect the top and back, and

kerfing is needed on these edges to provide enough gluing

surface. Install kerfing on the outside of the soundwell, once

again raised a slight 1/64" above the edge (7) for flush-sand-

ing on the flat sanding board. Flush-sand only one kerfed

edge of the soundwell — the edge that glues to the top —

and then flush-sand the back edge after the soundwell is

glued to the top. Sanding the soundwell kerfing in two

stages lets you carefully flush-sand the well with the back.

7. Flush-sand only one kerfed edge of the sound well — the edge

that glues to the top — then flush-sand the back edge after the

sound well is glued to the top.

Installing the soundwell

page 7

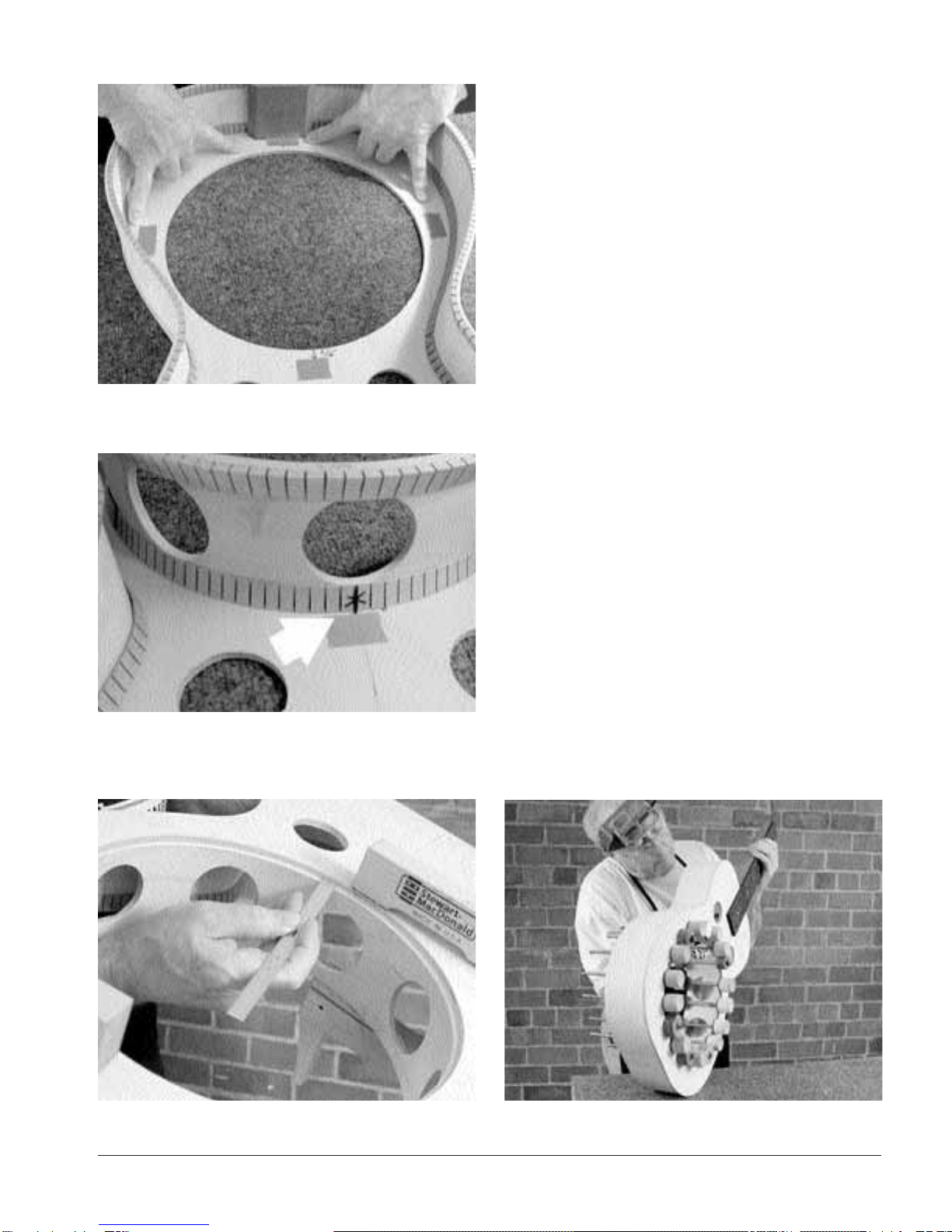

To align the soundwell concentrically with the hole in the

top, measure 5/16" out from the edge of the hole at four

opposite points, and place a piece of tape at each point as a

marker (8). The soundwell should be installed with one of

the soundwell’s “tone holes” (air-movement holes) in line

with the center of the guitar top — this hole provides access

for your wrench when you bolt on the neck. The soundwell’s

kerfing should almost touch the four masking tape markers

for alignment (9). The 5/16" measurements will leave about a

1/16" gap exposed between the outer edge of the kerfing

and the tape.

Important: Dry-clamp the soundwell to the top, and check to

see that the exposed ledge created by the edge of the

soundwell measures the same all around the hole in the top

(10). This ledge supports the cone and the spider; it’s not

very wide, so you must carefully center the soundwell when

gluing.

When the top/top alignment looks right, and is still dry-

clamped in position, pencil a mark around the kerfing on the

inside of the top as a quick reference for gluing the parts

together. Apply Titebond glue, and clamp the soundwell to

the top with spool clamps (11).

9. The sound well should center with an approximate 1/16" gap

exposed between the outer edge of the kerfing and the masking

tape.

8. Masking tape placed at four opposite points helps you align the

sound well.

10. This ledge supports the cone and the spider; it’s not very wide,

so you must carefully center the sound well when gluing.

11. Apply Titebond glue, and clamp the sound well to the top with

spool clamps.

page 8

With the soundwell glued to the top, the body assembly is

now very stable, and you can remove the waist clamp. Mark

the soundwell edge and the kerfing with pencil, and sand it

as you did the top and back. Put pressure in the center over

the soundwell, and not on the outer edges. You’ll sand away

the pencil marks quickly, so don’t work too hard!

To check that the soundwell is level with the back kerfing,

rest the body face down on your bench and place a straight-

edge across the soundwell kerfing. Rotate the straightedge

in a complete circle on the soundwell, and watch the gap

between the straightedge and the back kerfing: you’ll see

where it doesn’t touch the back kerfing. Perhaps those areas

will need a little extra pressure as you sand — mark them

with pencil as you did the top and back, and watch for the

pencil marks to disappear as you sand. Check your progress

until the straightedge contacts the side kerfing and the

soundwell kerfing evenly. The body is ready for the back to

be glued on.

At this point, you should have retained squareness between

the top and sides. Squareness is especially important at the

neck block in order to have the right playability later. If you

are out of square now, it can’t be by much. If you are, make a

note of it and adjust for that when you glue on the back, by

pushing or pulling the neck block and sides into square.

Install the back as you did the top. You don’t need the waist

clamp, but it won’t hurt to use. Start clamping at the waist

and sides, glue the tail block first, and the neck block last

(12). This is your last opportunity to square the neck block to

the top if needed.

To add extra pressure in the soundwell area, clamp a flat

board across the back (13). A little glue squeeze-out is a sign

that you have a good glue joint.

When the glue has dried, use the flush-cutting router bit to

trim the overhang from the top and back.

12. A good back clamping setup.

Installing the back

13. To add extra pressure in the sound well area, clamp a flat board

across the back.

page 9

The binding supplied with your kit measures approximately

1/4" x .060". Use StewMac’s Binding Router Cutter Set, with

the largest ball-bearing installed (14). This setup will rout a

ledge of approximately .060" for the binding width. Set the

height of the router bit’s cut at 15/64", or slightly more than

the thickness of the plywood guitar top/back, so the binding

hides the laminated edge of the plywood.

Rest the router squarely on the guitar’s top or back, and rout

a clean ledge for the binding. Be careful along the edge of

the soundwell because the router could tip easily with such

a small surface to rest on. It’s a good idea to practice routing

on scrap plywood or other wood to get a feel for the router

bit’s cut.

14. Set the height of the router bit’s cut at 15/64", or slightly more

than the thickness of the plywood, so the binding hides the lami-

nated edge of the plywood.

One strip of binding is not long enough to go completely

around the guitar, so you must use two strips and bind one

half of the top or back at a time. Bind both halves of the top

first, to practice getting a tight seam where the two bindings

meet. (The seam between the top bindings will be hidden

by the tailpiece, but on the back side the seam will show.)

With clean hands and careful work, it’s possible to produce

an invisible glue line between two pieces of binding by melt-

ing the seam together with Weld-On 16, the solvent-based

glue recommended for this work.

Start binding at the center seam of the tail block end. Trim

the binding square at the starting point (15) so that the butt-

jointed seam between the two halves is tight. Use Weld-On

16 glue in the channel and strong masking tape to hold the

binding in place. Weld-On 16 glue sets quickly, so glue and

tape in three or four short sections, working toward the neck

block (16).

Let the glue dry 24 hours before removing the masking tape.

Pull the tape off at a 45° angle to lessen the chance of pulling

up wood fibers. If you heat the tape lightly with a hair dryer

held 8 inches away, it will soften the sticky tape and allow it

to pull free easily.

Routing for binding

Installing the binding

15. Trim the binding square at the starting point so that the butt-

jointed seam between the two halves is tight.

16. Apply glue and tape, working in short sections.

page 10

When the tape’s removed, the binding will be slightly taller

than the routed channel. Use a sharp scraper to flush the

binding to the wood. Be careful not to dig into the top or

back as you scrape (17).

The router bit will cut slightly deeper than the actual thick-

ness of the binding — perhaps by as much .007" — so don’t

be surprised if the binding’s not quite flush to the sides (18).

The extra depth makes up for any slight unevenness that

may result from hand-held routing.

Scrape the wood to meet the binding all around the sides

(19). Combine scraping with sanding, using a backing block

and 150-grit Fre-Cut® sandpaper. Try to sand only the wood,

not the binding, since 150-grit sandpaper will leave scratch-

es. When close to being flush, switch to 220-grit Fre-Cut®

sandpaper, and sand the sides, back, and top smooth. The

top and back are made from high quality plywood, and other

than cleaning up marks that you make with tools, the ply-

wood requires very little finish sanding.

Before final sanding, use a flat block and 100-grit Fre-Cut®

sandpaper to flatten only the area of the sides at the neck

block where the flat “cheeks” of the neck heel will mate with

the sides (20). (Think of the end of the neck heel, where it

meets the guitar sides, as having two surfaces called “cheeks”

— a treble cheek and a bass cheek — i.e. a cheek on each

side of the mounting bolts that are on the centerline.) Clean

up any coarse sanding marks with 220-grit.

17. Use a sharp scraper to flush the binding to the wood. 18. The router bit will cut slightly deeper than the actual thickness

of the binding — perhaps by as much .007".

19. Scrape the wood to meet the binding all around the sides.

20. Use a flat block and 80- or 100-grit Fre-Cut®sandpaper to flat-

ten only the area of the sides at the neck block where it mates with

the flat cheeks of the neck.

page 11

The truss rod is installed so that it adjusts at the peghead

end. This makes it easy to adjust the truss rod under string

tension.

Roll the rods simultaneously between your thumb and fin-

gers to adjust them until the thread in the upper half of the

brass lug (the rod without the adjusting nut welded to it) is

flush with the face of the lug, and not protruding excessively.

Align the back edge of the adjusting nut with the break line

of the peghead angle. (21). This locates the front edge of the

truss rod’s brass lug just under the end of the fretboard. A flat

area of approximately 7/32" will remain between the end of

the fretboard and the break angle of the peghead — this is

where the bone string nut will be installed.

The adjusting nut is slightly wider than the slot machined

into the neck. Chisel a slight clearance in the slot walls until

the adjusting nut fits to the bottom of the channel.

Install the rod, adjusting nut facing down. Glue in a piece of

the supplied filler strip over the adjusting nut (22) and the

exposed truss rod threads, between the brass lug and the

rear of the adjusting nut. The filler strip will support the bone

string nut, which will be installed later. Of course, keep glue

off the truss rod threads. When the glue is dry, chisel the filler

strip flush with the surface of the neck. Glue a filler strip at the

opposite end of the rod too, to fill the remaining empty

channel, and trim it flush (23).

Assembling the neck

Installing the truss rod

21. Align the back edge of the adjusting nut with the break line of

the peghead angle.

22. The filler strip will support the bone string nut, which will be

installed later.

23. Glue a filler strip at the opposite end of the rod too, to fill the

remaining empty channel, and trim it flush.

page 12

The fingerboard has 24 fret slots, more than are needed for a

resonator guitar. Trim off the fingerboard at the 20th fret slot.

Draw a pencil line across the back of the fingerboard to mark

the location of the 12th fret slot. The end of the neck’s fin-

gerboard gluing surface, at the top of the heel, will line up

with this mark when the fingerboard is glued on. Align the

heel with the mark, center the neck on the fingerboard, and

draw the profile of the neck onto the fingerboard (24).

Extend the lines using a straightedge and white or yellow-

lead pencil.

Trim the fingerboard profile close to the pencil lines using a

band saw, coping saw, or a hand plane.

The edges of the fingerboard must be smoothed after

they’re trimmed. On your flat work surface, rest the finger-

board, backside down, on a spacer block approximately 1/4"

thick and as long and wide as the fingerboard. Slide the fin-

gerboard slightly off the edge of the spacer block so that one

long edge overhangs.

With a long flat sanding block, sand the overhanging fret-

board edge lengthwise to remove any trimming marks. We

used a carpenter’s level with 100-grit sandpaper double-stick

taped to its thin edge. Clamped and sanded in this fashion,

the fretboard will not only be straight end-to-end, but the

edge will be sanded at 90° to the work surface as well (25).

Reverse the procedure for the other edge of the fingerboard.

Clamped and sanded in this fashion, the fretboard will not

only be straight end-to-end, but the edge will be sanded at

90° as well.

Traditionally, single dot inlays are installed behind frets 5, 7, 9,

12, 15, 17, and 19. Frets 15 and 19 get two inlays each. These

will cover the four mounting screws that hold the finger-

board to the top. You won’t inlay frets 15 and 19 until later,

after the guitar is finished.

Lightly draw a centerline down the fingerboard in pencil. Use

an awl to mark for drilling along this centerline, measuring

halfway between the appropriate frets.

Drill 1/4" holes for each inlay, using a brad-point drill bit. Go

slightly deeper than the thickness of the dots. Be extremely

careful to keep the drill bit from“hogging”into the wood and

accidentally drilling all the way through (practice on scrap)!

As mentioned, frets 15 and 19 are drilled for double inlays.

They’re spaced 1-3/8" apart (11/16" to each side of the cen-

terline), and centered between the frets.

Shaping the fingerboard

Inlaying the fingerboard

24. Draw the profile of the neck’s taper onto the fingerboard using

a white pencil.

25. Clamped and sanded in this fashion, the fretboard will not only

be straight end-to-end, but the edge will be sanded at 90° as well.

page 13

Within the four 1/4" holes, just barely start a secondary hole

with a 7/32" twist drill (not a brad-point) (26). These sec-

ondary holes bevel the bottom of the 1/4" holes to form the

right shape for the fingerboard mounting screws. These

holes are difficult to drill without overdoing it, so practice on

scrap! This chamfering is very delicate; the slightest turn of

the drill bit will produce the desired shape.

Next, drill 1/8" holes through these chamfered holes at frets

15 and 19 for the four mounting screws to pass through the

fingerboard during final assembly.

Put on your protective safety glasses! Then, one at a time,

place a drop of medium-viscosity superglue in each drilled

hole and set the dot inlay in place. By using a piece of clear

acrylic as a caul (lightly waxed with paste-wax), you can

apply pressure without sticking to the superglue, and still be

able to see when the inlay is flush. Remember not to inlay at

frets 15 and 19! You may need to tap gently on the caul with

a hammer to seat the dot inlays. Don’t overdo the superglue,

and you won’t have a messy fretboard to clean up. Flush the

inlays to the fingerboard using a smooth mill file and a sand-

ing block. Sand equally from end to end so you don’t change

the flat surface of the fretboard.

A 1/16"-diameter plastic dowel is included with your kit for

making side dot fret position markers along the bass edge of

the fingerboard (for right-handed players, that is). Install

them now at frets 5, 7, 9, 12, 15, 17, and 19. The 12th fret often

gets two dots, spaced evenly between the 11th and 12th

frets, but some makers use only one. Often, side dots are not

used past the 12th fret — the choice is yours.

Clamp the fretboard on edge, mark the centers of each hole

with an awl, and carefully drill the holes with a sharp 1/16"

drill bit. Drill square to the fingerboard edge at all times.

Nip short lengths from the plastic inlay dowel and superglue

them into the drilled holes — they should extend out slight-

ly above the surface. When dry, file and sand the dots

smooth.

TIP: Smooth side dots

Clamp the fingerboard back on the spacer block

used earlier for truing the edge of the fingerboard,

and re-sand the edges lightly with the carpenter’s

level and 220-grit sandpaper.

Installing side dots

26. Create chamfers within the four 1/4" holes using a 7/32" twist

drill.

page 14

A scrap piece of unfretted fingerboard has been included

with your kit. Measure out the frets you will actually use on

your fretboard, and use the leftover fretwire to test your skills

on the scrap.

Drill 19 holes in a block of scrap wood to keep the frets in

order as you cut them to length. Using flush-cutting fret nip-

pers, cut the pre-radiused fretwire to length, allowing an

overhang of 1/8" on each side of the fingerboard.

Clamp the fretboard flat to a solid surface. We fretted on a

flat, 1-1/4" thick chunk of marble —a piece of plywood rest-

ing on a cement floor would work well, too. Set the fretwire

on the slot; since it’s curved, only the ends will enter the slot.

With your finger, balance the wire to keep it from tipping and

prying up a chunk of wood as you tap the two ends into the

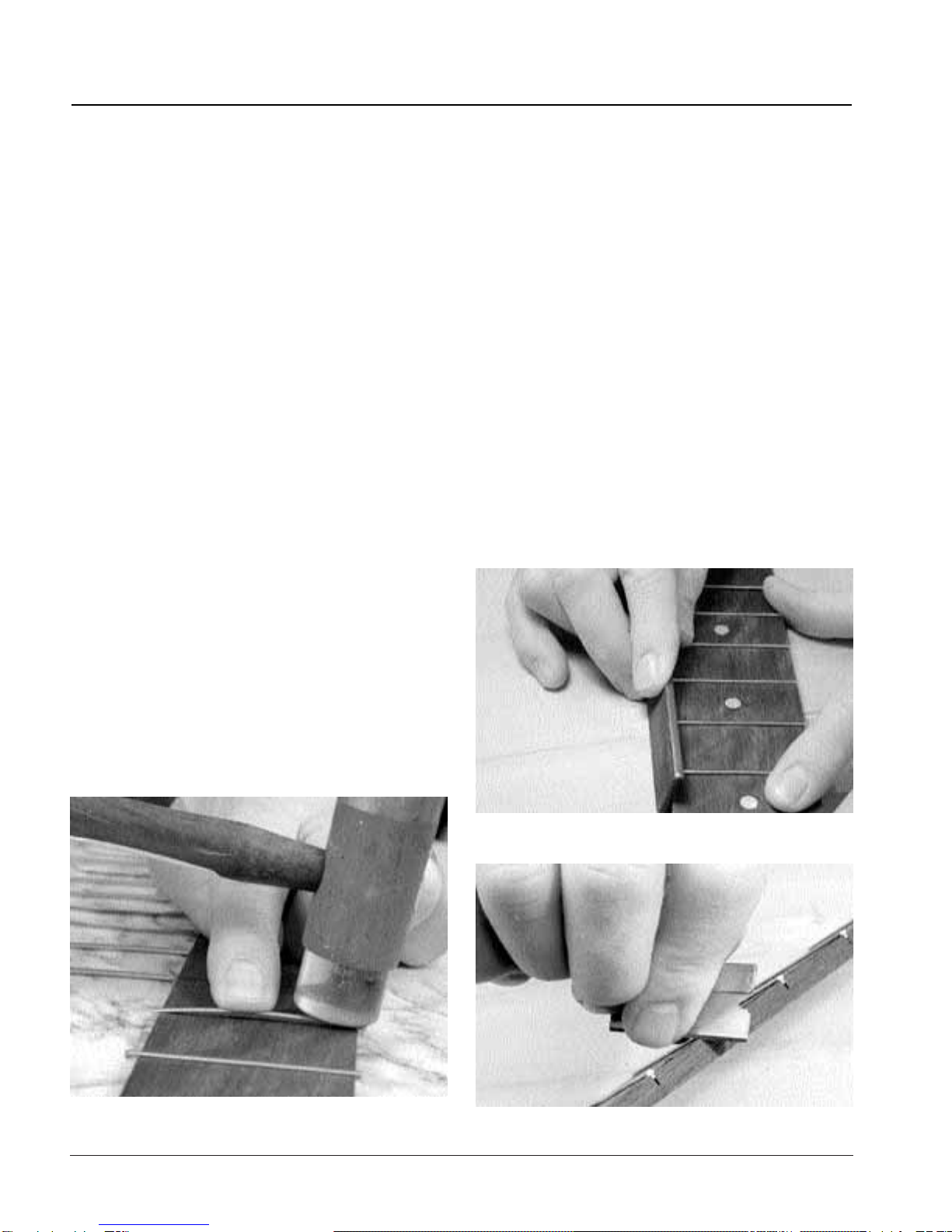

fret slot with a hammer (27). Once the two fret ends are

embedded in the fret slot, the fret is unlikely to tip as you

hammer it home.

Hammer back and forth across the fretboard in short, sharp

blows. Use the face of the hammer, not an edge, and try not

to hit the fretboard on either side of a fret. The fret tang, with

its diamond-shaped barbs, embeds itself into the finger-

board as the fret straightens end-to-end from the hammer

blows.

Test to see that the frets are seated well by prying on an

overhanging end with your fingernail. Loose frets can be

firmed up with superglue run into one end of the fret slot.

Keep the fretboard tilted at an angle to keep the glue from

getting onto the fretboard. Or, an option is to tape off the

fretboard on each side of a slot and run a bead of Titebond

into the slot before hammering in the fret. If you use

Titebond, let the frets dry overnight before nipping and filing

their ends.

When the frets are firm and the glue is dry, nip them almost

flush with the fingerboard edge. Do not nip right up to the

edge, or the nippers will pull into the fingerboard and possi-

bly unseat a fret end.

Use a smooth mill file to flush the fret ends to the edge of the

fingerboard. Then use the same file, held at an angle, to file

the fret-end bevels (28). Choose a bevel that suits you —

perhaps between 45° and 60°. Stop when the file hits the

wood.

Blunt the top edges of the fingerboard on the bass and tre-

ble sides with a single-edge razor blade (29). Later, when you

glue on the fingerboard using a rubber band clamp, there

will be no sharp edge to break the rubber band.

The fingerboard is now ready to be glued to the neck.

Fretting the fingerboard

27. Keep the wire from tipping and prying up wood as you tap the

two ends into the fret slot with a hammer.

28. To bevel the fret ends, use a smooth mill file held at an angle.

29. Blunt the sharp top edges of the fingerboard on the bass and

treble sides with a single-edge razor blade.

page 15

There should be a flat area approximately 3/16" to 7/32" wide

left between the end of the fingerboard and the break angle

of the peghead. This is where the bone nut will rest (30).

Install the fingerboard with Titebond glue. To get just the

right glue coverage, spread it with a flux brush. Work the glue

up to the edge of the truss rod channel, and then draw it

away from the edge with the flux brush to keep glue

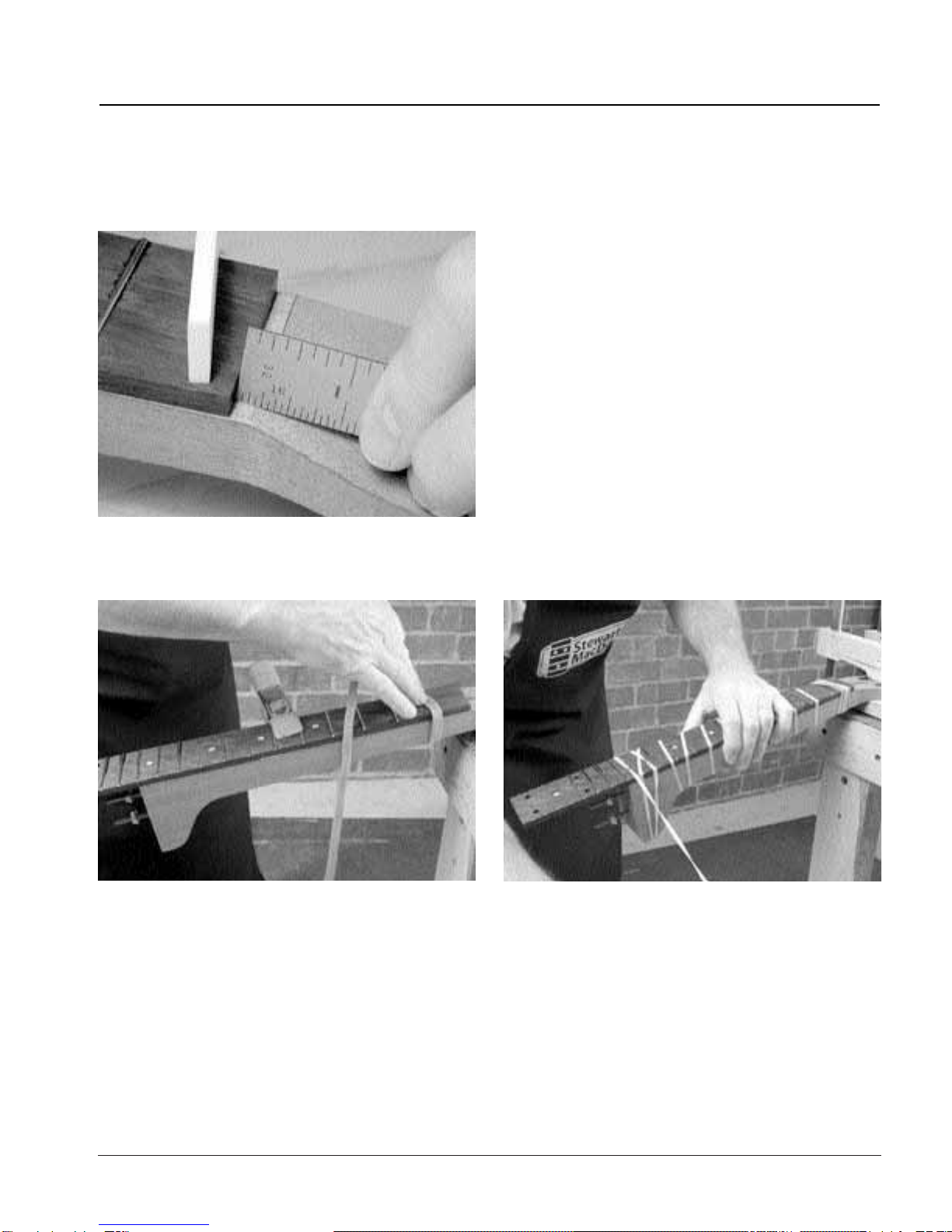

squeeze-out from getting into the channel.

Place the fingerboard onto the evenly-glued neck surface

and center the 12th fret slot directly over the edge of the

neck heel. Hold the fingerboard in place temporarily with a

spring clamp (31) as you start to wrap with the rubber bands

supplied with your kit. Tie the rubber band at the peghead

and wrap from end-to-end and back again. Get plenty of

wraps on the heel (32). You may find that one rubber band is

all that’s needed for the job. You can a shift the fingerboard

slightly from side-to-side as you wrap, but usually the board

will center itself nicely.

Installing the fingerboard

30. The bone nut will rest on the flat area approximately 3/16" to

7/32" wide, left between the end of the fingerboard and the break

angle of the peghead.

31. Hold the fingerboard in place temporarily with a spring clamp

as you start to wrap with the rubber bands supplied with your kit.

32. Get plenty of wraps on the heel.

page 16

When the fingerboard’s dry, remove the rubber band clamp.

The bone nut blank should be smooth-walled, square-bot-

tomed, and of uniform thickness. If it needs smoothing or

thicknessing, sand it with 100- and 220-grit sandpaper, dou-

ble-stick taped to a flat surface.

Place the nut blank on the flat ledge that remains between

the end of the fingerboard and the break angle of the peg-

head. File or sand a 14° angle on one end of the peghead

overlay so that it butts flush and tight up to the back edge of

the nut (33). Once the overlay is glued on, the space

between the overlay and the fingerboard will be a perfectly-

sized channel for the nut.

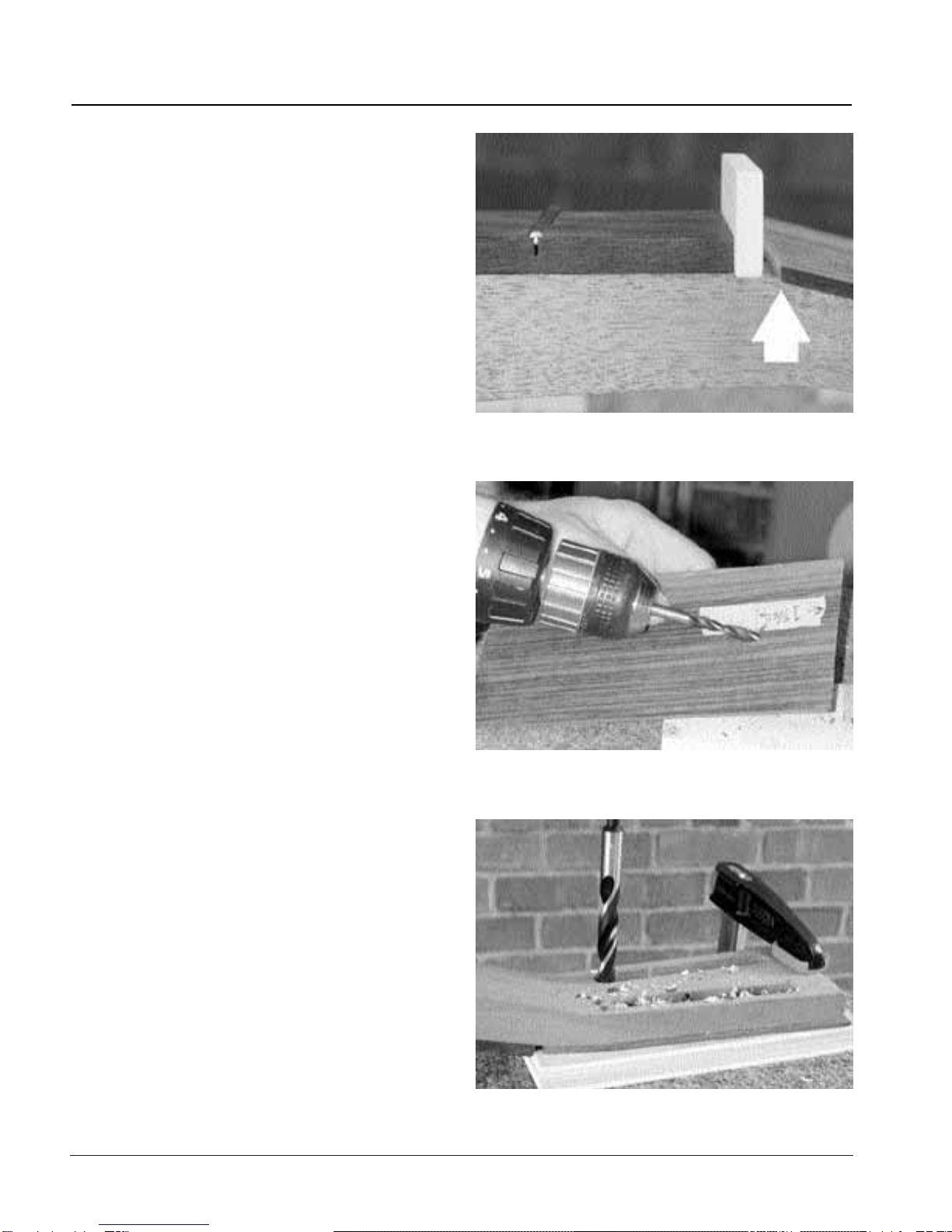

Dry-clamp the overlay in place. With a pencil, mark a point 1-

9/16" from the back edge of the nut, centered on the

peghead’s width. Drill a 1/4" hole at that point. This is the

access hole for the truss rod.

Remove the clamps from the overlay. Hold the overlay in one

hand and elongate the hole by slowly tilting the overlay

against a running drill bit (34). You may want to practice this

on a piece of scrap (there’s plenty of excess overlay that gets

trimmed away, so practice on that). You’ll end up with an

elongated access hole for the 1/8" Allen wrench that adjusts

the peghead.

Mark the peghead shape on the overlay. Trim away most of

the excess, to within 1/8" all around the peghead. Use pro-

tective cauls on the face and rear of the peghead, and glue

on the overlay. Keep the overlay pressed tightly against the

nut during alignment.

When the glue’s dry, clamp the peghead firmly, face down,

on a scrap of plywood. Use a 7/16" bit to drill holes against

each end of the tuning machine channels (the channel will

keep the drill bit lined up), and then drill several holes in

between these holes in the remainder of each channel (35)

to eliminate as much of the wood as possible.

Installing the peghead overlay

33. File or sand a 14° angle on one end of the overlay so that it fits

flush and tight to the nut.

34. Hold the overlay in one hand and elongate the hole by slowly

tilting the overlay against the running drill bit.

35. Use a 7/16" drill bit to drill holes against each end of the tuning

machine channels.

page 17

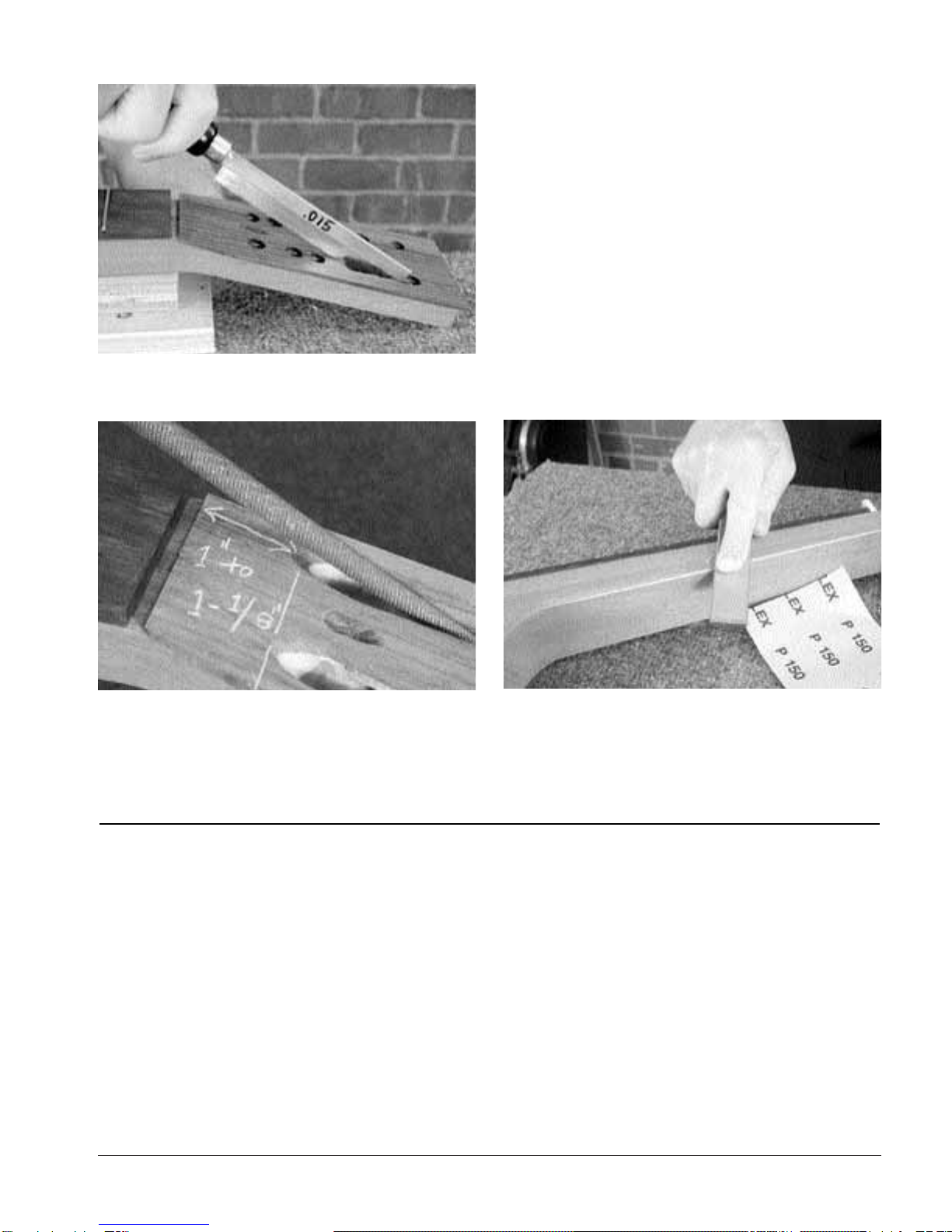

Saw, chisel, and file away the chaff left by drilling, until the

channel walls are smooth (36). Then carve and file ramps at

the nut end of each channel, so the strings don’t rub the

wood on their way to the tuning posts. The shape of the

ramps is up to you, but they extend approximately 1" to 1-

1/8" from the back side of the nut (37).

Carve and file away the overhanging peghead overlay, and

then sand the peghead face and sides smooth with 150-grit

Fre-Cut® sandpaper.

Use a file and sandpaper to round off the square machined

edges of the neck and heel (38). Leave the neck mostly the

way it is supplied, in the traditional squared-off style of the

instrument.

The tuner holes are pre-drilled with a distance between the

tuning post centers of 1-3/8". This is a common measure-

ment, and a variety of tuners will fit this hole spacing.

Set the tuners in the peghead, and use an awl or other sharp

tool to mark the mounting screw holes. Remove the tuners,

and drill the holes with a 1/16" bit. Mark the drill bit with a

piece of masking tape as a depth stop.

You may need to cut off the end of the tuner mounting

screws if they’re too long for the thin outer walls of the slot-

ted peghead. First use the untrimmed screws to “tap” the

thread for each hole, and then cut their ends off and install

the tuners temporarily, so you can fit the neck to the body.

Fitting the tuning machines

36. Saw, chisel and file away the chaff left by drilling, until the

channel walls are smooth.

37. Carve and file ramps at the nut end of each channel so the

strings don't rub wood on their way to the tuning posts.

38. Use a file and sandpaper to round off the square machined

edges of the neck and heel.

page 18

The guitar must be assembled and set up completely before

applying a finish, and then dismantled for finishing.

Place the neck mounting bolts through the neck block holes

in the body. Press the heel against the shoulders, and then

hold the neck in place as you install the two hex nuts. Tighten

the hex nuts just snug enough to hold the neck, because you

may need to move the neck a little.

Don’t use a socket wrench with a right angle drive to tighten

the nuts onto the neck bolts — you could get too much

torque and possibly crack the heel, or pull a bolt out of the

heel!

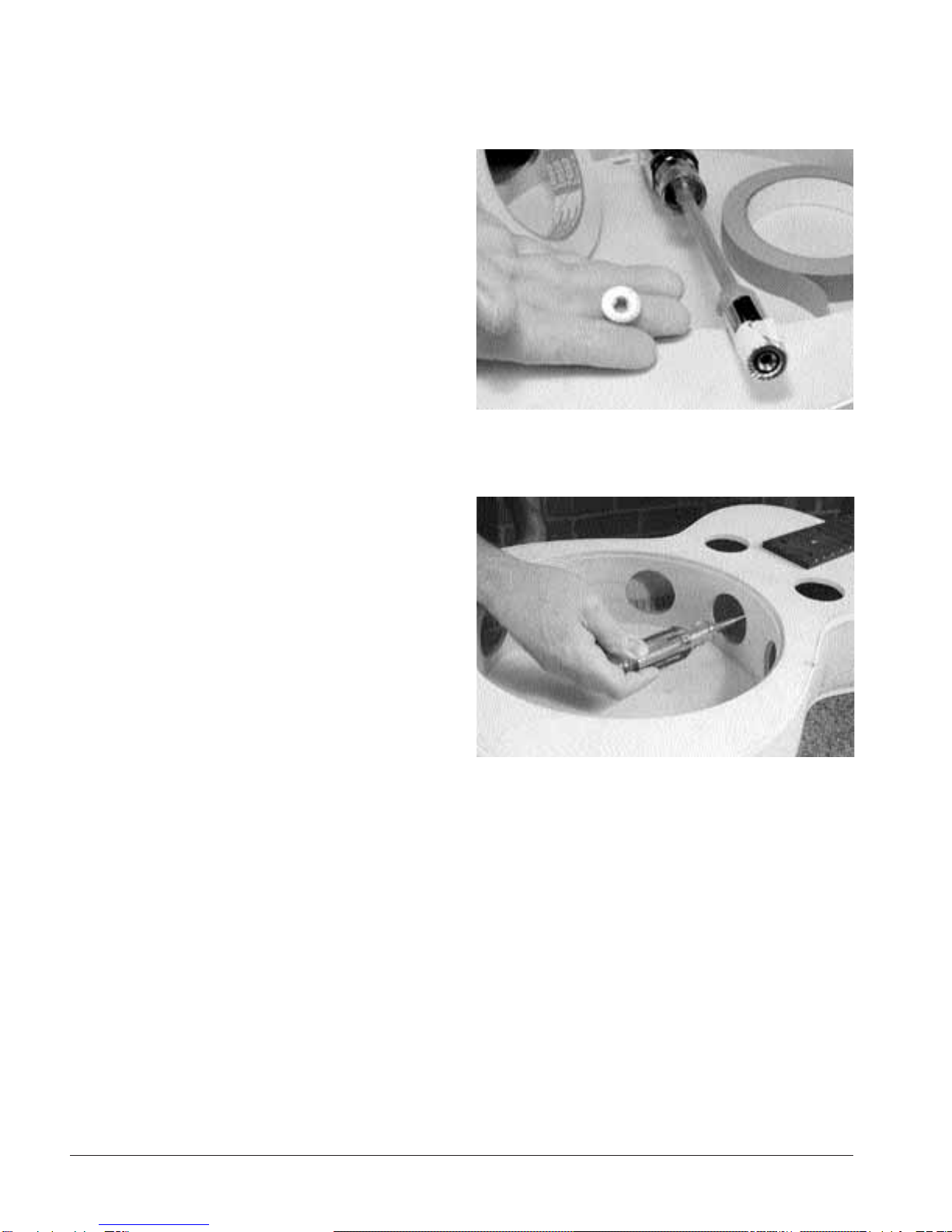

Instead, make your own nut driver as we did. We made a

long-handled nut driver from a deep-well, square-drive 7/16"

socket, and a #3 Phillips screwdriver that fit the 1/4" drive per-

fectly (39). Use tape to hold the socket onto the screwdriver

shaft (or do a little grinding and the screwdriver tip will force

in there permanently).

Also use a small piece of tape to hold the hex nut into the

socket as you reach into the body to start the nut onto the

bolt. Don’t over-tighten the nuts — the amount of pressure

you can apply with your thumb and fingers is probably

plenty (40).

Check that the neck is on center to the top’s centerline by

holding a long straightedge against the edges of the finger-

board and extending to the tail block. Do this on both the

bass and treble sides, one edge of the fingerboard at a time.

Make pencil marks representing this fingerboard projection,

and then measure in from each mark to the center. Ideally,

these two measurements will be the same. Our treble side

was about 1/32" too close to the center, so we removed the

neck and used a rat-tail file to slightly enlarge the holes in the

neck block. This allowed us to move the neck over a tiny bit

toward the treble side.

Final assembly and setup

39. We made a long-handled nut driver from a deep-well, square-

drive 7/16" socket, and a #3 Phillips screwdriver that fit the 1/4"

drive perfectly.

40. The amount of pressure you can apply with your thumb and

fingers is probably plenty.

page 19

For a more accurate neck alignment check, you must install

the cone, spider, saddle, tailpiece, and the two outside

strings. Before installing the cone, scrape off any glue residue

from the soundwell rim where the cone will rest, so the cone

will seat on a flat surface. Set the cone on the rim. Rotate it

until you find the point where it rocks the least; this is the

cone’s “sweet-spot.” Use a felt marker to mark the front of the

cone on center, pointing directly toward the neck (41).

The legs of a new spider are seldom perfectly aligned when

resting on a flat surface. They need to be adjusted to fit. Using

double-stick tape, fasten four pieces of 3/4" plywood in a rec-

tangular pattern on your flat workboard, as shown in the

photo. Space the blocks so the spider’s legs are in contact

with the upper surfaces of the blocks, and then fasten 80-grit

sandpaper to these surfaces with double-stick-tape.

With a black felt marker, blacken the underside of the spider

on every leg (42). You can follow your sanding progress by

watching the ink on the feet. One good sanding technique is

to sand in small circles; another good technique is to use a

clockwise/counterclockwise turn of the wrist in a short,

abbreviated motion. Use even pressure when sanding the

legs, until all the marker is removed (43). The metal dust on

the sanding blocks will show you which feet need the most

attention.

Fitting the cone

Truing the spider’s “legs”

41. Set the cone on the rim. Rotate it until you find the cone’s

“sweet-spot.” Mark the front of the cone with a felt marker.

42. Blacken the underside of the spider on every leg.

43. Use even pressure when sanding the legs, until all the marker is

removed.

Table of contents

Other Stewart MacDonald Guitar manuals