Stewart MacDonald 5297 User manual

Triple-O

Acoustic Guitar Kit

#5297 Assembly Instructions

www.stewmac.com

Getting started

Welcome to guitar building! ....................2

Recommended tools and supplies ...............2

Kit parts list .....................................3

Side Assembly

Assembling the sides ...........................4

Making a body mold ............................5

Installing kerfed linings .........................6

Squaring the neck block and tailblock ...........6

Leveling the kerfed linings ......................7

Soundboard bracing and fitting

Installing the soundhole rosette .................8

Shaping the X-braces............................8

Installing the soundboard bracing ..............8

Bridge and shoulder brace clamping cauls .......10

Fitting the soundboard to the sides .............10

Opening the dovetail joint ......................11

Installing the soundboard .......................12

Back bracing and fitting

Installing the back bracing ......................13

Fitting the back to the sides .....................13

Installing the side reinforcing strips .............14

Installing the back ..............................14

Routing and binding

Trimming the top and back overhang ...........15

Routing for the plastic body bindings ...........15

Shaping the heel cap and end trim ..............17

Installing the end trim ..........................17

Installing the bindings ..........................17

Fit and fill the truss rod channel

Fitting the truss rod .............................18

Fill the channel..................................18

Peghead shaping and drilling

Peghead overlay ................................19

Shape the peghead .............................19

Making a fretboard

Trimming the fretboard .........................20

Inlaying the fretboard ...........................20

Installing the fretboard side dots ................21

Installing the frets ..............................21

Installing the fretboard .........................22

Neck shaping and fitting

Shaping the neck ...............................23

Installing the nut ...............................24

Fitting the heel cap .............................24

Understanding the neck joint ...................24

The neck heel sets the neck angle ...............25

Fitting the neck to the body .....................25

Neck adjustment: side-to-side ...................26

Neck adjustment: tilt the neck back .............26

Neck adjustment: tilt the neck up ...............27

Tightening the dovetail joint ....................27

Installing the last frets ..........................27

Finishing

Introduction to finishing and materials ..........28

Sanding the body ..............................28

Filling the fret ends .............................29

Sanding the neck ...............................29

Spray handles and hangers .....................29

Masking the neck and body .....................29

Staining ........................................30

Applying a washcoat to seal the wood ..........30

Filling the wood grain pores ....................30

Lacquer spraying schedule ......................30

Sanding and rubbing-out the finish .............31

Final assembly and setup

Prepare for neck installation ....................32

Install the neck .................................32

Prepare for bridge installation ...................33

Installing the bridge ............................34

Fitting the bridge pins...........................34

Fitting the bridge saddle ........................34

Installing the tuning machines...................35

Seating the strings ..............................35

Understanding neck relief ......................35

Adjusting string action: nut slots & saddle height 36

Leveling the frets ...............................37

Installing the endpin ............................37

CONGRATULATIONS! ...........................37

Table of contents

stewmac.com

Small cam clamps (at least 2) #3724

Large cam clamp (2) #3725

Spool clamps (24) #3715

Clothes pins (50)

Medium bar-style clamp (2) #3714

X-Acto knife

Small carpenter’s square

Feeler gauges #1811

Supplies

3/4" plywood workboard 24" x 20"

Titebond glue #0620

Weld-On Cement #1975

Super Glue (#0010 thin and #0020 medium)

Double-stick tape #1689

Low tack protective tape #1682

Masking/binding tape (high tack) #0677

Rubber binding bands #1256 (option to using binding tape)

Sandpaper (80, 100, 150 and 220-grit)

Wax paper

White pencil

Felt-tip marker

Capo #4571

Clean cotton glove

Finishing materials (for aerosol nitrocellulose lacquer finish)

Guitar Finishing Step-By-Step book #5095

Fre-Cut® sandpaper 150, 220, 320, 600, 800, and 1200-grit at least 2 sheets

of each grit (included in Finishing Paper Sampler Package #5562)

ColorTone Concentrated Liquid Stain (tobacco brown #5034, red

mahogany #5032)

Grain filler

ColorTone Clear Gloss aerosol nitrocellulose lacquer (6) #3881

Blush Eraser #1313

Stewart-MacDonald Polishing Compound medium #1845 and fine #1846

Stewart-MacDonald Swirl Remover #1847 (optional)

Foam Polishing Pads (2 or 3) #3414 and electric hand drill

Naphtha solvent #0775

Paint stripper

Masking supplies: brown paper, masking tape, cardboard and

rubber balloon (or newspaper) for soundhole

The following tools and supplies are recommended to as-

semble your kit. Though all of these tools aren’t necessary

to build your kit, they make many assembly steps easier

and more professional. Where applicable, item numbers for

ordering from Stewart-MacDonald are included.

For binding installation, you have a couple of different

options to choose from depending on the tools you already

own. If you plan on using a laminate trimmer or router for

binding channels, we suggest our Binding Router Bit (#1298-

B) and bearings (#1298-060, 1298-100). It is our preferred

method. If you plan on routing your binding channels with

a Dremel tool, our Precision Router Set (#5263) ships with

everything you will need.

Tools

Electric hand drill

Coping saw

Center punch or awl

Glue brushes #4167

6" Steel rule #4894

1/2" Chisel #1623

File set #0842

Small rasp #4154

Fret Leveler #0862

Dressing stick #1939

Fret cutter #0619

Deadblow fret hammer #1296

18" Straightedge #3850

.020" gauged saw #3572

Scraper blade #0654

4mm Allen wrench #6113

Nut-slotting files: 0.016" width (#0827) and 0.035" width (#0832)

1/4"-diameter bit #4850

Bridge pin reamer #3227

Fret dressing file, medium # 1602

Radius-sanding block, 16" radius #0413

Recommended tools and supplies

daily to neutralize excessive warping. Depending upon your

location and the season, you may need to humidify or dehu-

midify your shop to maintain the desired relative humidity.

It is advisable to purchase a thermometer/hygrometer to

monitor your shop’s climate. If you’re unable to control the

relative humidity in your shop, we discourage building the

guitar during the transition from dry to wet seasons, or vise

versa. The radical change in humidity can cause warping,

splitting or other serious complications.

Throughout the assembly of the kit you’ll need a flat

workboard of 3/4" plywood approximately 24" long and 20"

wide, big enough for your guitar’s body assembly.

Be safe when using tools, glues, and chemicals. Wear

eye protection and gloves when needed, and always

use proper ventilation.

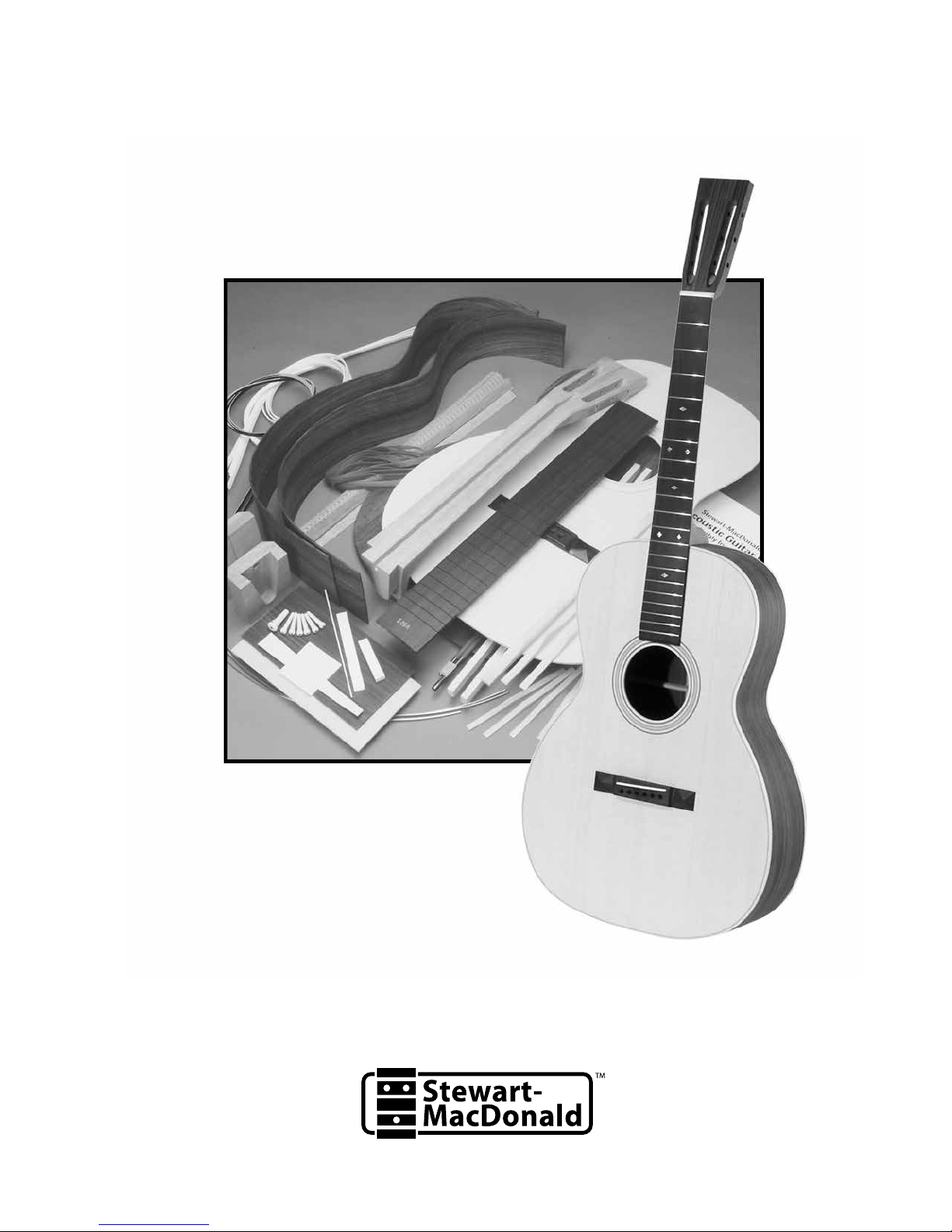

You are about to build a truly great guitar! We designed this

kit with the small shop builder and a modest tool budget in

mind, with the exception of a few specialty guitar making

tools.

Please read these instructions before building your guitar.

Some photos in these instructions use a Dreadnought gui-

tar as a model, though the technique is the same for either

Dreadnought or Triple-O guitar. Options include dovetail or

bolt-on neck and back and side woods of either mahogany

or rosewood.

It’s very important to acclimate the wood to your building

environment. The ideal building environment temperature is

70-80° Fahrenheit (21-26° Celsius), with a controlled relative

humidity of 45-50%. The kit wood should be laid out and al-

lowed to “equalize” for one week in your shop. Flip the wood

Getting started

Welcome to guitar building!

Stewart-MacDonald

has easy-to-order sets

of tools that kit builders

find most useful, search

“acoustic kit tools” at

stewmac.com

2

stewmac.com

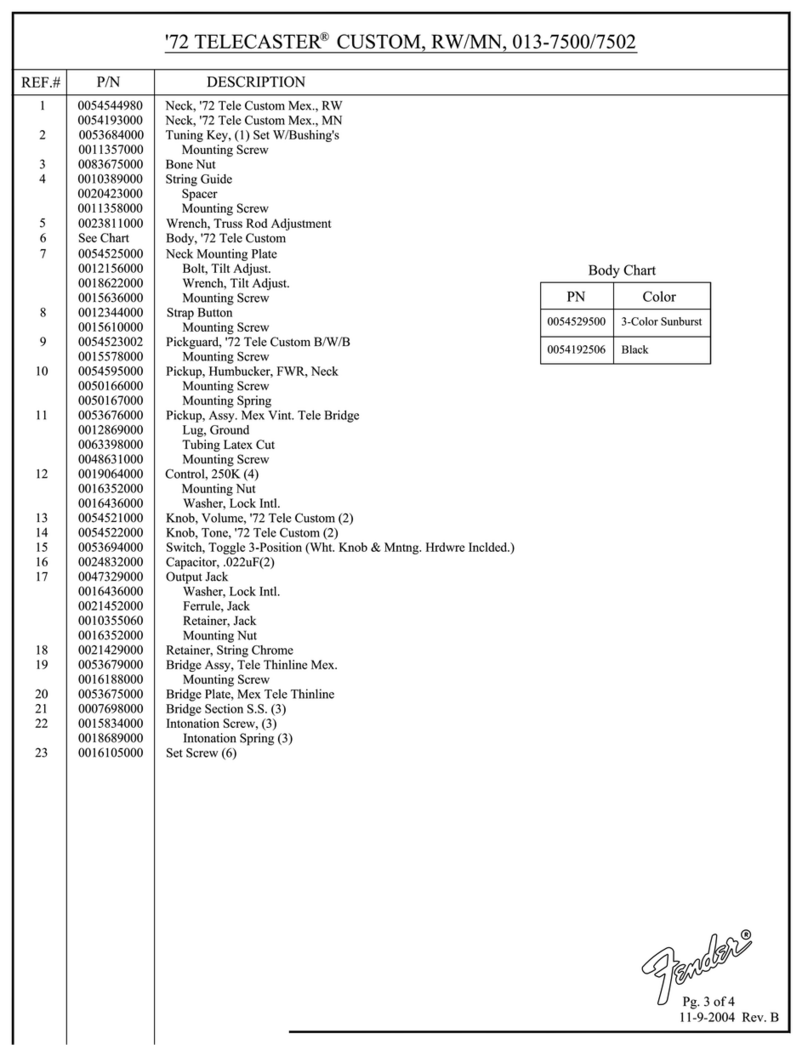

1Bent sides, rosewood or

mahogany, depending on

your kit (2)

2Kerfed lining (8)

3Fretboard

4Mahogany neck, dovetail

or bolt-on

5Rosewood peghead overlay

6Maple bridge plate stock

7Neck block, dovetail or

bolt-on

8 Tailblock

9 Thick binding, black or white

10 Thin binding, white and black

11 Sitka spruce soundboard

12 Bridge

13

Back, rosewood or mahogany

14 Building an Acoustic Guitar Kit

DVD

Kit parts list

15 Blueprint, body and bracing

patterns

16 Heel cap and end trim

17 Herringbone rosette (3 pieces)

18 Top brace set, plus 2 unshaped

X-braces

19 Fretwire (3)

20 Bone saddle blank

21 Bone nut blank

22 Diamond shaped inlays,

small (4), and large (3)

23 White side dot material

24 Back brace set (9 pieces)

25 Endpin

26 Bridge pins (6)

27 Hot Rod truss rod

28 Reinforcement strips (3)

29 Shim stock (not in bolt-on kit)

Not pictured: this assembly

instructions book, cardboard

body mold (2), scrap wood,

and large rubber band

12

3

4

5

6

7

8

9

10

11

12

13

16

14

15

17

18

19 20

21

22

23

24

25 26

27

28

29

3

Table of contents

Other Stewart MacDonald Guitar manuals