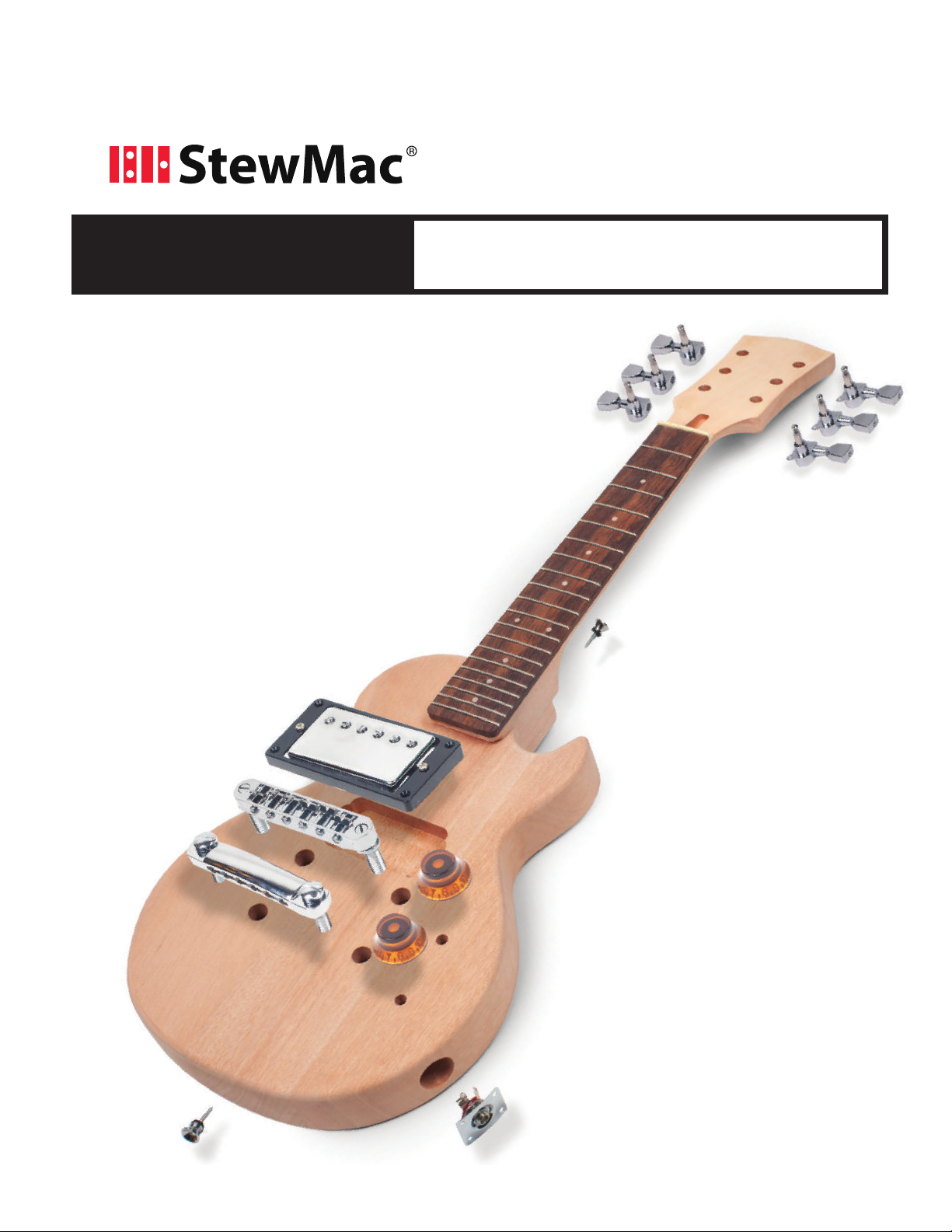

StewMac Mini-LP Guitar Kit User manual

Have a little fun.

Make a little noise.

Build a REAL guitar in a weekend.

• Easy to build, nish, and setup

• Pre-wired electronics

• All hardware included

Sheet #i-12259 Updated 06/20

MINI-LP GUITAR KIT

stewmac.com

2

These are the tools and supplies we recommend for assembling this kit. StewMac item numbers are included where applicable.

Tools

Electric hand drill

Foam sanding block (#3701 or #3699)

Phillips screwdrivers, size #1 & 2 (#3000)

Center punch or awl (#3000)

Drill bits:

1/16" (#1710)

5/64" (#1712)

10mm nut driver (#5890) or wrench (#3691)

Soldering iron (#0502)

6" StewMac Shop Rule (#4905)

12" Precision Straightedge (#3849)

Supplies

Sandpaper: 150, 220, 320, 400, 800, 1200 grits (#5562)

Light duty 3M Scotch-Brite pad (#7445) or 0000 steel wool

ColorTone Polishing Compound, Medium (#1845)

Naphtha solvent (#0766)

Glue Brush (#4167)

Rubber gloves

Finishing supplies

ColorTone Powdered Grain Filler, ebony (#0269-E)

Wipe-On Poly (#3622)

Vintage Amber Stain (#5030)

Black Fingerboard stain (#4237)

Tools and supplies

stewmac.com 3

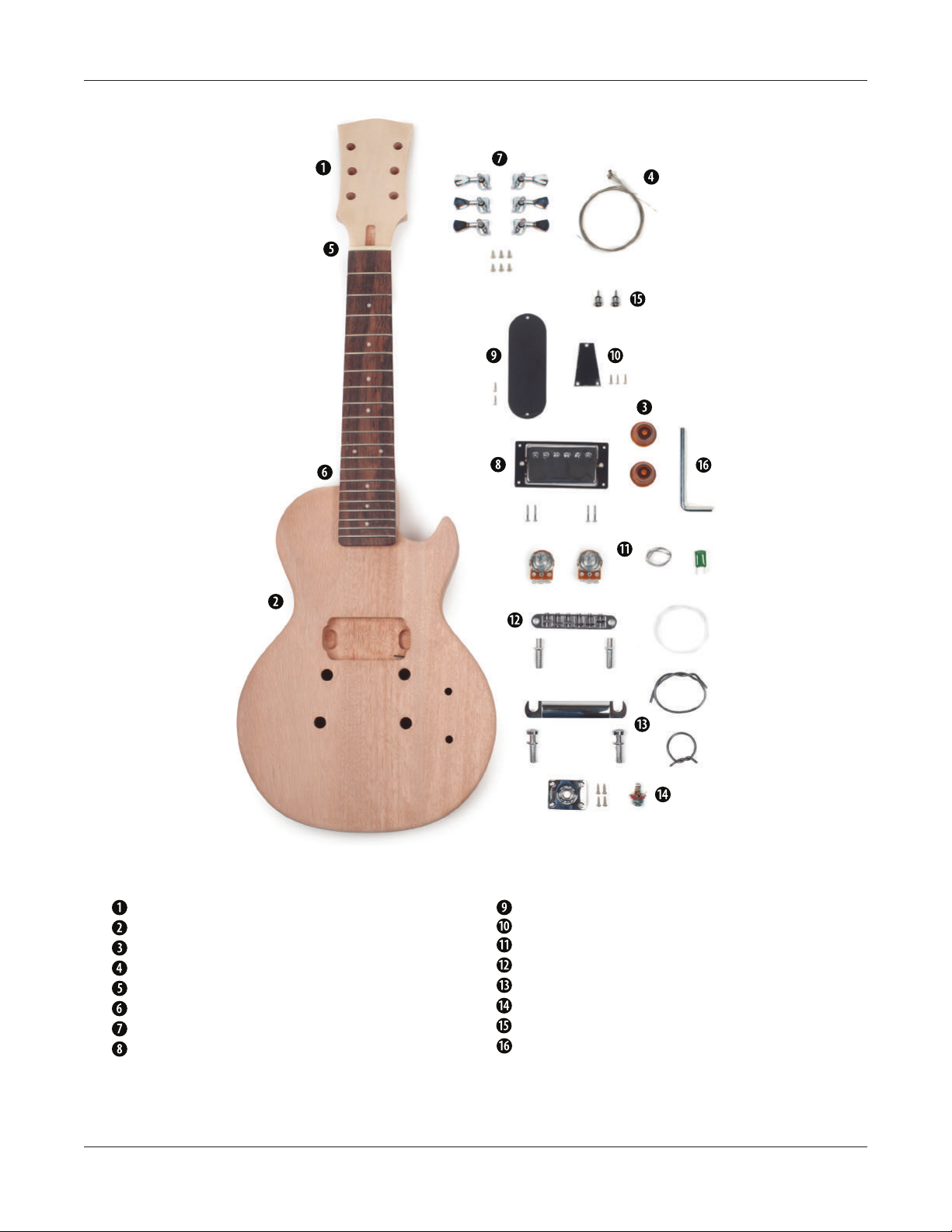

Parts List

Neck

Body

Knobs

Strings

Slotted string nut

Neck plate with screws (not pictured)

Tuners with bushings, washers, and screws (set of 6)

Pickup with mounting ring

Control cavity cover with mounting screws

Truss rod cover with mounting screws

Wiring Kit

Bridge with mounting studs

Tailpiece with mounting studs

Output jack with mounting screws

Strap buttons with screws and protective washers (2)

4mm hex wrench for adjusting truss rod

stewmac.com

4

Getting started

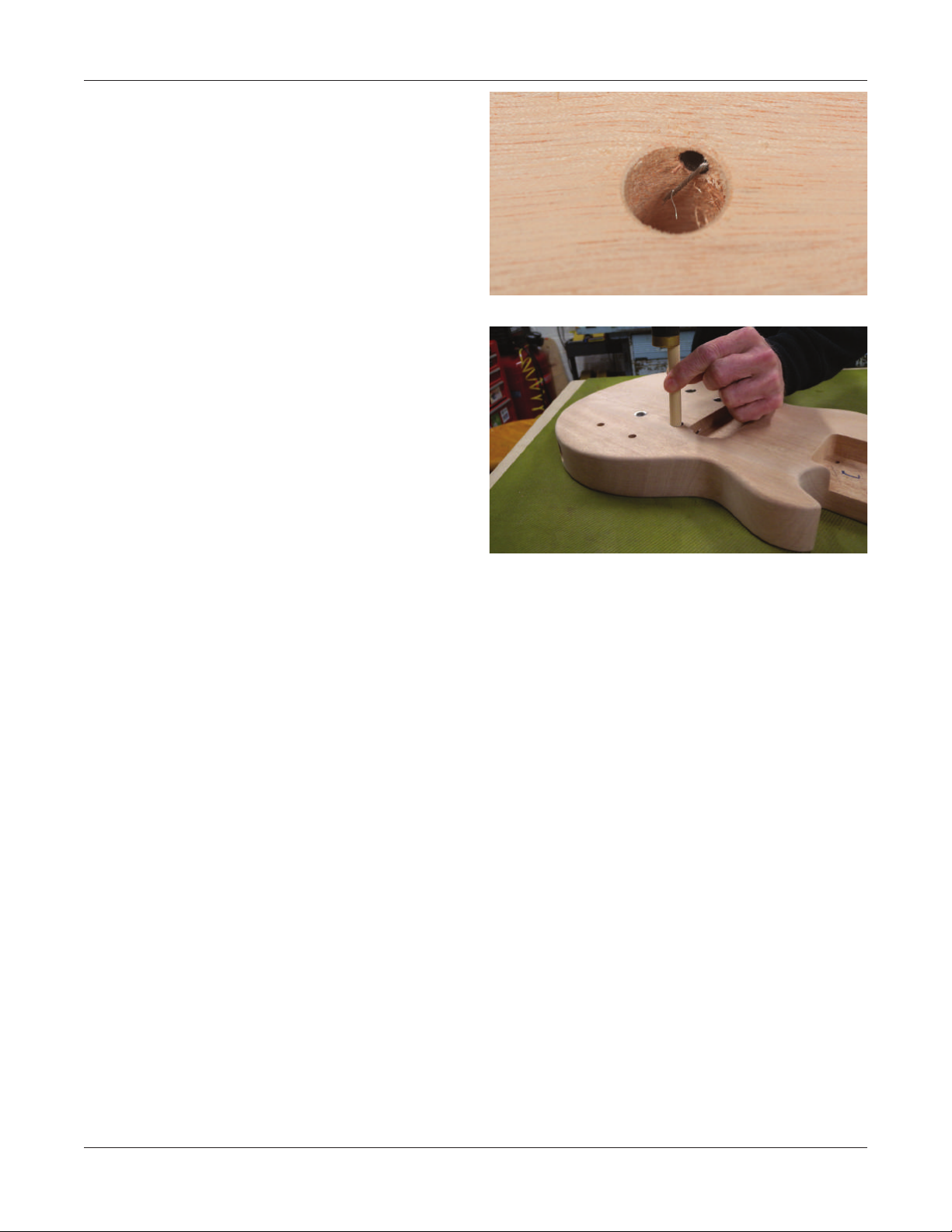

The neck of your guitar ships attached to the body. The rst

step is to remove the neck using a #2 screwdriver.

Install the bridge and tailpiece bushings

Note that there is a ground wire access hole connecting the

treble side tailpiece post hole to the control cavity; this is for

the string ground. The 4" ground wire needs to be installed

before the bushing. Strip 1/2" o of both ends and run the

wire through the hole into the cavity leaving the stripped

end to come in contact with the bushing once installed. In-

stall the tailpiece bushings. Pressing them in with a drill press

is the preferred method but they can also be installed with

gentle hammer taps using a block. Install bridge bushings

in the same fashion but without a ground wire.

Next, you will be preparing the neck and body for nish.

Preparing the neck and body for nish is just as important,

if not more important, than the nish application. The key to

a great looking nish is patience and lots of it. Be thorough

with your sanding and follow the nishing schedule on page

6 for best results.

stewmac.com 5

Prep for nishing

Inspect the body and neck for any dents, chips, or other

imperfections and repair them. Small dents can be steamed

out by placing a damp cloth over the dent and applying

heat with a soldering iron. Chips, tear out, and knotholes

will need to be lled.

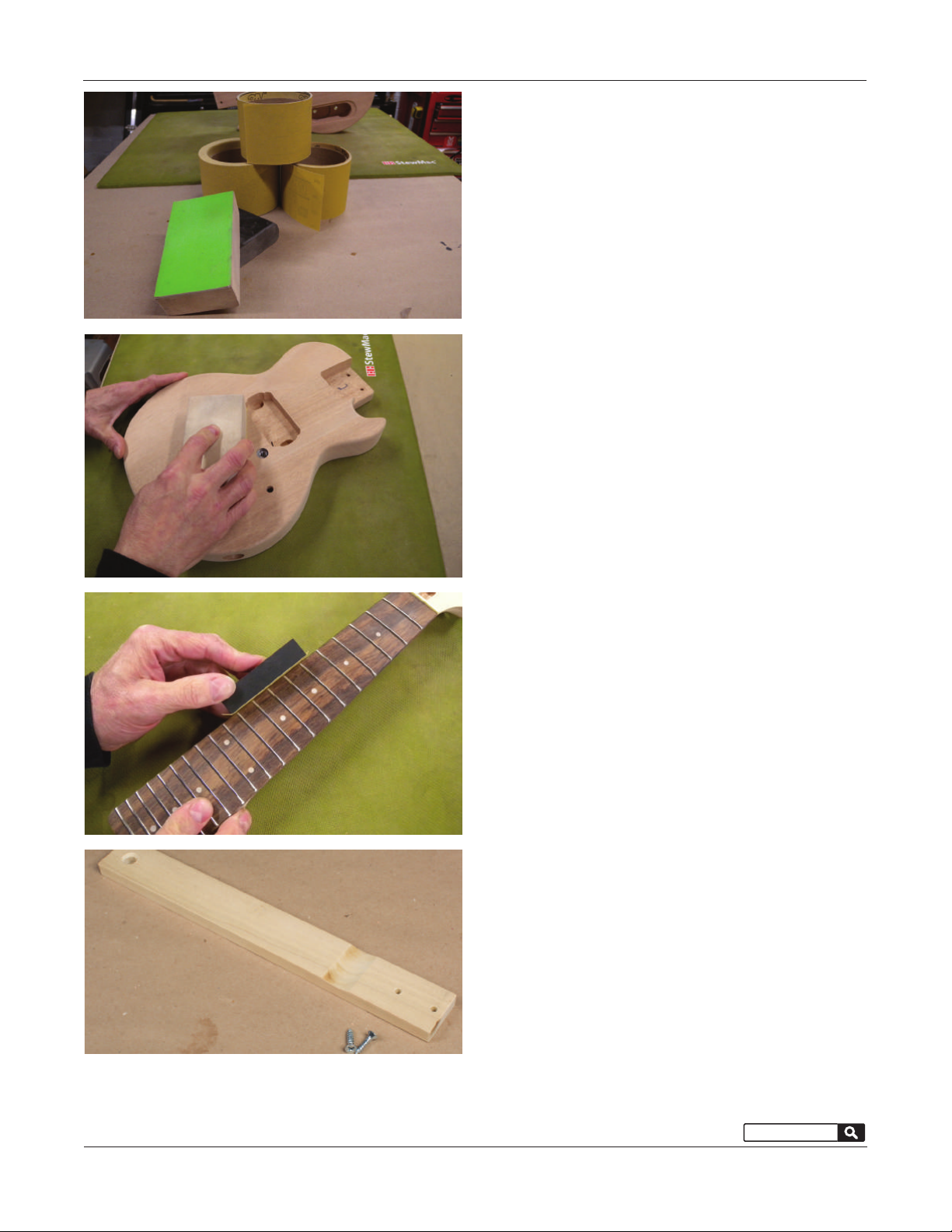

Sand the body and neck

Using 150-grit sandpaper on a at sanding block, sand the

entire body working only in the direction of the grain.

After a complete sanding, wipe the body with a damp

cloth to raise the grain and reveal bers that need more

sanding. Let the dampness dry, then sand the raised grain

with 220-grit sandpaper. After sanding, raise the grain again

and sand a third time, using 320-grit sandpaper. Follow the

same procedure with the neck, using care not to sand on

the fretboard face or frets.

Note that the peghead face is covered with a very thin ma-

hogany veneer. Very lightly sand with 320 using care not to

sand through.

Run your ngers along the edge of the fretboard and feel for

sharp fret ends. If the frets feel sharp where they meet the

edge of the neck, gently sand them back with long strokes

down the length of the neck. Use care not to change the

bevel of the frets in the process.

While sanding with 320-grit slightly break any sharp edges

on the fretboard body, ngerboard, and peghead. Soften-

ing hard edges promotes even nish coverage. Later, when

you’re nish sanding, these edges are less likely to sand

through to bare wood.

Degrease with naphtha

When you’ve nished sanding, wipe the body and neck with

a naphtha-dampened lint-free rag to remove any oils or

grease. From this point on, wear clean gloves when handling

so you won’t contaminate the wood.

Tape o the bridge and tailpiece bushings in the body, and

the string nut and fretboard face; they do not get lled or

nished.

Fill the grain

The body and neck of your guitar kit are made of mahogany,

which is an open grained wood. The grain will need to be

lled before nishing in order to achieve a at surface.

We suggest using our ebony ColorTone Powdered Grain

Filler following the instructions on the label. 2-3 applications

are recommended to get a nice at surface to build nish

coats over.

For more info on grain lling, see our article #i-0269 “Using

ColorTone Grain Filler” at stewmac.com.

stewmac.com search: i-0269

TIP! Make holding handles for the neck and body. These can

be clamped in a vise or to a bench for lling and nishing,

a hanging hole can be added for drying. Nothing fancy,

scrap wood will do.

stewmac.com

6

Tape off the edges around the peghead face—the nut

should still be taped o from lling. Use ngerboard stain to

color the peghead face black. A little goes a long way! Start in

the center and work your way out to the edges, as this helps

reduce bleed around the edges. Let dry for 1 hour. Peel the

tape and check for any signs of bleeding on the sides and

top of the peghead. Any stain that has bled onto the sides

can be removed with a scraper or sandpaper.

Color coats (optional)

ColorTone Liquid Stains mixed into Wipe On Poly make an

easy to apply and nice looking translucent nish for the body

and neck. It’s nonammable, simple to use, very forgiving,

and can be applied indoors.

Mix 1/4oz of Vintage Amber (or the color of your choice)

ColorTone Liquid Stain into 4oz of the Wipe On Poly nish

and mix well. Conduct a test on some scrap wood to ensure

the color looks the way you’d like it to. If it’s too dark, add a

little more nish to weaken the color. If it’s too light, add an

additional drop or two of stain. Remember, a small amount

of stain goes a long way!

As you apply the color watch for streaks and uneven areas.

Keep working the pad in a circular motion over these areas,

followed by long strokes running the length of the instru-

ment until you have uniform tinting over the entire surface

of the body.

Apply the color to the neck in the same fashion as the body.

Any residual nish that ends up on the fretboard face will be

scraped back once it dries.

Allow the color coats to dry 2-3 hours.

Final top coats

Do not sand on your color coats. Apply 4-8 additional coats

of clear over the top of the color or until you’ve reached your

desired thickness. Allow to dry for 24 hours.

In most cases nal sanding and bung of the ColorTone

Wipe-On Poly nish is not necessary but there are times

where it may be needed to level out uneven surfaces and

imperfections in the nish. If nish sanding is needed, we

suggest going over the instrument with 800-grit, followed

by 1200-grit sandpaper. Use care not to sand through the

topcoats into the color. Then follow up with ColorTone Me-

duim Polishing Compound on a soft cloth or bung pad.

Applying nish

stewmac.com 7

Assemble your guitar

During assembly, use a padded surface to protect the nish

from scratches and dents.

TIP! Drag the threads of all mounting screws over a bar of

soap or wax to help them thread in easier and help prevent

damaging the screw head.

Install the neck

The mounting screw holes in the neck and body come pre-

drilled for easy installation. Run the neck mounting screws

through the neck mounting plate and tighten down with a

#2 Phillips head screwdriver.

Install the tuners

Working from the bottom up, use a ruler to make sure the

tuners are square to one another. Mark out your mounting

holes with a scribe or center punch.

Tuner mounting screws are very delicate and will break o if

forced into wood without drilling. Use a 5/64" bit to drill 3/8"

deep pilot holes for the screws; if these holes are any smaller

you risk shearing o the screw heads. Lubricating the screws

by dragging them across a bar of soap or a candle will help

the screws go in smoothly.

With the tuners in place, install the screws in the pilot holes

with a #1 Phillips screwdriver. On the tuner string post, add

a washer then the threaded bushing. Tighten with a 10mm

nut driver or wrench.

Install the strap buttons

Mark the locations of your strap buttons. At the tail of the

guitar, position the button in line with the center of the neck

and bridge. The other button is typically located on the tip

of the upper horn.

Drill 1/2" deep holes with a 3/32" bit and install the strap

buttons with their protective washers using a #2 Phillips

screwdriver.

stewmac.com

8

Install the pickup

Line up the pickup and mark out the mounting screw loca-

tions. Drill 3/16" deep holes using a 1/16" bit. Install mounting

screws with a #1 screwdriver.

Drill for the jack plate

Mark out the 4 mounting screws with a scribe or punch using

care to keep the edge of the jack plate square to the body.

Drill the holes using a 1/16" bit, drilling 3/16" deep. Do not

install the jack yet.

Assemble your guitar

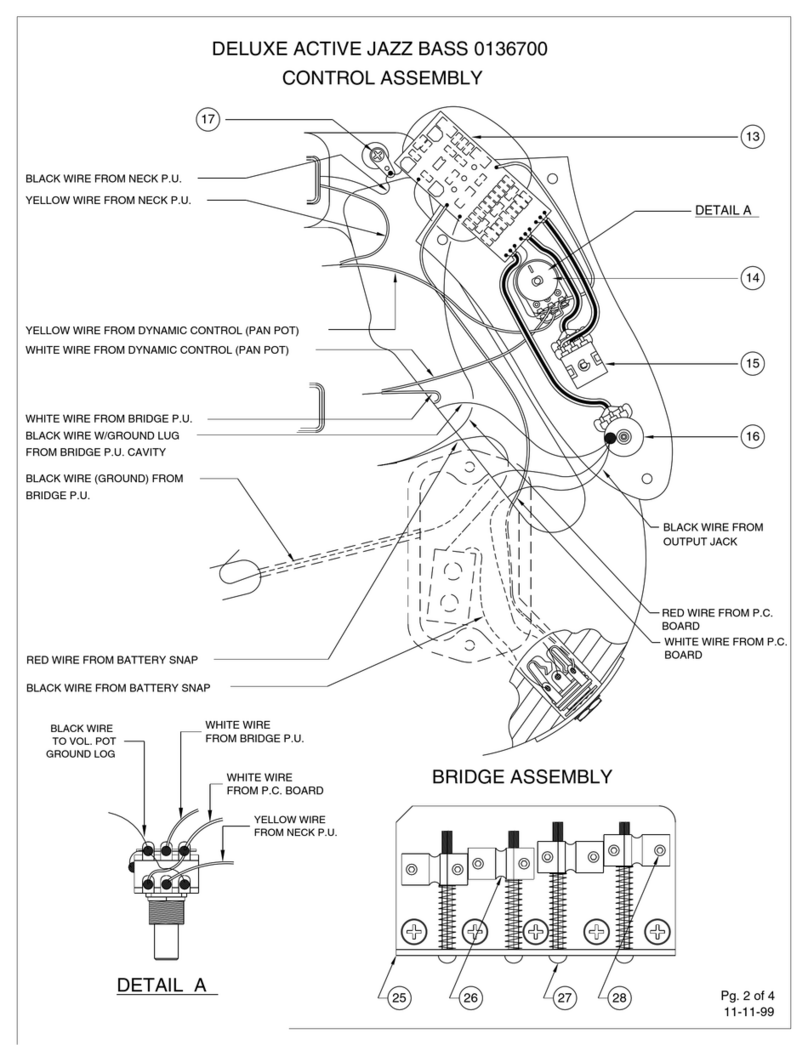

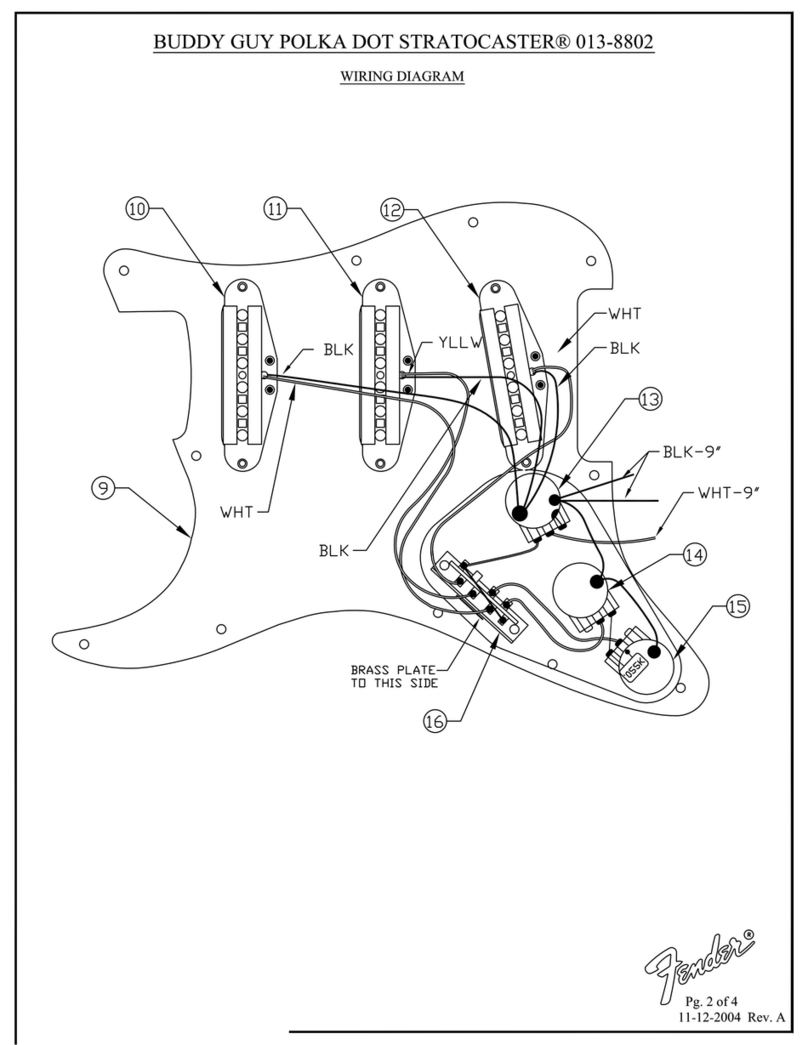

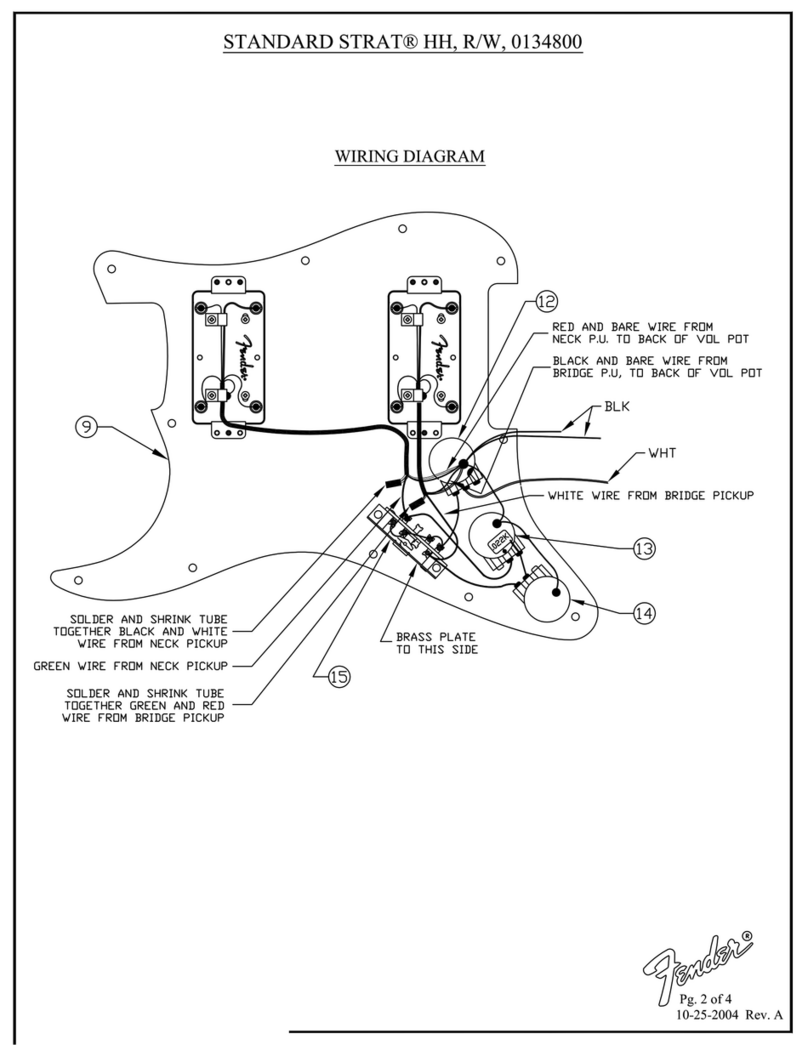

Install the wiring harness

Wire the pickup to the harness as shown in the diagram.

Then run the hot and ground wires through the output jack

hole on the body.

stewmac.com 9

Assemble your guitar

Wire the jack

The black ground wire gets soldered to the square (sleeve)

lug, solder the white hot wire to the round (tip). Once sol-

dered, install the jack plate with a #1 screwdriver and the

control cavity cover with a #2 screwdriver

Mark out the truss rod cover

Drill the holes using a 1/16" bit, drilling 3/16" deep.

Install the bridge and tailpiece

Tighten the tailpiece studs all the way down; the bridge

height will be set during nal set up. String up the guitar.

stewmac.com

10

Final setup

Straight neck, or a little relief?

Neck relief refers to adjusting a neck so that it has a very

slight upbow, rather than being perfectly straight. This relief

allows a little more room for string vibration, reducing the

chance of hitting the lower frets and causing fret buzz.

Depending on your playing style, and how perfectly level

your fret tops are, a neck should be anywhere from perfectly

straight to having 0.012" of relief. This measurement refers

additional string height over the 12th fret, compared to a

perfectly straight neck.

A straight neck tends to play and sound better, but very few

guitars end up with no relief at all, and several thousandths

of an inch or more is perfectly normal.

When the neck is adjusted to your satisfaction install the

truss rod cover using a #1 screwdriver.

Set the action at the nut

The string nut is pre-slotted for medium action, which is

comfortable for most players. If lower action is desired, you

can lower the slots using gauged nut les or needle les.

Set the action at the bridge

Adjust the action at the bridge by raising or lowering the

string saddles. Measure string height over the 12th fret,

between the bottom of the string and the top of the fret.

A good starting point is:

High (unwound) E string: 1/16" at the 12th fret. Low (wound)

E string: 5/64" at the 12th fret.

You can always go lower or higher depending on your

playing style.

Set the intonation

Intonate the guitar by adjusting the string lengths at the

bridge saddles so the guitar plays in tune all the way up

the neck.

Using a strobe or other accurate tuner, rst tune the strings

to pitch. Then, press the high E string lightly at the 12th fret

using just enough pressure to sound the note. Check it with

your tuner.

If the note reads at, the saddle needs to be adjusted forward

towards the nut, shortening the length of the string.

If the note reads sharp, the saddle needs to be adjusted back

away from the nut, increasing the string length.

Turn the truss rod nut

counterclockwise to bring

the neck up, adding relief.

Measure string relief

at the 12th fret.

Turn clockwise to pull the

neck back, reducing relief.

Go slow: a little does a lot!

stewmac.com 11

Adjust the pickup height

Holding down the low E and high E strings at the 22nd fret,

adjust the bass side of the pickup to 1/8" from the top of

the pickup pole to the bottom of the low E string. Adjust

the treble side to 1/8".

You’re done!

Congratulations! Your guitar is ready to play. We hope this

is the rst of many that you have fun assembling and cus-

tomizing.

Final setup

21 N. Shafer St • Athens, Ohio 45701 • USA

USA & Canada call toll-free: 800-848-2273

9am-5pm weekdays Eastern time

stewmac.com

Table of contents