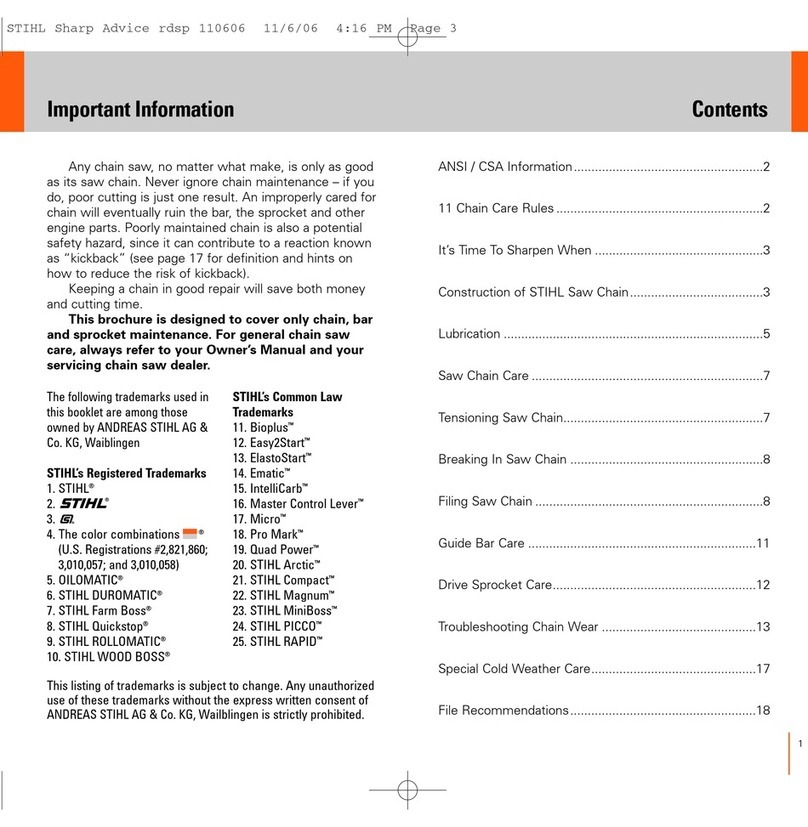

STIHL 020 T 1

Service Manual

020 T Chain Saws

This manual contains detailed

descriptions of all repair and

servicing procedures for 020 T

chain saws.

You should make use of the

illustrated parts list while carrying

out repair work. It shows the

installed positions of the individual

components and assemblies.

Microfilmed parts lists are always

more up to date than printed lists.

A fault on the machine may have

several causes. Consult the

"Troubleshooting Charts" when

tracing faults.

Refer to the "Technical Information"

bulletins for engineering changes

which have been introduced since

publication of this service manual.

Technical information bulletins also

supplement the parts list until a re-

vised edition is issued.

The special servicing tools mentioned

in the descriptions are listed in the last

chapter of this manual. Use the part

numbers to identify the tools in the

"STIHL Special Tools" manual.

The manual lists all special servicing

tools currently available from STIHL.

Service manuals and all technical

information bulletins describing

engineering changes are intended

exclusively for the use of STIHL

servicing dealers. They must not be

passed to third parties.

Always use original STIHL

replacement parts.

They can be identified by

the STIHL part number, the

STIHl

logo

and the STIHL parts symbol (

The symbol may appear alone on

small parts.

STIH

© 1999, Andreas Stihl AG & Co., Waiblingen

Servicing and repairs are made

considerably easier if the machine

is mounted on the assembly stand

(1). This enables the machine to be

swivelled to the best position for the

ongoing repair and leaves both hands

free.

The machine is secured to the stand

by means of the guide bar mounting

nut (after removing the sprocket

cover).