Utg.19 Page 6

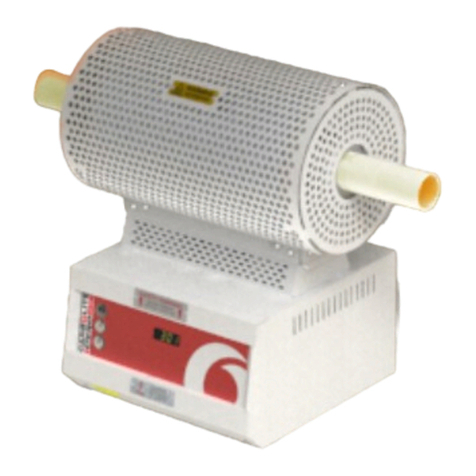

6.2. Heat radiator circuit

Normal arrangement:

The feed outlet is on the top of the furnace side (top feed). This should be coupled to the ventilating valve, safety

valve, shunt valve and circulation pump for further transport to the radiators in the house. The expansion vessel

connected to the lower connection point should be dimensioned for the system’s total water volume. The target value

for a closed vessel is about 10% of the total volume and for an open vessel 5 % can be sufficient.

The return pipe goes into the tank in the middle via a diffuser that lets the return water be allocated slowly to the

furnace without the temperature layers in the furnace being destroyed. (upper radiator return (solar)).

Low temperature outlet:

An additional feed outlet is in the middle of the furnace (middle feed). This outlet mainly makes it possible to use the

solar energy produced in the tank’s lower part and only when this is not sufficient shunt in hot water from the

furnace’s upper connection.

Winter arrangement:

If the solar system is not connected or during the darkest winter months the return piping can be reconfigured so that

the return water flows into the tank via the lower connection (return/filling/drawing off).This means that the entire

tank’s water volume is intermixed in the system and the burner gets a larger quantity of water to heat. This means that

the burner must work for longer intervals and the number of ignitions for the burner decreases. Observe that this

connection should not be used if the system is to receive solar energy.

Summer arrangement:

When the furnace been coupled to the solar system the solar panels load the tank with energy a large part of the year.

Asupply of peak energy is needed, however, more during autumn, winter and spring than during the summer. The

peak energy can be allocated in various ways. With burners that start and stop automatically pellet heat can be used

and for smaller needs it is appropriate to use electricity.

During the summer when the need of extra energy is small pellet heating is less effective and it is most often more

economical to use electricity as peak energy for the sun.

Pellet burners are not yet equipped with appliances that close off incoming air when they are not ignited. This means

that there is always a certain ventilation through the burner fan and the furnace to the chimney. If the system is to be

optimised during the summer and use electricity as extra energy the draught limiter can be disassembled or opened,

whereupon there will be free ventilation in the chimney. The temperature adjustment on the electricity cartridge can

also be lowered to about 50ºC without risking condensation in the furnace. Thus it is possible for the sun to take over

as large a part of the system as possible.

When it is time to start pellet heating again is it only necessary to reassemble or to close the draught limiter and to

start the burner. N.B.! Do not forget this before starting the burner!

6.3. Hot water heater.

Hot water is produced by two series 12 m cam loops made of copper D 22 mm. (throughput heater). The first loop is

placed in the bottom part of the furnace and the other one in the top part of the furnace. When warm water is drawn

cold tap water flows into the lower loop’s inlet part where preheating takes place to then be heated to full heat in the

upper loop.

Both loops are coupled together in the tank. One T connection is assembled between the lower and the upper loop

and a connection pipe is brought from this point to the top of the furnace. This makes it possible to get dilution water

to the mixing valve via the preloop. The solar efficiency increases then since more energy is got from the bottom of

the tank via the colder preloop and more scope for solar energy is created.

Observe that an additional mixing valve must be assembled that takes its dilution water directly from the cold water

pipe to ensure the correct temperature during daylight-saving time when the sun can heat up to high temperatures in

the entire tank.

Warm tap water should not be held at a higher temperature than 60oC at the taps (eliminate the risk of burns).

Calcium that is always in the water in greater or smaller quantities can stick in pipes and other hot water devices in

the house while heating. This problem can be solved simply with a so-called calcium remover assembled on the inlet

pipe for cold water.