Contents

1Safety instructions 1-1

1.1 Proper use ............................................................................................................................ 1-1

1.2 Organizational measures...................................................................................................... 1-2

1.3 Personnel qualifications and selection ................................................................................. 1-3

1.3.1 Personnel qualification ........................................................................................... 1-3

1.3.2 Selection of personnel ............................................................................................ 1-4

1.4 Warning................................................................................................................................. 1-5

1.4.1 Warnings used........................................................................................................ 1-5

1.4.2 Explanation to the Pictograph (ANSI)..................................................................... 1-7

1.4.3 Warnings in the documentation .............................................................................. 1-8

1.5 General safety instructions ................................................................................................... 1-9

1.5.1 Danger by mechanical parts................................................................................... 1-9

1.5.2 Danger by electrical energy.................................................................................... 1-9

1.5.3 Danger by operating materials. ............................................................................ 1-10

1.5.4 Other dangers....................................................................................................... 1-10

1.6 Safety instructions for the individual Operation Phases ..................................................... 1-11

1.6.1 Safety instructions for the transport...................................................................... 1-11

1.6.2 Safety instructions for lubrication.......................................................................... 1-11

1.6.3 Safety instructions for the electrical connection ................................................... 1-12

1.6.4 Safety instructions for the exchange of data ........................................................ 1-12

1.6.5 Safety precautions for production......................................................................... 1-12

1.6.6 Additional Safety Instructions for the operation with open cover hoods............... 1-13

1.6.7 Safety Instructions for the lubrication, cleaning and maintenance ....................... 1-14

1.6.8 Safety instructions for dismantling work ............................................................... 1-14

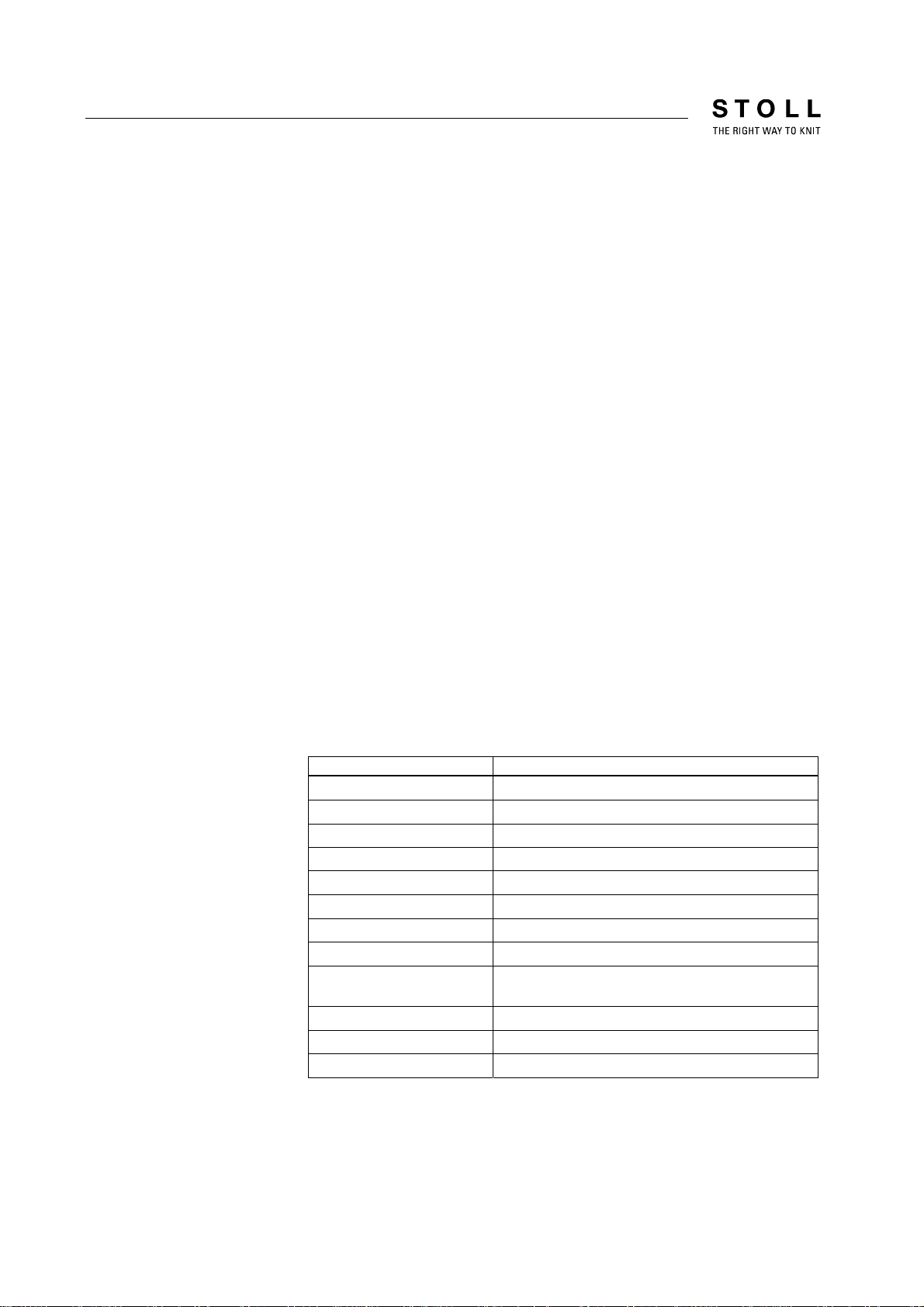

2Electrical data of the machine 2-1

2.1 Dimensions and weights....................................................................................................... 2-1

2.2 Electrical data ....................................................................................................................... 2-2

2.3 Electrical data (component type 000 and 001)..................................................................... 2-3

2.4 Gauge ranges ....................................................................................................................... 2-4

2.5 Operating conditions............................................................................................................. 2-4

2.6 Storage conditions ................................................................................................................ 2-5