STRIKE-ARC SACUT40 User manual

USER MANUAL

DC INVERTER PLASMA CUTTER

MODELS: SACUT40

PLEASE READ THE USER MANUAL BEFORE USE.

INTRODUCTION

The Air Plasma Cutter can be used for a wide range of cutting applications:

stainless steel, alloy steel, copper, aluminum, and all other color metal materials.

You will need a suitable Compressor to operate the CUT40Air Plasma Cutter.

Clean dry air supply is required: 350KPA/3.5 BAR - 550KPA /5.5BAR, to the

machine. Air pressure must be regulated lower or higher depending on cutting

requirements and adjustment the required amperage. Note - Lower air & amps for

thinner material/ increasing for thicker materials.

We all know the first three states of matter, which are solid, liquid and gas. The

fourth state of matter is plasma. When arc is transferred to the gas it elevates the

temperature of the gas to the fourth state of matter. Plasma is a high energy

electrically charged mixture of ions and electrons.

The gas could be of any of the following: air, nitrogen, argon, oxygen etc.

Through the restricted opening (nozzle) the gas passes through causes it to

squeeze by at a high speed. This high-speed gas cuts through the molten metal.

The gas is also directed around the perimeter of the cutting area to shield the cut.

Plasma cutting can be used on any conductive metals such as mild steel, aluminum

and stainless are some examples. The plasma cutter will cut mild steel much faster

than alloys. It doesn’t reply on oxidizing the element it is cutting, which makes it a

unique cutting tool.

WARNING!

Protect yourself and others from injury - read and follow these precautions.

Only suitably qualified persons should maintain and repair this unit.

During operation, keep everybody, especially children and pets, away.

CUTTING can cause fire or explosion resulting from hot metal and sparks from the

cutting arc.

* The flying sparks, hot metal, hot work piece, and hot equipment can cause fires

and burns.

Ensure the area is safe before doing any cutting.

* Remove all flammables within 12m of the cutting arc. If this is not possible, tightly

cover them with approved covers. Do not cut where flying sparks can strike

flammable material.

* Protect yourself and others from flying sparks and hot metal.

* Be aware that sparks and hot metals from cutting can easily go through small

cracks and openings to adjacent areas.

* Be alert for fire and keep a fire extinguisher and trained operator nearby.

* Be aware that cutting on a ceiling, floor, bulkhead, or partition can cause fire on

the backside side.

* Do not cut on closed containers such as tanks, drums, or piping.

* Connect work cable to the work as close to the cutting area as practical allowing

maximum current to the cut and eliminating electric shock in the path.

* Never cut containers with potentially flammable or combustible materials inside.

They must be emptied and properly cleaned first. Blow out with clean air as fumes

can ignite

* Do not cut in areas containing explosive dust or vapors.

* Do not cut pressurized containers of any kind.

* Wear oil-free clothing and protective gear such as leather gloves, heavy shirt, cuff

less pants, high tight shoes, and a cap.

* Touching live electrical parts can cause fatal shocks or

severe burns. The torch and work circuit are electrically live whenever the output

is on.

The input power circuit and machines internal circuits are also live when power is

on. Plasma arc cutting requires higher voltages than welding to start and maintain

the arc (200 to 400 volts dc are common), but also uses torches designed with

safety interlock systems which turn off the machine when the shield cup is loosened

or if tip touches electrode inside the nozzle. Incorrectly installed or improperly

grounded equipment is a hazard.

ELECTRIC SHOCK CAN KILL

* Never touch live electrical parts.

*Always wear dry, hole-free insulating gloves and body protection.

* Insulate yourself from work and ground using dry insulating mats or covers big

enough to prevent any physical contact with the work or ground.

* Do not touch torch parts if in contact with the work or ground.

* Disconnect the power before checking, cleaning, or changing torch parts.

* Disconnect input power before installing or servicing this equipment.

* Properly install and ground this equipment according to its Owner’s Manual and

statutory regulations and requirements.

* Check and be sure that input power cord ground wire is properly connected to

ground terminal in disconnect box or that cord plug is connected to a properly

grounded receptacle outlet − al- ways verify the supply ground.

* Frequently inspect input power cord for damage − replace cord immediately if

dam aged − exposed wiring can kill.

* Turn off all equipment when not in use.

* Inspect and replace any worn or damaged torch cable leads.

* Do not wrap torch cable around your body.

* Use only well-maintained equipment. Repair or replace damaged parts at once.

* Keep all panels and covers securely in place.

* Do not bypass or try to defeat the safety interlock systems.

* Use only a torch specified in Owner’s Manual.

* Keep away from torch tip and pilot arc when trigger is pressed.

* Clamp work cable with good metal-to-metal contact to work piece (not the piece

that will fall away) or worktable as near the cut as practical.

* Insulate work clamp when not connected to workpiece to prevent contact with any

metal object.

After disconnecting the power supply, there is still

SIGNIFICANT DC VOLTAGE in the inverter power sources.

If you must open the unit for any reason, Turn Off unit, disconnect input power, and

check input Voltage. Capacitors store electricity, ensure that they are near zero (0)

volts before touching any parts. Check capacitors according to instructions in

Maintenance Section of Owner’s Manual or Technical Manual before touching any

parts.

CAUTION:

On inverter power sources, failed parts can explode or cause other parts to explode

when power is applied. Always wear a face shield and long sleeves when servicing

inverters.

EXPLODING PARTS:

Sparks and hot metal blow out from the cutting arc. Chipping and grinding cause

flying metal that can injure you and others.

FLYING SPARKS:

Wear approved face shield or safety goggles with side shields. Wear proper body

protection to protect skin to protect from flying sparks.

Wear flame-resistant ear plugs or earmuffs to prevent sparks from entering ears.

Arc rays from the cutting process produce intense visible and invisible (ultraviolet

and infrared) rays that can burn eyes and skin.

ARC RAYS:

Wear face protection (helmet or shield) with a proper shade of filter lenses to

protect your face and eyes when cutting or watching.

Wear approved safety glasses with side shields under your helmet or face shield.

Use protective screens or barriers to protect others from flash, glare and sparks.

Wear protective clothing made from durable, flame-resistant material (leather,

heavy cotton, or wool) and protective footwear.

EXCESSIVE NOISE:

Use approved ear plugs or earmuffs if noise level is excessive.

TECHNICAL DETAILS

Plasma Defined

Plasma cutters work by sending a pressurized gas, such as air, through a small

channel. In the center of this channel, you'll find a negatively charged electrode.

The electrode is at the center, and the nozzle is just below it. The swirl ring causes

the plasma to turn rapidly as it passes. When you apply power to the negative

electrode, and you touch the tip of the nozzle to the grounded work piece, the

connection creates a circuit. A powerful spark is generated between the electrode

and the metal. As the inert gas passes through the channel, the spark heats the gas

until it reaches the fourth state of matter (plasma). This reaction creates a stream of

directed plasma, approximately 16,600°C or more and moving at 6,000 per m per

second that reduces metal to vapor and molten slag.

The plasma itself conducts electrical current. The cycle of creating the arc is

continuous as long as power is supplied to the electrode and the plasma stays in

contact with the metal that is being cut. The cutter nozzle has a second set of

channels. These channels release a constant flow of shielding gas around the

cutting area. The pressure of this gas flow effectively controls the radius of the

plasma beam.

NOTE! This machine is designed to use only compressed air, referred to as the

“gas”. Voltage Regulation

The Automatic Voltage Compensation circuit prevents voltage loads from

exceeding the maximum in accordance with the main technical data sheet to

prevent against shorting the life of the machine.

Thermal Protection

The thermal protection circuits will engage if unit exceeds its maximum duty cycle.

This will cause the machine to stop working. The indicator will be lit on the front of

the machine. The fan will continue to run until unit cools down (if the fans stop

checking your circuit breaker). When it reaches an acceptable temperature, it will

operate again.

Duty Cycle

Duty cycle is the percentage of on time (measured in minutes) in a 10-minute

period in which the machine can be operated continually, in an environment of a

specified temperature.

Exceeding duty cycle ratings will cause the thermal overload protection circuit to

become energized and shut down output until the unit cools to normal operating

temperature. Continual exceeding of duty cycle ratings can cause damage to the

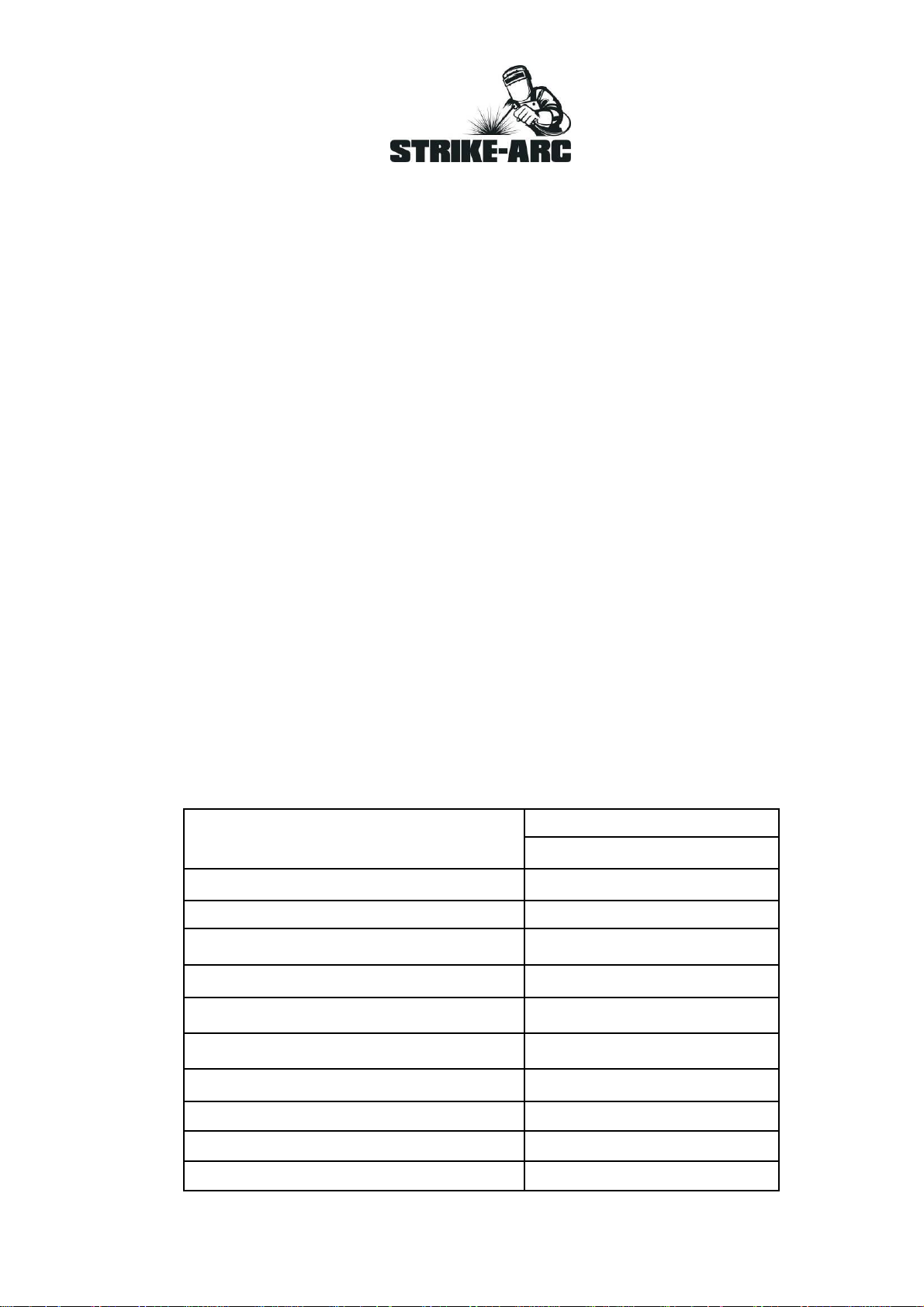

machine. TECHNICAL DATA

D

A

T

A

CUT-40

single phase220V

Rated input power (KVA)

7

Rated input current (A)

34

No-load voltage (v)

280

Output current range(A)

20-40

Rated output voltage (v)

96

Duty cycle

60%

Burner inner diameter (mm)

1.0

Pressure of air compressor PSI (kg)

70 psi (4-5)

Cutting Thickness (mm)

1-10

Dimensions(mm)

350X142X255

INSTALLATION

Unpacking

Unpack all items and verify that all items have been received according to the

packing list enclosed.

Operating Environment

Make sure working area is well ventilated. The unit is cooled by an flow fan which

provides airflow through the back panel over the electronics and out the machine

cover vents. Provide at least 150mm in the rear and 150mm on each side for air

circulation. If unit is operated without sufficient cooling the duty cycle will be

greatly reduced.

Input Power Cord Connection

Every machine includes a primary power cord capable of handling the input voltage

and current for this unit. If the unit is connected to power that exceeds the required

voltage, or is of the incorrect phase, serious damage will be incurred.

This machine may operate on 220V to 240V volts single phase power. Proper input

voltage can be determined by observing the labels next to the power cord strain

relief and will be labeled 220V-240V Circuit Breaker must be at least 40Amp.

The power supply is a molded 15 Amp 3 Pin South African plug; Do not remove this

plug or attempt “other” unsafe connection. This could/will result in electric shock

and possible death.

If using an extension cord, make sure that it meets or exceeds the

following recommendations: Minimum 30Amp rating and not exceeding 10M in

length.

Long extension cords result in voltage drop and increase amperage that could be

hazardous and could cause damage to the machine.

CONNECTIONS

Torch Connection

Connect the Torch to the Cutter by screwing the airline fitting at the end of the torch

to the front of the machine: attach the secondary connector to the face of the

machine.

Secure by tightening with wrench slightly. DO NOT OVER TIGHTEN!

Earth Clamp Connection

Connect earth clamp to face of the machine (+).

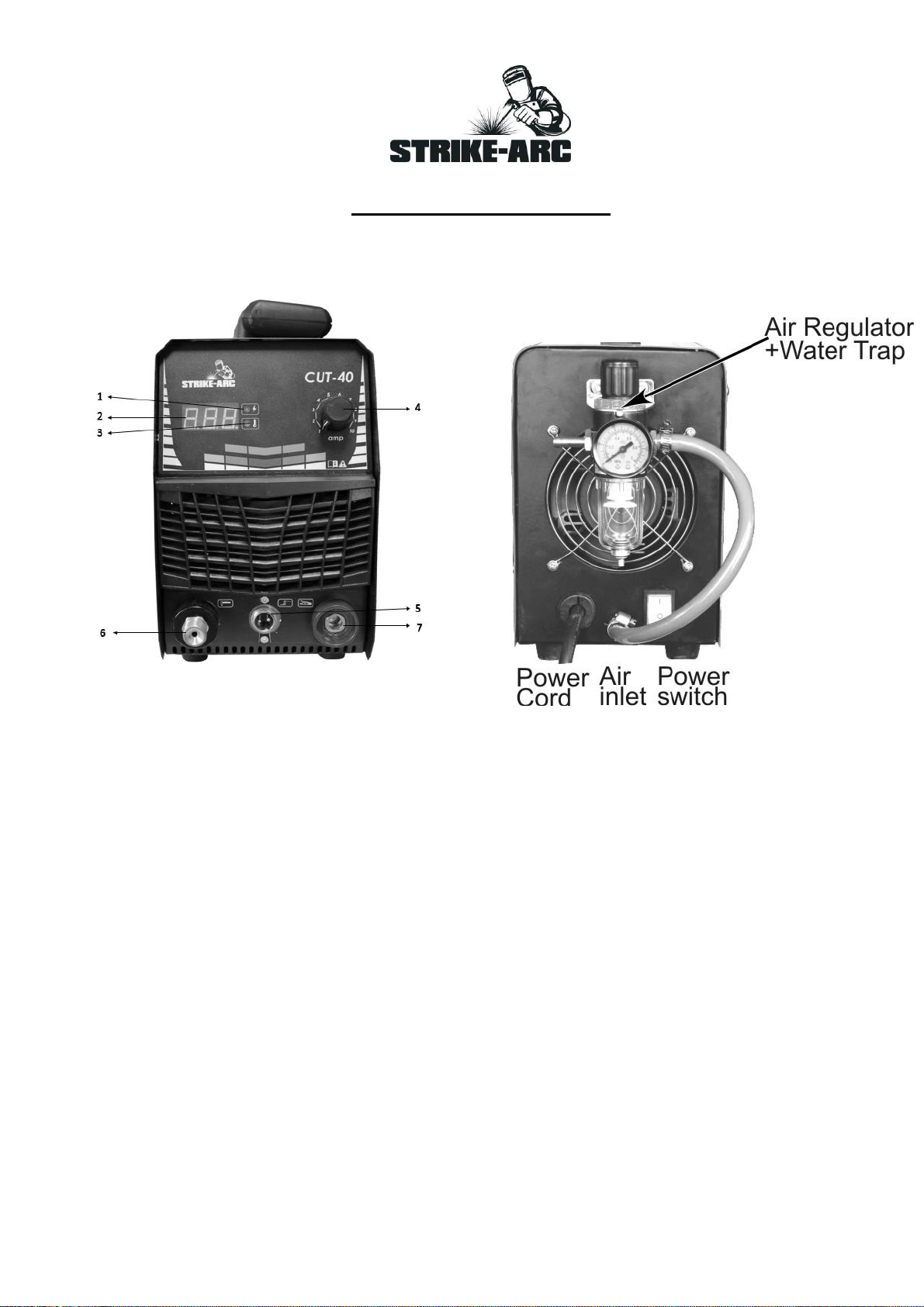

Air Connection

Connect the air supply to the regulator located on the back of the unit. Using the

supplied host clamps; connect the air hose to the back of the machine

Ensure the Water Trap is properly secured and serviced regularly: this is NOT an

Air Dryer.

Air Dryers can be purchased as an optional extra and installed on the air supply

(Compressor).

TORCH ASSEMBLY/MAINTENANCE

Torch Assembly Procedure:

Position the torch with the shield cup facing upward and unscrew and remove the

shield cup from the torch head assembly.

Unscrew the electrode.

Install the new electrode, and tip. Replace worn parts, where necessary. Install and

hand tighten the shield cup until it is seated on the torch head. If resistance is felt

when installing the cup, check the threads and parts before proceeding.

OPERATION

Process

Turn the Power Switch to the ON position.

Position yourself to where you can read the air pressure. Press the torch switch (air

will flow from the torch, adjust the air regulator to read approximately 350KPA to

550KPA(3.5 BAR to 5.5 BAR) and release torch switch.

Note: The generally accepted air pressure range is 350KPAto 550KPA (3.5 BAR to

5.5 BAR). You may experiment as desired, but be careful not to lower the pressure

too much as you may damage the torch/ mainly the torch electrode etc.

Secure earth clamp to work piece. Connect clamp to main part of your work piece,

and not the part being removed (the part that might fall to the floor.

Cutting

Drag Cutting

Position torch tip slightly above work piece, press torch switch and lower torch tip

toward work piece until contact is made and a cutting arc is established. After the

cutting arc is established, move the torch in the desired direction keeping the torch

tip slightly angled, maintaining contact with the work piece.

This methodology is called Drag-Cutting. Avoid moving too fast as would be

indicated by sparks radiating from the top side of work piece. Move the torch just

fast enough to maintain sparks concentration at the underside of the work piece

and making sure the material is completely cut through before moving on. Adjust

drag speed as desired/required.

Stand-off Cutting

In some cases, it may be beneficial to cut with the torch tip raised above the work-

piece approximately 2mm to 3mm to reduce material blow-back into the tip and to

maximize penetration of thick material cuts.An example of "stand-off cutting" would

be used when penetration cutting, or gouging operation is being performed. You

can also use “stand-off” technique when cutting sheet metal to reduce the chance

of splatter-back tip damage.

Piercing

For piercing, position the tip approximately 3mm above the work piece. Angle the

torch slightly to direct sparks away from the torch tip and operator. Initiate the pilot

arc and lower the tip of the torch until the main cutting arc transfers, sparks start.

Start the pierce off the cutting line on the scrap piece or template and then continue

the cut onto the cutting line.

Hold the torch perpendicular to the work piece after the pierce is complete and

continue cutting as desired.

Clean spatter and scale from the shield cup and the tip as soon as possible.

Quality Cuts

Dross (slag) is the excess material that spatters and builds up on the underside of

the workpiece as you cut.

Dross occurs when the operating procedure and technique is less than optimal. It

will require practice and experience to obtain cuts without dross. Although less than

optimal cuts will contain dross, it is relatively easy to remove by breaking it off using

pliers or chipping off with a chisel or scraping or grinding the finished cut as needed

and is generally only a minor inconvenience.

A combination of factors contributes to the build-up of dross. They include material

type, material thickness, amperage used for the cut, speed of the torch across the

workpiece, condition of the torch tip, input line voltage, air pressure, etc. Generally,

there is an inversely proportional relationship between output current and speed of

cut. Do not use more output current than is necessary and adjust speed of cut

toward minimizing dross build up on underside of cut. Experiment with adjusting

current and speed to minimize dross. For more specific issues regarding quality of

cuts and general operation, go to the Troubleshooting section of this manual.

MAINTENANCE

Pre-Operational check

Each time you use the plasma cutter; check the Torch, Tip/Nozzle, Electrode and

Shield Cup.

Inspect Torch for any wearing, cracks, or exposed wires. Replace or repair before

use.

A worn Torch Tip/Nozzle contributes to reduced speed, voltage drop and crooked

cuts.

A worn Tip/Nozzle is indicated by an elongated or oversized orifice.

The face of the electrode should not be recessed more than 3mm. Replace if

worn beyond this point.

If the Shield Cup does not go on easily, check the threads. Test the fan to see that is

working.

Weekly Checks

Blow or vacuum any dust and dirt from of the entire machine. Check your air and

moisture filter/separator/ drain water.

TROUBLESHOOTING

PROBLEM

CAUSE

SOLUTION

Power SwitchOff

Power SwitchOff

Turn Power Switch to the On

Position

Air supply is

compromised

Another indication of this is a

greener flame.

Check air supply.

Work piece Ground

Clamp not attached

Attach to work piece or to

steel table with work piece

securely clamped to table.

Sparks are shooting upward

Instead of down through the

Material.

PlasmaTorchis not

piercing thematerial.

Increase current.

Torchmay too far

away from stock

Decrease the distance of your

torch to stock

Material may not be

grounded properly

Check connections for

proper ground.

Travel speed too fast

Reduce speed

Beginning of cut not completely pierced

Possibleconnection

problem

Check all connections

Dross build-up on parts of

cuts

Tool/Material building

up heat

Allow material to cool then

continue cut.

Cutting speed too slow

or Current too high.

Increase speed and/or

reduce current until dross is

reduced to minimum.

Worn torch parts

Inspect and repair or replace

worn parts.

Arc stops while cutting

Cutting speed too slow

Increase speed until

problem solved

Torchis too high,

away from material

Lower torch to

recommendedheight

Arc stops while cutting

Worn torch parts

Inspect and repair or replace

worn parts

Work piece ground

cable disconnected

ConnectWork piece Ground

Clampto work- piece or

steel table.

Insufficient penetration

Cutting speed too fast

Slow travel speed

Torch tilted too much

Adjust tilt.

Metal too thick

Several passes maybe

necessary

Worn torch parts

Inspect and repair or replace

worn parts

Consumables w

ea

r

qu

i

ck

l

y

Exceeding unit

capability

Material too thick, increase

angle to prevent blow back

into torch tip.

Excessive Pilot arc

time

Do not pilot for more than 5

seconds. You can also start

with torch in contact with

metal or within 3mm of metal

Improperlyassembled

torch

See section titled “Torch

Assembly”

Inadequate air

supp

l

y

,

pressure too

l

ow

.

Check air filter, increase air

pressure.

Faulty air compressor

Check air compressor

operation and make sure

input air pressureis at least

400KPA/4.8BAR

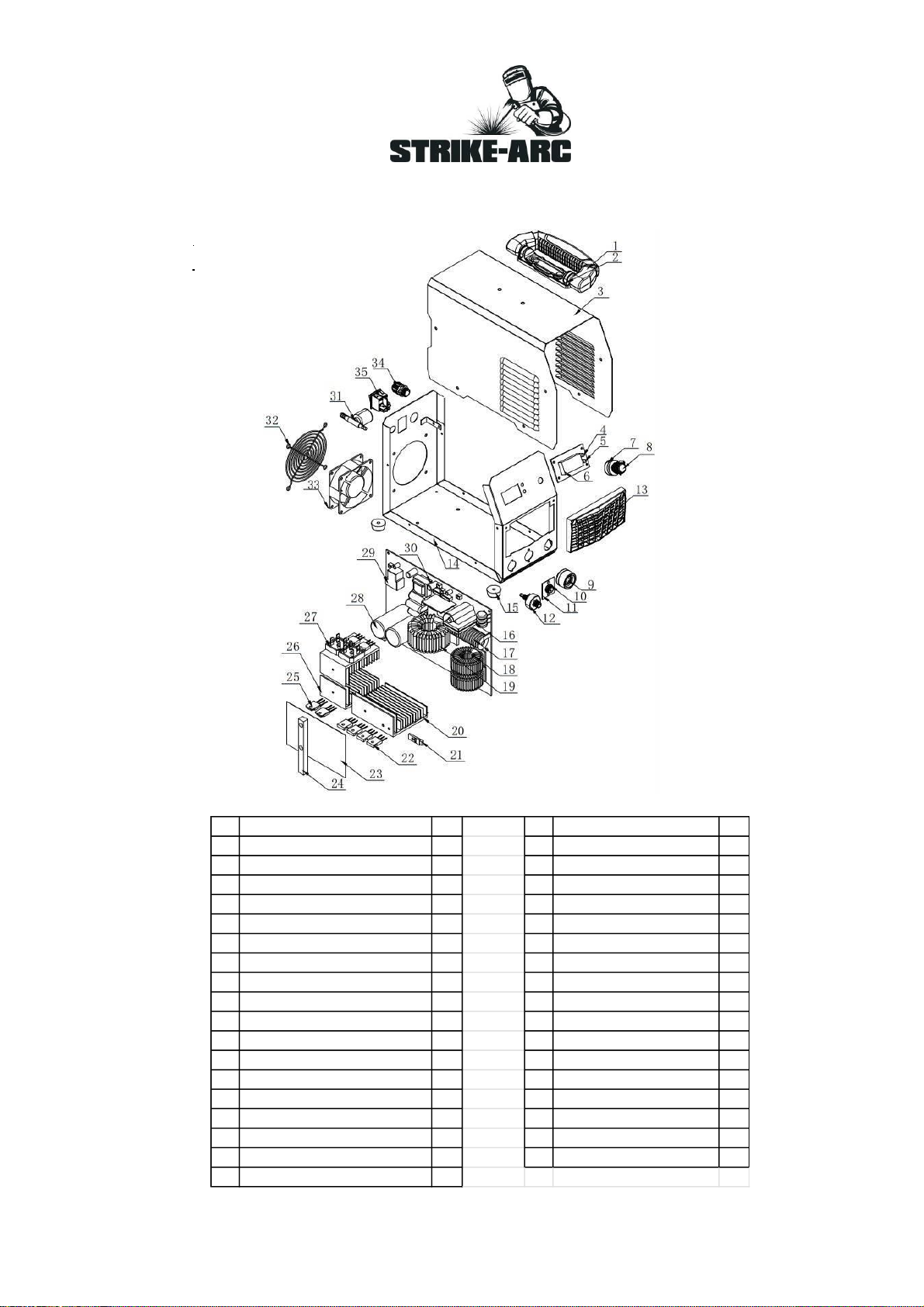

PARTS LISTING

No. PART QTY No. PART QTY

1. HANDLE 1 19. MAIN TRANSFORMER 1

2. HANDLE SEAT 1 20. RADIATOR 1 1

3. METAL COVER 1 21. THERMOSTAT 1

4. LED 1 22. RECTIFIER TRANSITOR 4

5. LED 1 23. BAKELITE 1

6. DIGITAL DISPLAY 1 24. UPRIGHT 1

7. POTENTIALMETER 1 25. IGBT 4

8. POTENTIALMETER KNOB 1 26. RADIATOR 2 2

9. FAST CONNECTOR 1 27. RECTIFIER BRIDGE 2

10. AVIATION SOCKET 1 28. CAPACITOR 2

11. BRACKET 1 29. RERLAY 4

12. P&E INTEGRATED CONNECTOR 1 30. DRIVE TRANSFORMER 1

13. PLASTIC FRONT PANEL 1 31. SOLENOID VALVE 1

14. METAL BOTTOM BOARD 1 32. FAN COVER 1

15. RUBBER FEET 4 33. FAN 1

16. HIGH PRESSURE PAGAGE 1 34. POWER CABLE FASTENER 1

17. COUPLING TRANSFORMEFR 1 35. SWITCH 1

18. TRANSFORMER 2

PANEL INSTRUCTION

Model: SACUT40

1. POWER INDICATOR LIGHT

2. CURRENT METER

3. OVER-LOAD (HEAT) INDICATOR LIGHT

4. CURRENTADJUSTER

5. TORCH AVIATION SOCKET OUTLET

6. NEGATIVE OUTPUT (TORCH)

7. POSITIVE OUTLET (EARTH CLAMP)

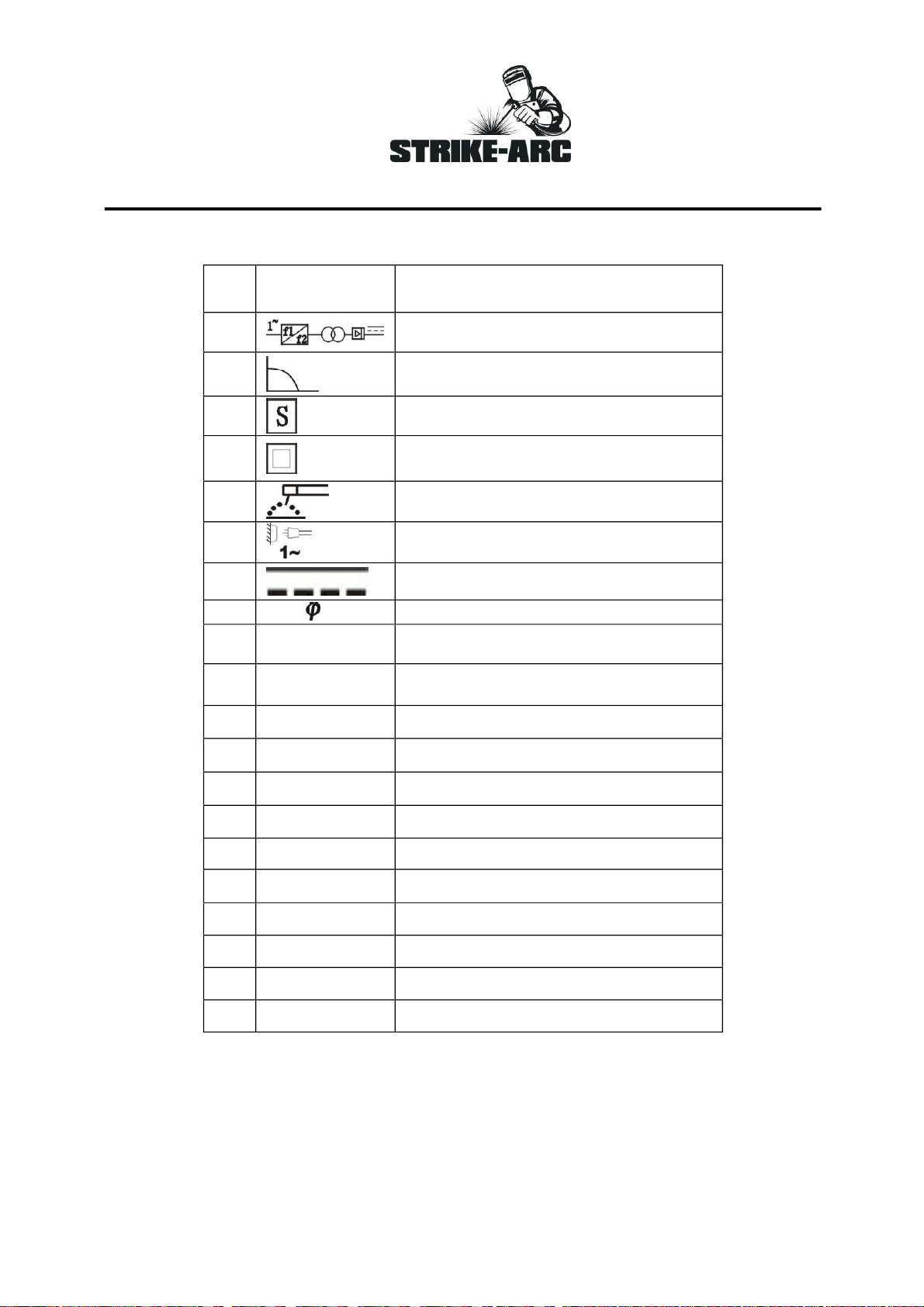

NAMEPLATE SYMBOL AND GRAPHIC MEANING

NO.

Symbol

Meanings

1

Single phase static frequency

changer-transformer-rectifier

2

Static External Characteristics is

dropping characteristic

3

Welding Power source symbol of

Fit welding operation

4

II Category Protection Symbol

5

Manual arc welding with coated

electrode

6

/ 3~

Single phase power source/ three

phase power source

7

DC (direct current)

8

COS

Power Factor

9

IEC60974-1

Confirmed Welding power source

files quote

10

~50/60Hz

AC power, rated frequency

50HZ/60HZ

11

U0(V)

No load voltage unit: V

12

X

Symbol for load continuance rate

13

I2(A)

Rated welding current unit: A

14

U2(V)

Rated load voltage unit: V

15

…%.....100%

Duty cycle

16

I1(A)

Rated Input current unit: A

17

U1(V)

Rated Input voltage unit: V

18

I CL.H

Insulation Class

19

IP21S

Protection Degree

20

COOLING AF

Fan cooling

After-sales Service

This machine is covered by the manufacturer’s warranty for a period on 12 months from date of

purchase against faulty material and or poor workmanship. Misuse/abuse and tampering of the

machine will not be covered by the warranty. Contact your dealer for repair/warranty claims.

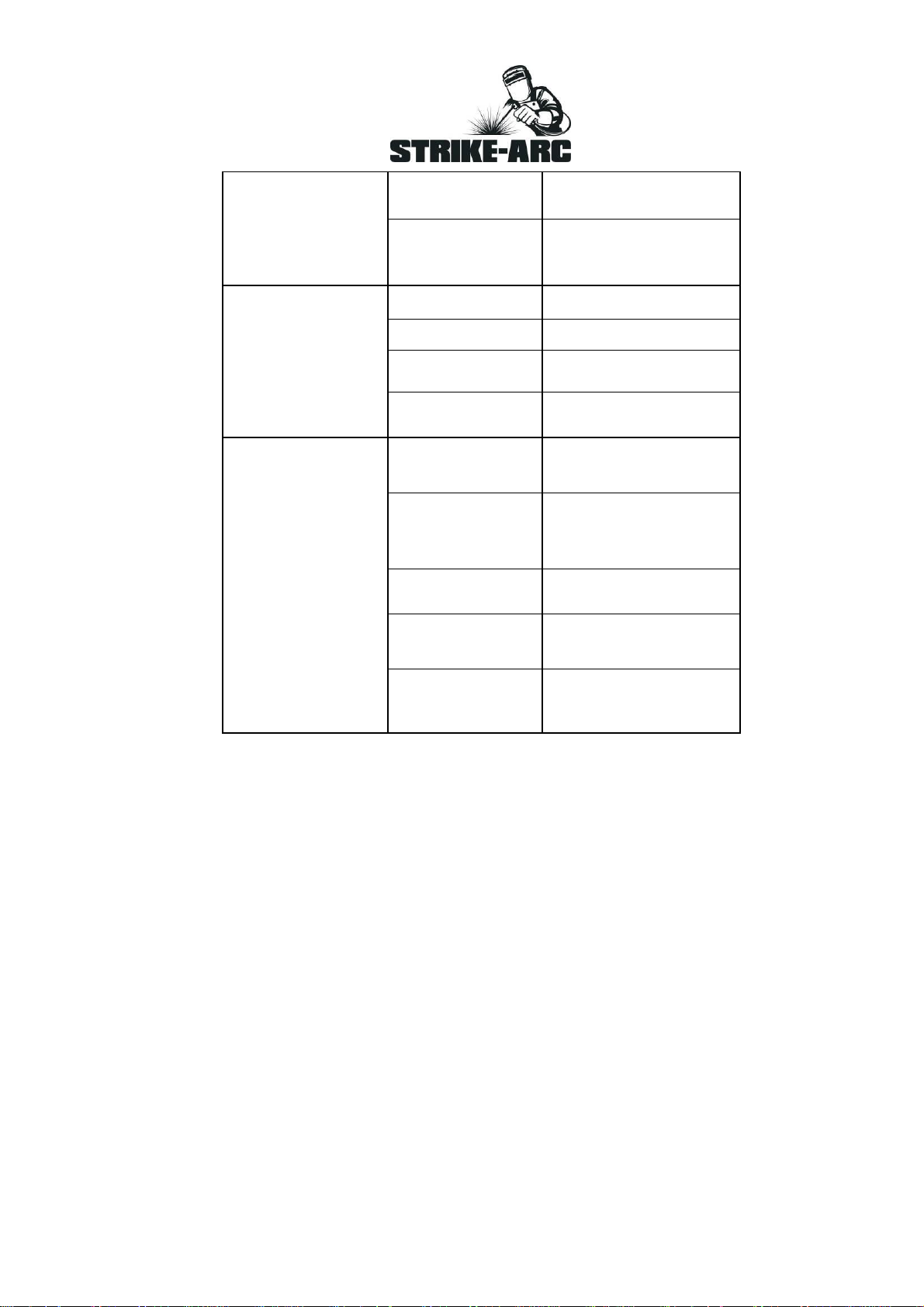

Packing List

Name

NO.

Main Body

1

Cutting Torch

1

Pressure Reducing Value

1

Ground Wire

1

Manual

1

Strike-Arc products are exclusively manufactured for and distributed by Agrinet(Pty)

Ltd.

Private Bag x165,Centurion,0046

T: +27(0) 12 657 2222

Made in PRC

Table of contents