Content

Safety Instruction

.............................................................................................

3

For Commercial Use

.......................................................................................

3

Please Read all Instructions before Using this Machine

...................

3

1. Hand Shank...................................................................................................4

2. Control Panel.................................................................................................4

a.......Stopwatch.......................................................................................................4

b.......Battery Status Indicator.................................................................................4

c.......Brush Motor Switch ......................................................................................4

d.......Water Suction Motor Switch.........................................................................4

e.......Solution Tank Switch....................................................................................4

f.......Lock Switch ...................................................................................................4

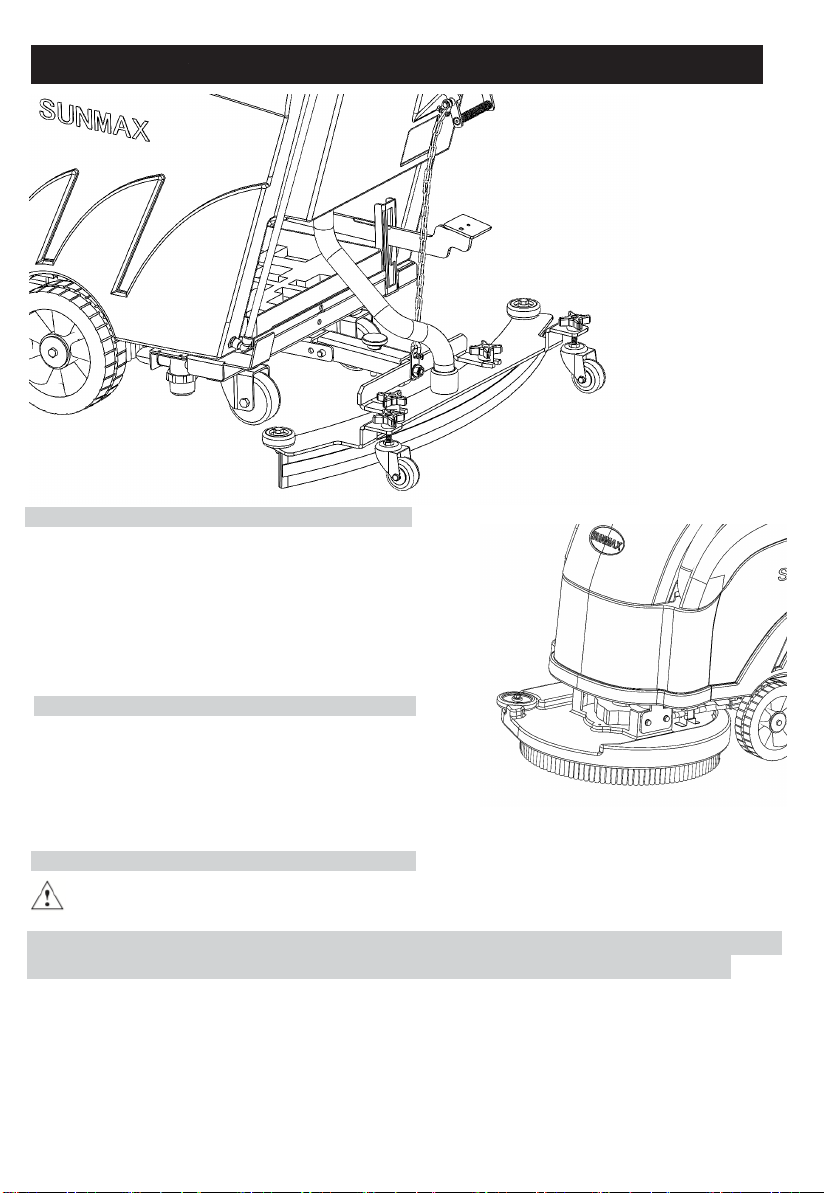

3. Looseingn Handle of Squeezee

..........................................................................

4

4. Brush Plate Lifting Pedal ..............................................................................4

5. Pump Impeller...............................................................................................4

6.Installment Handle of Squeegee .........................................................................4

7.Squeegee..............................................................................................................4

8 Water Level Pipe of Clear Water Tank.........................................................4

Battery Installment

..........................................................................................

5

Battery Charging

..............................................................................................

5

Squeegee Installment..............................................................................................5

Needle Holder and Brush Tray Installment...........................................................5

Water Injection in Clear Water Tank.....................................................................5

Water Suction Motor Switch..................................................................................6

Brush Plate/Needle Holder Lifting ........................................................................6

Squeegee Lifting.....................................................................................................6

Setting of Clear Water Tank Flow.........................................................................6

Water Suction Operation........................................................................................7

What should we do when there are too much foam in the sewage tank...............7

Sewage Tank Emptying .........................................................................................7

Current Maintenance..............................................................................................7

Weekly Maintenance..............................................................................................7

Monthly Maintenance ............................................................................................7

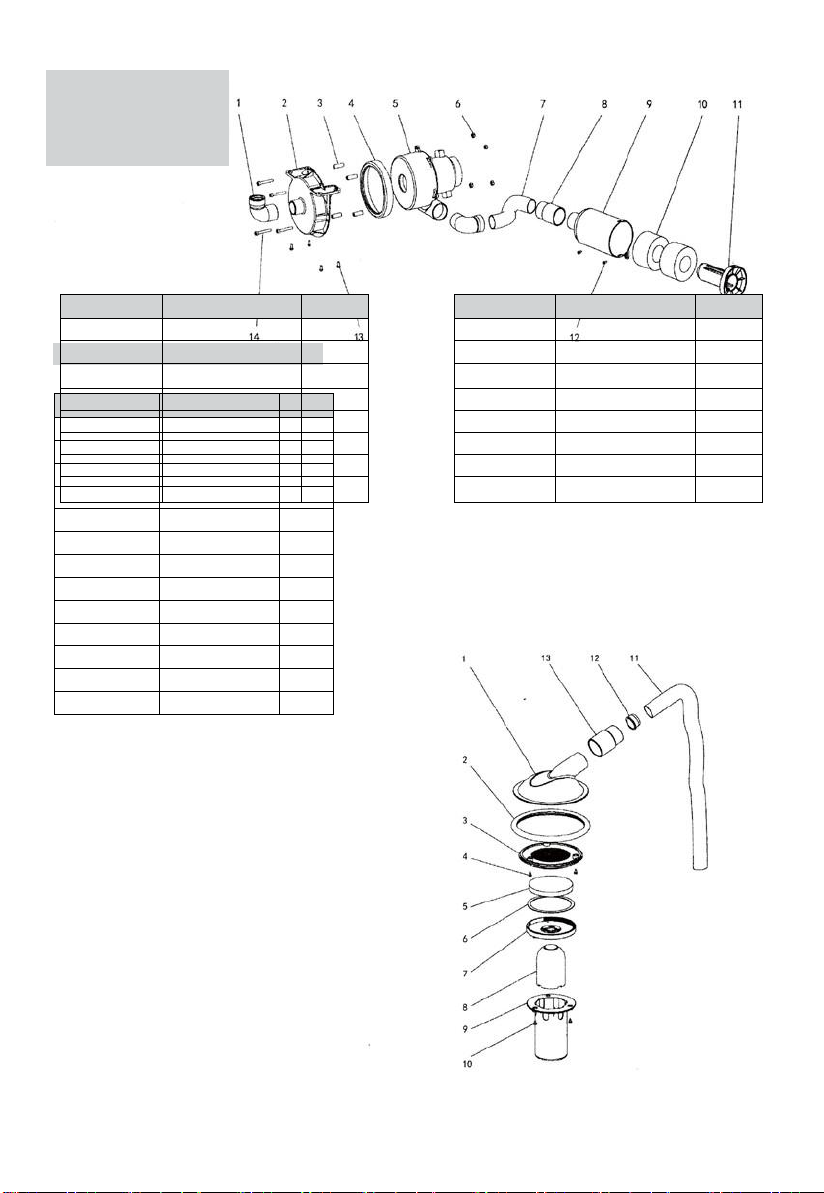

Valve components..................................................................................................6

Control Pabel Applications....................................................................................8

Floating Head components.....................................................................................9

Squeegee components............................................................................................10

Clear Water Tank components

...............................................................................

11