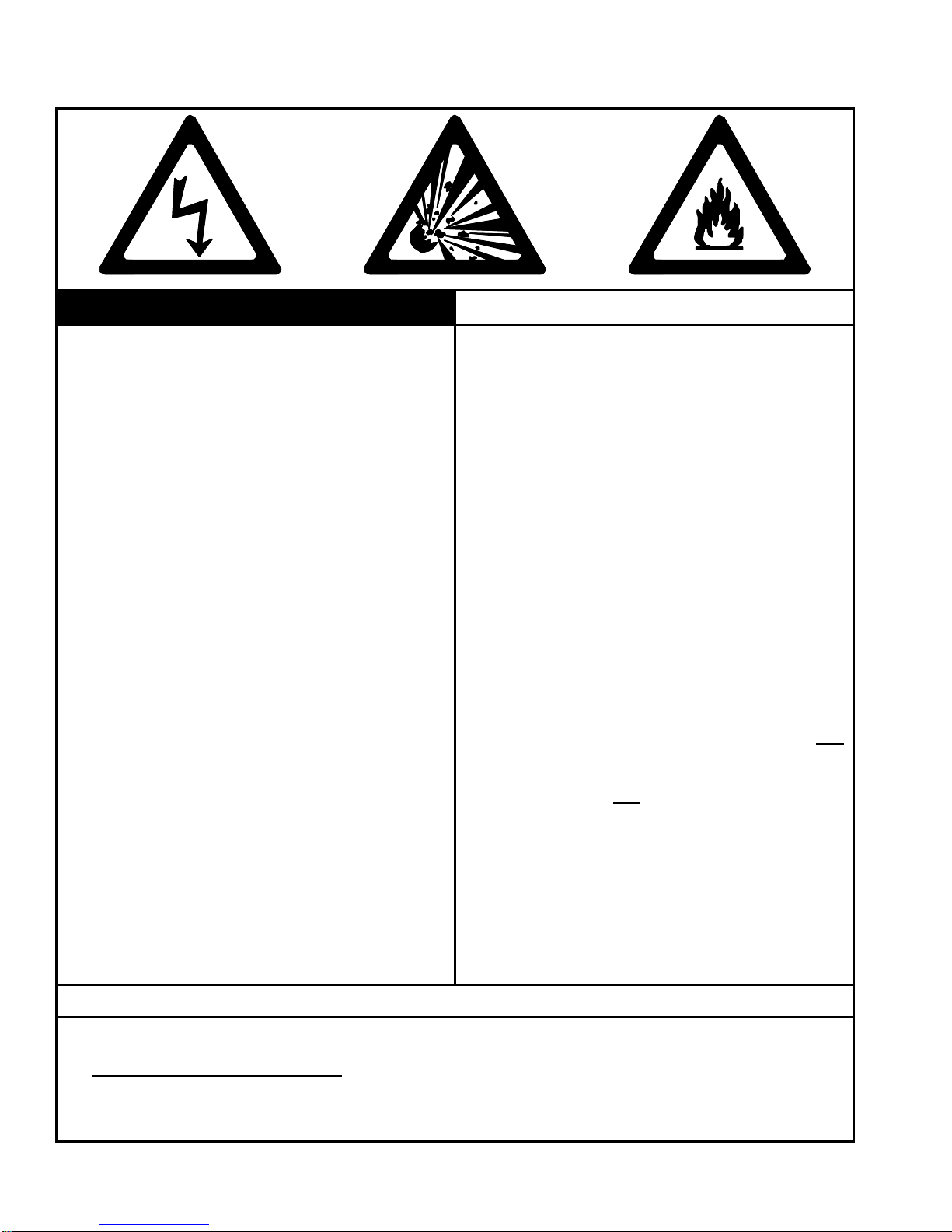

SRH pg. 2 WARNINGS

WARNING CAUTION

FIRE OR EXPLOSION HAZARD

Can cause property damage, severe injury or

death.

Read manual carefully before installing, or

servicing this equipment, or serious injury or

death may result.

Check minimum clearance to combustibles to

make certain that heater is in a safe location.

Combustible items located too close to the

heater could cause a serious fire hazard. In

storage areas, signs for maximum permissible

stacking height to maintain clearance from the

heater to combustible materials must be

posted adjacent to the heater thermostats or in

the absence of such thermostats in a

conspicuous location.

Operating the heater in an atmosphere

containing combustible dust or flammable

vapors is dangerous and may potentially result

in injury or death.

Heaters must be oriented in such a way as to

maintain minimum clearances to vehicles

parked underneath them.

This heater expands and contracts with each

cycle. The installation of the gas connection

and mounting hardware must accommodate

this movement; otherwise, a fire or explosion

hazard may occur.

This heater is equipped with an automatic

ignition and does not contain a pilot. DO NOT

attempt to light the burner manually, this could

result in serious personal injury or fire hazard.

MECHANICAL HAZARD

•DO NOT use high pressure to test the gas

pipes with the burner still attached. This will

cause damage to the controls within the

burner requiring them to be replaced.

If heater is being operated in an atmosphere

with a negative pressure or an atmosphere

containing contaminants, an outside

combustion air supply is required. Failure to

provide outside combustion air may allow

excessive heat to back up to the blower wheel

and bearings severely shortening service life.

•Correct inlet pressure is important to efficiency

and long lasting operation of the burner.

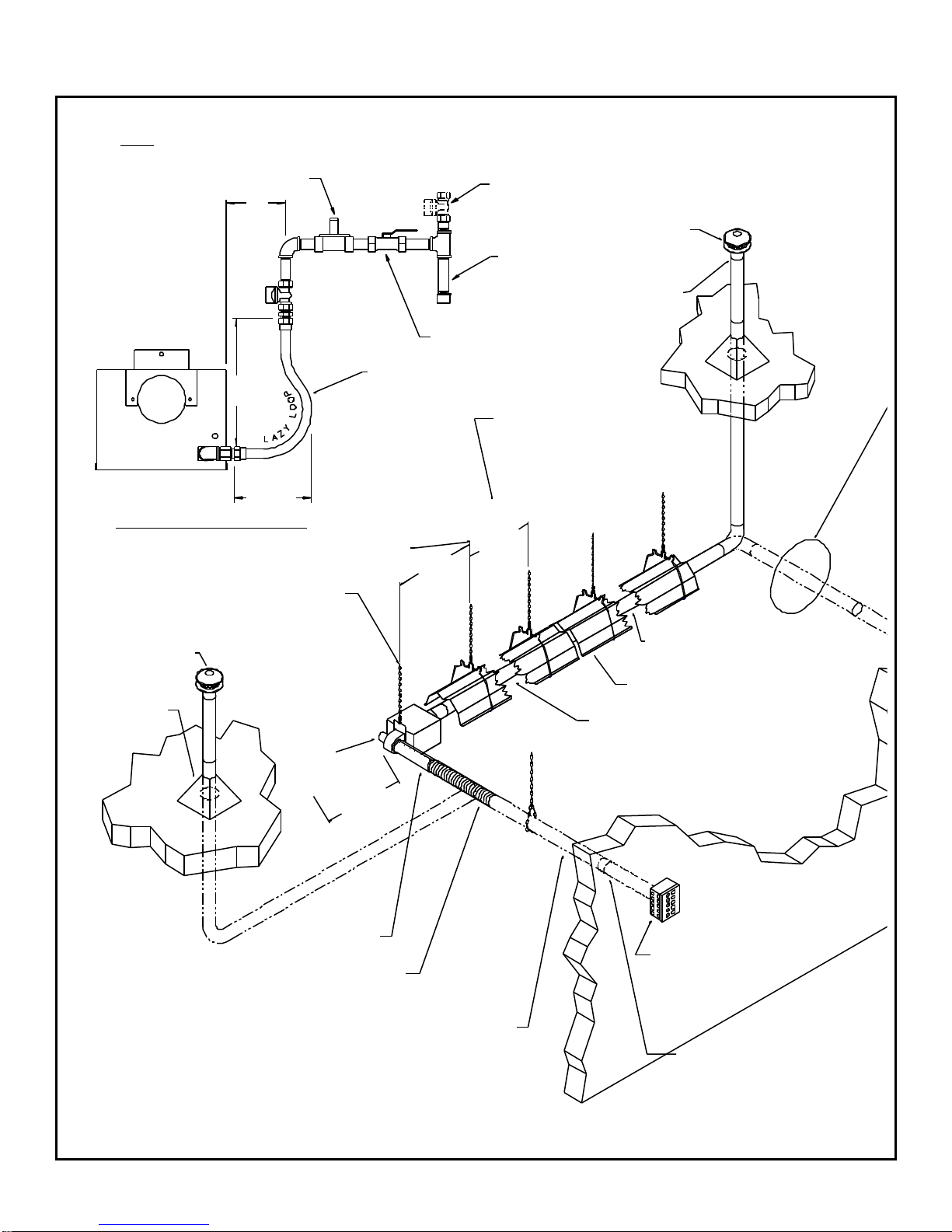

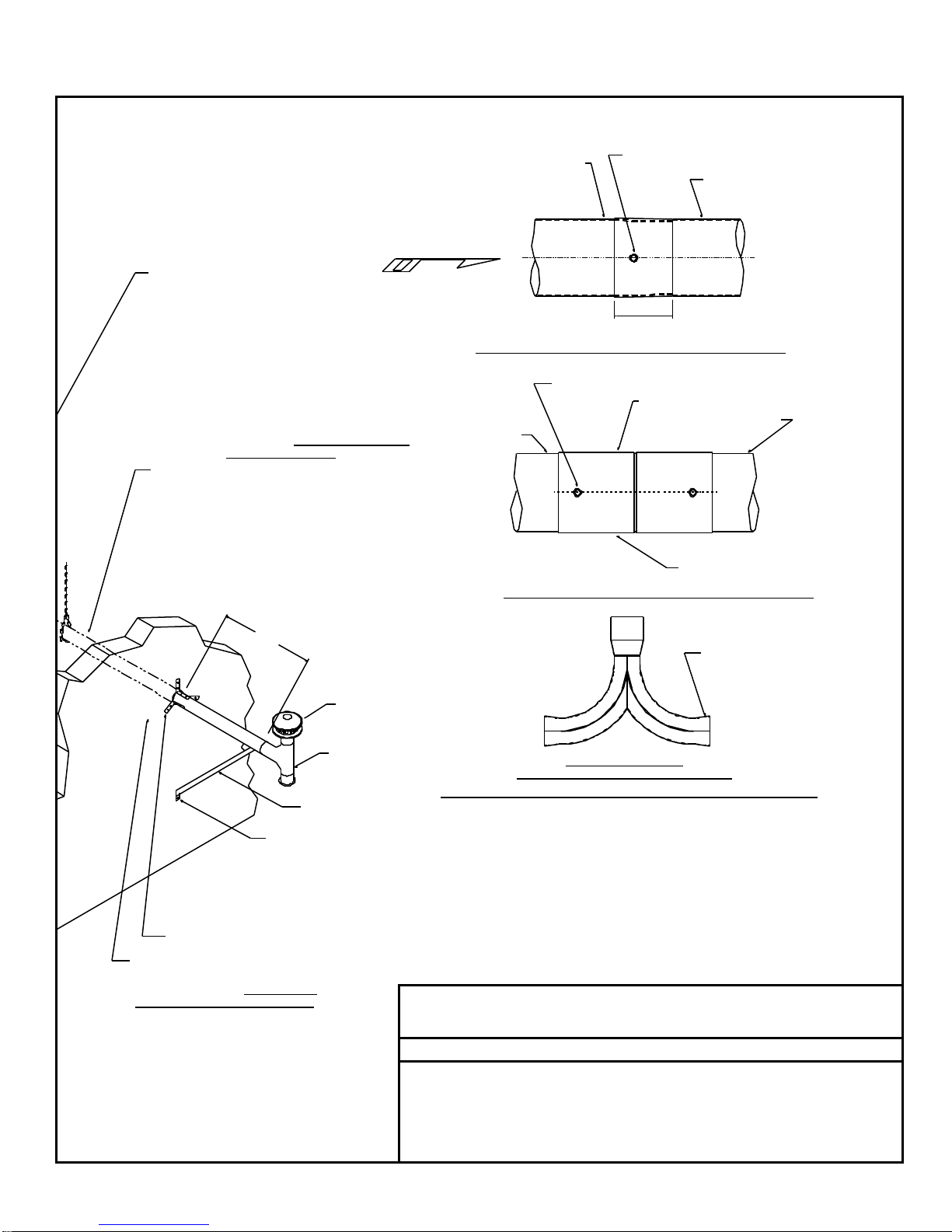

The burner, tubing, and accessories expand

and contract with each cycle. The system

must be installed so that the mounting

hardware and gas line will accommodate

these changes.

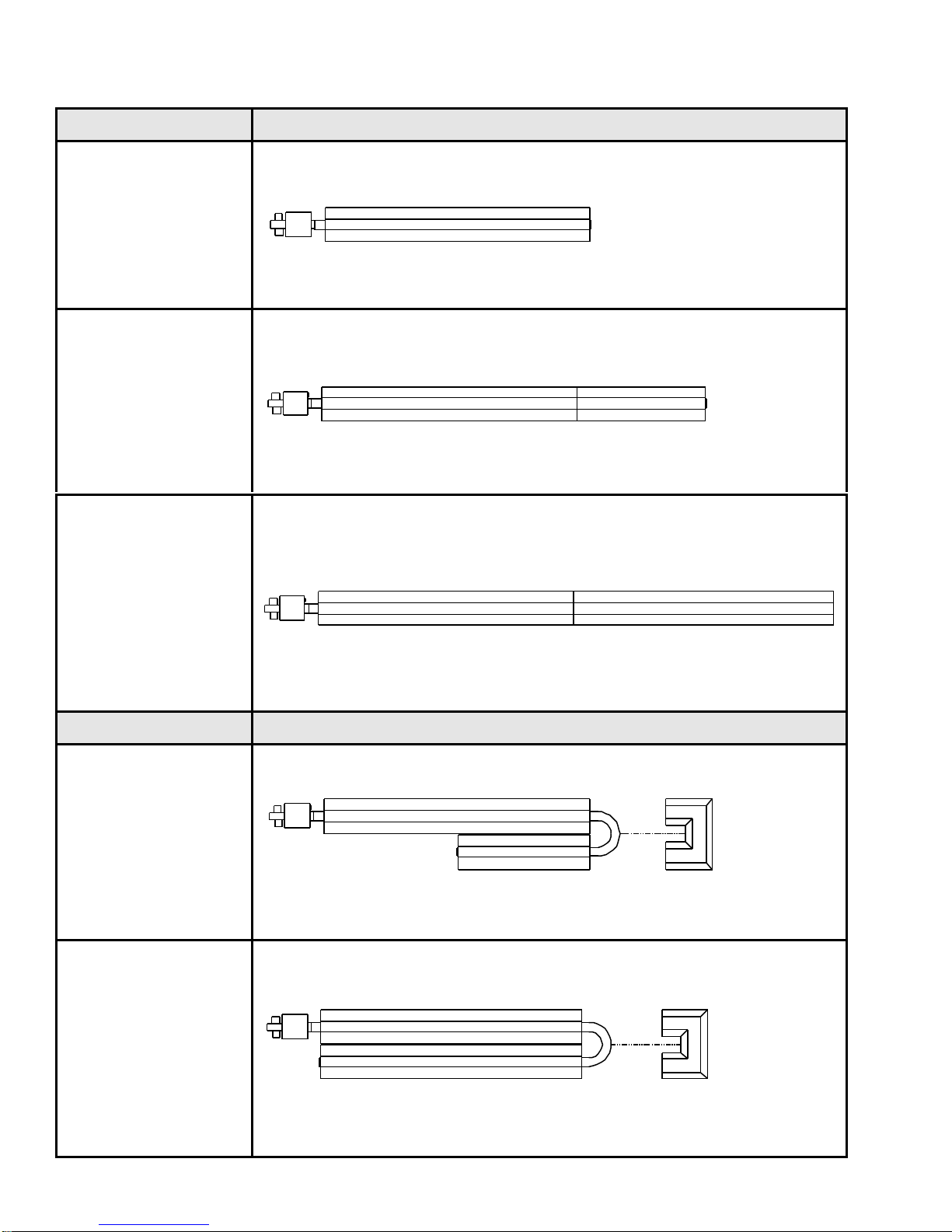

All models of low-intensity heaters include a

turbulator, which must be located in the last

ten (10) feet (3.0 m) of the burner tube

[exception: 15-foot (4.6 m) units have the

turbulator in the first10 feet (3.0 m).]

Before servicing the burner or removing the

cover panel, all electrical and gas supplies

must be disconnected.

Give consideration to construction such as

partitions, storage racks, hoists, etc., and their

relation to the installation of the heater.

The heater must be installed and serviced

ONLY by trained gas installation and service

personnel.

IMPORTANT

Failure to follow these instructions may result in injury or property damage.

RH Residential Heaters shall not be used in the following environments:

•Indoor living/sleeping quarters

•Enclosed swimming pools

•Outdoors

•Explosion-proof environments

•Process heating

•Contaminated atmosphere applications.

NOTE: Contact factory if in any doubt.