4

5. Plug power cord into outlet. Use correct power source.

See page 2 for specifications. Keep power cords short

to avoid power losses. The console motor may

function at lower voltage, but motor speed and oil flow

will be reduced and motor may become damaged.

6. Press “I” on the console switch to turn power on.

Pressing “I” activates the electrical circuit, but does

not turn the console motor on. The console motor is

activated by the pendant switch.

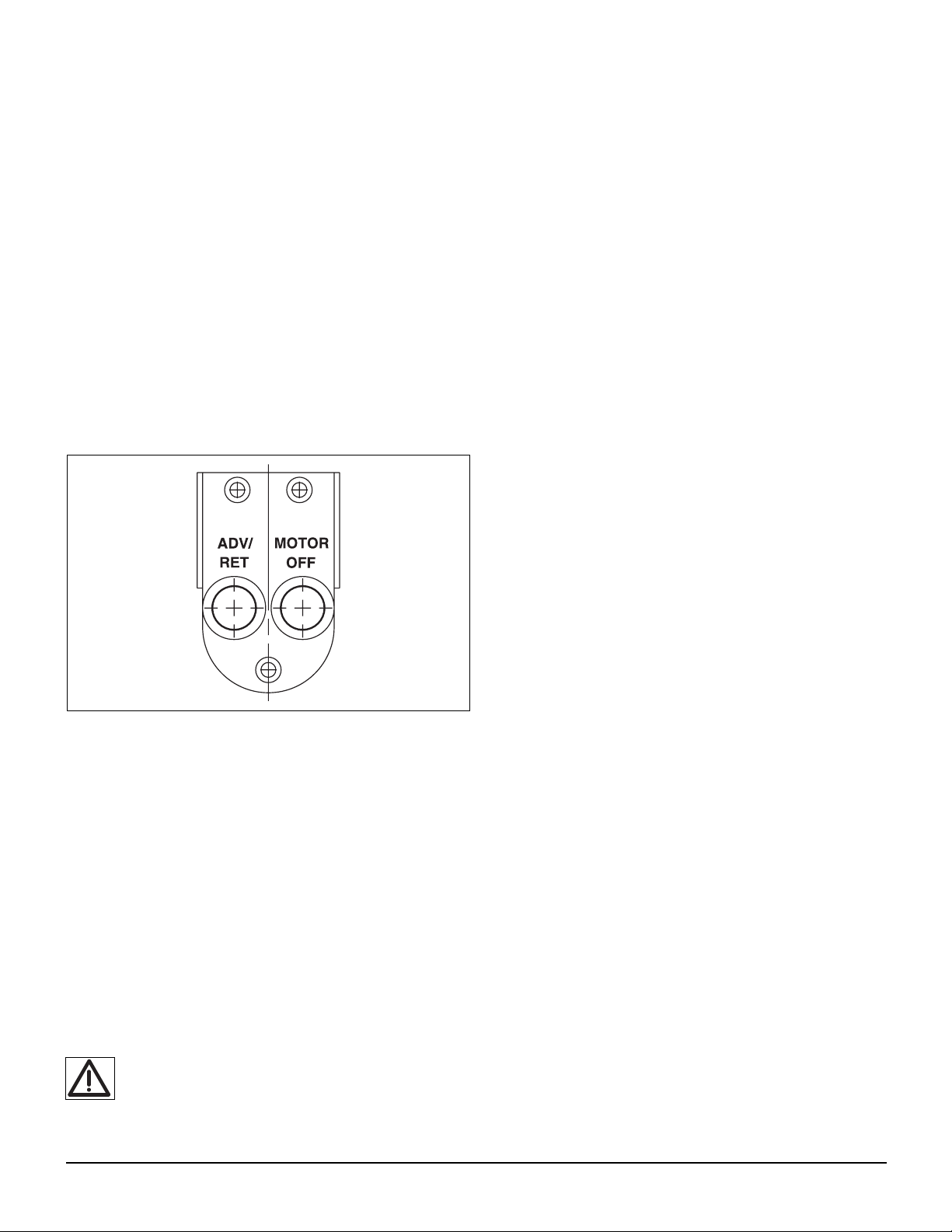

5.1 Pendant Operation

The pendant has two push button switches (See Figure

5). Press momentary push button (1) for “Advance.”

Release “Advance” and the torque wrench piston will

retract. Use the (2) “Motor off” push button if you need to

shut the unit off at any time.

NOTE: The electric motor keeps running after the pendant

is released. Within 15 seconds of your last command

from the pendant, the motor will time-out and turn

off, preventing heat build-up and unnecessary wear.

5.2 Air Removal

When the wrench is first connected to the console, air will

be trapped in the components.To ensure smooth and safe

operation, remove air by cycling wrench several times

without load. Cycle until wrench advances and retracts

without hesitation.

Check oil level before operation.

NOTE: Perform Air Removal and Pressure (Torque)

Adjustment:

1. during initial operation or start-up.

2. when connecting a different wrench to the console.

3. when changing torque value (pressure adjustment

only).

5.3 Pressure (Torque) Adjustment

WARNING: Make these adjustments BEFORE

putting torque wrench on nut or bolt head. The

console pressure setting may be above the pressure

needed to provide the required torque for your application.

Exceeding required torque will cause equipment damage

and may lead to serious personal injury.

REFER TO TORQUE WRENCH INSTRUCTIONS FOR

WRENCH OPERATING PROCEDURE.

1. The console is supplied with a pressure gauge

installed. See torque wrench instructions for amount

of pressure required to produce desired torque. Note

that the maximum pressure varies for different

wrenches and accessories.

2. Loosen locknut and back out relief valve to prevent

unintended pressure build-up. See Figure 1.

3. Turn the console on.

4. Press and hold the “Advance” push button and read

pressure gauge.

5. While holding the “Advance” push button, turn relief

valve in (clockwise) to increase pressure or out

(counter-clockwise) to decrease maximum pressure.

Repeat until correct pressure is obtained.

NOTE: When adjusting the pressure while the pump is

running the pressure must always start out at a

lower setting and then adjust the pressure

upwards.

6. Tighten locknut on relief valve to maintain setting.

7. Run the console several times to test the pressure

setting.

6.0 MAINTENANCE

6.1 Adding oil to the console

Check reservoir hydraulic oil level every 40 hours of

operation. Add hydraulic oil when necessary to bring oil

level up to 1 inch below the vent/fill opening.

6.2 Changing the oil

Completely drain the reservoir after every 100 hours of

operation. If console is operated in very dusty areas or at

high temperatures, drain and refill after 50 hours of

operation.

1. Remove the vent/fill plug from reservoir.

2. Tip the console until all old oil has drained out.

3. Add new hydraulic oil through vent/fill opening until

the oil level is 1 inch below the vent/fill opening.

Reservoir capacity is 0.75 gallon (2.8 liters).

4. Replace the fill plug.

5. DISPOSE OF USED OIL PROPERLY

6.3 Cleaning the reservoir

The reservoir can be removed for cleaning, and should be

cleaned at least once a year.

1. Remove vent/fill plug from reservoir. Tip the console

until all old oil has drained out.

2. DISPOSE OF USED OIL PROPERLY.

3. You will need to remove the blue shroud to get at the

screws that hold the console to the reservoir. Use a

hex wrench to remove the six screws securing shroud

to the reservoir.

4. Disconnect wire(s) from solenoid valve. Mark wires

before disconnecting them from the 4-way valve.

Figure 5, Pendant