1-8-5 TD900EA

9. Focus Adjustment

Purpose: Set the optimum Focus.

Symptom of Misadjustment: If Focus Adjustment is

incorrect, blurred images are shown on the display.

Note: Focus VR (FBT) --- H.V. CBA

FBT= Fly Back Transformer

1. Operate the unit more than 30 minutes.

2. Face the unit to the East and degauss the CRT

using a Degaussing Coil.

3. Input the monoscope pattern.

4. Adjust the Focus Control on the FBT to obtain clear

picture.

10. SIF Adjustment

Purpose: To set the SIF (Sound Intermediate Fre-

quency).

Symptom of Misadjustment: Audio may not sound

correctly.

Note: This adjustment automatically done by the

chrominance IC (IC1301).

11. CCS Text Box Location

Note: This adjustment automatically done by the

microcomputer.

12. Head Switching Position Adjustment

Purpose: Determine the Head Switching Point during

Playback.

Symptom of Misadjustment: May cause Head

Switching Noise or Vertical Jitter in the picture.

Note: Unit reads Head Switching Position automati-

cally and displays it on the screen (Upper Left Corner).

1. Playback test tape (FL8A, FL8N).

2. Enter the Service Mode. (See page 1-8-1.)

Then press the number 5 button on the remote

control unit.

3. The Head Switching position will display on the

screen; if adjustment is necessary follow step 4.

6.5H(412.7µs) is preferable.

4. Press "CH o" or "CH p" button on the remote con-

trol unit if necessary. The value will be changed in

0.5H steps up or down. Adjustable range is up to

9.5H. If the value is beyond adjustable range, the

display will change as:

Lower out of range: 0.0H

Upper out of range: -.-H

5. Turn the power off and on again.

The following 2 adjustments normally are not

attempted in the field. They should be done

only when replacing the CRT then adjust as a

preparation.

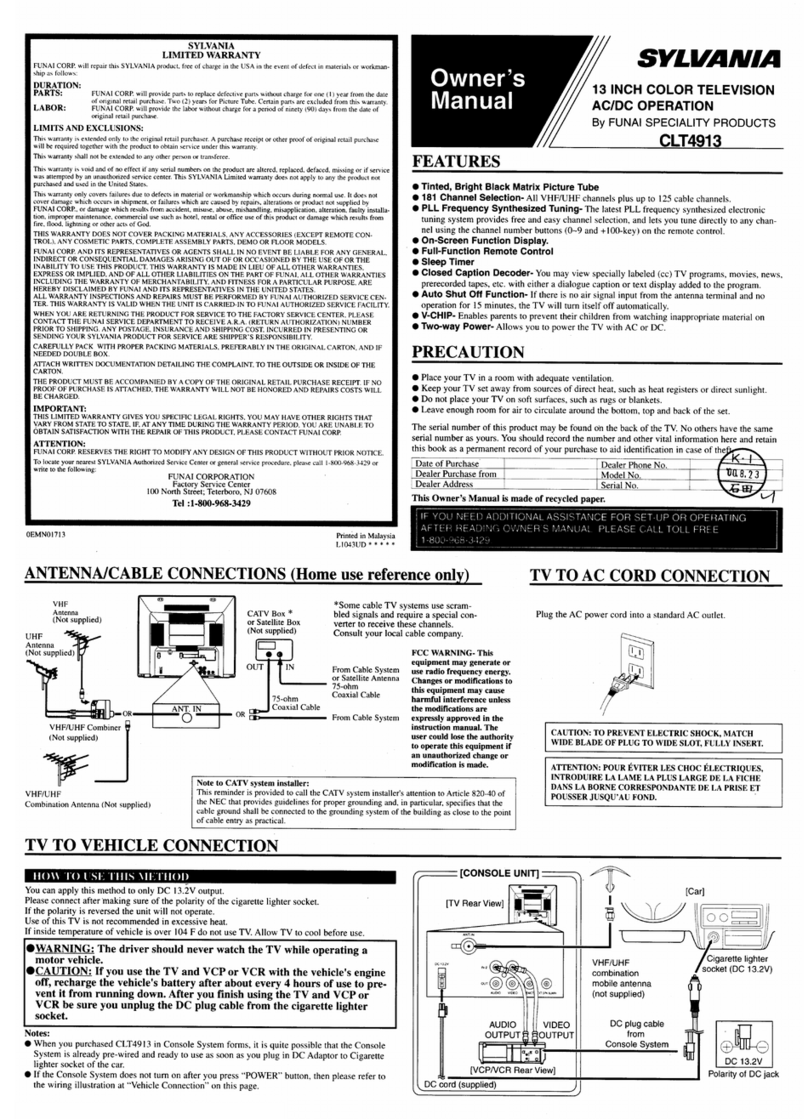

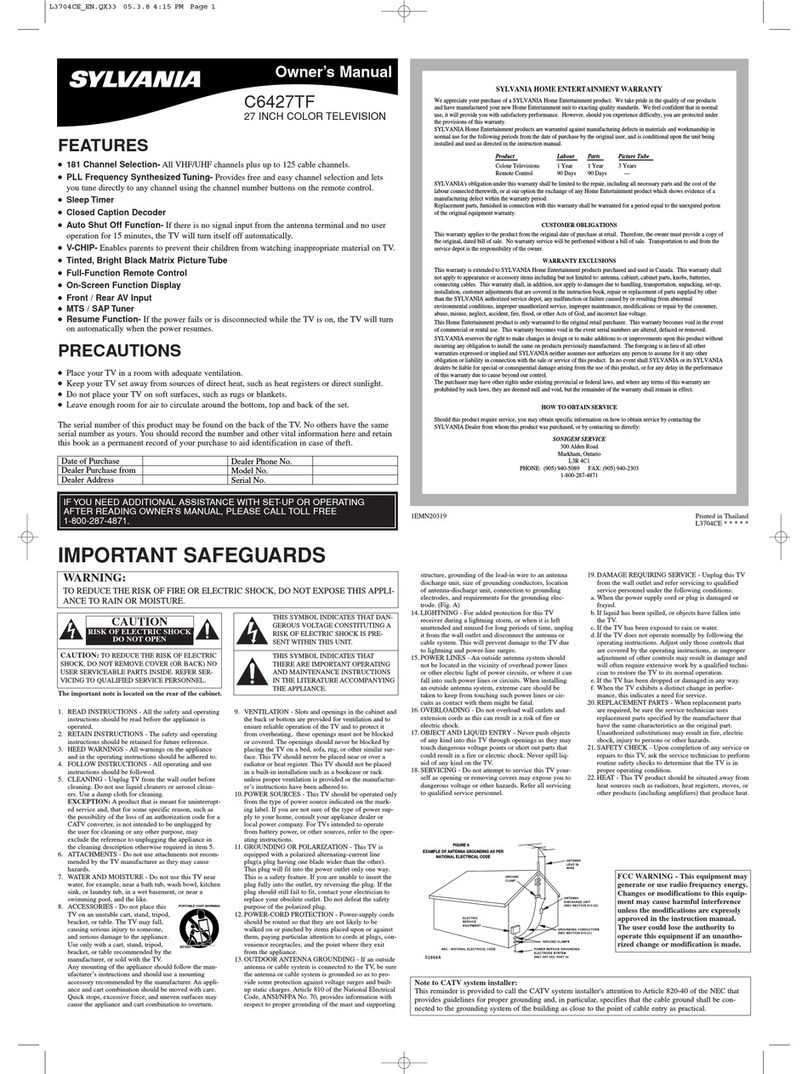

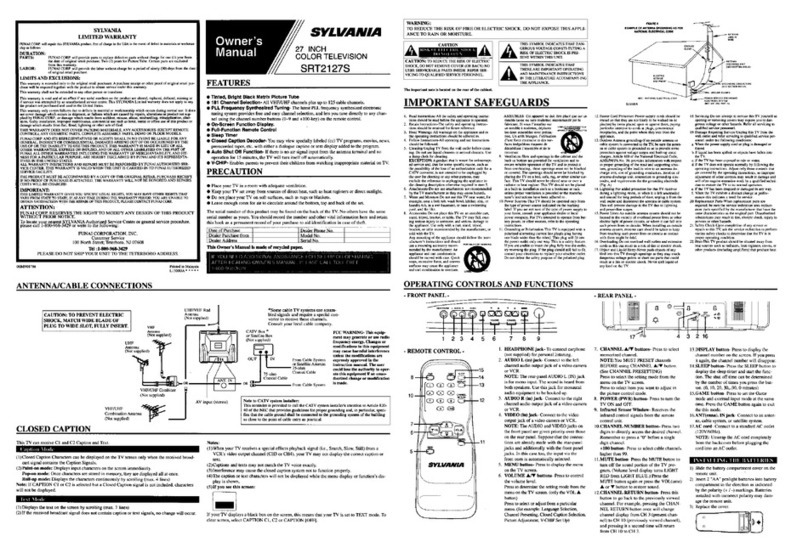

13. Purity Adjustment

Purpose: To obtain pure color.

Symptom of Misadjustment: If Color Purity Adjust-

ment is incorrect, large areas of color may not be

properly displayed.

1. Set the unit facing east.

2. Operate the unit for over 30 minutes before adjust-

ing.

3. Fully degauss the unit using an external degauss-

ing coil.

4. Set the unit to the AUX Mode which is located

before CH2 then input a red raster from video in.

5. Loosen the screw on the Deflection Yoke Clamper

and pull the Deflection Yoke back away from the

screen. (See Fig. 6.)

6. Loosen the Ring Lock and adjust the Purity Mag-

nets so that a red field is obtained at the center of

the screen. Tighten Ring Lock. (See Fig. 5,6.)

7. Slowly push the Deflection Yoke toward the bell of

the CRT and set it where a uniform red field is

obtained.

8. Tighten the clamp screw on the Deflection Yoke.

Test point Adj. Point Mode Input

--- Focus Control --- Monoscope

Tape M. EQ. Spec.

--- Pattern Generator See below.

Test point Adj. Point Mode Input

--- Deflection Yoke

Purity Magnet --- Red Color

Tape M. EQ. Spec.

--- Pattern Generator See below.

Figure

BLUE

GREEN RED

Fig. 5