Under no circumstances open the

charger. In the event of a fault, take it to an

authorized repair shop.

Do not place any objects on the charger

and do not place the charger on soft

surfaces. Fire hazard!

Special safety instructions

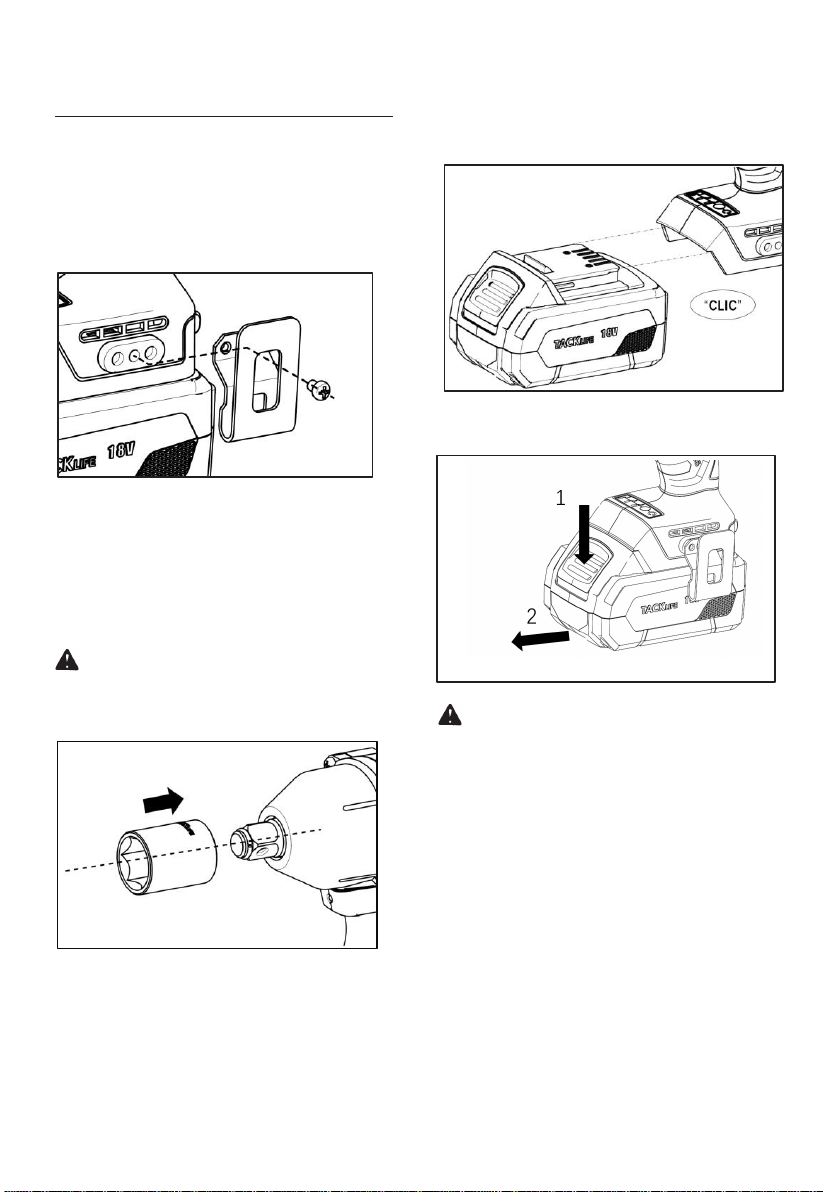

Before carrying out any work on the power

tool, move the direction pre-selector

switch (7) to the middle position.

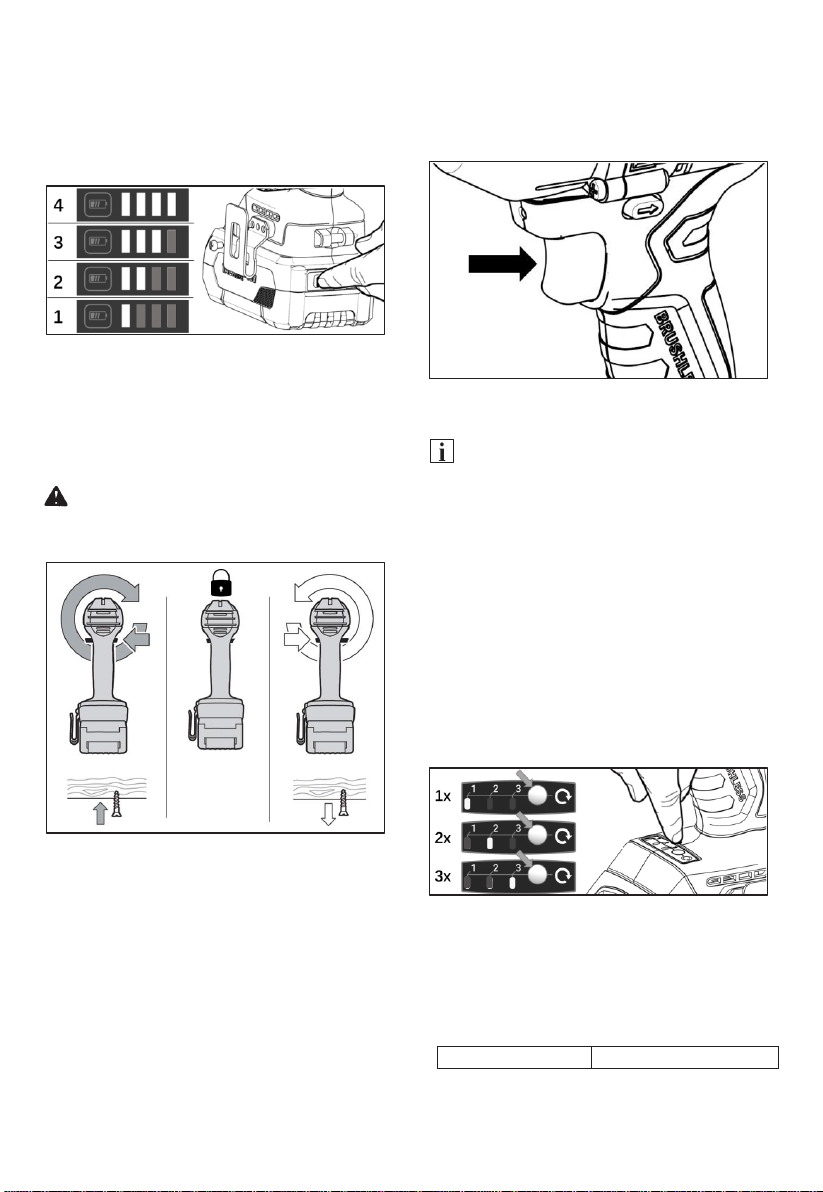

Operate the direction pre-selector

switch (7) or Speed control panel

(3) only when the tool is stopped.

Identify the power tool with stickers only.

Do not drill any holes into the housing.

It is recommended that the bolting time

should not exceed 15 seconds.

Noise

and

vibration

NOTE

The noise and vibration values have been

determined in accordance with EN 62841.

The values are set out in the “Technical

data” table.

WARNING!

The indicated measurements refer to new

power tools. Daily use causes the noise and

vibration values to change.

NOTE

The vibration emission level given in this

information sheet has been measured in

accordance with a measurement method

standardized in EN 62841 and may be used

to compare one tool with another. It may be

used for a preliminary assessment of

exposure. The specified vibration emission

level represents the main applications of the

tool.

However, if the tool is used for different

applications, with different cutting

accessories or poorly maintained, the

vibration emission level may differ.

This may significantly increase the

exposure level over the total working period.

To make an accurate estimation of the

vibrationexposurelevel,itisalsonecessaryto

take into account the times when the tool is

switchedofforrunningbutnotactuallyinuse.

This may significantly decrease the exposure

level over the total working period.

Identify additional safety measures to protect

the operatorfromthe effectsof vibration such

as: maintain the tool and the cutting

accessories, keep the hands warm,

organization of work patterns.

CAUTION!

Wear ear defenders at a sound pressure

above 85 dB(A).

In this manual and/or on the machine the following

symbols are used:

Symbols

800295

WARNING / CAUTION

WARNING – To reduce the risk of injury,

user must read instruction manual.

Wear eye and ear protection and dust

mask.

Comply with relevant UL and CSA

regulations.

Dispose this appliance according to the

regulations and requirement of the local

council.

Do not dispose of battery packs in fire.

They will explode and cause injury.

Do not expose to rain or wet

conditions.

This appliance can be

recycled.

This appliance can be

recycled.

Batteries and battery pack should not be

disposed of with household waste.