6

(1) Disassembly

1) Loosenthescrew① andpulloutthecover④ upwardtoremovetheconnector.

2) Removethescrew① andremovethegasket2afromthecover④.

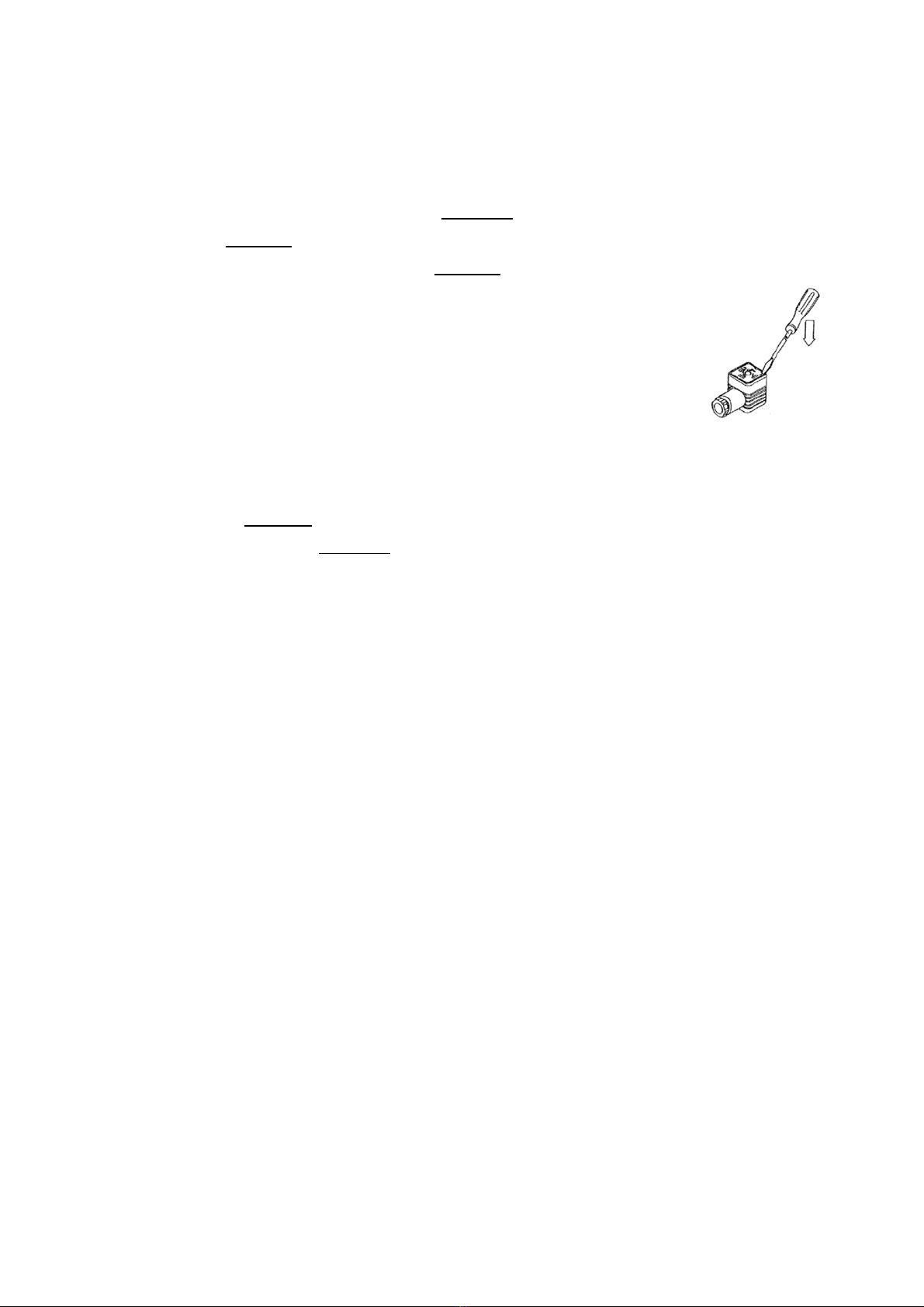

3) Thereisanotch3aatthebottomoftheterminalblock③.

Insertaflatheadscrewdriverintothenotch3aandlifttoremoveterminalblock③ from

thecover④.(Refertothefigureontheright.)

4) Removecablegland⑤ andtakeoutwashers⑥ andpacking ⑦.

(2) Wiring

1) Insertthecable⑧ throughthecablegland⑤,thewasher⑥,andthepacking⑦inthis

order,andinsertitintothecover④.

2) Crimptheroundpressureterminal⑨tothecable⑧.

Removethescrew3ewithawasherandattachwiththeroundpressureterminal⑨,and

tightenthemwiththescrew3easshownintheexplodedviewonpage7.

Note:Thescrewtighteningtorqueshouldbewithintherangeof“0.5N∙m±15%.”

※Remarks

a:Usearoundpressureterminal⑨.

b:Themaximumsizeofaroundpressureterminal⑨ is“1.25‐4M”.

c:Cablewithdiameterbetween"6‐12mmφ"canbeusedasthecable⑧.

(Whenusing"9‐12mmφ"outerdiametercable,removetheinnerpartofpackingbefore.)

(3) Reassemble

1) Installtheterminalblock③tothecover④.(Pressuntilhearingaclick.)

2) Insertthepacking⑦ andthewasher⑥ intothecableinletofthehousing④ inorder,and

tightenthecablegland⑤.

3) Insertthegasket2atothebottomoftheterminalblock③ andconnectittopinsofthe

fanmotor,andinsertthescrew① fromthetopofthecover④ totightenthem.

Note:Thescrewtighteningtorqueshouldbewithintherangeof“0.5N∙m±20%”.

※Remarks

a:Directionoftheconnectorcanbechangeddependingontheassemblyofthecover④

andtheterminalblock③.