ACCESSORIES (OPTIONAL)

A special transponder for motorcycles is available.

For motorcycles order the TARGET LT400-M. The control

elements of this set are completely waterproof and

weatherproof. This system also has a special optical sig-

nalling system that is always visible to the motorcyclist.

IMPORTANT INFORMATION

Nearly all laser systems using infrared light emit their

information on a frequency of 904 nanometre (this is the

wave length which emits infrared laser light). This is also

true for the LaserTrack. This wave length has become the

worldwide standard. Even the police laser guns emit

speed measurements on this wave length. TARGET

LaserTrack is the only system that has intelligent elec-

tronic technology that can recognize the signals of laser

guns and other laser systems that use the same wave

length. After recognizing an infrared signal that is not its

own, TARGET LaserTrack temporarily shuts itself off to

prevent failures and, for example, to allow a laser speed

measurement to take place. You are informed of this

through a visual and audio signal.

INSTALLATION

Follow the instructions below to the letter to ensure

that the system performs optimally.

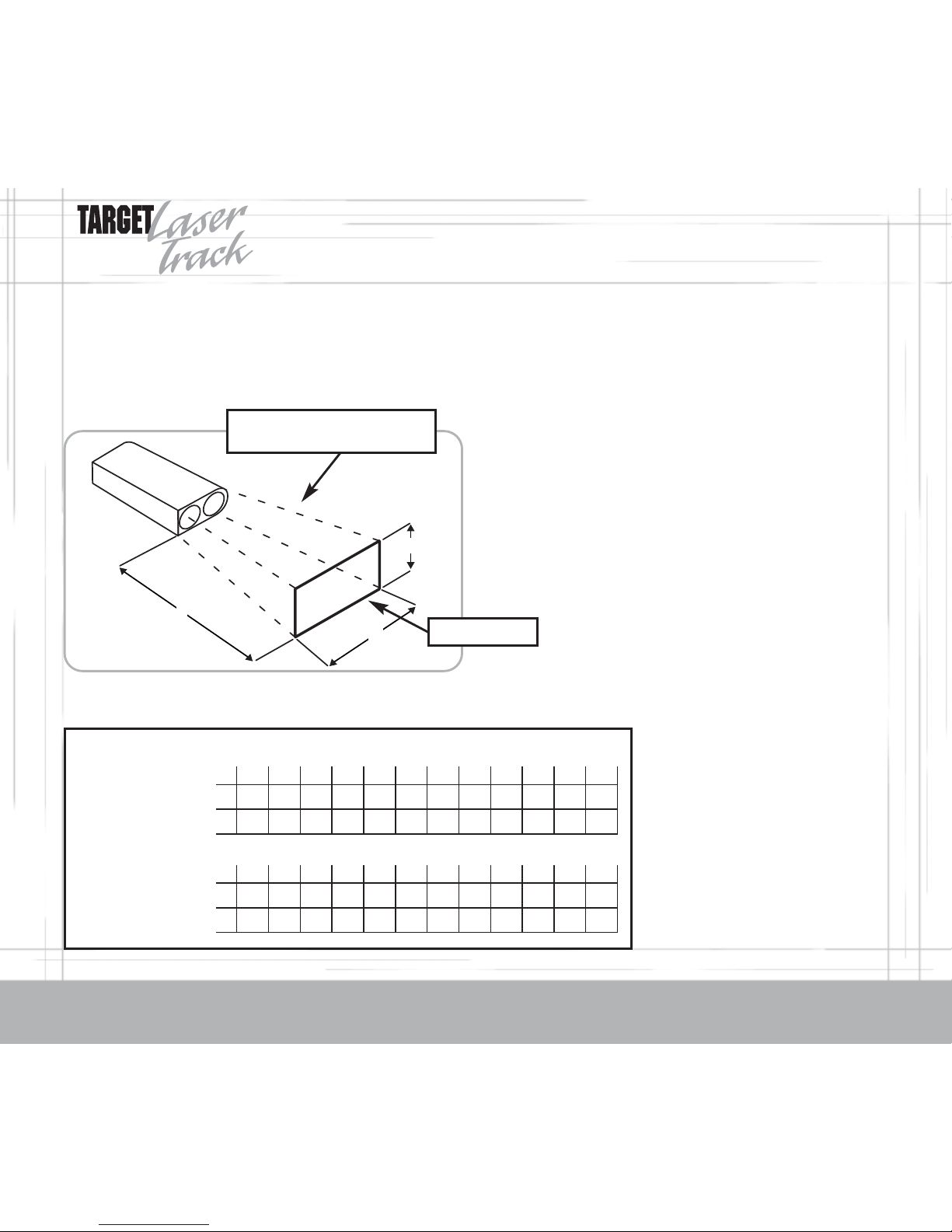

MOUNTING AND CONNECTING

THE LT400 CAR TRANSPONDER

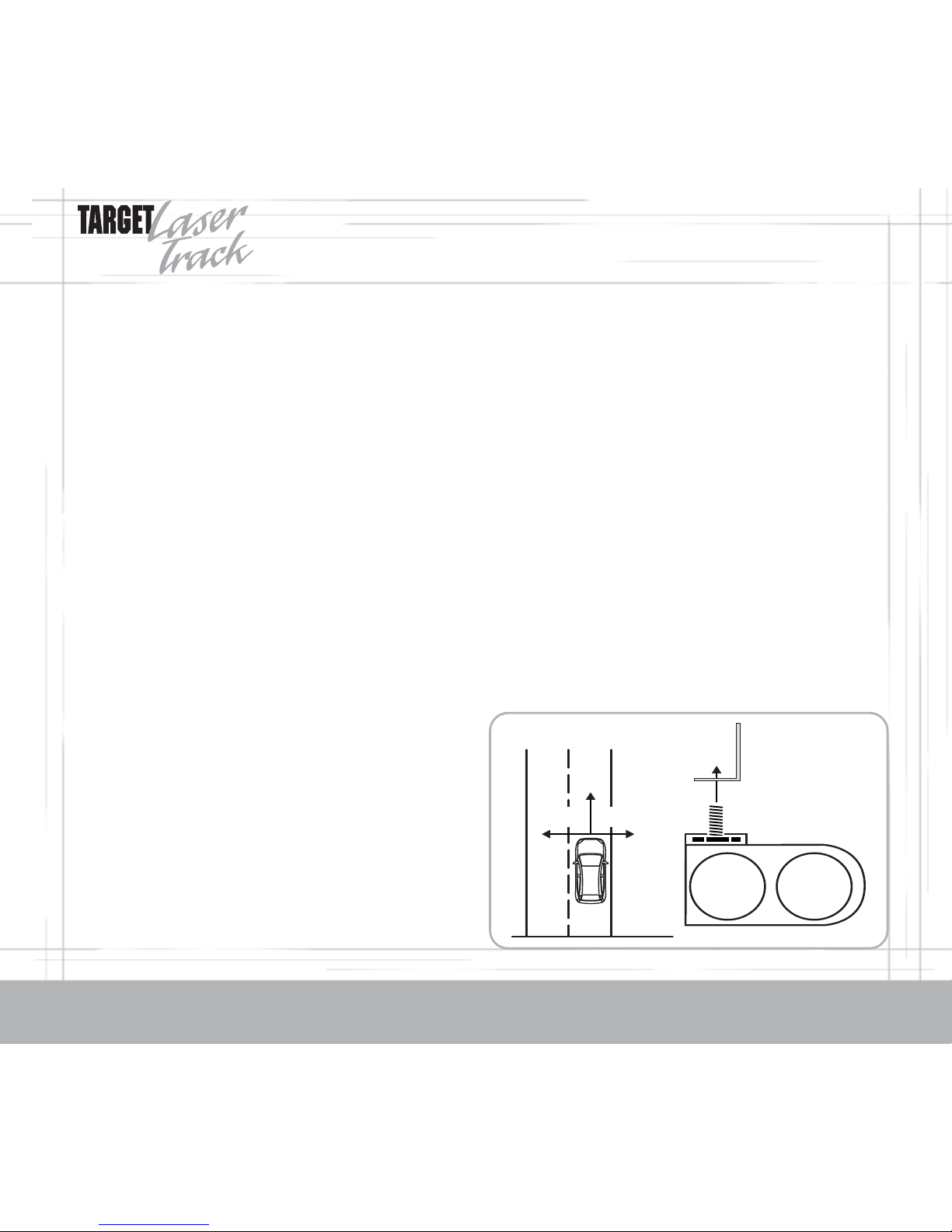

1. Mount the transponder preferably in the middle at the

front of the vehicle (preferably very near to the number

plate). The transponder may also be mounted behind the

grill. The free passage opening should be larger when the

distance from the transponder to the opening is greater.***

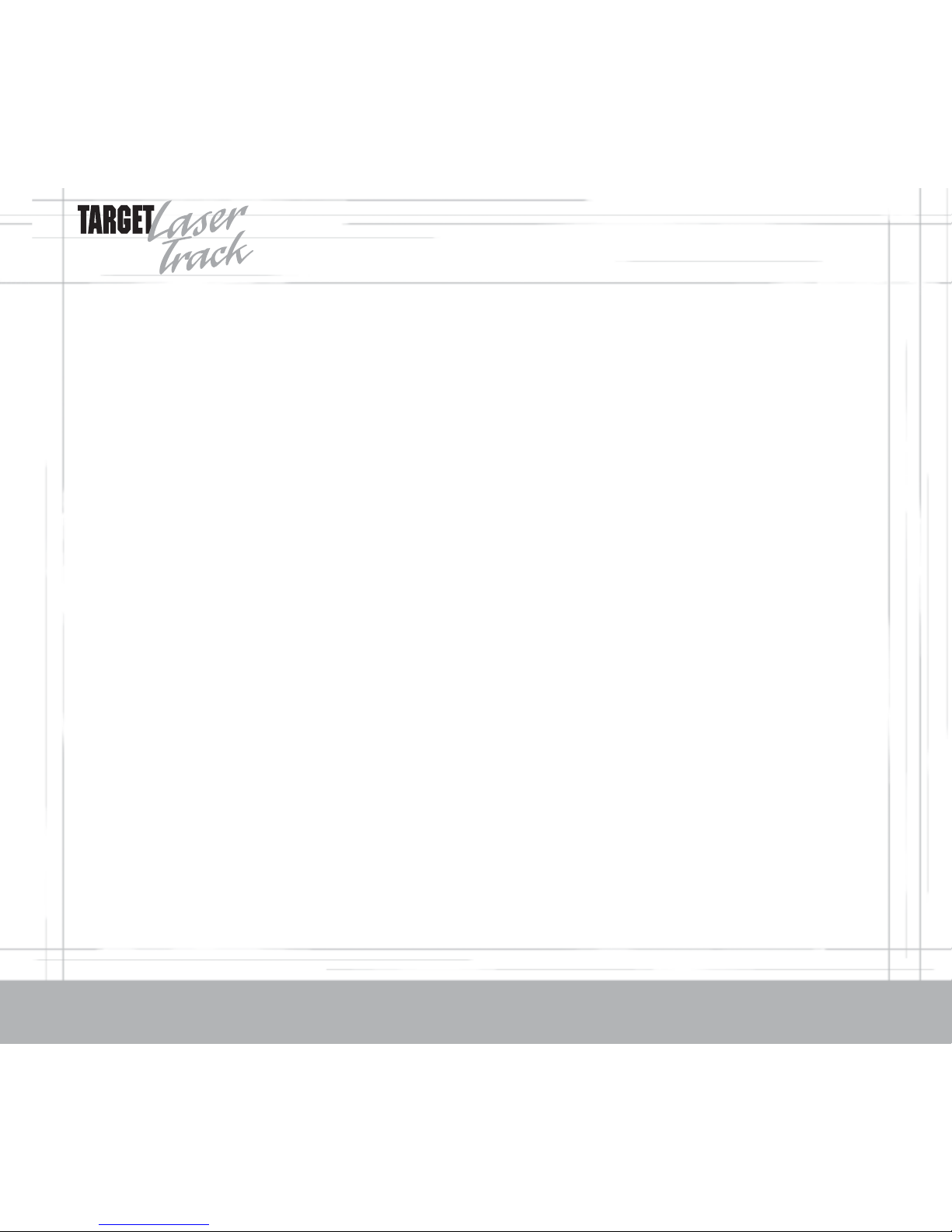

Refer to the calculation table on page 8.

2. Mount the transponder using the tee bolt and

mounting bracket included in the package.

(Refer to Transponder Alignment on page 7.)

3. Ensure the transponder is aligned correctly

(refer to Transponder Alignment on page 7).

4. Lead the transponder cable through the engine com-

partment. Use the cable guides already present when

possible. Do not pull the cable too tightly and do not

kink the cable. Lead the cable through the existing grom-

met to the interior. Connect as indicated in the diagram

on page 88.

ENGLISH

6