Technische Alternative CAN-MTx2-CO2 User manual

www.ta.co.at

Manual version 1.18.1 English

CAN-MTx2

CAN-MTx2-CO2

CAN Monitor

Instruction manual

Table of contents

Version 1.18.1 EN

Safety requirements ............................................................................................................................5

Maintenance.............................................................................................................................................. 5

Disposal...............................................................................................................................................6

Principles.............................................................................................................................................6

Installing and connecting the device ...................................................................................................7

Installing the device .................................................................................................................................. 7

Dimensions ........................................................................................................................................... 7

Power supply ............................................................................................................................................. 8

CAN bus connection ................................................................................................................................. 8

CAN bus cable selection and network topology ..................................................................................... 8

User manual - Technician / Expert.......................................................................................................9

Function overview display ........................................................................................................................ 9

Standard view ....................................................................................................................................... 9

Full screen view .................................................................................................................................. 10

Main menu............................................................................................................................................... 11

Date / time / location .............................................................................................................................. 12

Inputs ....................................................................................................................................................... 13

Sensor correction ............................................................................................................................... 14

Average ............................................................................................................................................... 14

Sensor check for analogue sensors ................................................................................................. 14

Sensor error ................................................................................................................................... 15

Carbon dioxide and safety................................................................................................................. 15

Messages from other X2 devices ..................................................................................................... 16

Internal CAN monitor messages....................................................................................................... 17

CAN bus ................................................................................................................................................... 18

Datalogging......................................................................................................................................... 19

CAN settings....................................................................................................................................... 20

CAN inputs.......................................................................................................................................... 20

CAN analogue outputs....................................................................................................................... 21

Transmission condition ................................................................................................................ 21

CAN digital outputs ............................................................................................................................ 22

Designation.................................................................................................................................... 22

Transmission condition ................................................................................................................ 22

Active CAN nodes .............................................................................................................................. 23

General settings ...................................................................................................................................... 24

Language ............................................................................................................................................ 24

Brightness........................................................................................................................................... 24

Display timeout................................................................................................................................... 24

Simulation........................................................................................................................................... 25

Access to menu.................................................................................................................................. 25

Currency.............................................................................................................................................. 25

User defined designations................................................................................................................. 26

User .......................................................................................................................................................... 27

Current user ........................................................................................................................................ 27

Changing the password..................................................................................................................... 28

List of permitted actions.................................................................................................................... 28

Version and serial number...................................................................................................................... 29

Data administration ................................................................................................................................ 30

Function data...................................................................................................................................... 30

Load................................................................................................................................................ 31

Deleting, renaming and sending saved files................................................................................ 32

Save................................................................................................................................................ 33

Firmware Load.................................................................................................................................... 34

Function overview Load…/Delete... ................................................................................................... 34

Status .................................................................................................................................................. 35

Total reset........................................................................................................................................... 35

Restart................................................................................................................................................. 36

LED indicator light ................................................................................................................................... 36

LED status indicators at start............................................................................................................ 36

Reset ........................................................................................................................................................ 37

Loading the firmware with the factory settings ............................................................................... 37

Calibration ............................................................................................................................................... 37

User manual - final user.................................................................................................................... 38

User levels ............................................................................................................................................... 39

Function overview ................................................................................................................................... 40

Standard view..................................................................................................................................... 40

Full screen view .................................................................................................................................. 41

5

Safety requirements

These instructions are intended exclusively for authorised contractors.

All installation and wiring work on the device must only be carried out in a zero

volt state.

The opening, connection and commissioning of the device may only be carried

out by competent personnel. While doing so, they must observe all local safety

requirements.

This device is state of the art and meets all necessary safety regulations. It may only be used in ac-

cordance with the technical data and the safety requirements and regulations listed below. When us-

ing the device, also observe the statutory and safety regulations apposite to the particular use. Any

other use will automatically void all warranty rights.

►The device must only be installed in a dry interior room.

►Solar thermal systems can become very hot. Consequently there is a risk of burns. Proceed with

caution when fitting temperature sensors.

►For safety reasons, the outputs should only be left in manual mode when testing. In this operating

mode, no maximum temperatures or sensor functions are monitored.

►Safe operation is no longer possible if the CAN monitor or connected equipment exhibits visual

damage, no longer functions or has been stored for lengthy periods in unsuitable conditions. If this

is the case, disable the CAN monitor and equipment and secure against unintentional use.

Maintenance

If treated and used correctly, the device will not require any maintenance. Use a cloth moistened with

mild alcohol (such as methylated spirits) to clean. Never use corrosive cleaning agents or solvents

such as chloroethylene or trichloroethylene.

No components relevant to long term accuracy are subject to loading if the device is used correctly.

Consequently long term drift is extremely low. The device therefore cannot be calibrated. Thus apply-

ing any compensation is impossible.

The design characteristics of the device must not be changed during repairs. Spare parts must corre-

spond to the original spare parts and must be used in accordance with the build version.

6

Disposal

➢Devices no longer in use or beyond a state of repair must be disposed of in an

environmentally responsible manner by an authorised collection point. They

must never be treated as ordinary household waste.

➢We can undertake the environmentally responsible disposal of devices sold by

Technische Alternative upon request.

➢Packaging material must be disposed of in an environmentally responsible

manner.

➢Incorrect disposal may result in considerable damage to the environment, as many of the mate-

rials used require professional handling.

Standard delivery

•CAN-MTx2 CAN monitor

•SD memory card

•Operating pen

•Operating instructions

•Installation material

Principles

The CAN-MTx2 CAN monitor is used as a control and display unit for the freely programmable con-

trollers UVR16x2 and RSM610 as well as all other devices in the X2 series.

The CAN monitor has a combined temperature and humidity sensor built in and can therefore also be

used as a room sensor.

The "Function overview" allows user friendly operation and display of X2 devices in the CAN bus net-

work. The function overview is designed using the TA-Designer software and can comprise several

pages.

As with the UVR16x2, it is operated via a 4.3" touchscreen. It is also possible for multiple CAN moni-

tors in one CAN network to access the available X2 devices at the same time.

7

Installing and connecting the device

Installing the device

The device must only be installed in a dry interior room. For correct detection of the room tempera-

ture, the CAN monitor must always be installed vertically.

Permissible ambient temperature: +5°C - +45°C

Press the two locking clamps on the left and right and lift the cover. The control electronics are locat-

ed in the cover.

Screw the base to the flat mounting surface using the supplied fastening materials, ideally with the

opening arranged over a mounting box fitted in the wall at eye level (approx. 1.6 m).

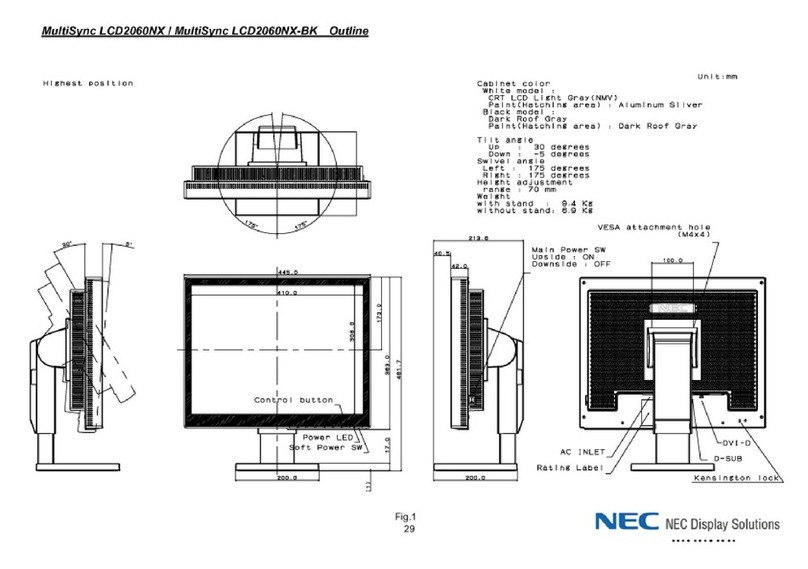

Dimensions

in mm

Operating pen

SD card

8

Power supply

The CAN monitor requires a 12 V power supply originating from a freely programmable controller

(UVR16x2 or RSM610). No more than three devices (CAN monitor, CAN-I/O module etc.) can be sup-

plied from each controller. With 4 or more devices in the CAN network, a 12 V power unit is required.

CAN bus connection

The screwless terminals for the CAN bus are located in the base of the CAN monitor. Pressing the

small white button with a screwdriver unlocks the terminal and allows the connected lead to be in-

serted or removed again. Spring contacts provide the electrical connection to the CAN monitor once it

is fitted.

CAN bus cable selection and network topology

The principles of CAN bus cabling are described extensively in the manuals for the freely program-

mable controllers. Therefore they are not included here in any detail, apart from the termination.

Each CAN network must be provided with a 120 Ω bus terminator at the first and last network node

(termination with jumper). A CAN network therefore always has two terminators (one at each end).

Spur lines and star-shaped CAN topologies are not permitted by the official specification.

The termination jumper for the CAN monitor is located on the back of the PCB and is visible when the

upper part is removed from the base.

Terminated Not terminated

The CAN monitor is terminated if the jumper is set on the side labelled "term" (as shown above).

Release tabs

Spring contacts

9

User manual - Technician / Expert

If a function overview was loaded onto the CAN monitor, the display will show the function overview

once it is connected to the CAN bus.

The function overview can be programmed as standard view or full screen view.

Function overview display

Standard view

Example: Start page with 4 links

From the start page (= first page), tapping takes you to the CAN monitor's main menu. If only

technicians or experts are permitted to access the menu, then the relevant password must be

entered.

If you press the background image for 3 seconds, 2 buttons appear which serve to access the version

information and the general settings respectively.

You can go back to the page displayed previously by tapping .

V 1.01

MTX2-000000

10

Full screen view

In the full screen view, the upper status bar and the side buttons are hidden.

Example: Start page with 4 links

If you press the background image for 3 seconds, 4 buttons appear which enable access to the ver-

sion information of the CAN monitor, the general settings or the date, time and location settings, and

the main menu of the CAN monitor.

This button takes you

to the main menu of

the controller. If only technicians

or experts are permitted to access

the menu, then the relevant

password must be entered.

To go back to the start page of

the function overview,

tap .

You can go back to the page displayed previously by tapping . .

11

Main menu

•Inputs –The CAN-MT16x2 CAN monitor has a sensor for temperature and humidity

•Messages –Sensor and network errors from the CAN-MTx2 are displayed here

•CAN BUS –CAN settings, definition of CAN inputs and outputs

•General settings –Setting of the language, display screen properties and definitions of user

defined designations

•User –Setting of the user level, changing of passwords

•Version –Information about the device version, serial number, the loaded function overview

and the loaded function data

•Data admin –Loading and saving of function data and the function overview, loading of firm-

ware, total reset

Tap the "Home icon" to go to the Function overview.

12

Date / time / location

The "Date" and "Time" are shown in the status line at top right.

As the CAN monitor does not have its own clock function, the time and date are taken from network

node 1 and cannot be changed in the CAN monitor. For this reason, at least one CAN bus device

which has its own clock function must have the node number 1 (UVR16x2, UVR1611, RSM610, C.M.I.).

Tapping that status field takes you to the menu for the date, time and location details.

Display example:

•Time zone –Specifies the time zone relative to UTC (= "Universal Time Coordinated", also

known as GMT (= Greenwich Mean Time)). In the example, the time zone is set to "UTC +

01:00".

•Summertime –"Yes" if summertime is active.

•Automatic time change –If "Yes", the time will switch over automatically to summertime

according to the specifications of the European Union.

•Date –The current date (dd.mm.yy).

•Time –The current time

13

•GPS latitude –Geographical latitude according to GPS (= global positioning system)

•GPS longitude –Geographical longitude according to GPS

The values for geographical latitude and longitude are used to determine the location-specific solar

data. That data can be used in functions (e.g. shading function).

The factory default settings for the GPS data are for the location of Technische Alternative in

Amaliendorf, Austria.

•Sunrise –Time

•Sunset –Time

•Solar altitude –Specified in ° as measured from the geometric horizon (0°),

zenith = 90°

•Direction of the sun –Specified in ° as measured from the north (0°)

North = 0° / East = 90° / South = 180° / West = 270°

Inputs

The CAN-MTx2 CAN monitor has a combined temperature, humidity and air pressure sensor built in.

In addition, the CAN-MTx2-CO2 CAN monitor has a CO2sensor. 5 values are displayed in the Inputs

menu: temperature, relative humidity, dew point temperature, absolute air pressure (in mbar) and CO2

content (in ppm). These 5 values are already preset (as shown in the bottom graphic) at inputs 1 –5.

In CAN-MTx2 (without CO2sensor), the fifth value is always 0.

14

Sensor correction

The option of sensor correction is available for the measured variables The corrected value is utilised

for all calculations and displays.

Example:

Average

This setting refers to the average of the measurements over time.

Averaging over 0.3 seconds leads to extremely rapid reactions on the part of the display and the unit.

However, this can be expected to cause fluctuations of the value.

A high average value results in lagging and is only recommended for special applications.

For simple measuring operations approx. 1-3 seconds should be selected.

Sensor check for analogue sensors

When "Sensor check" is active (setting: "Yes"), a short circuit or a lead break will automatically

generate an error message: A warning symbol is displayed in the upper status line, and the defective

sensor is shown with a red border around it in the "Inputs" menu.

Example:

Short-circuit of

sensor 1

Standard value

15

Sensor error

When "Sensor check" is active, Sensor error is available as the source for digital CAN outputs: status

"No" for a sensor that is working correctly and "Yes" for a defect (short circuit or lead break). This

allows the controller to react to the failure of a sensor, for example.

In System values / General, a sensor error for all inputs is available.

If the Standard thresholds are selected, a short circuit will be indicated if the value falls below the

lower measurement limit and a lead break will be indicated if the value exceeds the upper

measurement limit.

The Standard values for temperature sensors are -9999.9 °C for a short circuit and 9999.9 °C for a

lead break. Those values are utilised in the internal calculations in the event of an error.

By selecting the thresholds and values appropriately, a fixed value can be specified for the controller

in the event of sensor failure, in order to allow a function to continue operating in emergency mode.

Example: If the temperature value falls below the threshold of 5.0 °C (= "Threshold value"), a value of

20.0 °C (= "Output value") is issued and displayed for that sensor (fixed hysteresis: 1.0 °C). At the

same time the "Sensor error’ status is set to "Yes".

The short circuit threshold must be defined below the lead break threshold.

Example: The temperature sensor has fall-

en below 5.0 °C, so 20.0 °C is issued as the

measurement, and a sensor error is dis-

played at the same time.

Note: In the event of temperature sensor failure, the humidity and dew point will be calculated incor-

rectly.

Carbon dioxide and safety

Carbon dioxide is a non-toxic and non-flammable gas. However, in higher concentrations it can be life

threatening.

For mechanically ventilated rooms, the Austrian Federal Ministry of Agriculture, Forestry, Environment

and Water Management requires a target value below 800 ppm and a maximum value of 1400 ppm.

CO2 requirements for mechanically ventilated interior rooms

(Source: Kohlenstoffdioxid als Lüftungsparameter [Carbon Dioxide as a Ventilation Parameter], August 2011, authors: BOOS,

DAMBERGER, HUTTER, KUNDI, MOSHAMMER, TAPPLER, TWRDIK, WALLNER)

Target range: Individual values < 800 ppm

Minimum specification: Maximum moving hourly average < 1000 ppm

Minimum specification: All individual values in the evaluation period < 1400 ppm

16

Messages from other x2 devices

Depending on the setting in the x2 device, messages from other x2 devices can be displayed on the

CAN monitor with a pop-up window, a changed status LED and/or a warning tone.

The pop-up window works in the same way as on the display of the UVR16x2 controller.

Example: Message type "Error"; warning tone activated

After the message has been triggered and the cause of the fault has been removed, the following dis-

play appears (red):

If the pop-up window has been hidden, it can be shown again by tapping the warning symbol in the

status bar on the left.

More information about generating messages can be found in the programming manuals for the x2-

devices.

Warning symbol on the left

Message type

Message name

Hide message = Hide

the message window

only visible for "Fault"

message type

Message

window

Delete message (only

possible once the

cause of the message

ceased)

Time

17

Internal CAN monitor messages

The "Messages" menu displays messages that are caused by sensor or CAN bus errors in the CAN-

MTx2.

Message from other x2 devices are not displayed here.

Example: Fault on input 1

If at least one internal message is active, the warning symbol will appear in the upper status line on

the right. If the message window has been hidden, it can be shown again by tapping the warning

symbol in the status bar.

18

CAN bus

The CAN network allows communication between CAN bus devices. When analogue or digital values

are sent via CAN outputs, other CAN bus devices can utilise those values as CAN inputs.

Up to 62 CAN bus devices can be operated in one network.

Every CAN bus device must be given its own node number in the network.

The cable topology of a CAN bus network is described in the installation instructions.

19

Datalogging

This menu cannot be selected in the User mode.

This menu is used to define the parameters for CAN datalogging of analogue and digital values.

CAN datalogging requires at least version 1.25 on the C.M.I. datalogger and a Winsol version of at

least 2.06.

CAN datalogging is only possible with the C.M.I. datalogger. The data to be logged can be freely

selected. Es erfolgt keine ständige Datenausgabe. There is no constant data output. When requested

by a C.M.I., the controller saves the current values to a logging buffer and locks it to prevent it from

being overwritten (when requests are received from another C.M.I.) until the data is read out and the

logging buffer has been enabled again.

The settings required on the C.M.I. for datalogging via CAN bus are described in the C.M.I.'s online

help.

Each CAN-MTx2 can issue a maximum of 64 digital and 64 analogue values that are defined in the

menu "CAN bus/datalogging" of the CAN-MTx2.

The sources for the logged values can be inputs and CAN bus inputs.

20

CAN settings

Node

Define a unique CAN node number for the device (setting range: 1 –62). The factory-set node number

of the CAN-MTx2 is 50.

Designation

Every device can be given its own designation.

Bus rate

The standard bus rate of the CAN network is 50 kbit/s (50 kBd), which is specified for most

CAN bus devices.

Important: All devices in the CAN bus network must have the same transfer rate in order to be

able to communicate with each other.

The bus rate can be set to between 5 and 500 kbit/s, with lower bus rates allowing longer cable net-

works (see installation instructions of the controllers).

CAN inputs

As CAN inputs are of no practical use in the CAN monitor, this sub-menu is not described in this man-

ual.

This manual suits for next models

1

Table of contents