TECNOTER RC4.32E16CL4 User manual

AUTOMATIC WHEEL WASHING SYSTEM

AUTOMATIC WHEEL WASHING SYSTEM

MODEL

MODEL

RC4.32E16CL4

RC4.32E16CL4

Operator ma ual

Rev. 1.42

Tecnoter srl unipersonale Wheel washi g

system

RC4.32

E16CL4

S/N Page 1/39 Rev: 1.42 –

22/02/2017

Index

1 INTRODUCTION.............................................................................................................................3

1 Scope of the ma ual......................................................................................................................3

2 How to read the ma ual................................................................................................................4

3 Preservatio of the ma ual...........................................................................................................5

4 Update of the ma ual....................................................................................................................5

5 Addressees....................................................................................................................................5

1 GENERAL INFORMATION............................................................................................................6

1 System ide tificatio ....................................................................................................................6

2 Declaratio s .................................................................................................................................7

3 Safety rules.................................................................................................................................10

4 I formatio o tech ical assista ce............................................................................................10

2 INSTALLATION AND PARTS.......................................................................................................11

1 Ha dli g......................................................................................................................................11

2 Prelimi ary..................................................................................................................................11

5 Testi g a d adjusti g..................................................................................................................26

3 USE..................................................................................................................................................29

1 Prelimi ary check list.................................................................................................................29

2 Use..............................................................................................................................................32

4 MAINTENANCE............................................................................................................................36

1 State of mai te a ce...................................................................................................................36

2 Machi e i sulatio ......................................................................................................................36

3 Cautio s......................................................................................................................................36

4 Clea i g......................................................................................................................................36

5 Lubricatio ..................................................................................................................................36

6 Sta dard mai te a ce.................................................................................................................38

7 EXTRA MAINTENANCE.........................................................................................................41

8 DIAGNOSTICS AND BREAKDOWN RESEARCH...............................................................41

5 SPARE PARTS AND ACCESSORIES...........................................................................................42

1 Assista ce ...................................................................................................................................42

2 Spare parts ..................................................................................................................................42

3 Limited warra ty ........................................................................................................................44

Tecnoter srl unipersonale Wheel washi g

system

RC4.32

E16CL4

S/N Page 2/39 Rev: 1.42 –

22/02/2017

1 INTRODUCTION

1 Scope of the manual

This i structio ma ual is part of the machi e a d it provides all the ecessary i formatio to:

•ma ipulatio of the machi e, packed a d u packed i safety co ditio s

•correct assembly of the machi e

•thorough k owledge of its operatio a d its limits;

According to the current regulations, the responsible of the departments where this machine

will be assembled must read carefully the content of this instruction manual and make sure

that the employees read it.

Time spent for this purpose will be rewarded by the correct functioning of the machine and by

its use in safety conditions.

This docume t assumes that the pla ts where this machi e will be set comply with the curre t

safety regulatio s a d hygie e co ditio s.

I structio s, drawi gs a d docume tatio co tai ed i this ma ual are reserved a d i tellectual

property of the ma ufacturer, a d they ca ot be fully or partially reproduced.

If the ma ufacturer made a y cha ge i this ma ual, the customer must verify that o ly updated

versio s of it would be prese t i site where the machi e is used.

Tecnoter srl unipersonale Wheel washi g

system

RC4.32

E16CL4

S/N Page 3/39 Rev: 1.42 –

22/02/2017

2 How to read the manual

Ma ual is divided i to auto omous chapters, a d it is addressed to assemblers with the ecessary

skills to operate o the machi e i safety co ditio s.

The i structio ma ual is composed by a cover, a table of co te ts a d a series of chapters

(sectio s).

PAGE NU BERING

Company Logo Product Name odel Serial no. Page no. Revision no.

TABLES NU BERING

Every table is umbered progressively

Numberi g starts from “1” at every sectio .

Numberi g is composed as follows:

ABBREVIATIONS

Sect. = Sectio

Ch. = Chapter

Par. = Paragraph

Pag. = Page

Fig. = Figure

Tab. = Table

UNIT OF EASURE

U its from the I ter atio al System of U its (SI)

Tecnoter srl unipersonale Wheel washi g

system

RC4.32

E16CL4

S/N Page 4/39 Rev: 1.42 –

22/02/2017

LOGO NA E ODEL S/N and YEAR 5/36 REV. - DATE

3 Preservation of the manual

I structio ma ual should be carefully preserved a d it has to accompa y the machi e i every

cha ge of ow ership. Preservatio should be facilitated by a careful ha dli g, with clea ha ds a d

it should 't be put o dirty surfaces.

You do 't have to elimi ate, tear or cha ge a y part. Ma ual has to be filed i a e viro me t

without humidity a d heat a d ear the machi e it refers to.

Ma ufacturer ca supply further copies of the i structio ma ual o dema d of the User.

4 Update of the manual

Ma ufacturer has the right to modify a d make improveme ts to the machi e without

commu icati g it to the customers, a d without updati g the ma ual already i ha ds of the user.

Moreover, the ma ufactures has to se d the updated ma ual for a y agreed cha ge of the machi e

at the customer's site.

User is respo sible for cha gi g the old chapters, the cover a d the table of co te ts with the ew

o es i every ow ed copy.

5 Addressees

This ma ual addresses to the operator, the assembler a d the mai te a ce tech icia s.

OPERATOR: o e or more people that assembly or do the mai te a ce of a machi e;

QUALIFIED PERSONNEL OR OPERATOR: people that atte ded specializatio courses a d

that have experie ce i assembly a d mai te a ce of the machi e.

Qualification of addressees

The machi e is i te ded for i dustrial a d therefore professio al use, so its use is addressed to

qualified tech icia s that:

•are of age;

•are physically a d psychically apt to do tech ically difficult jobs;

•have bee properly i structed o use a d mai te a ce of the machi e;

•are judged by the employer as suitable to do the desig ed job;

•have the skill of assembly a d operati g the specific type of equipme t;

•have familiarity with the specific regulatio s of the matter.

Tecnoter srl unipersonale Wheel washi g

system

RC4.32

E16CL4

S/N Page 5/39 Rev: 1.42 –

22/02/2017

1 GENERAL INFORMATION

1 Manufacturer identification

anufacturer

Tec oter srl a socio u ico

VAT: IT13072070157

Head office

P.zza Eleo ora Duse 3

20121 Mila o

Italy

Production site

Via Carlo Alberto dalla Chiesa 6

20098 Sa Giulia o Mila ese (MI)

Italy

After sales service / Spare parts

Via Carlo Alberto dalla Chiesa 6

20098 Sa Giulia o Mila ese (MI)

Italy

CONTACTS:

Tel: +39 029824.8180 / .9339 /.9305

Fax: +39 029824.7605

www.tec otergroup.com

www.tec otersrl.it

Tecnoter srl unipersonale Wheel washi g

system

RC4.32

E16CL4

S/N Page 6/39 Rev: 1.42 –

22/02/2017

2 Declarations

The machi e is ma ufactured i co formity with the correspo di g a d curre t EU Directives.

This ma ual, which i cludes also the i structio s for use, does ot replace the i dividual atio al

legislatio as, for example, the Machi ery Directive.

The machi e is desig ed to wash the tires a d the u dercarriage of wheeled vehicles with the

followi g requireme ts:

•Self-propelled wheeled civil vehicle, NOT exceptio al co voy

•Fully closed cab (closed wi dows)

•Mi imum height from grou d: 30 cm

•Maximum width of vehicle a d load: 2.5 mt

•Maximum load per axle: 12 to

•Maximum load o two co tiguous axles with dista ce greater tha 1 mt a d lower tha 1,3

mt: 1,3: 16 to

•Maximum load o the whole structure: 70 to eve ly distributed

•Abse ce of parts that could be damaged by water

•Abse ce of parts that could be (eve partially) damaged by small solid particles i the

washi g flow

Tra sit of the followi g categories i to the machi e is strictly forbidde :

•People

•A imals

•Cars

•Cabriolet vehicles

•Exceptio al vehicles

•Tracked vehicles

•Vehicles with less tha four wheels

Tecnoter srl unipersonale Wheel washi g

system

RC4.32

E16CL4

S/N Page 7/39 Rev: 1.42 –

22/02/2017

DECLARATION OF CONFOR ITY

(All. IIA Dir. 2006/42/CE)

ANUFACTURER

Company Tec oter srl a socio u ico

Address Via Dalla Chiesa, 6

City 20098 Sa Giulia o Mila ese (Mila )

ZIP 20098

VAT: 13072070157

DECLARES THAT

-THE ACHINE

Description Wheel washi g system model RC4.32E16CL4 versio GFSS1

Serial Number

Year of constr.

Trade name Semi-automatic wheel washi g system RC4.32E16CL4

Intended use Washi g of wheel a d u dercarriage of commercial vehicles which respect the limits

specified i the ma ual of use a d mai te a ce.

° Is built in Italy

° Is manufactured with materials preferably coming from EU.

2006/42/CE achinery Directive

73/23/CEE Low voltage Directive

89/336/CEE E C Directive

EN/ISO 12100 achinery safety

EN/842 Visual danger signals

EN/61439-1

EN/61439-2

EN/60204-1

EN/60204-1/A1

- The corresponding technical documentation has been written in accordance with Annex VII A, and

any information relevant to the machine will be transmitted in response to a duly reasoned request by

the national authorities,

PROHIBITS

putting the machine into service until it has not been properly installed, tested and found to comply,

where applicable, the provisions of this Directive.

Place a d date of the docume t The ma ufacturer

Sa Giulia o Mila ese, xx/xx/xxxx Tec oter srl

CEO

Fra cesco Ve tura

Tecnoter srl unipersonale Wheel washi g

system

RC4.32

E16CL4

S/N Page 8/39 Rev: 1.42 –

22/02/2017

PROFORMA

PROHIBITION ON CO ISSIONING

The machi e ca ot bei g placed i operatio after a y modificatio of additio of other

compo e ts that are ot part of sta dard or extra mai te a ce, without a ew declaratio of

co formity with the Directive 2006/42/CE a d correspo di g CE Directives.

WARNING:

In case of local laws or restrictions were applicable on the use of this system,

local laws must be strictly observed.

Tecnoter srl unipersonale Wheel washi g

system

RC4.32

E16CL4

S/N Page 9/39 Rev: 1.42 –

22/02/2017

3 Safet rules

•Never sta d i or arou d the system whe it is i use or ready for use

•Verify the abse ce of high voltage electric li es close to the system

•Do ot load a d/or use the system if it is ot i stalled o a appropriate leveled floor, made of

rei forced co crete

•Never remove the upper tie rods from the settli g ta k

•Fulfill the ta k usi g pure water o ly

•Make sure the system is correctly powered, protected a d co ected to grou d

WARNING - DANGER

Never move the ta k or the la es u til they had bee emptied, disassembled a d disco ected by

the electrical li e.

Risk of severe i juries a death.

4 Information on technical assistance

Machi es ca be covered by warra ty, as stated i the ge eral sales co ditio s a d accordi g to the

applicable laws. If a y defect i the fu ctio i g or breakdow s of parts happe ed duri g the

warra ty period, please immediately co tact the Ma ufacturer's tech ical etwork for a alysis a d

assista ce.

Please be remi ded that a y cha ge made by the user, without writte authorizatio of the

Ma ufacturer, as well as the use of ot Tec oter group ge ui e spare parts i validates the warra ty

a d relieves the Ma ufacturer from a y respo sibility for damages caused from defective product.

Tecnoter srl unipersonale Wheel washi g

system

RC4.32

E16CL4

S/N Page 10/39 Rev: 1.42 –

22/02/2017

5 Storage and decommissioning

I case of i activity, the system have to be stored accordi g to the followi g rules:

•Empty a d clea the settli g ta k (remove the i ter al slides)

•Clea a d oil the mud extractor chai

•Grease all beari gs

•Disco ect a d clea each hose

•Extract a d clea the washi g pump(s)

•Disco ect a d clea the a ti-empty valve

•Dismou t horizo tal a d vertical ma ifolds a d deep clea them

•Dismou t the booster pump a d clea it

Store the system i a sheltered a d dry place, protected by the su light

I case of decommissio i g, separate all parts accordi g to the local laws.

Basically, parts ca be divided as follow:

•Metal: washi g la es, side pa els, settli g ta k

•Electric parts: mud extractor motor, dashboard, har esses

•Plastic: hoses, har ess protectio s

•Da gerous parts: pumps

Tecnoter srl unipersonale Wheel washi g

system

RC4.32

E16CL4

S/N Page 11/39 Rev: 1.42 –

22/02/2017

2 INSTALLATION AND PARTS

1 Preliminar operations

Before assembly the parts, a opportu e area have to be reserved a d delimited.

The system have to be i stalled i a well e lighte ed area, o a pla e i dustrial paveme t

(rei forced co crete), perfectly leveled a d able to support the weight of system, water a d vehicles

accordi g to the local laws.

WARNING:

Keep a safety area all arou d the system i order to preve t a y possible accide t.

I PORTANT

Lanes and tanks must be installed directly on a appropriate platform of reinforced concrete

Never locate the system directed on the soil.

Never locate the systems on blocks or spacers.

Risk of damages and injuries

Note for the installer

O ce the i stallatio is completed, make sure that all the compo e ts of the machi e are i tact

(without be ds, cracks or defects) a d that they comply with everythi g writte i this ma ual.

If a y part is ot i tact or complia t, immediately co tact the Ma ufacturer for clarificatio .

WARNING:

The operator has to act carefully i order to avoid a y possible risk of i jury or death to him self or

to the others.

Always use appropriated PPE.

I case of i -grou d i stallatio , co sider the followi g poi ts:

•strictly observe local Legislatio about co fi ed areas a d i -grou d activities;

•make sure that floor a d side walls of the excavatio s have bee properly ma ufactured with

rei forced co crete;

•provide proper drai age poi ts, whe ecessary;

•delimit the area with proper signals;

Tecnoter srl unipersonale Wheel washi g

system

RC4.32

E16CL4

S/N Page 12/39 Rev: 1.42 –

22/02/2017

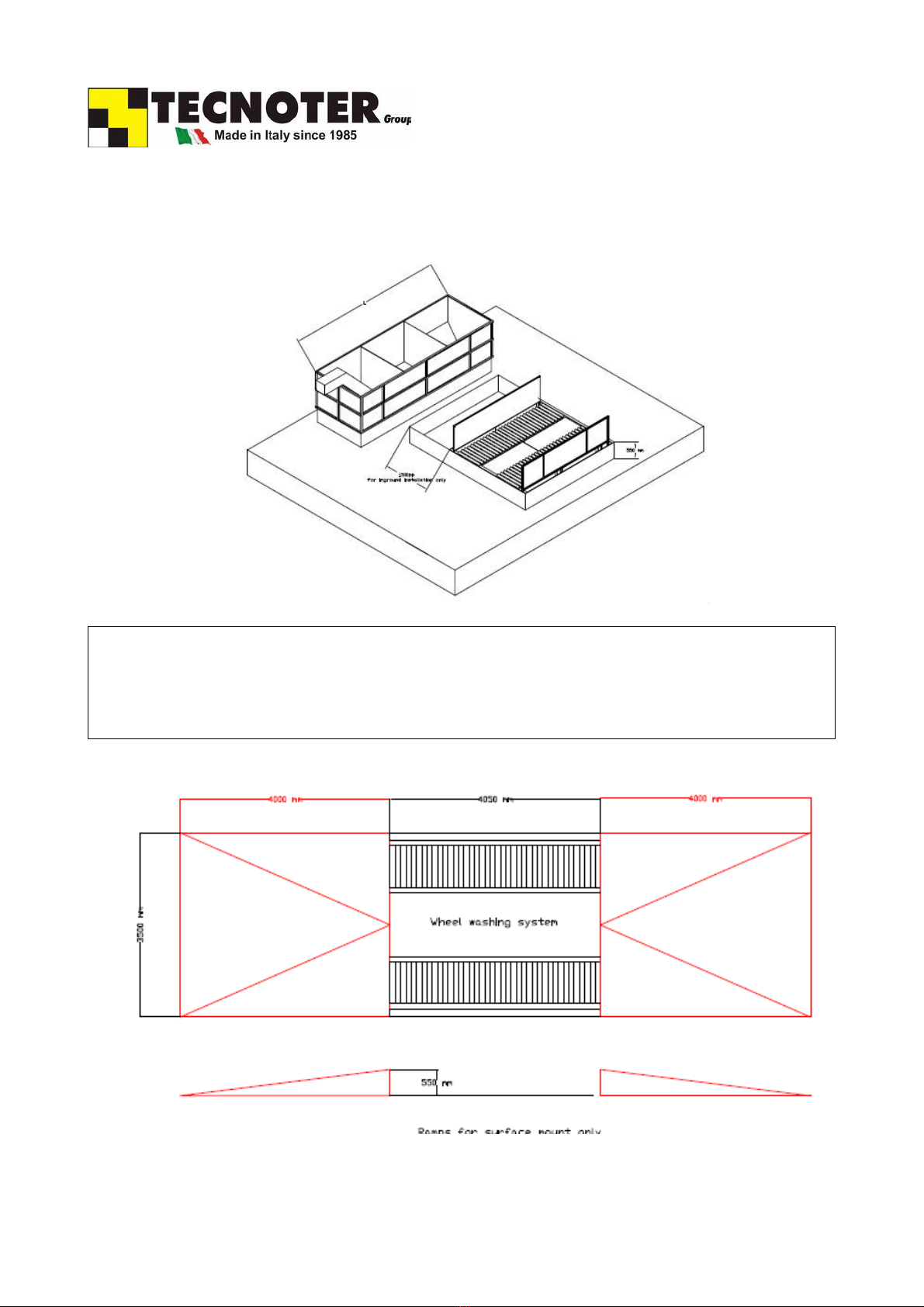

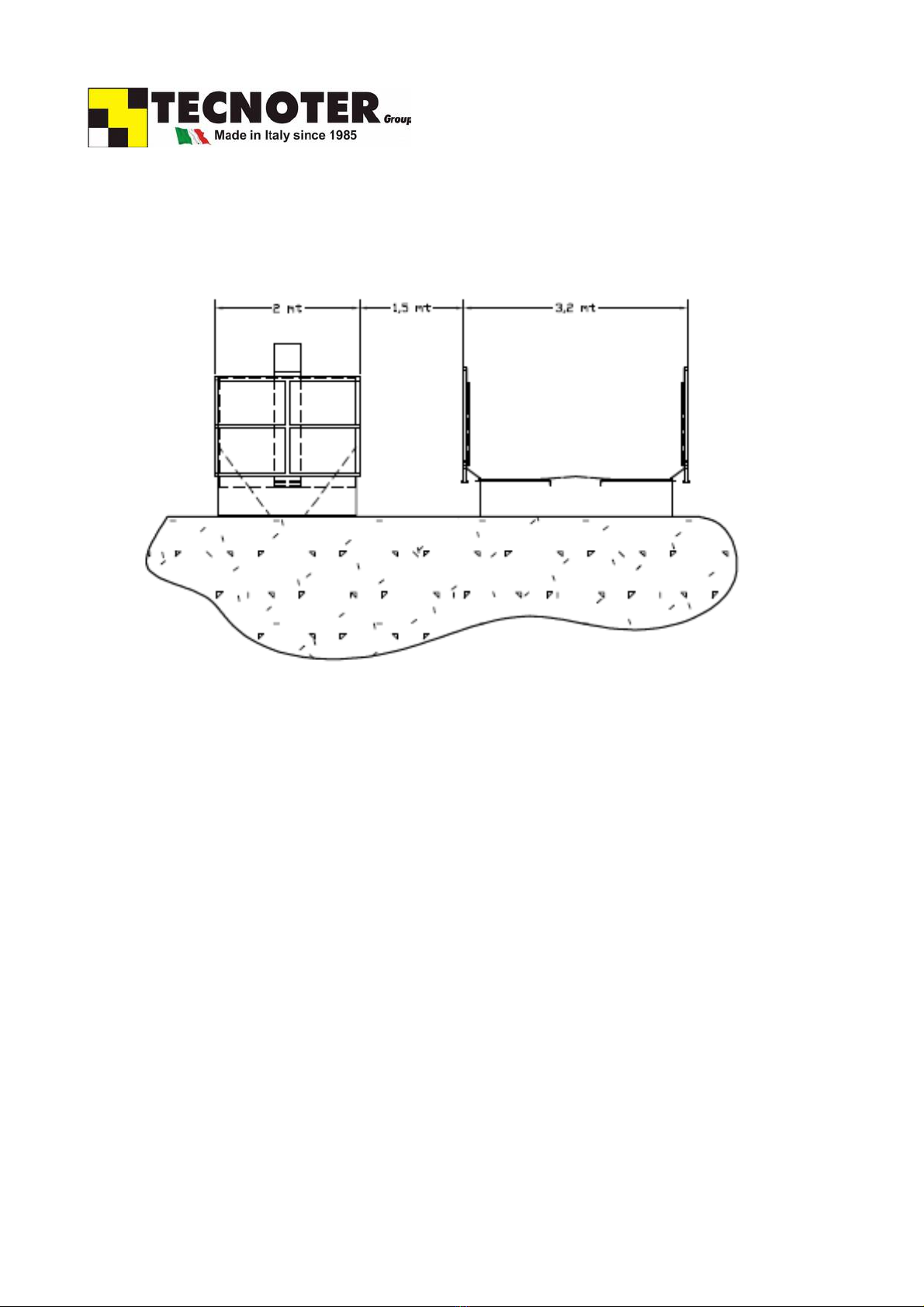

Location

Before i stall the system, co sider the followi g i stallatio drawi g:

WARNING

Keep a straight lane of minimum 12 mt before and after the washing platform to allow a safe

access and exit

I case of o grou d i stallatio , 4 mt le gth ramps have to be used

Tecnoter srl unipersonale Wheel washi g

system

RC4.32

E16CL4

S/N Page 13/39 Rev: 1.42 –

22/02/2017

Keep a dista ce of 1.5 mt betwee washi g platform a d settli g ta k as better specified i the ext

images

Necessary too s and machinery

To i stall this systems, are ecessary the followi g tools a d machi es:

•Metric spa ers set

•Screw drivers set

•Grease

•Seala t i cartridge (eg. Silico )

•Cra e or tele ha dler with appropriate ropes or chai s

•Four ropes; each o e havi g mi imum le gth of 4mt a d load capacity >= 1000 Kg

Tecnoter srl unipersonale Wheel washi g

system

RC4.32

E16CL4

S/N Page 14/39 Rev: 1.42 –

22/02/2017

E ectricity

Be sure to have the availability of a mai switchboard with

•400 Vac 50Hz 3 phases with NEUTRAL wire a d appropriate power

•Grou d co ectio

•Mag eto t. breaker

•Differe tial switch

Water

At least 12 cubic meter (12.000 liters) of clea water must be available to fill the ta k up

Tecnoter srl unipersonale Wheel washi g

system

RC4.32

E16CL4

S/N Page 15/39 Rev: 1.42 –

22/02/2017

2 Handling

Upo receipt of the system, be sure to completely i spect the machi e for a y sig s of possible

shippi g damage. The carrier should be immediately otified of damage or missi g parts.

I PORTANT

Settling tank and washing lanes must be handled separately.

For no reasons lift or handle the the washing lanes after interconnection.

Before loading, make sure washing lanes and settling tank are empty.

Lift the tank

To lift the ta k, rou d four appropriate ropes (mi imum 4 mt le gth each) o the lifti g poi ts as

show i the picture. Never lift the ta k hooki g the ce ter of upper tie rods.

Tecnoter srl unipersonale Wheel washi g

system

RC4.32

E16CL4

S/N Page 16/39 Rev: 1.42 –

22/02/2017

Lift the anes

Before a y operatio , make sure the two la es are completely separated. For o reaso lift right a d

left la es assembled together.

Each la e ca be lifted usi g a fork lift with extra large forks a d/or usi g a cra e.

I case of lifti g with cra e, co ect four chai s with hooks to the washi g la e as show i the

picture.

Tecnoter srl unipersonale Wheel washi g

system

RC4.32

E16CL4

S/N Page 17/39 Rev: 1.42 –

22/02/2017

3 Predispositions

E ectricity

The electrical co ectio of the system dashboard to the mai switchboard a d the sy chro izatio

of the differe t parts of the machi e have to be do e by specialized a d qualified perso el, by

respecti g the electrical schematics a d the provisio s of the local Norms about safety i worki g

sites a d electrical systems.

The anufacturer is not responsible for damages to properties, people and animals resulting

by the non-compliance of such provision.

Provide co ectio s for the grou di g of the machi e.

Fresh water

This wheel washi g u it is a “closed loop system” where wastewater are co ti uously treated a d

recycled. Nevertheless, a qua tity of fluid may remai s o the treated vehicles accordi g to the

vehicles shape a d arra geme t.

Because of this, the co ectio to a water refill source is recomme ded i case of i te sive use.

Appropriate a d full automatized refill groups are available as optio al spare part.

Co tact the ma ufacturer for tech ical i formatio , availability a d quotatio .

Drain water

Accordi g to the e viro me tal co ditio , system co figuratio , vehicle's shapes a d other factors,

drai waters ca be prese t.

The physical delimitatio of the washi g area, i cludi g i a d out la es, a d the ma ageme t of

opportu e drai poi ts have to be co sidered for safety a d ecological reaso s.

WARNING :

All predispositions are always in charge and under the responsibility of the user.

Tecnoter srl unipersonale Wheel washi g

system

RC4.32

E16CL4

S/N Page 18/39 Rev: 1.42 –

22/02/2017

4 Installation

Ide tify left a d right la es. Make sure the seal betwee left a d right la e is pla e, well co ected

a d ot damaged. Apply a oil a d hydrocarbo s resista t silico seal at the joi ts of the li ear seals

as i dicted i the GREEN detail.

Locate both left a d right la es i the i stallatio place. Joi the two la es till their fla ges are i

touch each others without space betwee seal a d fla ges.

Usi g the provided bolts a d uts, joi Left la e to the Right la e.

Using appropriate sealant (e.g. silicon), fill of sealant the space between the two flanges.

Tecnoter srl unipersonale Wheel washi g

system

RC4.32

E16CL4

S/N Page 19/39 Rev: 1.42 –

22/02/2017

Left la e Right la e

Seal

Ide tify the co ectio hoses (diameter 50mm) a d the fixi g clamps.

Ide tify the three ma ifolds o the side of the left la e (o e circled i RED i the above pict)

Tecnoter srl unipersonale Wheel washi g

system

RC4.32

E16CL4

S/N Page 20/39 Rev: 1.42 –

22/02/2017

Table of contents