TempMaster Omni Premier 25 Ton Product manual

Form Number: 5881373-TIM-421

New Release

Installation Guide

Issue Date: 2021-04-01

Tempmaster

Tempmaster® Omni™ Premier 25 Ton

to 80 Ton Rooftop Units Installation and

Maintenance Guide

2Tempmaster® Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide

Tempmaster

Contents

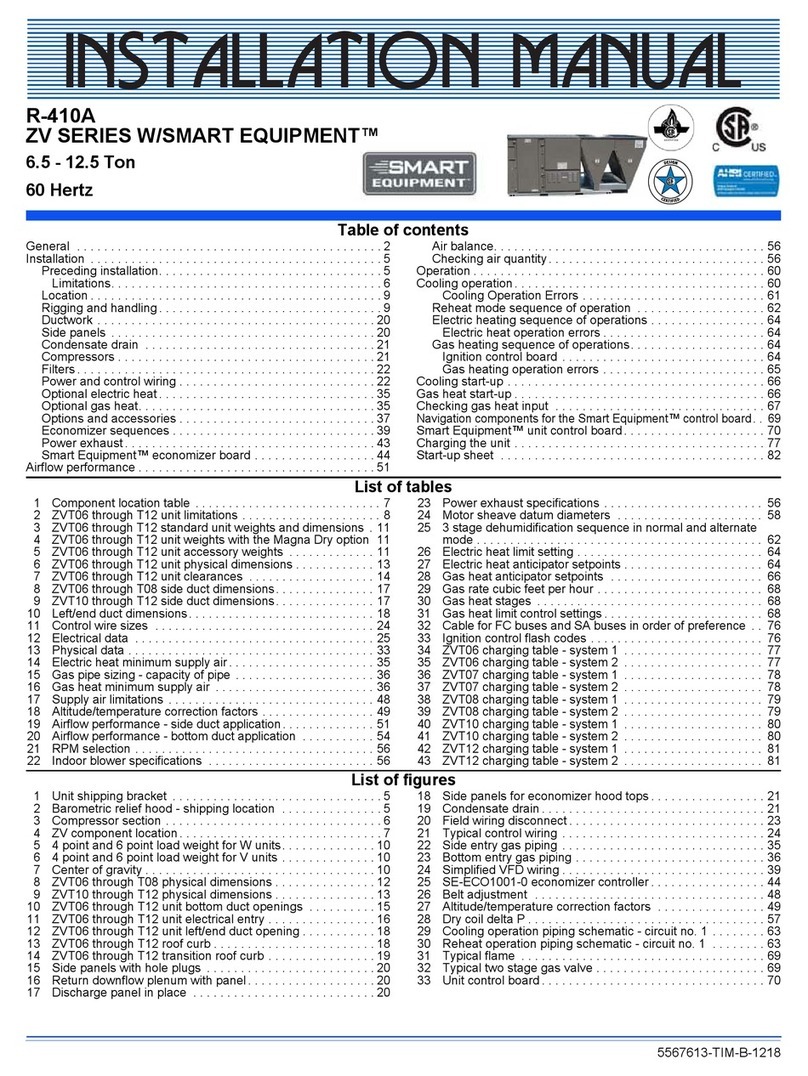

ContentsChangeability of this document.................................. 5

Associated literature............................................... 5

Nomenclature 25 ton to 80 ton model number........ 6

General........................................................................... 9

Introduction........................................................... 15

Ecological and economical design...................... 15

Condensing section.............................................. 15

Scroll compressors.......................................... 15

Multiple compressor staging......................... 15

Compressor circuiting.................................... 16

Compressor sound blankets.......................... 16

Replaceable core filter driers......................... 16

Low ambient operation.................................. 16

Condenser fan motors................................... 16

Condenser coils............................................... 16

Condenser coil protection.............................. 16

Blank section......................................................... 16

Sound attenuator............................................ 16

Humidifier........................................................ 16

Air blender....................................................... 16

Evaporator section................................................ 16

Evaporator coils............................................... 16

Modulating hot gas reheat............................ 16

Double sloped stainless steel drain pan....... 17

Heating section..................................................... 17

Gas heat........................................................... 17

Electric heat..................................................... 17

Hydronic heat.................................................. 17

Air management................................................... 17

Fans................................................................... 17

Premium efficiency motors............................ 17

Building pressure control............................... 17

Variable frequency drives............................... 17

Fan spring isolation........................................ 18

Energy recovery wheel................................... 18

Controls.................................................................. 18

Rooftop unit controller................................... 18

BACnet®/Modbus™/N2/Customer

terminal board.................................................. 18

Indoor air quality.................................................. 18

Indoor air quality............................................ 18

Double wall construction............................... 18

Demand control ventilation........................... 18

Smoke control.................................................. 19

Filtration........................................................... 19

Ultraviolet lights.............................................. 19

Electrical................................................................. 19

Single point power.......................................... 19

Dual point power............................................. 19

Power phase monitor..................................... 19

Unit-mounted disconnect, 65 kA SCCR......... 19

Service and Installation........................................ 19

Split ship........................................................... 19

Internal lights.................................................. 19

Access doors, padlocks, viewports,

safety latch and door tiebacks........................ 19

Service valves and sight glasses.................... 20

Convenience outlet......................................... 20

Condenser safety tie-off................................. 20

Condenser cleaning hatch............................. 20

Burglar bars..................................................... 20

Inlet, belt guard and spare belts................... 20

Start-up and air balancing wizard................. 20

Factory run-tested........................................... 20

RTUToolKit app and QR code......................... 20

Safety considerations........................................... 22

Limitations............................................................. 23

Reference............................................................... 23

Approvals............................................................... 23

Installation................................................................... 24

Unit inspection...................................................... 24

Long term storage.......................................... 24

Unit placement...................................................... 24

Roof curb................................................................ 24

Clearances and locations............................... 24

Rigging and handling........................................... 26

Weights and unit dimensions.............................. 30

Weights............................................................. 30

Dimensions...................................................... 33

Roof curb dimensions..................................... 47

Submittal data....................................................... 61

Electrical data........................................................ 61

Electrical service sizing................................... 62

Control wiring........................................................ 69

Occupancy input............................................. 69

Safety switch input.......................................... 69

Tempmaster

Tempmaster® Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide 3

Main control board.................................................. 69

Customer terminal board....................................... 69

Options board.......................................................... 70

Display panel.................................................................. 72

Display panel adjustment....................................... 72

Reset switch.................................................................... 74

Unit enable switch......................................................... 74

UV light reset switch...................................................... 75

Field tubing..................................................................... 75

Discharge air static pressure transducer.............. 75

Building static pressure transducer....................... 75

Outdoor pressure reference................................... 75

Outside air temperature sensor............................. 76

Gas piping....................................................................... 76

Gas connection......................................................... 77

Gas piping recommendation.................................. 77

Flue gas chimney installation................................. 78

Hydronic piping.............................................................. 78

Hot water coil........................................................... 78

Steam coil.................................................................. 80

Humidifier....................................................................... 80

Ductwork......................................................................... 81

Discharge panel....................................................... 82

Air hoods......................................................................... 83

Outside air hood...................................................... 83

Exhaust air hood...................................................... 84

Filters............................................................................... 84

Ultraviolet lights............................................................. 85

Condensate drain........................................................... 85

Fan tie-downs................................................................. 86

Start-up and operation.................................................. 91

Maintenance......................................................................... 92

General............................................................................ 92

Safety......................................................................... 92

Condenser safety tie-off.......................................... 92

Periodic maintenance - monthly........................................ 93

Belt tensioning............................................................... 93

Filters............................................................................... 93

Linkages.......................................................................... 93

Compressors................................................................... 93

Oil level check........................................................... 93

Oil analysis................................................................ 93

Condenser and evaporator coils.................................. 93

Hot water and steam coils............................................ 94

Periodic maintenance - 3 months to 6 months................ 95

Motor bearing lubrication............................................. 95

Lubrication preparation.......................................... 95

Lubrication procedure............................................. 95

Fan bearing lubrication................................................. 97

Condensate drain........................................................... 98

Periodic maintenance - yearly............................................ 99

Entire unit inspection.................................................... 99

Condensate float switch................................................ 99

Ultraviolet lights............................................................. 99

Internal lights................................................................. 99

Sheave alignment.......................................................... 99

Belts............................................................................... 100

Belt replacement.......................................................... 100

Filter drier replacement.............................................. 100

Energy recovery wheel................................................ 101

Remove the wheel holder supports..................... 101

Sliding the ERW...................................................... 102

Remove wheel segments...................................... 103

Install wheel segments......................................... 104

Periodic maintenance - as needed.................................. 105

Replacing the main control board............................. 105

Phase monitor checks and adjustments................... 105

Compressor replacement........................................... 105

Technical supplement....................................................... 106

25 ton to 50 ton power wiring side penetration for

slab-mounted units...................................................... 106

Installing the power wiring through the side

panel of the rooftop unit........................................ 106

60 ton to 80 ton power wiring side penetration for

slab-mounted units...................................................... 107

Installing the power wiring through the side

panel of the rooftop unit........................................ 107

Technical supplement....................................................... 108

Installing door tie-back brackets (5881370-UTS-

A-0420)............................................................................ 108

Supplément technique...................................................... 109

Instructions d'installation du chauffage au gaz...... 109

Chauffage à gaz..................................................... 109

Les dégagements................................................... 110

Tuyauterie de gaz................................................... 111

Connexion de gaz.................................................. 112

Recommandation sur la tuyauterie de gaz......... 113

Installation de cheminée de gaz de

combustion.............................................................. 113

Tempmaster® Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide

4

Tempmaster

Changeability of this

document

In complying with the manufacturer's policy

for continuous product improvement, the

information contained in this document is

subject to change without notice. There is no

commitment to update or provide current

information automatically to the manual or

product owner. Updated manuals, if applicable,

can be obtained by contacting the nearest

service office.

It is the responsibility of rigging, lifting,

and operating/service personnel to verify

the applicability of these documents to the

equipment. If there is any question regarding

the applicability of these documents, rigging,

lifting, and operating/service personnel

should verify whether the equipment has been

modified and if current literature is available

from the owner of the equipment prior to

performing any work on the equipment.

Associated literature

Manual Description Form Number

Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and

Maintenance Guide 5881373-TIM

Omni™ Premier 25 Ton to 80 Ton Rooftop Units R-410A Start-Up and

Operation Guide 5881376-TSG-A

Omni™ Premier 60 Ton to 80 Ton Rooftop Units Split Ship Assembly

Installation Manual 6011418-TIM

Omni™ Premier 25 Ton to 80 Ton Rooftop Units Advanced Graphic

Touchscreen Display 5795594-TIM-A

Mobile Access Portal Gateway (MAP) Technical Guide 1154578-UTG-A

Note: Unit-specific documents such as unit drawings, curb information, performance

summary, weights, center of gravity, electrical data, rigging and shipping instructions,

sequence of operation, BAS controls points, and hydronic valve specifications are available

in the Selection Navigator program. Contact your local sales office or representative for

additional unit-specific information.

WARNING

Cancer and Reproductive Harm — www.P65Warnings.ca.gov.

5

Tempmaster® Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide

Tempmaster

Nomenclature 25 ton to 80 ton model number

Digits 1–2: Product brand name

GT: Tempmaster

Digit 3: Capacity

A: 25 ton

B: 30 ton

C: 40 ton

D: 50 ton

F: 60 ton

H: 70 ton

J: 80 ton

Digit 4: Efficiency

1: Standard capacity, standard efficiency, staged control

2: Standard capacity, high efficiency, modulating control

3: High capacity, standard efficiency, staged control*

4: Standard capacity, standard efficiency, low sound, staged

control*

5: Standard capacity, high efficiency, low sound, modulating

control*

6: High capacity, standard efficiency, low sound, staged

control*

Digit 5: Heat source

A: Cooling only

B: Staged gas aluminized burner

C: Staged gas stainless steel (SST)

G: Modulating gas stainless steel

K: Steam coil*

L: Hot water coil*

M: Electric heat*

Digit 6A: Electric heat capacity

0: None

1: Low heat*

3: High heat*

4: Low heat with silicon controlled rectifier (SCR)*

6: High heat with SCR*

Digit 6B: Natural gas heat capacity

0: None

1: 250 MBH

2: 500 MBH

3: 750 MBH

4: 1,000 MBH

5: 1,250 MBH

6: 1,500 MBH

Digit 6C: Hot water or steam heating coil option

0: None

1: Low heat without valves*

2: Low heat with valves*

3: High heat without valves*

4: High heat with valves*

Digit 7: Unit type

A: Single zone VAV (SZVAV) (no duct pressure transducer)

B: Variable air volume (VAV) (duct pressure transducer)

Digit 8: Motor control options

1: Supply fan variable frequency drive (VFD)

2: Supply fan VFD with line reactor*

3: Supply fan VFD with bypass (redundant VFD) / Supply fan

with dual VFD

4: Supply fan VFD with line reactor and bypass (redundant

VFD) / Supply fan with dual VFD with line reactor*

5: Supply fan VFD and return/exhaust fan VFD

6: Supply fan VFD with line reactor and return/exhaust fan

VFD with line reactor*

7: Supply fan VFD and return/exhaust fan VFD with bypass

(redundant VFD for supply fan and bypass for return or

exhaust fan) / Supply fan with dual VFD and redundant VFD

for return fan / manual bypass for exhaust fan

8: Supply fan VFD with line reactor and return/exhaust

fan VFD with line reactor with bypass (redundant VFD for

supply fan and bypass for return or exhaust fan / Supply

fan with dual VFD and redundant VFD for return fan /

manual bypass for exhaust fan, and line reactors (for all

fans)*

Digit 9: Voltage

A: 208-230 V 3Ph 60 Hz, single point terminal block

B: 208-230 V 3Ph 60 Hz, dual point terminal block

C: 208-230 V 3Ph 60 Hz, single point non-fused DISC

D: 208-230 V 3Ph 60 Hz, single point terminal block, 65KA

short-circuit current rating (SCCR)*

E: 208-230 V 3Ph 60 Hz, dual point terminal block, 65KA

SCCR*

F: 208-230 V 3Ph 60 Hz, single point fused DISC, 65KA SCCR*

G: 460 V 3Ph 60 Hz, single point terminal block

H: 460 V 3Ph 60 Hz, dual point terminal block

J: 460 V 3Ph 60 Hz, single point non-fused DISC

K: 460 V 3Ph 60 Hz, single point terminal block, 65KA SCCR*

L: 460 V 3Ph 60 Hz, dual point terminal block, 65KA SCCR*

M: 460 V 3Ph 60 Hz, single point fused DISC, 65KA SCCR*

N: 575 V 3Ph 60 Hz, single point terminal block

P: 575 V 3Ph 60 Hz, dual point terminal block

Q: 575 V 3Ph 60 Hz, single point non-fused DISC

R: 575 V 3Ph 60 Hz, single point terminal block, 65KA SCCR*

S: 575 V 3Ph 60 Hz, dual point terminal block, 65KA SCCR*

T: 575 V 3Ph 60 Hz, single point fused DISC, 65KA SCCR*

Digit 10: Return configuration

A: Bottom return, right outside air (OA), side exhaust

B: Bottom return, right OA, front exhaust

C: Bottom return, left OA, side exhaust

D: Bottom return, Left OA, front exhaust

E: Top return, right OA, side exhaust (no return fan

available)*

F: Top return, right OA, front exhaust (no return fan

available)*

G: Top return, left OA, side exhaust (no return fan

available)*

H: Top return, left OA, front exhaust (no return fan

available)*

J: Left return, right OA, front exhaust

K: Right return, left OA, front exhaust*

L: Front return, left OA, right exhaust*

M: Front return, right OA, feft exhaust*

N: Bottom return, no OA, no exhaust air (EA) (no return fan

available)

P: Top return, no OA, no EA (no return fan available)*

Q: Left return, no OA, no EA (no return fan available)

R: Right return, no OA, no EA (no return fan available)*

S: Front return, no OA, no EA (no return fan available)*

Digit 11: Discharge locations

1: Bottom discharge, from discharge plenum

2: Bottom discharge, discharge through heat section

3: Top discharge, from discharge plenum*

4: Right discharge, from discharge plenum

5: Left discharge, from discharge plenum

6: Left discharge, discharge through heat section

Digit 12: Supply configuration

A: None

B: Small blank

C, D: Large blank*

E, G: Large blank with final filter*

F: Small blank with humidifier and SST drain pan*

H, K: Large blank with humidifier and SST drain pan*

L: Small blank sound attenuator*

M, N: Large blank sound attenuator*

P: Small blank final filter

Q, T: Large blank with sound attenuator and final filter*

S, V: Large blank with sound attenuator and humidifier and

SST drain pan*

Digit 13: Final filter options

1: MERV 15 bag final filters with 2 in. MERV 8 filters

2: MERV 14 rigid final filters with 2 in. MERV 8 filters

3: MERV 17 high efficiency particulate air (HEPA) final filters

with 2 in. MERV 8 filters*

4: MERV 14/15 filter rack (no filters)

5: HEPA filter rack (no filters)*

6: None

Digit 14: Final filter control options

0: None

1: Combined pre- and post- filter transducer

2: Separate pre- and post- filter transducer

3: Combined pre- and post- filter transducer and combined

magnehelic gauge

Tempmaster® Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide

6

Tempmaster

4: Separate pre- and post- filter transducer and magnehelic

gauge

5: Combined pre- and post- filter magnehelic gauge

6: Separate pre- and post- filter magnehelic gauge

7: Combined pre- and post- filter transducer, separate pre-

and post- filter magnehelic gauge

Digit 15: Supply fan

A: Direct drive plenum (DDP) supply fan with 1 in. spring

isolation

B: DDP supply fan with 2 in. spring isolation

C: DDP supply fan with 2 in. spring isolation and seismic

restraint

D: Dual direct drive plenum supply fans with 1 in. spring

isolation

E: Dual direct drive plenum supply fans with 2 in. spring

isolation

F: Dual direct drive plenum supply fans with 2 in. spring

isolation and seismic restraint

Digit 16: Supply fan motor horsepower

A: 5 HP / 5 HP x 2

B: 7.5 HP / 7.5 HP x 2

C: 10 HP / 10 HP x 2

D: 15 HP / 15 HP x 2

E: 20 HP / 20 HP x 2

F: 25 HP / 25 HP x 2

G: 30 HP / 30HP x 2

H: 40 HP

J: 50 HP

Digit 17: Supply fan motor type

2: ODP premium efficiency 1,800 RPM

4: TEFC premium efficiency 1,800 RPM

Digit 18: Supply fan options

0: None

1: Inlet guard

2: Airflow measurement station

3: Shaft grounding ring

4: Inlet guard and airflow measurement station

5: Inlet guard and shaft grounding ring

6: Airflow measurement station and shaft grounding ring

7: Shaft Grounding Ring, Inlet Guard and Airflow

Measurement Station

Digits 19: Building pressure control

0: None

1: Barometric damper

2: Exhaust with VFD and backdraft damper

3: Modulating damper (on/off exhaust fan only without

VFD)

4: Modulating damper (return fan only with VFD)

Digit 20: Return/exhaust fan

A: None

B: Exhaust fan with 1 in. spring isolation

C: Exhaust fan with 2 in. spring isolation

D: Exhaust fan with 2 in. spring isolation and seismic

restraint

E: Return fan with 1 in. spring isolation

F: Return fan with 2 in. spring isolation

G: Return fan with 2 in. spring isolation and seismic

restraint

H: DDP return fan with 1 in. spring isolation

J: DDP return fan with 2 in. spring isolation

K: DDP return fan, fan with 2 in. spring isolation and seismic

restraint

Digit 21: Return/exhaust fan motor horsepower

A: None

E: 3 HP

F: 5 HP

G: 7.5 HP

H: 10 HP

J: 15 HP

K: 20 HP

L: 25 HP

M: 30 HP

N: 40 HP

Digit 22: Return/exhaust fan motor type

0: None

1: ODP premium efficiency 1,200 RPM

2: ODP premium efficiency 1,800 RPM

3: TEFC premium efficiency 1,200 RPM*

4: TEFC premium efficiency 1,800 RPM*

Digit 23: Return/exhaust fan options

A: None

B: Shaft grounding ring

C: Extended grease lines

D: Extended grease lines and shaft grounding ring

E: Belt guards*

F: Belt guards and shaft grounding ring*

G: Return fan airflow measurement station

H: Return fan airflow measurement station and shaft

grounding ring

J: Extended grease lines and belt guards*

K: Extended grease lines and belt guards and shaft

grounding ring*

L: Extended grease lines and return fan airflow

measurement station

M: Extended grease lines and return fan airflow

measurement station and shaft grounding

N: Belt guards and return fan airflow measurement station

P: Belt guards and return fan airflow measurement station

and shaft grounding ring

Q: Extended grease lines and belt guards and return fan

airflow measurement station

R: Extended grease lines and belt guards and return fan

airflow measurement station and shaft grounding ring

R: Extended Grease Lines and Belt Guards and Return Fan

Airflow Measurement Station and Shaft Grounding Ring

Digits 24: Return/exhaust fan drive

A: None (25-50 ton)

0: None (60-80 ton)

1-9: RPM

A-Z: RPM

Digit 25: Evaporator options

G: Aluminum fin evaporator with SST drain pan

H: Aluminum fin evaporator with SST drain pan with

condensate overflow switch

J: E-Coat aluminum fin evaporator with SST drain pan*

K: E-Coat aluminum fin evaporator with SST drain pan with

condensate overflow switch*

L: Copper fin evaporator with sst drain pan*

M: Copper fin evaporator with SST drain pan with

condensate overflow switch*

Digit 26: Condenser coil options

2: With wire guards

3: Full louvered panels*

4: Partial louvered panels with wire guards*

6: E-Coat condenser with wire guards*

7: E-Coat condenser, full louvered panels*

8: E-Coat condenser, partial louvered panels with wire

guards*

Digit 27: Draw-through filter options

A: Angled filter rack, no filters

B: Angled filter rack, 2 in. throwaway filters

C: Angled filter rack, 2 in. MERV 8 filters

D: Rigid filter rack, no filters

E: Rigid filter rack, MERV 15 bag filters with 2 in. MERV 8

pre-filters

F: Rigid filter rack, MERV 14 rigid filters with 2 in. MERV 8

pre-filters

G: Vertical filter rack, no filters

H: Vertical filter rack, 4 in. MERV 8 filters

Digit 28: Draw-through filter control options

0: None

1: Combined pre- and post- filter transducer

2: Separate pre- and post- filter transducer

3: Combined pre- and post- filter transducer and combined

magnehelic gauge

4: Separate pre- and post- filter transducer and magnehelic

gauge

5: Combined pre- and post- filter magnehelic gauge

6: Separate pre- and post- filter magnehelic gauge

7: Combined pre- and post- filter transducer, separate pre-

and post- filter magnehelic gauge

Digit 29: Economizer options

A: None

C: Dry bulb economizer, low leak dampers

D: Single enthalpy economizer, low leak dampers

E: Dual enthalpy economizer, low leak dampers

F: Dry bulb economizer, low leak dampers with airflow

measurement station

G: Single enthalpy economizer, low leak dampers with

airflow measurement station

H: Dual enthalpy economizer, low leak dampers with

airflow measurement station

K: Dry bulb economizer, ultra low leak dampers

L: Single enthalpy economizer, ultra low leak dampers

S: Dual enthalpy economizer, ultra low leak dampers

T: Dry bulb economizer, ultra low leak dampers with airflow

measurement station

U: Single enthalpy economizer, ultra low leak dampers with

airflow measurement station

V: Dual enthalpy economizer, ultra low leak dampers with

airflow measurement station

Digit 30: Energy recovery options

0: None

1: Low cubic feet per minute (CFM) energy recovery wheel

(ERW) without VFD*

2: Low CFM ERW with VFD*

3: High CFM ERW without VFD*

4: High CFM ERW with VFD*

Tempmaster® Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide 7

Tempmaster

Digit 31: Refrigeration system piping options

A: None

B: Suction and discharge valves

C: Suction, discharge, and liquid valves

D: Suction, discharge, and liquid valves with replaceable

core filter driers*

E: Hot gas reheat (HGRH)

F: Suction and discharge valves with HGRH

G: Suction, discharge, and liquid valves with HGRH

H: Suction, discharge, and liquid valves with replaceable

core filter driers with HGRH*

N: E-Coat HGRH*

P: Suction and discharge valves with E-Coat HGRH*

Q: Suction, discharge, and liquid valves with E-Coat HGRH*

R: Suction, discharge, and liquid valves with replaceable

core filter driers with E-Coat HGRH*

Digit 32: Lights/detectors/ convenience options

A: None

B: Convenience outlet

C: Convenience outlet and internal lights*

D: Supply smoke detector

E: Return smoke detector

F: Supply and return smoke detector

G: Convenience outlet with supply smoke detector

H: Convenience outlet with return smoke detector

J: Convenience outlet with supply and return smoke

detectors

K: Convenience outlet and internal lights with supply smoke

detector*

L: Convenience outlet and internal lights with return smoke

detector*

M: Convenience outlet and internal lights with supply and

return smoke detectors*

Digit 33: Controls options

A: None

B: Low ambient

D: Subcool and superheat measurement

E: Low ambient with subcool and superheat measurement

Digit 34: Interface options

A: BACnet® MS/TP, Modbus™, N2

B: BACnet IP

G: BACnet MS/TP, Modbus, N2 with mobile access portal

(MAP)

H: MAP with BACnet IP

K: BACnet MS/TP, Modbus, N2 with MAP and touchscreen*

L: Touchscreen with MAP with BACnet IP*

N: BACnet MS/TP, Modbus, N2 with customer terminal

board

P: BACnet IP with customer terminal board

U: BACnet MS/TP, Modbus, N2 with MAP and customer

terminal board

V: MAP with BACnet IP and customer terminal board

X: BACnet MS/TP, Modbus, N2 with touchscreen and MAP

and customer terminal board*

Y: Touchscreen with MAP with BACnet IP and customer

terminal board*

Digit 35: Indoor air quality (IAQ) options

0: None

1: Ultraviolet (UV) lights*

2: Carbon Dioxide (CO2) sensors, demand controlled

ventilation

3: UV lights, CO2 sensors, demand controlled ventilation*

Digit 36: Gas heat shipped loose kits

0: None

1: Gas heat, side penetration

2: Gas heat, bottom penetration

3: Gas heat, high altitude kit natural gas (NG), side

penetration*

4: Gas heat, high altitude kit NG, bottom penetration*

5: Gas heat, high altitude kit liquid propane (LP), side

penetration*

6: Gas heat, high altitude kit LP, bottom penetration*

7: Gas heat, LP conversion kit, side penetration*

8: Gas heat, LP conversion kit, bottom penetration*

Digit 37: Security options

0: None

1: Supply and return opening burglar bars

2: Supply opening burglar bars

3: Return opening burglar bars

Digit 38: Door options

0: None

1: Viewport*

2: Single handle with padlock*

3: Single handle with padlock and viewport*

Digit 39: Cabinet shipping options

1: Single piece construction

2: Two piece construction

Digit 40: Curb options

A: No roof curb

B: Full perimeter roof curb

C: Pedestal curb

Digit 41: Pre-evap options

0: None

1, 2: Blank pre-evap extension, no air blender*

3, 4: Blank pre-evap extension, with air blender*

1, 2: Blank Pre-Evap Extension, No Air Blender

3, 4: Blank Pre-Evap Extension, with Air Blender

Digit 42: Shipped loose options

0: None

1: Spare Belts for Return/Exhaust

Digit 43: Construction standard

0: None

Digit 44: Supply fan VFD frequency

1: 68 Hz

2: 70 Hz

3: 72 Hz

A: 66 Hz

B: 64 Hz

C: 62 Hz

D: 60 Hz

E: 58 Hz

F: 56 Hz

G: 54 Hz

H: 52 Hz

J: 50 Hz

K: 48 Hz

L: 46 Hz

M: 44 Hz

N: 42 Hz

P: 40 Hz

Q: 38 Hz

R: 36 Hz

S: 34 Hz

T: 32 Hz

U: 30 Hz

V: 28 Hz

W: 26 Hz

X: 24 Hz

Y: 22 Hz

Z: 20 Hz

Digit 45: Supply fan brake horsepower (each motor)

A: 2 HP

B: 3 HP

C: 5 HP

D: 7.5 HP

E: 10 HP

F: 15 HP

G: 20 HP

H: 25 HP

J: 30 HP

K: 40 HP

L: 50 HP

M: 60 HP

N: 75 HP

Digit 46: Return fan brake horsepower

B-L : Internal use only

Digit 47: Future 4

0: None

Digit 48: Testing and special quotation (SQ)

0, Y, Z: None

T: Record test report

M: Mechanical special

1: Mechanical special and record test report

S: Software special

3: Software special and record test report

B: Mechanical and software special

5: Mechanical and software special and record test report

Digit 49: Generation/revision level

1: First generation

2: Second generation

Note:

*Item noted will be available in the future for the 60 ton to 80 ton cabinet.

Tempmaster® Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide

8

Tempmaster

General

Table 1: Physical data

Unit size 25 ton 30 ton 40 ton 50 ton 60 ton 70 ton 80 ton

Compressor data - standard capacity, standard efficiency

Quantity/size

(nominal HP) 1/4.5, 1/7, 1/10 1/5.5, 1/7,

1/7, 1/7.5

1/5.5, 1/8.5,

1/10, 1/11.5

1/7.5, 1/10,

1/11.5, 1/15

1/12, 1/12,

1/15, 1/15

1/10, 1/15,

1/15, 1/20

1/15, 1/15,

1/15, 1/20

Type Scroll Scroll Scroll Scroll Scroll Scroll Scroll

Capacity steps 7 11 15 15 8 9 7

Number of circuits 2 2 2 2 2 2 2

Compressor data - high capacity, standard efficiency

Quantity/size

(nominal HP) 1/5, 1/7.5, 1/10 1/5.5, 1/7,

1/7, 1/ 8.5

1/7, 1/13,

1/8.5, 1/10

1/8.5, 1/15,

1/7.5, 1/15

Type Scroll Scroll Scroll Scroll

Capacity steps 7 11 15 11

Number of circuits 2 2 2 2

Compressor data - standard capacity, high efficiency

Quantity/size

(nominal HP) 1/5, 1/7.5, 1/13 1/7, 1/7, 1/18.5 1/7.5, 1/7.5,

1/10, 1/13

1/10, 1/10,

1/12, 1/17.5

1/10, 1/15,

1/15, 1/17.5

1/13, 1/15,

1/15, 1/27

1/15, 1/15,

1/15, 1/27

Type Scroll Scroll Scroll Scroll Scroll Scroll Scroll

Capacity steps 15–100% 15–100% 15–100% 15–100% 15–100% 15–100% 15–100%

Number of circuits 2 2 2 2 2 2 2

Supply fan

Quantity of fans/

motors 1/1 1/1 1/1 1/1 2/2 2/2 2/2

Type Direct drive

plenum

Direct drive

plenum

Direct drive

plenum

Direct drive

plenum

Direct driven

plenum

Direct driven

plenum

Direct driven

plenum

Size (in.) 27 27 33 33 27 27 27

Motor size range each

fan (min to max HP) 5–25 5–25 10–50 10–50 5-30 5-30 5-30

Airflow range (min to

max CFM) 5,000–12,000 5,000–12,000 8,000–20,000 8,000–20,000 12,000-24,000 14,000-32,000 14,000-32,000

Total static pressure

range (min to max iwg) 1.0–8.0 1.0–8.0 1.0–8.0 1.0–8.0 1-8.3 1-8.3 1-8.3

Return fan

Quantity of fans/

motors 1/1 1/1 1/1 1/1 1/1 1/1 1/1

Type Belt-driven

plenum

Belt-driven

plenum

Belt-driven

plenum

Belt-driven

plenum

Direct driven

plenum

Direct driven

plenum

Direct driven

plenum

Size (in.) 27 27 30 30 33 33 33

Motor size range (min

to max HP) 5–10 5–10 5–20 5–20 7.5-40 7.5-40 7.5-40

Airflow range (min to

max CFM) 5,000–12,000 5,000–12,000 8,000–20,000 8,000–20,000 12,000-24,000 14,000-32,000 14,000-32,000

Total static pressure

range (min to max iwg) 0.5–3.0 0.5–3.0 0.5–3.0 0.5–3.0 0.5–3.0 0.5–3.0 0.5–3.0

Exhaust fan

Quantity of fans/

motors 1/1 1/1 1/1 1/1 1/1 1/1 1/1

Type Belt-driven

forward curved

Belt-driven

forward curved

Belt-driven

forward curved

Belt-driven

forward curved

Belt-driven

forward curved

Belt-driven

forward curved

Belt-driven

forward curved

Size (in.) 18–18 18–18 25–25 25–25 30-30 30-30 30-30

Motor size range (min

to max HP) 3–15 3–15 5–20 5–20 5-25 5-40 5-40

Tempmaster® Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide 9

Tempmaster

Table 1: Physical data

Unit size 25 ton 30 ton 40 ton 50 ton 60 ton 70 ton 80 ton

Airflow range (min to

max CFM) 5,000–12,000 5,000–12,000 8,000–20,000 8,000–20,000 12,000-24,000 14,000-32,000 14,000-32,000

Total static pressure

range (min to max iwg) 0.5–3.0 0.5–3.0 0.5–3.0 0.5–3.0 0.5–3.0 0.5–3.0 0.5–3.0

Condenser fan

Quantity 2 2 4 4 4 6 6

Type Propeller Propeller Propeller Propeller Propeller Propeller Propeller

Size (diameter in in.) 30 30 30 30 30 30 30

Power (HP) 2 2 2 2 2 2 2

Evaporator coil - standard capacity, standard efficiency

Size (sq. ft.) 24 24 36 36 49.5 66 66

Number of rows/fins

per in. 3/17 5/17 4/17 4/17 5/17 5/17 6/17

Size (tube diameter in

in.) 3/8 3/8 3/8 3/8 3/8 3/8 3/8

Evaporator coil - high capacity, standard efficiency

Size (sq. ft.) 24 24 36 36

Number of rows/fins

per in. 4/17 6/17 4/17 6/17

Size (tube diameter in

in.) 3/8 3/8 3/8 3/8

Evaporator coil - standard capacity, high efficiency

Size (sq. ft.) 24 24 36 36 49.5 66 66

Number of rows/fins

per in. 4/17 6/17 4/17 6/17 6/17 6/17 6/17

Size (tube diameter in

in.) 3/8 3/8 3/8 3/8 3/8 3/8 3/8

Hot gas reheat (HGRH) coil

Coil type Microchannel Microchannel Microchannel Microchannel Microchannel Microchannel Microchannel

Control type Modulating Modulating Modulating Modulating Modulating Modulating Modulating

Size (area in sq. ft./

thickness in in.) 19.5/0.8 19.5/0.8 19.5/1 19.5/1 28/1 33.4/1 33.4/1

Number of rows/fins

per in. 1/23 1/23 1/23 1/23 1/23 1/23 1/23

Minimum outside air

(OA) temperature for

mechanical cooling

45.0°F

Low ambient option

minimum OA

temperature for

mechanical cooling

-10.0°F

Condenser coil - standard capacity, standard efficiency

Size (sq. ft.) 61 61 98 98 153 191 191

Number of rows/fins

per in. 1/23 1/23 1/23 1/23 1/23 1/23 1/23

Size (thickness in in.) 0.8 0.8 0.8 1 1 1 1

Type Microchannel Microchannel Microchannel Microchannel Microchannel Microchannel Microchannel

Tempmaster® Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide

10

Tempmaster

Unit size 25 ton 30 ton 40 ton 50 ton 60 ton 70 ton 80 ton

Condenser coil - high capacity, standard efficiency

Size (sq. ft.) 61 61 98 98

Number of rows/fins

per in. 1/23 1/23 1/23 1/23

Size (thickness in in.) 0.8 0.8 0.8 1

Type Microchannel Microchannel Microchannel Microchannel

Condenser coil - standard capacity, high efficiency

Size (sq. ft.) 61 61 98 98 153 191 191

Number of rows/fins

per in. 1/23 1/23 1/23 1/23 1/23 1/23 1/23

Size (thickness in in.) 1 1 0.8 1 1 1 1

Type Microchannel Microchannel Microchannel Microchannel Microchannel Microchannel Microchannel

Energy recovery wheel (ERW) - High CFM

Cassette dimensions (L

in. x W in. x H in.) 50 x 4.36 x 50 50 x 4.36 x 50 62.42 x 6.07

x 62.42

62.42 x 6.07

x 62.42

Wheel segments 6 6 8 8

Motor (V, ph, Hz)

208-230/3/60,

460/3/60,

575/3/60

208-230/3/60,

460/3/60,

575/3/60

208-230/3/60,

460/3/60,

575/3/60

208-230/3/60,

460/3/60,

575/3/60

Horsepower (HP) 1/6 1/6 1/4 1/4

Filter type 2 in. MERV 8 Pleated

RA filters - size

(number) 25 x 25 (2) 25 x 25 (2) 15 x 20 (6) 15 x 20 (6)

OA filters - size

(number) 25 x 25 (2) 25 x 25 (2) 15 x 20 (6) 15 x 20 (6)

Energy recovery wheel (ERW) - low CFM

Cassette dimensions (L

in. x W in. x H in.) 44 x 4.36 x 44 44 x 4.36 x 44 56.19 x 4.36

x 56.19

56.19 x 4.36

x 56.19

Wheel segments 6 6 6 6

Motor (V / ph / Hz)

208-230/3/60,

460/3/60,

575/3/60

208-230/3/60,

460/3/60,

575/3/60

208-230/3/60,

460/3/60,

575/3/60

208-230/3/60,

460/3/60,

575/3/60

Horsepower (HP) 1/6 1/6 1/6 1/6

Filter type 2 in. MERV 8 Pleated

RA filters - size

(number) 25 x 25 (2) 25 x 25 (2) 15 x 20 (6) 15 x 20 (6)

OA filters - size

(number) 25 x 25 (2) 25 x 25 (2) 15 x 20 (6) 15 x 20 (6)

Electric heat (208 V / 230 V)

Size range - low/high

(kW) 50/100 50/100 60/120 60/120

Heating steps - low/

high 3/6 3/6 4/8 4/8

Electric heat (460 V/ 575 V)

Size range - low/high

(kW) 60/120 60/120 80/160 80/160

Heating steps - low/

high 3/6 3/6 4/8 4/8

Gas furnace

250 / 202.5 / 2 500 / 405 / 2 500 / 405 / 2

500 / 405 / 2 750 / 607.5 / 4 1000 / 810 / 4

Staged furnace sizes

(input/output/stages) 750 / 607.5 / 4 1,250 / 1012.5 / 6 1500 / 1215 / 6

Tempmaster® Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide 11

Tempmaster

Unit size 25 ton 30 ton 40 ton 50 ton 60 ton 70 ton 80 ton

Airflow range (min to

max CFM) 5,000–12,000 8,000–20,000 12,000-24,000 14,000-32,000 14,000-32,000

Gas heat steady state

efficiency (SSE) 81% 81% 81%

250 / 202.5 / 10:1 500 / 405 / 20:1 500 / 405 / 10:1

500 / 405 / 20:1 750 / 607.5 / 30:1 1000 / 810 / 20:1

Modulating furnace

sizes (input/output/

turndown) 750 / 607.5 / 30:1 1,250 / 1012.5 / 50:1 1500 / 1215 / 30:1

Airflow range (min to

max CFM) 5,000–12,000 8,000–20,000 12,000-24,000 14,000-32,000 14,000-32,000

Hot water coil

Coil tube diameter (in.) 1/2 1/2 1/2 1/2

Material Copper Tube/

Aluminum Fin

Copper Tube/

Aluminum Fin

Copper Tube/

Aluminum Fin

Copper Tube/

Aluminum Fin

Fins per in. - low/high 13/10 13/10 13/10 13/10

Size (H in. x L in.) /

rows low 25 x 70 / 1 25 x 70 / 1 42.5 x 70 / 1 42.5 x 70 / 1

Size (H in. x L in.) /

rows high 25 x 70 / 2 25 x 70 / 2 42.5 x 70 / 2 42.5 x 70 / 2

Steam coil

Coil tube diameter (in.) 1 1 1 1

Material Copper Tube/

Aluminum Fin

Copper Tube/

Aluminum Fin

Copper Tube/

Aluminum Fin

Copper Tube/

Aluminum Fin

Fins per in. - low/high 8/14 8/14 8/14 8/14

Size (H in. x L in.) /

rows low 24 x 68 / 1 24 x 68 / 1 42 x 68 / 1 42 x 68 / 1

Size (H in. x L in.) /

rows high 24 x 68 / 1 24 x 68 / 1 42 x 68 / 1 42 x 68 / 1

Draw-through - 2 in. throwaway angled filters

Quantity 18 24 28

Size (L in. x W in.) 16 x 20 16 x 20 16 x 24

Total filter face area

(sq. ft.) 40.00 53.33 70.83

Draw-through - 2 in. MERV 8 angled filters

Quantity 18 24 28

Size (L in. x W in.) 16 x 20 16 x 20 16 x 24

Total filter face area

(sq. ft.) 40.00 53.33 70.83

Draw-through - MERV 15 bag filters with 2 in. MERV 8 pre-filters

Quantity 4 / 6 8 / 4 9 / 6

Size (L in. x

W in.) 24 x 24 / 16 x 20 24 x 24 / 12 x 24 24 x 24 / 20 x 24

Pre-filters Total filter

face area

(sq. ft.)

29.33 40.00 53.61

Quantity 3 / 3 / 2 / 2 6 / 7 / 2 9 / 6

Size (L in. x

W in.)

24 x 24 / 24 x 20 /

12 x 20 / 12 x 24 24 x 24 / 12 x 24 / 12 x 12 24 x 24 / 20 x 24

Bag filters Total filter

face area

(sq. ft.)

29.33 40.00 53.02

Tempmaster® Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide

12

Tempmaster

Unit size 25 ton 30 ton 40 ton 50 ton 60 ton 70 ton 80 ton

Draw-through - MERV 14 rigid filters with 2 in. MERV 8 pre-filters

Quantity 4 / 4 8 / 4 9 / 6

Size (L in. x

W in.) 24 x 24 / 24 x 20 24 x 24 / 12 x 24 24 x 24 / 20 x 24

Pre-filters Total filter

face area

(sq. ft.)

29.33 40.00 53.61

Quantity 3 / 3 / 2 / 2 6 / 7 / 2 9 / 6

Size (L in. x

W in.)

24 x 24 / 24 x 20 /

12 x 20 / 12 x 24 24 x 24 / 12 x 24 / 12 x 12 24 x 24 / 20 x 24

Rigid

filters Total filter

face area

(sq. ft.)

29.33 40.00 53.02

Draw-through - vertical 4 in. MERV 8 filters

Quantity 6 / 6 18 9 / 6

Size (L in. x W in.) 16 x 25 / 16 x 20 16 x 20 24 x 24 / 20 x 24

Total filter face area

(sq. ft.) 30.00 40.00 53.02

Final filters - MERV 15 bag filters with 2 in. pre-filters

Quantity 4 / 4 8 / 3 6 / 8

Size (L in. x

W in.) 24 x 24 / 20 x 20 24 x 24 / 12 x 24 24 x 24 / 20 x 24

Pre-filters Total filter

face area

(sq. ft.)

27.11 38.00 48.47

Quantity 3 / 4 / 2 6 / 7 6 / 4 / 4

Size (L in. x

W in.) 24 x 24 / 20 x 20 / 12 x 24 24 x 24 / 12 x 24 24 x 24 / 24 x 20 / 20 x 24

Bag filters Total filter

face area

(sq. ft.)

27.11 38.00 47.93

Final filters - MERV 14 rigid filters with 2 in. pre-filters

Quantity 4 / 4 8 / 3 6 / 8

Size (L in. x

W in.) 24 x 24 / 20 x 20 24 x 24 / 12 x 24 24 x 24 / 20 x 24

Pre-filters Total filter

face area

(sq. ft.)

27.11 38.00 48.47

Quantity 3 / 4 / 2 6 / 7 9 / 6

Size (L in. x

W in.) 24 x 24 / 20 x 20 / 12 x 24 24 x 24 / 12 x 24 24 x 24 / 20 x 24

Rigid

filters Total filter

face area

(sq. ft.)

27.11 38.00 53.02

Tempmaster® Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide 13

Tempmaster

Unit size 25 ton 30 ton 40 ton 50 ton 60 ton 70 ton 80 ton

Final filters - MERV 17 HEPA® filters with 2 in. pre-filters

Quantity 4 / 4 8 / 3

Size (L in. x

W in.) 24 x 24 / 20 x 20 24 x 24 / 12 x 24

Pre-filters Total filter

face area

(sq. ft.)

27.11 38.00

Quantity 6.00 15 / 3

Size (L in. x

W in.) 24 x 24 12 x 24 / 12 x 17

HEPA®

filters Total filter

face area

(sq. ft.)

24.00 34.26

Figure 1: 25–80 ton packaged rooftop unit cabinet assembly

Note: Some components listed are optional.

1. Economizer 8. Condenser coil cleaning hatch (not shown)

2. Evaporator coil 9. Unit controller and power

3. Direct drive plenum (DDP) supply fan 10. Filter section

4. Modulating or staged gas heat 11. Collapsible rain hoods

5. Condenser maintenance safety tie-off 12. Exhaust or return fan

6. Condenser fans 13. Final filter

7. Scroll compressors

Tempmaster® Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide

14

Tempmaster

Introduction

The Tempmaster® Omni™ Premier rooftop units are

a single package with cooling only or cooling with

gas, electric, hot water, or steam heat. The units

can be ordered with a variety of factory-installed

options.

The units are designed to be installed on a factory

provided roof curb, a field manufactured roof curb,

a field provided dunnage steel metal frame, or

at grade level on a concrete pad. The units are

intended for outdoor installations only.

The units are completely assembled on rigid,

permanently attached base rails. All internal piping,

electrical wiring, and the proper refrigerant charge

is completed at the factory, as well as factory

testing. The units require field electrical wiring

for power and controls, field connected ductwork,

field connected gas piping (if applicable), field

connected hot water or steam piping (if applicable),

and condensate drain(s). Units with gas heat also

require the installation of a factory provided flue gas

outlet hood.

The Premier rooftop unit is designed for

serviceability. With small details, such as a

maintenance safety tie-off on the roof of the

condenser section that complies with OSHA

requirements, along with an optional single

handle latching mechanism for doors, the unit was

designed for easy service.

Options to make the unit serviceable include a

convenience outlet to power lights and tools:

internal lights in the air handler section; viewports

in doors of serviceable compartments to enable

easier unit inspection; and extended grease lines

to simplify fan bearing lubrication for belt-driven

return and exhaust fans. Standard DDP supply

fans do not require lubricating the fan bearings or

changing belts.

Numerous refrigeration options are also available,

including replaceable core filter driers, liquid and

suction isolation valves, as well as high and low

pressure transducers in each circuit that enable

easier sub-cooling and superheat measurements.

Compare the model number on the unit you're

installing or maintaining to the Nomenclature 25

ton to 80 ton model number included in this manual

to find the options that were selected for your unit.

Ecological and economical

design

The Premier rooftop units feature a capacity range

from 25 ton to 80 ton. The units are configured

to order with a wide selection of factory installed

options. A complete range of heating and cooling

options are provided to meet today’s customers’

requirements. The unit has also been thoughtfully

designed to include several features that reduce

service and installation time.

Tempmaster provides a product offering that meets

or exceeds the following regulations:

• ASHRAE 90.1-2019 EER/IEER requirements

• Department of Energy 2023 IEER

requirements

• ASHRAE 189.1-2014 IEER requirements

• Consortium of Energy Efficiency (CEE) 2019

highest tier efficiency ratings

• California Title 24-2016 standards

• ASHRAE 62 requirements for indoor air quality

(IAQ)

• All units are rated in accordance with the AHRI

Standard 340/360

All units with gas heat shall meet the requirements

of AHRI CFRN Certification Program and Code

of Federal Regulations, 10 CFR Part 431. This

references efficiency test method in standard ANSI

Z21.47.

Condensing section

Scroll compressors

Reliable, efficient, trouble-free operation is the

true measure of a rooftop unit’s value. That’s why

Premier air conditioners use established scroll-

compressor technology to deliver dependable,

economical performance in a wide range of

applications.

Premier units offer the latest generation of

compressor enhancements added to the scroll’s

inherent strengths. The simplicity of a hermetic

scroll compressor allows the use of fewer moving

parts to minimize breakdown.

Multiple compressor staging

Through the use of the standard fixed speed or

optional variable speed drive scroll compressors,

the unit has the capability to stage its cooling by

enabling and disabling compressors on multiple

circuits. Smaller steps of cooling capacity provide

tighter control of the building environment

and occupant comfort while optimizing energy

efficiency.

The unit provides a best in class, number of cooling

capacity steps, providing seven or more steps of

capacity control, on fixed speed compressors.

Tempmaster® Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide 15

Tempmaster

Variable speed drive compressors provide a

modulating cooling capacity range of 15–100%.

Compressor circuiting

The Premier unit is designed to achieve efficient

system capacity by using multiple compressors

and refrigeration circuits. With multiple circuits, if a

compressor should ever fail on one circuit, the other

circuit remains operational to work to maintain

occupied loads. This means a more reliable unit and

less equipment downtime.

Compressor sound blankets

Optional factory installed compressor sound

blankets can help to further reduce sound radiated

from the compressor. In applications such as

downtown areas, where acoustics are important,

sound blankets are especially helpful with reducing

outdoor unit sound.

Replaceable core filter driers

The optional replaceable core filter driers remove

moisture, dirt, and debris from the refrigeration

circuit in the event it is opened. Additionally, the

optional replaceable core filter drier helps to

maintain and optimize the unit's refrigeration

system.

Low ambient operation

Head pressure control is accomplished via a variable

frequency drive (VFD) motor controller rather than

an inefficient and noisy condenser fan damper.

By varying the speed of the condenser fan, better

control and quieter operation is obtained during the

colder months.

In low ambient mode, compressors have the

capability to operate down to -10.0°F and resume

cooling at -7.0°F, thereby giving customers an

improved envelope control.

Condenser fan motors

The condenser fan motors used on the units are

permanently lubricated open drip proof (ODP) type

to provide maximum durability through any season.

The roof above the condensers includes a drain

location to prevent pooling of water.

Condenser coils

Condenser coils are available to suit almost any

type of application. Post-coated aluminum fins are

available.

The use of an epoxy coated coil is recommended for

units installed in a corrosive environment.

Condenser coil protection

The unit is available with a wire mesh guard or

louvered hail guard for optimum coil protection.

Blank section

Sound attenuator

To meet customer specific requirements in sound-

sensitive applications such as theaters, libraries,

or hospitals, a sound attenuator is provided as an

option in the downstream section of the cooling

coil. Sound travels through the supply air duct

path, hence it needs particular attention. Contact

Tempmaster Application Engineering for application

specific requirements.

Humidifier

A humidifier option should be considered

for applications that have dry air and need

humidification in the occupied space. The unit

ships with a steam control valve, cast iron steam

traps, and an iron wye strainer and can be easily

connected on the bottom right-hand side of the

unit. An additional drain pan is provided in the

humidifier section for condensate removal.

Note: Steam must be field provided.

Air blender

The unit has an option to install an air blender in the

pre-evaporator section to help improve temperature

control accuracy, mixing of outdoor air, and evening

of the air velocity profile.

Evaporator section

Evaporator coils

Interlaced, circuited evaporator coils are a standard

feature on all units. Copper tubes are internally

enhanced and expanded to bond with either

aluminum or copper fins. All coils are pressure

tested at the factory to meet the established

quality standards. Epoxy coated coils are optionally

provided as an enhanced feature to provide

substantial resistance to corrosion.

Modulating hot gas reheat

The unit has an option for modulating hot

gas reheat (HGRH). The HGRH system is an

efficient approach for moisture removal and

dehumidification of the space. Temperature and

humidity are efficiently maintained in the space,

reducing energy costs and improving customer

comfort.

Tempmaster® Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide

16

Tempmaster

Double sloped stainless steel drain pan

The unit is offered with a standard stainless steel

drain pan that meets ASHRAE 62 requirements for

condensate drainage removal, thus improving IAQ.

An intermediate drain pan is offered on 40 ton to 80

ton units that has drip tubes to guide condensate to

the main drain pan.

To monitor condensate accumulation and notify

the customer of a possible overflow concern, a

condensate overflow switch option is provided for

all units.

Heating section

Gas heat

For gas heat, the gas utilizes an induced-draft gas

furnace designed for high efficiency and reliability.

The furnace uses an aluminized steel tubular

heat exchanger and operates at temperatures

sufficient to prevent acidic exhaust gases from

condensing in the heat exchanger at low fire rates,

unlike drum and tube style furnaces that generate

condensation formation. An optional stainless steel

heat exchanger is also available.

Fully modulating gas heat and greater steps of

capacity control offer superior design performance

while maintaining optimum occupant comfort. The

gas heat option allows up to 50:1 turndown for

modulating gas furnace and up to six stages for

staged heating control. Refer to the gas furnace

section in Table 1.

Electric heat

Electric heat is available either with staged or

modulating (silicon controlled rectifier (SCR)) control

from 50 kW up to 160 kW, applicable to 25 ton to 50

ton.

Depending on the size of the heat required, the

unit can have multiple steps of control helping

to provide tighter control of the supply and zone

conditioned air. With the utilization of this multi-

step function, the unit can effectively reduce energy

consumption by bringing on smaller stages of heat

while maintaining the maximum level of comfort.

Hydronic heat

The unit has a hydronic low or high heat option. The

unit ships to the site with a completed coil, including

headers and connections that are tested to ensure

leak-free operation.

Customers can opt to have valves shipped with

the unit. For ease of installation, the unit has hole

markings for the field to drill holes either through

the base or side of the unit.

Air management

Fans

High efficiency fans are used to improve application

flexibility and address sound and application

concerns. The fan section is equipped with a single

width, single inlet (SWSI) airfoil plenum wheel on 25

ton to 50 ton and dual SWSI airfoil plenum wheels

on 60 ton to 80 ton as a standard feature. Plenum

fans are direct drive. An exhaust fan is provided with

a double width, double inlet (DWDI) forward curved

centrifugal type fan, while the return fan has a SWSI

airfoil plenum wheel on 25 ton to 50 ton. On 60 ton

to 80 ton units with return fan, a SWSI airfoil direct

driven plenum wheel is available.

Premium efficiency motors

Premium efficiency motors are available for

optimum energy efficiency. All motors used on

the rooftop air conditioner meet U.S. EPACT 1992

minimum requirements. High efficiency motors

are standard. Motors are available in ODP or totally

enclosed fan-cooled (TEFC) construction.

Building pressure control

Return fan, exhaust fan, and barometric relief

damper are available to meet building pressure

control requirements. Fan tracking is offered as

an option with supply and return fan airflows. The

return fan capacity can be controlled to maintain

a constant difference between supply and return

airflow. A fan bypass option is provided on return

(25 ton to 50 ton) and exhaust (25 ton to 80 ton)

fans that enables the fan to continue operation, in

case of failure in the primary drive. A redundant

VFD option is available for DDP return fan (60 ton to

80 ton), to ensure continuous operation. Extended

grease lines are an option for return/exhaust fan

shaft bearings to simplify bearing lubrication.

Variable frequency drives

The unit is provided with a standard VFD for all

supply and return fan applications. An exhaust fan

with VFD is available as an option. The VFD can

optimize system performance by modulating the

fan motor speed to reduce energy consumption and

provide precise airflow control.

WARNING

Never operate the unit without a VFD controlling the

DDP supply and return fan. Bypassing the VFD will

cause a catastrophic failure of the DDP supply and

return fan.

Tempmaster® Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide 17

Tempmaster

Line reactors are provided as an option for fans

with a VFD that help reduce harmonic distortion. On

25-50 ton units to ensure continuous operation, the

supply fan has an option for a redundant VFD. This

VFD is enabled in case of failure of the primary VFD.

On 60-80 ton units, to ensure continuous operation

dual supply fans have an option for dual VFD's.

These VFD's are supplied to independently operate

the two supply fan motors. A shaft grounding ring

is an option available with the unit to protect motor

bearings by diverting motor bearing currents safely

to the ground.

Fan spring isolation

1 in. spring, 2 in. spring, and seismic spring fan

isolation are available as an option to prevent

vibration transmission from the unit’s fans to the

building.

Energy recovery wheel

The unit is provided with a single speed and

variable speed energy recovery wheel (ERW)

option. Operating costs are reduced significantly

by transferring energy from the exiting exhaust

air to the entering outside air, thereby reducing

the cooling load of the unit. Freeze protection is

available as standard for all ERWs. The wheel is

specially designed to slide out of the unit for easy

maintenance of wheel segments.

Controls

Rooftop unit controller

The unit is supplied with a factory commissioned,

configured, and run tested Applied Smart

Equipment controller. The unit controller is easily

compatible with all Smart Equipment platforms.

The software and user programmed setpoints

are stored in nonvolatile memory for the 20-year

expected life of the microprocessor. The real time

clock (RTC) information is retained for a minimum of

72 hours during power loss with a super capacitor-

backed circuit.

The unit ships with a USB drive installed in the port

on the main control board, which is used to capture

all trend data and start-up wizard results. This USB

drive should remain in the main control board.

The unit controller is accompanied with an organic

light-emitting diode (OLED) display that provides

a 5 row × 35 character display. The display is a

simplified design, making it easy to understand.

Specific keys are individually assigned for quick

selections. An optional color wide screen, thin

film transistor (TFT) with multitouch capacitive

touchscreen and 1280 × 800 resolution is also

available to order factory installed or to field install.

The user interface display along with all VFD

displays are located in the control cabinet section.

When cabinet and control panel sizes allow, the

display mounted panel can be adjusted according to

the height preference of the operator.

BACnet®/Modbus™/N2/Customer

terminal board

Using the standard Applied Smart Equipment

controller, the unit can be adapted to operate

with any building automation system (BAS) that

is BACnet, Modbus, or N2 compatible, making it

the most flexible commercial rooftop unit on the

market.

For BACnet IP integration, an optional BACnet IP

interface board is available during unit selection.

Indoor air quality

Indoor air quality

Outside air economizers provide energy savings

in free cooling mode and can provide a healthier

and more comfortable building environment by

introducing fresh outside air into the building

as needed. Dry bulb, single, or dual enthalpy

economizer options are provided with the unit. Fault

detection and diagnostics (FDD) monitoring and

alarms are a standard feature with the economizer

to meet ASHRAE 90.1-2019 and California Title

24-2016 standards.

Optional airflow measurement is provided for

accurate tracking of air quantity and alerting

the occupants or building owner to unhealthy

situations. Low and ultra-low leak dampers are

provided as an option to meet application specific

requirements.

Double wall construction

The unit incorporates foam-injected double wall

construction for maximum rigidity as standard on

all units. Double wall construction of the roof, floor,

doors, and walls prevents insulation from entering

the conditioned air. The inner liner also facilitates

periodic cleaning of the unit to prevent harmful

buildup of bacteria or contaminants.

Demand control ventilation

To improve IAQ and help manage indoor

pollutants,such as carbon dioxide (CO2) or other

harmful airborne contaminates, out of the occupied

spaces for maximum comfort and safety, the unit

is provided with built-in sequences for demand

control ventilation (DCV).

Tempmaster® Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide

18

Tempmaster

The unit has adaptive controls to monitor indoor

CO2 or comparative CO2 requirements. This helps

the unit to introduce a variable amount of fresh

air into the building, maintain IAQ, and improve

customer comfort while reducing energy costs.

Smoke control

The unit is offered with factory installed supply and

return smoke detector options. Auxiliary smoke

control points are also available for smoke purge,

pressurization, and de-pressurization sequences

using the optional customer terminal board. These

sequences are assigned higher priorities to ensure

customer safety.

Filtration

The unit is configured for various types of draw-

through and final filtration options to meet the

different needs and requirements of today's

rooftop applications. This includes throwaway,

pleated, cleanable, and high efficiency filters. Filter

transducers and magnehelic gauges are available to

monitor contamination in filters.

Ultraviolet lights

UV lights are offered as an option and are installed

in the downstream side of evaporator coil. The

UV lights help improve system efficiency, indoor

environmental quality, and occupant comfort.

Growth of mold and bacteria is inhibited when UV

lights are ON. To ensure operator safety, all doors

that have access to UV lights are interlocked with a

switch that disables UV light operation when a door

is opened.

Electrical

Single point power

The unit comes standard with single point power

connections to make installation quick and easy.

Dual point power

Applications that require the mechanical heating

and cooling functions to be separated from the air

handling functions come equipped with dual point

power. The air handling function includes the ability

to operate gas and hydronic heat. This enables the

unit to be operated in an emergency condition while

minimizing power consumption.

Power phase monitor

A power phase monitor is offered as standard

for all products. On dual point power, the phase

monitor is provided on both electrical circuits. The

power phase monitor helps protect the unit from

certain electrical issues, such as phase loss, phase

imbalance, and high and low voltage. To ensure

operator safety, high and low voltage connections

are separated in the controls cabinet.

Unit-mounted disconnect, 65 kA SCCR

Factory provided disconnect is available as an option

to minimize time during installation of equipment

and to reduce necessary field installed items. 65 kA

short circuit current rating (SCCR) is available as an

option to safely withstand the short circuit current.

Service and Installation

Split ship

Tempmaster Omni Premier 60 ton to 80 ton units

are provided with a split ship option, to meet

specific applications. Split ship units are factory

tested, pre-charged with refrigerant and delivered

to the job site split in two segments (air handling

and condenser section) for an easy lift and seamless

integration between power and refrigeration

connections. Units which are shipped split are

intended to be reconnected into one on a common

curb.

See the installation instructions, found in the

Tempmaster Omni™ Premier Split Ship Assembly

Installation Manual (6011418-TIM) shipped with the

unit.

Internal lights

Marine LED lights are offered as a factory installed

option. Servicing or troubleshooting the unit is

simplified by the presence of lights that improve

cabinet visibility. Depending on the options selected,

lights are installed in the pre and post evaporator,

economizer, evaporator coil, and supply fan

sections. The internal lights switch is located in the

low voltage side of control panel.

Access doors, padlocks, viewports,

safety latch and door tiebacks

Full-sized access doors provide easy access into

the unit for routine maintenance and inspection.

Doors are provided with a padlock option to secure

them from unauthorized access and improve site

safety. Specially designed viewports are offered as

an option on access doors that help with inspection

of the unit under operation. A safety latch that

requires a 5/16 in. Allen wrench is standard on

all positive pressure doors, and door tiebacks are

standard on all doors to secure them for operator

safety during servicing. Refer to the technical

supplement, Installing door tie-back brackets

(5881370-UTS-A-0420) for installation instructions of

Tempmaster® Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide 19

Tempmaster

door tie-back brackets that are shipped along with

the unit.

Service valves and sight glasses

Suction, discharge, and liquid line valves are

provided as an option for isolation, monitoring

pressures, reclamation, and charging of refrigerant

to minimize downtime and simplify service and

repair. A sight glass is a standard feature on all

units and is located in an easy access area for quick

inspection of refrigerant in the unit. Units with

replaceable core filter driers include liquid line

valves in the upstream and downstream section to

allow for ease of maintenance.

Convenience outlet

For maintenance tasks requiring power tools, an

optional 115 V, 15 amp GFCI continuous duty outlet

can power lights, drills, or any other power hand

tools needed.

Condenser safety tie-off

The unit is provided with a condenser safety tie-

off on the condenser section roof as standard on

all units. A safety harness can be secured by the

operator to the tie-off while servicing the unit to

prevent an accidental fall from the unit.

Condenser cleaning hatch

Periodic cleaning of condenser coils has never been

easier. The 25 ton to 60 ton units (Figure 59 and

Figure 60) are provided with hatches on both sides

of the condenser frame. On 70 ton to 80 ton units

(Figure 61), the dual hatches are provided on the

accessible section of the condenser.

Burglar bars

The units are designed to provide the customer

peace of mind. Intrusion through the ductwork

is prevented by installing burglar bars in the

accessible sections with a bottom opening.

Inlet, belt guard and spare belts

To ensure operator safety, optional inlet guards

are provided on the supply fan inlet, and optional

belt guards are provided to enclose the drive and

sheave package on the return (25 ton to 50 ton) and

exhaust (25 ton to 80 ton) fan. A spare set of belts

for the return (25 ton to 50 ton) and exhaust (25 ton

to 80 ton) fan are available as a ship loose option.

Start-up and air balancing wizard

One of the most critical phases of the unit's life is

during installation and start-up. Proper start-up

ensures the unit operates without any trouble. The

unit controller has a start-up wizard, which ensures

field technicians follow all start-up procedures as

mandated by the start-up documentation. All testing

data is stored and can be downloaded to a USB.

For any unit that has dampers, fans, or airflow

measurement stations, air balancing is critical. The

unit controller has an air balancing wizard that

assists both technicians and commissioning agents

to test and calibrate airflow.

Factory run-tested

Each unit is subjected to a series of quality

assurance checks as well as an automated quality

control process before being run-tested. Fans and

drives are checked for proper balancing at the

factory during testing. The factory run-test ensures

safe, proper operation when the unit is installed and

reduces installation and commissioning time.

RTUToolKit app and QR code

Tempmaster believes in empowering our customers

with all unit-specific information at all times, even

on the roof. Download the RTUToolKit app, available

through the Apple® App Store® and the Google

Play™ store.

In the app, using the included QR code scanner,

users have the ability to scan the QR code on a

unit. The QR code is unique to each manufactured

unit and provides information specific to the unit

installed.

Figure 2: RTUToolKit app

Tempmaster® Omni™ Premier 25 Ton to 80 Ton Rooftop Units Installation and Maintenance Guide

20

Tempmaster

This manual suits for next models

6

Table of contents

Other TempMaster Air Conditioner manuals