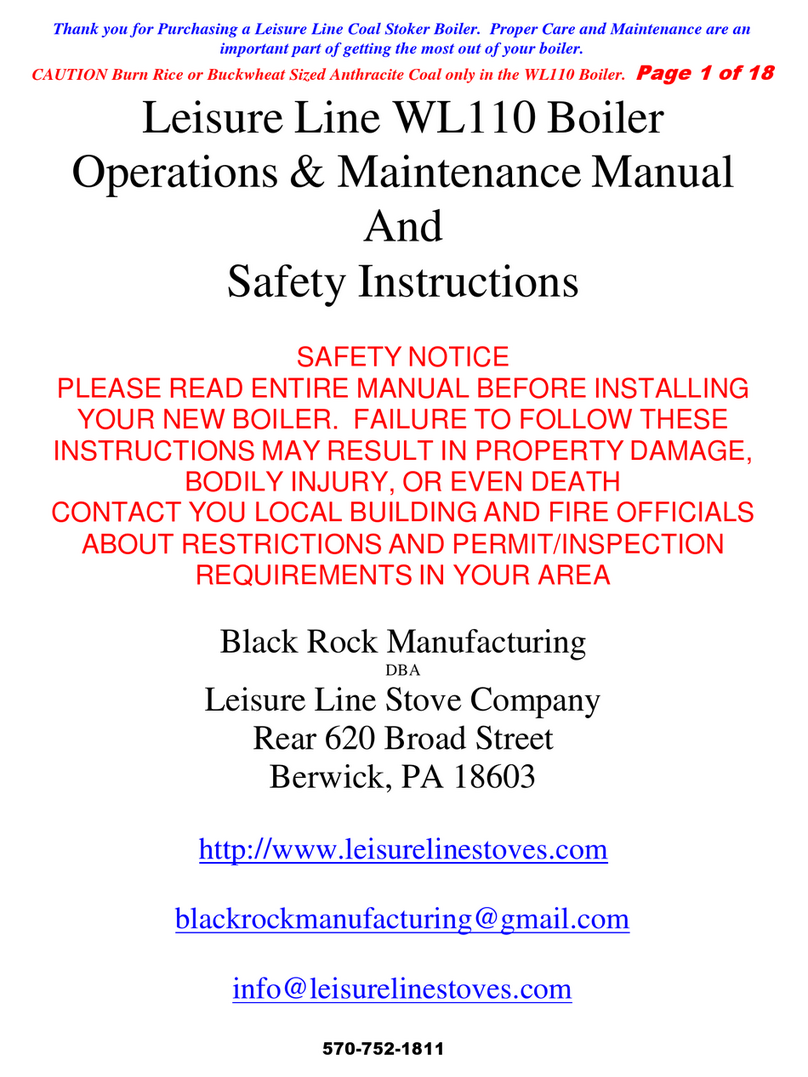

Automatic boiler for wood pellets

2

CONTENT

COntent ......................................................................................................................................................2

pictures.......................................................................................................................................................3

TABle..........................................................................................................................................................4

1IMPORTANT NOTES ..............................................................................................................................5

2use of the boiler and its advantages........................................................................................................6

3Technical data of the boilers KP x2S, KP X2 - ES ......................................................................................7

4structural description of products............................................................................................................8

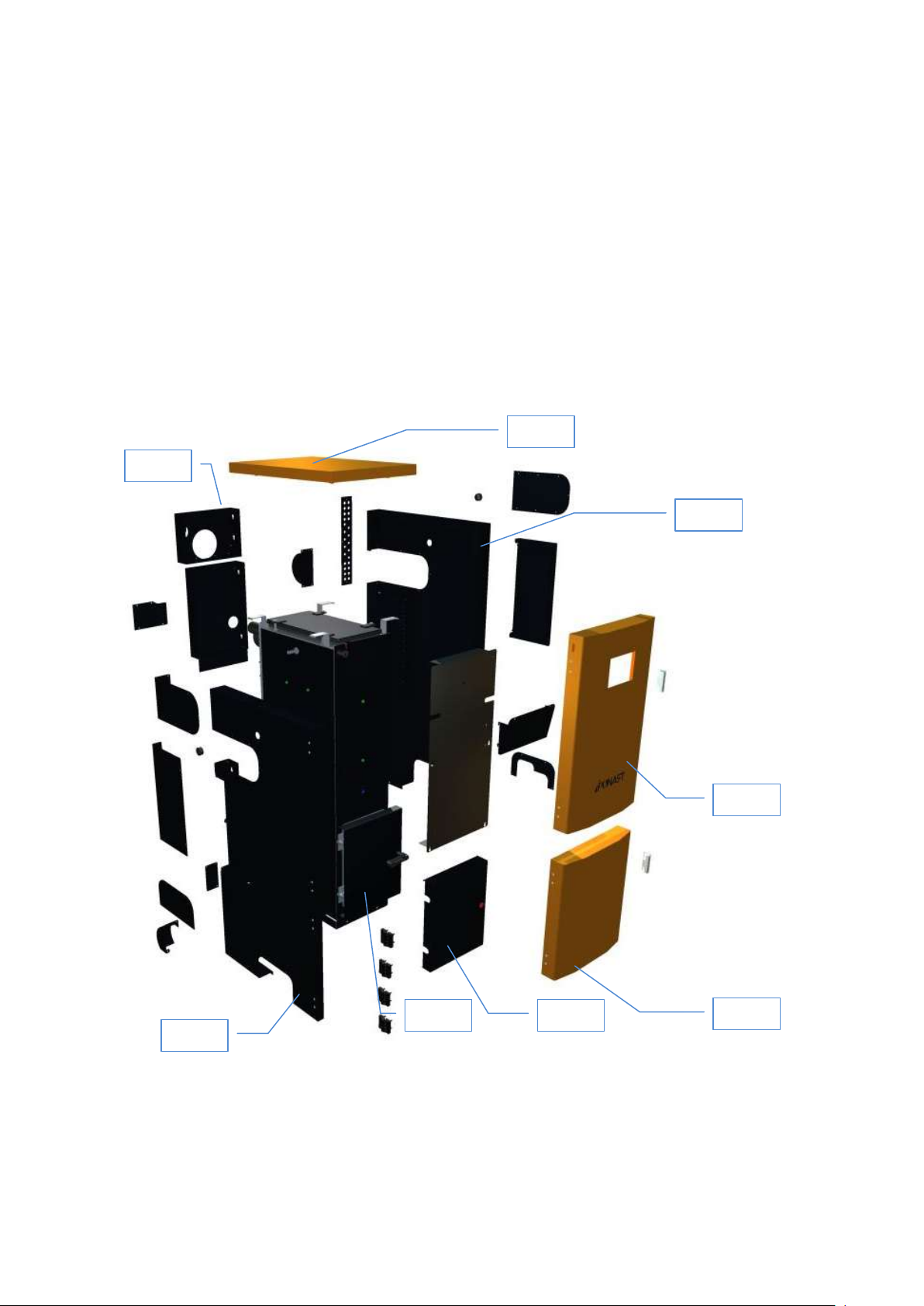

PICTURE OF PRODUCT AND MAIN PARTS......................................................................................................8

4.1 BOILER BODY, SCHEMA OF THE PRODUCTS AND DESCRIPTION OF THE MAIN PARTS.........................9

Boiler body..................................................................................................................................................9

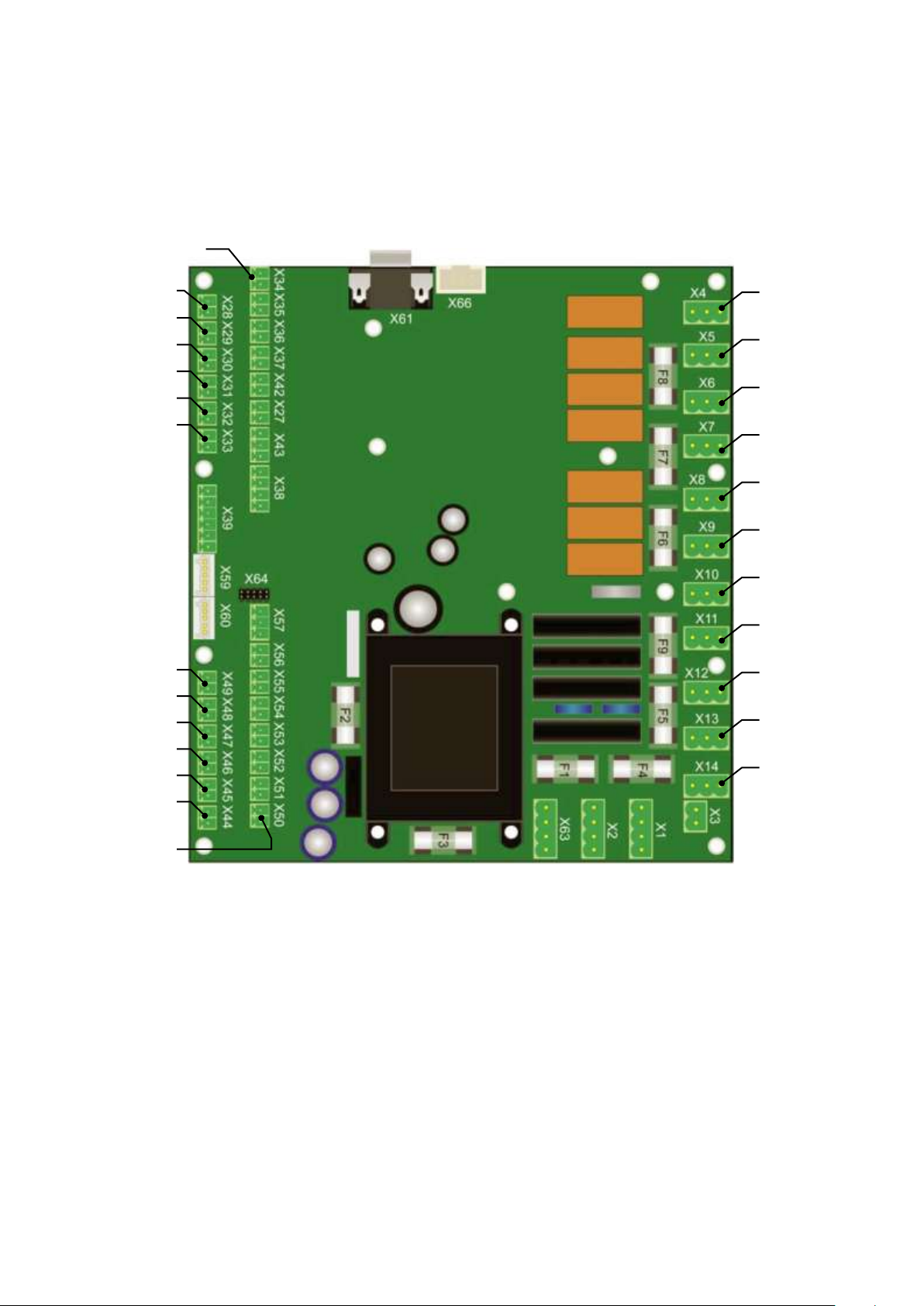

4.2 CONTROL UNIT ............................................................................................................................10

4.2.1 Boiler Function Module HZS 521-G........................................................................................11

4.2.1.1 Technical base data .........................................................................................................13

4.2.2 Terminal HZS 555-S with USB .............................................................................................14

4.2.2.1 Description......................................................................................................................14

CLEANING THE TOUCH SCREEN ..............................................................................................................14

CAUTION!...........................................................................................................................................14

Before cleaning the touch screen, the terminal must first be turned off to avoid unintentionally triggering

functions or commands!.......................................................................................................................14

4.2.2.2 Technical data.................................................................................................................14

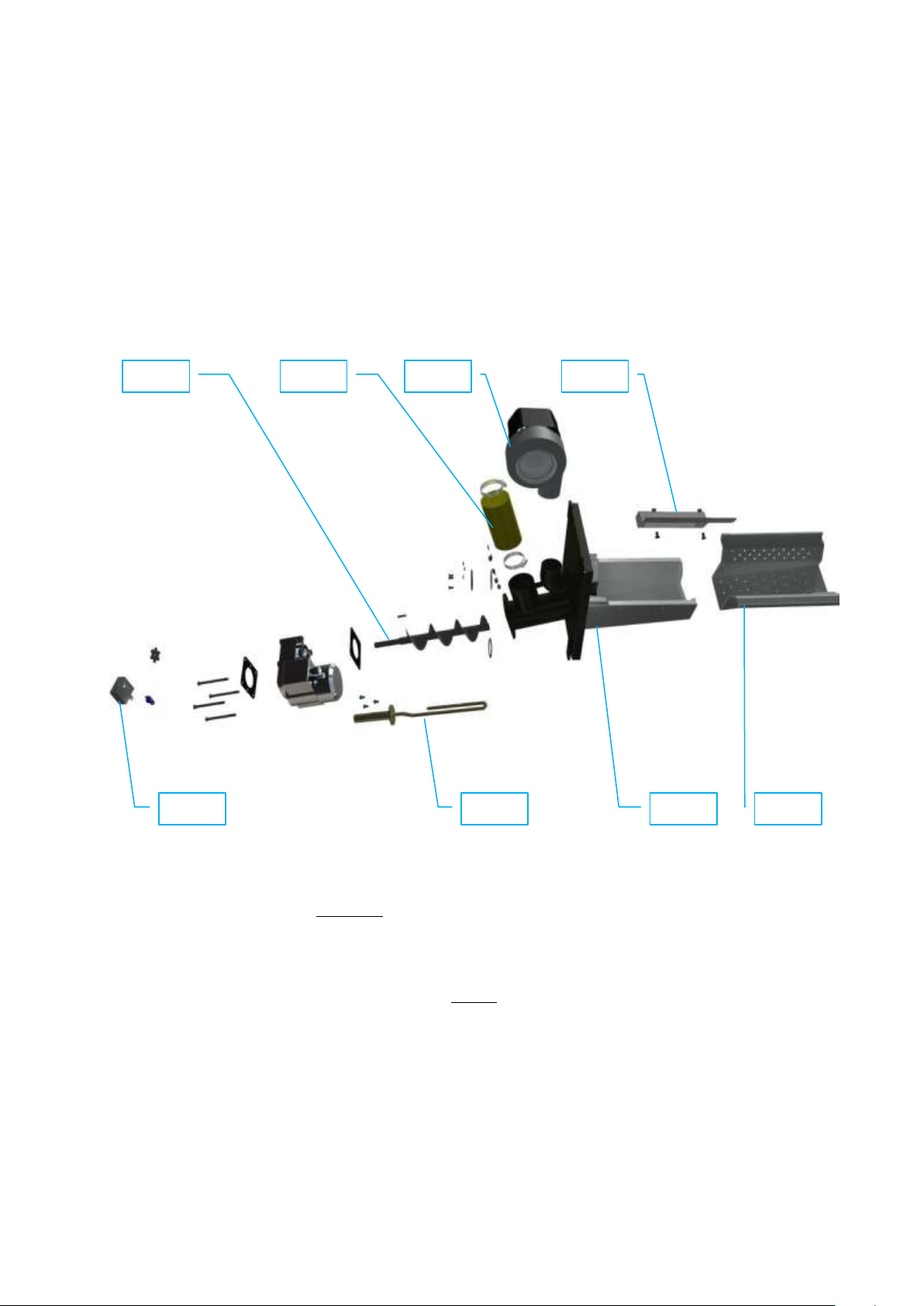

4.3 BURNER HEATING CHAMBER INCL. FEEDER F1 WITH INDEPENDENT DRIVE.....................................16

CERAMIC PARTS.....................................................................................................................................17

4.4 FEEDER F1 WITH INDEPENDENT DRIVE (FROM FUEL STORAGE)......................................................18

4.5 BOILER SHEATHING INCLUDING HEAT INSULATION.......................................................................19

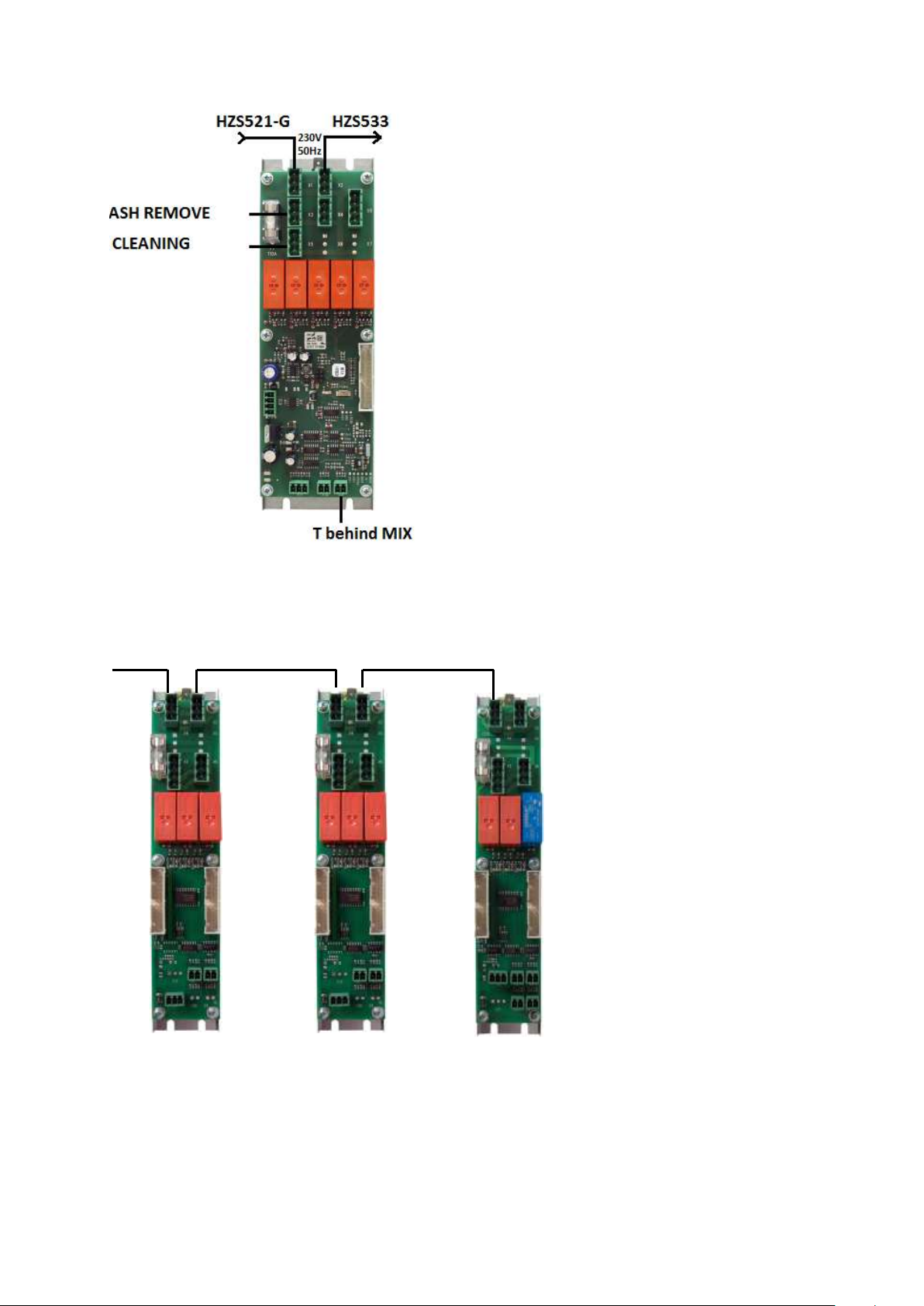

4.6 CLEANING SYSTEM.......................................................................................................................22

4.6.1 Ash removal .......................................................................................................................22

4.6.2 Heat exchanger cleaning .....................................................................................................22

4.6.3 External ash container.........................................................................................................23

4.7 STANDARD ACCESSORIES.............................................................................................................24

4.8 OPTIONAL ACCESSORIES..............................................................................................................24

4.9 FUEL BIN .....................................................................................................................................24

5Placement OF THE PRODUCT IN BOILER ROOMS, PRINCIPLES OF INSTALLATION ...................................26

5.1 PLACEMENT OF PRODUCTS IN BOILER ROOMS...............................................................................26

5.2 SAFE DISTANCE FROM COMBUSTIBLE MATERIAL............................................................................26

5.3 LEGISLATION IN FORCE................................................................................................................26

4.1.1 Heating system and boiler ...................................................................................................26

4.1.2 Venting ..............................................................................................................................26

4.1.3 Fire regulations...................................................................................................................27

4.1.4 Electrical ............................................................................................................................27

4.1.5 Protection against noise.......................................................................................................27

5.4 STORAGE OF FUEL .......................................................................................................................27

5.5 BOILER ROOM VENTILATION ........................................................................................................27

6putting the PRODUCTS INTO OPERATION .............................................................................................28

6.1 CONNECTION TO THE SYSTEM......................................................................................................28

6.2 INSTALLATION OF THE BURNER....................................................................................................29

6.3 INSTALATION OF THE CERAMIC CATALYTIC REFLECTOR ................................................................30

6.4 INSTALLATION OF SECONDARY CERAMIC GRATE ...........................................................................31

6.5 INSTALLATION OF CERAMIC SHIELD .............................................................................................32

6.6 CONNECTION OF ELECTRICAL PARTS ............................................................................................32

6.7 CHECKING TASKS BEFORE BOILER FIRST OPERATION ....................................................................33

7boiler service and maintanance during operation....................................................................................34

7.1 SERVICE ......................................................................................................................................34

7.1.1 Refueling............................................................................................................................34

7.1.2 Emptying of the external container .......................................................................................34

7.1.3 Flue gases exchanger cleaning .............................................................................................35

7.2 MAINTANANCE.............................................................................................................................35

7.2.1 Burnt gases exchanger cleaning ...........................................................................................35

7.2.2 Burner grate cleaning ..........................................................................................................35

7.2.3 Ceramic grate cleaning ........................................................................................................35

7.2.4 Annual audit.......................................................................................................................36

8disposal of product after teh end of its service life..................................................................................38

8.1 NATURAL PERSON ........................................................................................................................38

8.2 LEGAL ENTITY..............................................................................................................................38