The global Selection 333SK User manual

The L

Selection

333SK

HIGH

SPEED

LOCKSTITCH

SEWING

MACHINE

WITH

EDGE

CUTTER

Service

manual

Parts

catalog

From the library of: Superior Sewing Machine & Supply LLC

ATTENTION:

To avoid wrong performance

of

sewing ntachine or potential damage

towards it , anake sure

of

the following items before operation:

0 Wipe

and

clean the machine before initial operation.

0 Oil

the

machine aftea· cleaning it.

0

The

voltage

is

correct.

0 Plug is pa·operly connected.

0 Running

under

impa·oper voltage

is

strictly foa·bidden.

0

Motor

pulley rotates in right direction.

1.

MAIN

SPECIFICATIONS

I)

Max

se\ving speed:

2) Stitch length:

3) Presser foot lift:

4) Needle bar stroke:

5)

Take-up lever stroke:

6) Knitc stroke: 5mm

7)

Needle:

8) Application:

9) Reverse teed device:

2.

MACHINE

INSTALLATION

4SOOrpm

0-Smm

Smm (by hand)

13mm (by knee)

31.8mm

58mm

DBxS #

14

light to medium heavy weight material

available

I) Put the rubber cushions to the tbur corners

of

the oil reservoir, then

set

the

oil

reservoir to the table.

2) Insert the hinge(}) to the hole tor the hinge on the machine head. then set

the

n1achine head onto the rubber cushions and the hinge

sockets®

on the table.

3) Align Motor Pully Groove (B) and Balance Wheel Groove (A)

by

moving

the

n1otor(C) let\ward or rightward.

1 .

From the library of: Superior Sewing Machine & Supply LLC

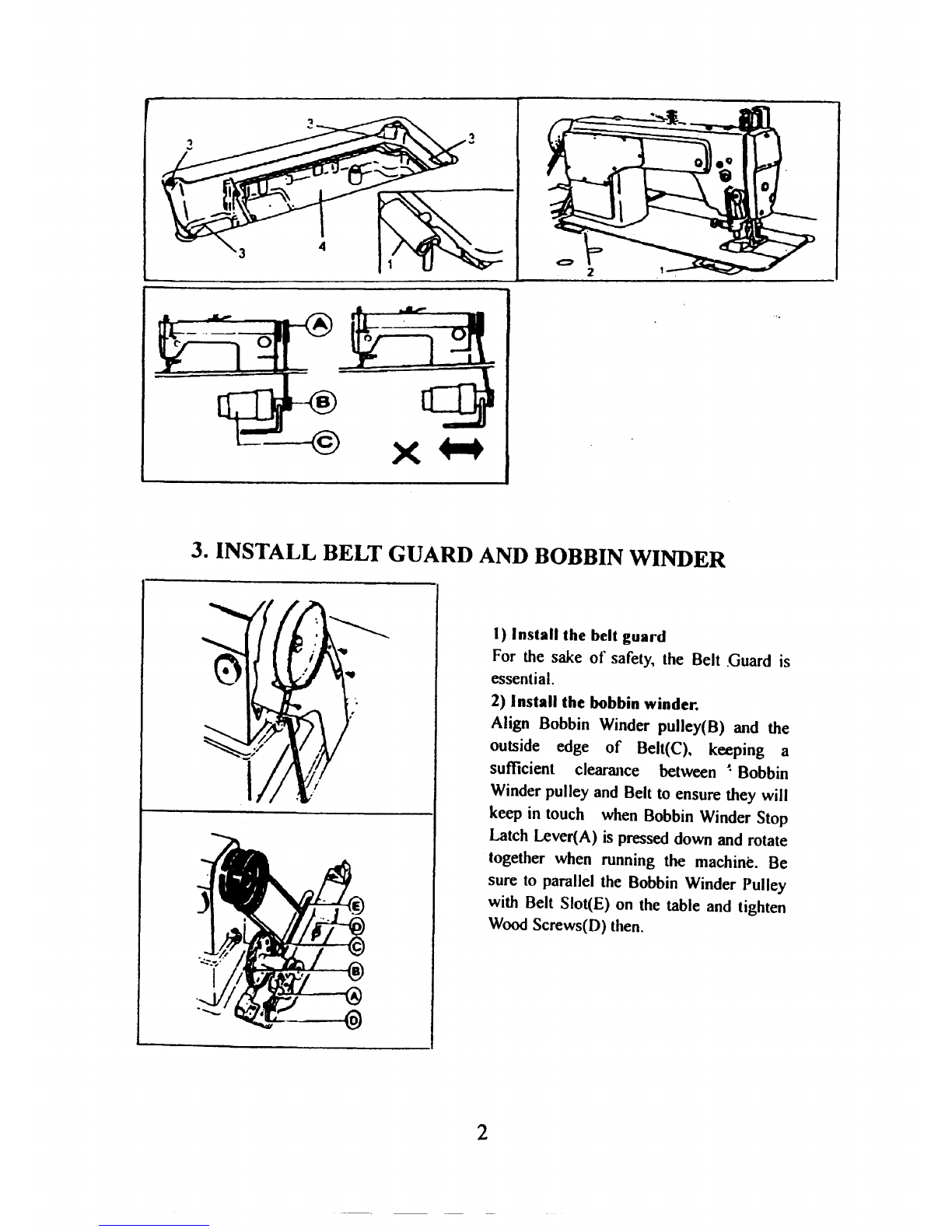

3. INSTALL BELT GUARD AND BOBBIN WINDER

2

I)

Install

the

belt

guard

For the sake

of

safety, the Belt .Guard is

essential.

2) Install

the

bobbin winder.

Align Bobbin Winder pulley(B) and the

outside edge

of

Belt(C).. keeping a

sufficient clearance between

~

Bobbin

Winder pulley and Belt to ensure they will

keep in touch when Bobbin Winder Stop

Latch Lever(A)

is

pressed down and rotate

together when running the n1achine. Be

sure to parallel the Bobbin Winder Pulley

with Belt Slot(E) on the table and tighten

Wood

Screws(D) then.

From the library of: Superior Sewing Machine & Supply LLC

4.

INSTALL

CHIP

RETAINING

PLATE

4

-€>

~-3

Install Chip Retaining

PlateQ) on Chip Funnel

Plate ® to completely

prevent chips

fro1n

getting

out. Then set the

.oil

guide

chute onto the oil

reservoir as following:

I) The forepart

of

the oil

guide chute n1ustn

't

stretch lettwards too

far

fro1n

the

lengthened line

of

Plane (A).

2) Part (B)

of

the chip

funnel

won't

touch the

oil guide chute when

turning up or down

the 1nachine head.

5.

CONNECl~

CLUTCH LEVER WITH PEDAL

X

I)

The optinuun tile angle

of

Pedal is approximately

15

deg.

2) Adjust Clutch Cover so ·that

Clutch-lever and Draw

bar

run

in line.

3) The balance wheel should

rotate counter-clock wise when

vie\ved

fro1n

the outside

of

Balance wheel. The direction

of

1notor pulley rotation can be

reversed by reversing (turning

over

180

deg) the power plug

of

the anotor.

4)

Adjust the tension

of

V-belt

by

moving the motor up and down. The proper tension

of

the

V-belt

is

a slack

of

I0-20mm when the belt

is

depressed at the center

of

the belt

by

tinger.

3

From the library of: Superior Sewing Machine & Supply LLC

6.01LING

I) Required amount

of

----------------------,

oil

I

,.

H L I

j~~

"-

Line

(H)

on

the

oil

reservoar:

Max.

oil

level

Line

(L)

on

the oil

reservoir:

Min.

oil level

If oil

level

goes down

under Line(

L)~

oi

I can

not

be

distributed

to

each part

of

the

machine. thus causing

the

parts a seizure.

2) AIways

use

18#

special

n1achine

oil

for

high

speed sewing machine

only.

Be

sure

to

replenish

oil

to

Line

(H)

before operation.

3)

To

replace oil, loosen Screw(C)

to

drain used

oil.

After completely draining on· oil, clean

the

oil

rt·servoir and securely tighten Screw(C), then

till

the

reservoir

with

fresh

oil.

7.

RUN-IN

OPERATION

..

--·:c··

,

______

, .

4

Run-in operation

is

required

for

a

new

sewing

anachine.

or a sewing

machine lell out

of

operation tor a

considerable length

of

time.

I)

Remove

Rubber Plugs(

A)

on

the

top

of

the ann

and

replenish sufticient

amount

of

oil.

2)

Lift Presser Foot(B)

3)

Run

the

machine

at

a

lo\v

speed

(2000-2500span) to check oil distributing

condition through

Oil

Check

Windo\v(C).

4

)Perton11

run-in operation

at

2000-2500spnl tor 30

aninutes.

Afler a

lapse

of

one

anonth

of

service during

which

the

working speed

is

increased

gradually, the machine

runs

sufficiently

well, and the high speed 4500spm can

be

adopted according to

the

nature

.of

the

work.

From the library of: Superior Sewing Machine & Supply LLC

8.

I{Ef>LACE NEELJLES

§

I.

I~~

t •

1!~

. a u

'·!-'"

1)

X

'

v'

b

I

'

~

c

I

,

/

a

1

Turning the balance

wheel to lift needle bar to the

upper end

of

its stroke.

Loosen Needle claaup Screw

(I).

While keeping the long

groove

of

the needle lethvard.

fully insert the needle shank

up

to

the bouoan

of

the

net=dle

socket. Then tighten Needle

clamp Screw

(I

).Note:

Fig.(

b)

insufficient insertion.

Fig.(c) wrong direction

of

long groove.

9.

ADJUSl

..

PRESSURE AND HEIGHT OF PRESSER FOOT

5 .

I) l)ressua·c

adjusllnent:

Pressure

of

presser

ft)(lt

as

to he adjusted according, to

the

thil:kncss

or

materials

to

be

sewn.

Loosen Lock Nut

(A)

ti

rst.

for

heavy anaterials.

tun1

the

pressure regulating

thuanb

screw

as

shown

in

Fig.

(a) to

increase the pressure. while

tor light anaterials.

tun1

the

pressure regulating thumb

screw

as

shown

in

Fig.

(b) to

decrease the pressure. Then

tighten I.ock Nut

(A).

2)

llcigbt

adjushncnt:

I)

Ren1ove

Rubber plug

(C)

troan

Face plate (B).

2)

Loosen scre\v o

t:

presser

bar guide

bra<.:ket

and

adjust the height

of

Presser

Bar.

3) Tighten screw again and

put

in

Rubber Plug(

C).

From the library of: Superior Sewing Machine & Supply LLC

I

0.

THREADING

11.

ADJUST THREAD TENSION

6

I) To thread the needle

thread. raise needle bar to

the upper end

of

its stroke,

lead the thread from spool

and perform threading as

per threading sequence.

2) To draw the bobbin thread.

hold the end

of

the needle

thread and turn the balance

wheel to lower the needle bar

and then to lift

it

to its highest

position. Pull the needle

thread and the bobbin thread

is

drawn

up.

Put the ends

of

needle thread and bobbin

thread frontward under

presser foot.

I)

To

adjust bobbin thread

tension. turn Tension

Spring Regulating Screw

(A)

of

Dobbin case

clockwise f(n more

tension, or turn the screw

counter -clockwise for

less tension.

2) The needle thread tension

should be adjusted with

reference to the bobbin

thread tension and it can

be

adjusted by setting the

thread take-up spring

tension~

the thread take-up

spring stroke and the

position

of

thread tension

discs

or

thread guide.

From the library of: Superior Sewing Machine & Supply LLC

12.

INSTALLATION

AND

OPERATION

OF

THE KNIFE

Knife operation:

(I)

To

actuate the cutting knife

..

press

down Knife operating plate (

1)

to

lo\ver the knife while running the

sewing machine.

II"'Cn'--+ (2)

To

stop cutting

of

the knife tor

7

sewing only. pull out Knob(2) as

indicated

by

the arrow.

Knife installation:

Install the cutting knife

as

shown in the

tigure. When bringing the knife to the

lowest position. move it up and down to

make sure the part A

of

the knite

is

0-0.Smm lower than the surface

of

the

needle plate.

Cutting

width change:

(I)

The cutting width can be varied

by

changing needle plate assy. When

changing, loosen Set Screw(I) and

pull out cutting knife parallely to

ensure a good cutting quality.

(2) Due to the change

in

the size

of

needle plate assy. you nuast change

the position

of

the cutting knife

accordingly. Loosen Screw(2) to

anake

the edge

of

cutting knife touch

the edge

of

needle plate assy, then

tighten the screw·again.

(3) 3.2mm is the standard

specification

of

this needle plate

assy.

From the library of: Superior Sewing Machine & Supply LLC

13.

ADJUST TENSION

OF

NEEDLE & BOBBIN

THREAD

l.

•

•

a

b

c

d

e

The position

of

the thread guide

affects stitch tightness and theref(lre

must be adjusted according to sewing

material and sewing conditions. Fig.

(a)

sho\vs the correct stitch.

Abnormal sti.tches cause puckering

and thread breakage.

In

such a case

the tension

of

needle thread and

bobbin thread must be adjusted

accordingly.

I)

In

case

of

needle thread tension

is

too

strong

or

bobbin thread tension

is

too weak. turn the thumb nut

counterclockwise to decrease the

needle thread tension.

or

tighten the

tension spring regulating screw

of

bohhin case to increase the bobbin

thread tension.

2)

In

case

of

needle thread tension

is

too weak

or

bobbin thread tension

is

too strong. turn the thumb nut

clockwise to increase the needle

thread tension.

or

loosen the tension

spring

regul«;~ting

screw

of

bobbin

case to decrease the bobbin thread

tension.

3)

In

case

of

the stitch f(lrnls

of'·d

.. and

'"e"·.

adjustments can be made with reference

to

the ahove rneans.

14.

REPLACE

OT~1ER

PARTS

I)

When not usmg the cutting

kni

fc.

place the cover onto the

opening A

of

the chip tunnel.

2) Atter putting on the cover. the

machine can

sew

only.

u

8

From the library of: Superior Sewing Machine & Supply LLC

15.

I{ELAI'ED

PARI'S FOI{ CI-IANGINU CU'J"J'INU

WILJI'I

I

~NAME.-

..--------

..

--r-··

----,

------

~

NEEDLE

FEED

PRESSER

KNIFE

CHIP CHIP I CHIP

FUNNEL

PLATE

DOG

FOOT

FUNNEL

GUIDING I

PLATE

PE

PLATE

!

WIDTH

3/32'" 3/32"" 3/32'" 1/8" 1/8"' 1/8'"

1/H

..

l/8"

(2.4mm)

I

M---'•0

---

·-

.

··-----

-------

-·-·

~-------

r---------

------

--~

-

--

,_

___

---

--

..

-~-

.

·-

-

-------·--t--

··--

i/8;:-----

i

I/8

..

1/8'"

1/8

..

1/8'" 1/H''

1/H

..

I 1/8.. 1

(3.2mm)

I I

I

(4mm)

5/32""

1/8

..

1/8" 1/8" 1/8''

1/H'"

: J/8

..

(4.Hmm)

3/16"

1/8" I;g··

1/H

..

1/8" 1/8" 1/8'"

(6.4mm)

1/4" 1/4.. 1/4.. 1/8''

114'"

I

/4"

1/8"

(9.5mm)

3/8" 3/8"

3/8'' 1/8'" 3/8'"

3/8"

1/8"

9

From the library of: Superior Sewing Machine & Supply LLC

A:

ARM

BED AND ITS

ACCESSORIES

.

n==

49

10

From the library of: Superior Sewing Machine & Supply LLC

A: ARM BED AND ITS

ACCESSOI~IES

No. Ref. No. Name

Quantity

H57AOOI

Face plate 1

2 H57A002 Gasket for face plate I

3 H57A003 Rubber

spacer

I

4 H57A004 Screw 3

5 H57A005 Arm bed assy.

6 H57A006 Rubber plug(

<1>

19)

7 H57A007 Rubber plug(

<l>

11.8)

8 H57A008 Rubber plug(

<1>

5.

7)

9 H57A009 Screw 8

10

H57AOIO Arm side cover

II H57AOII Gasket for arm side cover

12

H57A012 Pre-tension assy.

13

H57AOIJ Pre-tension stud

14

H57/\014 Spring for pre-tension

15

H57A015 Disc tor pre-tension 2

16

H57A016 Spacer for pre-tension thread guide

17

H57AOI7 Stop ring

18

H57A018 Pre-tension thread guide

19

H57A019 Rubber plug(

<l>27)

20 H57A020 Three-hole thread guide

.21

H57A021 Set screw

22 H57A022 Thread guide

23 H57A023 Screw

24 H57A024 Thread tension assy.

25 H57A025

Thumb

nut

26 H57A026 Stopdisc

27 -H57A027 Thread tension spring

28

1-157A028

Thread tension releasing disc

29

H57A029 Thread tension disc

30

H57A030 Thread tension stud

31

H57A031 Thread take-up spring

32 H57A032 Thread tension regulating bushing

33 H57A033

Set

screw

34 H57A034

0-ring

35 H57A035 Set screw

36 H57A036 Thread tension releasing pin

37 H57A037 Needle plate

38 H57A038 Screw 2

39 H57AU39 Thread guide on face plate

II

From the library of: Superior Sewing Machine & Supply LLC

No. Ref. No.

Name

Quantity

40

H57A040 Thread guide screw I

41

1-157

;\041 Rubber plug(

<1>

11.8)

42 I

157

A042 Face plate screw 2

43 1157/\043 Slide plate assy

44

1157t\044 Slide plate

45

1157/\045 Slide plate spring

46

H57A046 Screw 2

47 H57A047 Leg 3

48

H57A048 Washer 2

49

H57A049

Chip

guide plate 1

50 H57A050 Screw 2

51

H57A051

Chp

plate

52 H57A052

Chip

funnel

53

HS?/\053

Chip

funnel plate

54 H57A054 Screw 2

55 H57A055 Screw

2•

56

H57A056

Chip

funnel cover I

57 H57A057 Spring for

chip

funnel

cover

1

58 H57A058 Screw 2

59

H57A059 Rubber plug(

<J>

8.8

).

2

6(}

1157/\060 Oil window

12

From the library of: Superior Sewing Machine & Supply LLC

__..

w

23

~---

'

'\ \"

14

13

I 1

11

10

49

53~lf\

54

55

53

39

,

-----~

~

~

(j

:::o.

>

2

llllool(

en

~

0:

..

>

.......

~

3:

C/J

.....

-

>

~

~

..

<

~

-

"""'

~

-

('")

>

r-

{,/)

....

..

>

~

~

>

:z

-

'-'

'

~

....

-

.....

,....

~

>

-

'-oil

~

:>

~

~

I

c::

-c

From the library of: Superior Sewing Machine & Supply LLC

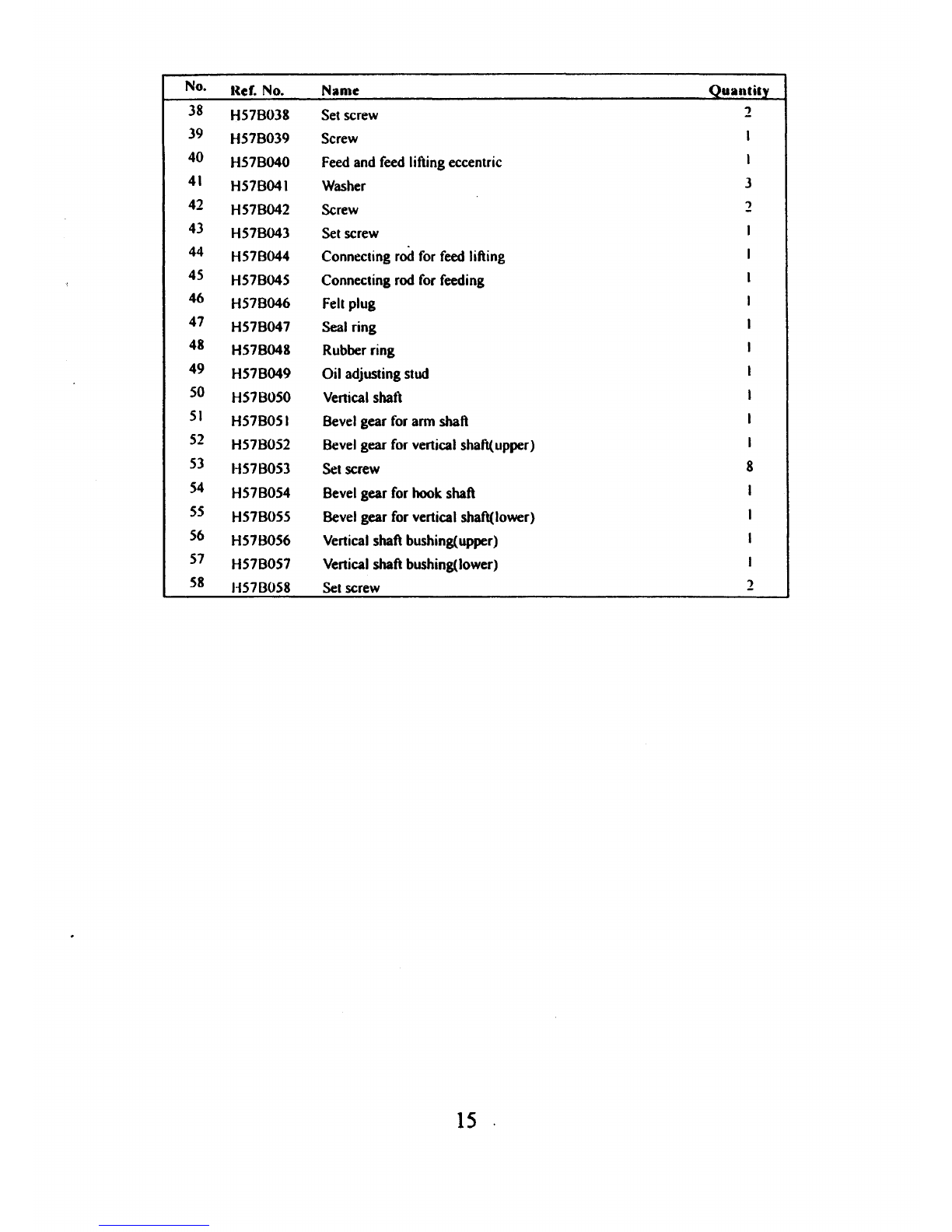

8:

ARM

SHAFT

,VERTICAL

SHAFf

AND

TAKE-UP MECHANISM.

No. Ref. No. Name

I

H57BOOI

Thread take-up lever

2 H578002 Thread take-up lever link

3 H57B003 Hinge pin

4 H578004 Crank

5 H578005 Needle bearing

6 H57B006 Set screw(counter-clockwased)

7 H57B007 Needle bar link

8 H57B008 Needle bar adaptor

9 H57B009 Set screw

10

H57BOIO Set screw

II

H57BOII Thread take-up guard

12

H57BOI2 Screw

13

H57BOI3 Needle bar crank

14

H57BOI4 Sel screw

15

I-157BO

15

Sel screw

16

H57BOI6 Set screw

17

H57BOI7 Needle bar

bu~hing(upper)

18

H578018 Rubber plug

19

H57B019 Needle bar bushing(lower)

20 H578020 Thread guide for needle bar bushing

21

H578021 Needle bar

22 H57B022 Thread guide for needle bar

23

H578023 Needle

24 H57B024 Needle clamp screw

25 H57B025 Guide tor slide block

26 H578026 Set screw

27 HS78027 Slide block

28 H578028 Arm shaft

29 H57B029 Rubber plug(

Cl>7.4x

10)

30 H57B030 Collar tor arm shaft

31

HS7B031 Set screw

32

H578032 Arm shaft bushing(left)

33

H57B033 Arm shaft bushing(middle)

34

H578034 Set screw

35

H578035 Arm shaft bushing(right)

36 H57B036 Oil seal

37

H57B037 balance wheel

14

THREAD

Quantity

I

I

I

I

2

I

I

I

I

I

I

I

I

I

2

I

I

I

I

I

I I

1

I

I

I

2

I

I

2

I

2

I

1

I

I

I

I

From the library of: Superior Sewing Machine & Supply LLC

No.

Iter. No. Name

Quantity

38 H57B038 Set screw 2

39 H57B039 Screw

40 H57B040

Feed

and

feed

lifting eccentric I

41

H57B041 Washer 3

42 H57B042 Screw 2

43 H57B043

Set

screw

44

H57B044 Connecting

rod

for

feed

lifting

45 H57B045 Connecting

rod

for

feeding

46 H57B046

Felt

plug

47 H57B047 Seal ring

48 H57B048 Rubber ring

49 H57B049 Oil adjusting stud

50 H57B050

Vertical

shaft

51

H57B051

Bevel

gear

for

arm shaft

52 H57B052

Bevel

gear

for

vertical shaft(upper) I

53 H57B053 Set screw 8

54

H57B054 Bevel gear

for

hook shaft

55

H57B055

Bevel

gear

for

vertical shaft(lower)

56 H57B056 Vertical shaft bushing(upper)

51

H57B057 Vertical shaft bushing(lower)

58 1-1578058 Set screw 2

15

.

From the library of: Superior Sewing Machine & Supply LLC

30

....

0'\

\

47 48

\

16

()

..

..,

~

~

0

;,

~

~

.....

'....,;

r-

-

~

~

,._

2

C)

>

2

0

"'

0

~

,;;

~

....

:z

Ci

.....

~

0

0

~

~

~

(j

...,...

,....

>

z

~

(J)

~

From the library of: Superior Sewing Machine & Supply LLC

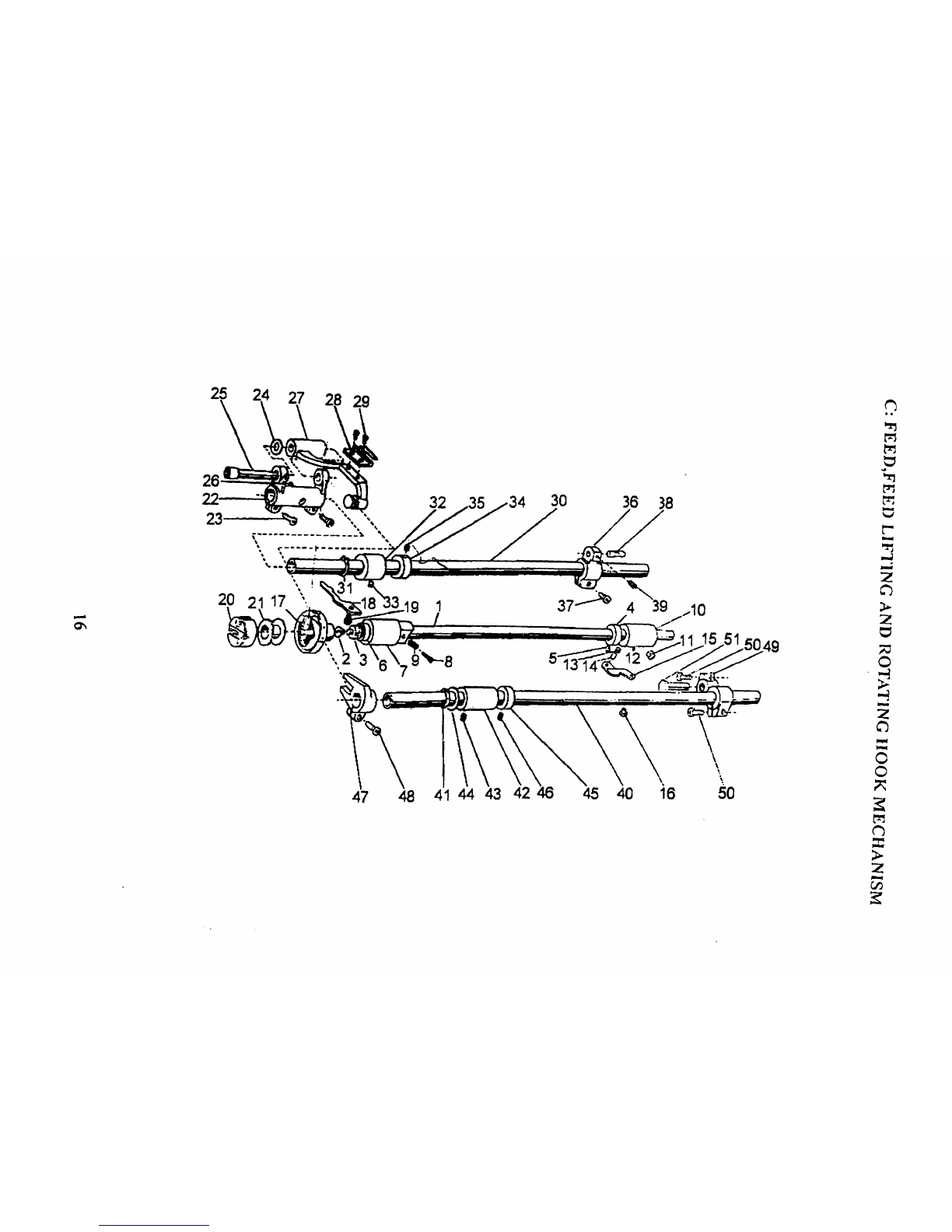

C: FEED,FEED LIFTING

AND

ROTATING

HOOK

MECHANISM

No. Ref. No.

Name

Quantity

I H57COOI Hook shat\ I

2 H57C002 Filter screw I

3 H57C003 Filter I

4 H57C004 Collar tor hook

shan

I

5 H57C005 Set screw 2

6 H57C006 Oil seal tor

ro~ating

hook shalt I

7 H57C007 Hook shaft bushing(left) I

8 H57C008 Oil adjusting screw I

Q H57C009

Spnng

for oil adjuster I

10

H57COIO Hook shaft bushing(right) I

II H57COII Screw for hook shaft bushing(right) 1

12

H57COI2 Oil pipe

tor

hook shaft bushing I

13

H57COI3 Plunger I

14

H57C014 Plunger

spring

I

15

H57COI5 Guide plate 1

16

H57COI6 Screw I

17

H57COI7 Rotating hook complete I

18

H57COI8 Rotating hook positioner I

19

H57C019 Screw 1

20 1157l'02() Buhhin case I

21

H57C021 Bobbin I

22 H57C022 Crank for feed bar I

23 H57C023 Screw 2

24 H57C024 Washer I

25 H57C025 Eccentric shaft tor teed bar crank I

26

H57C026 Screw I

27 H57C027 Feed bar I

28 H57C028 Feed

dog

I

29

H57C029 Screw 2

30

1·157C030 Feed rock

shan

I

31

H57C031 C-type stop

ring

I

32 H57C032 Bushing tor teed rock

shan

I

33 H57C033 Set screw I

34 H57C034 Collar I

35 H57C035 Set screw 2

36

H57C036 Feed rock

shaft

crank(right) I

37

H57C037 Screw I

17

From the library of: Superior Sewing Machine & Supply LLC

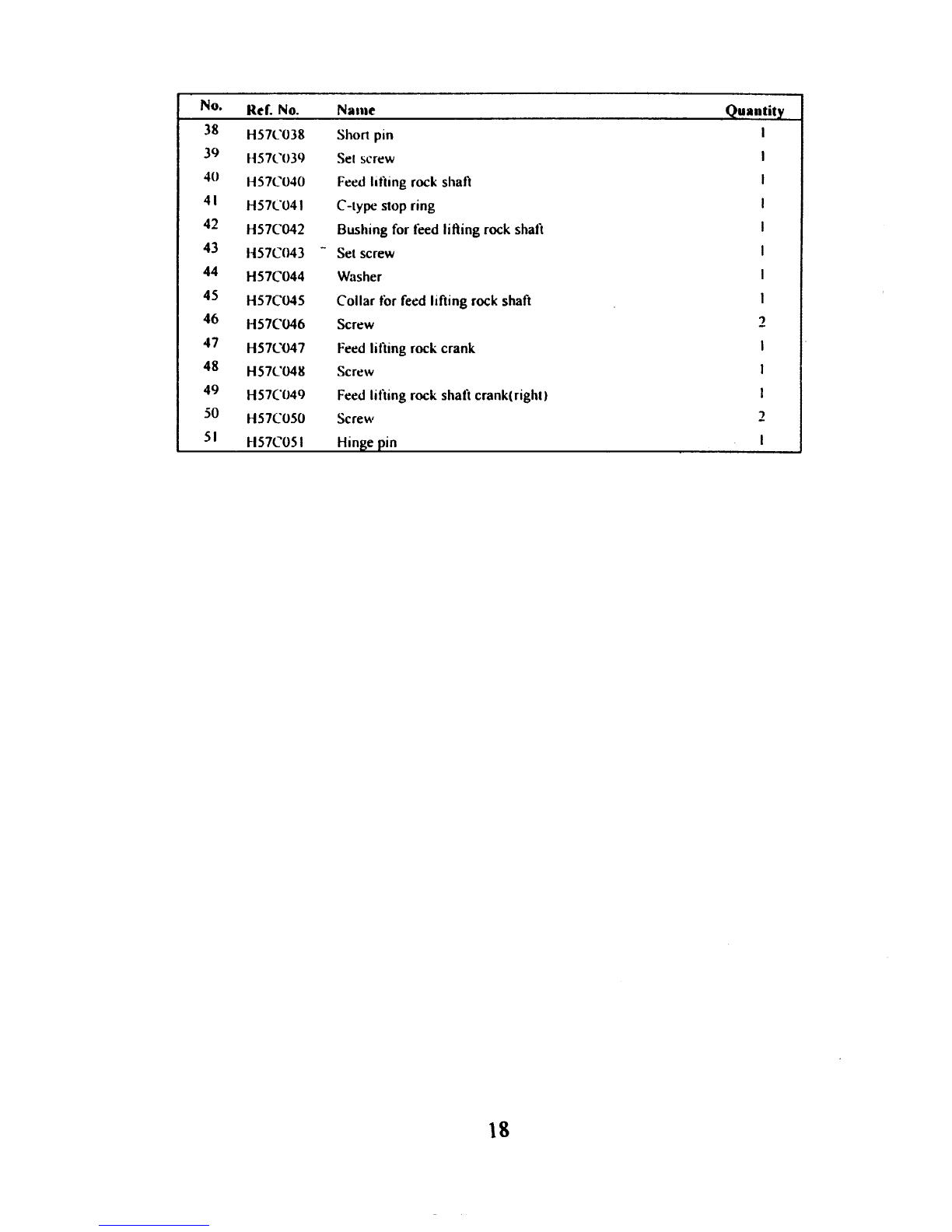

No.

R~f.

No.

Nam~

Quantity

38 H57C038 Short pin I

39 H57C03Q Set screw

40

H57C040 Feed lifting rock shaft

41

H57C041 C-type stop ring

42 H57C042 Bushing for teed lifting rock shaft

43 H57C043 -Set screw

44 H57C044 Washer

45 H57C045 Collar tor feed lifting rock shaft

46

H57C046 Screw 2

47

H57C047 Feed lifting rock crank

48 H57C04H Screw

49 H57C049 Feed lifting rock shaft crank(right}

50 H57C050 Screw 2

51

H57C051 Hinge pin

18

From the library of: Superior Sewing Machine & Supply LLC

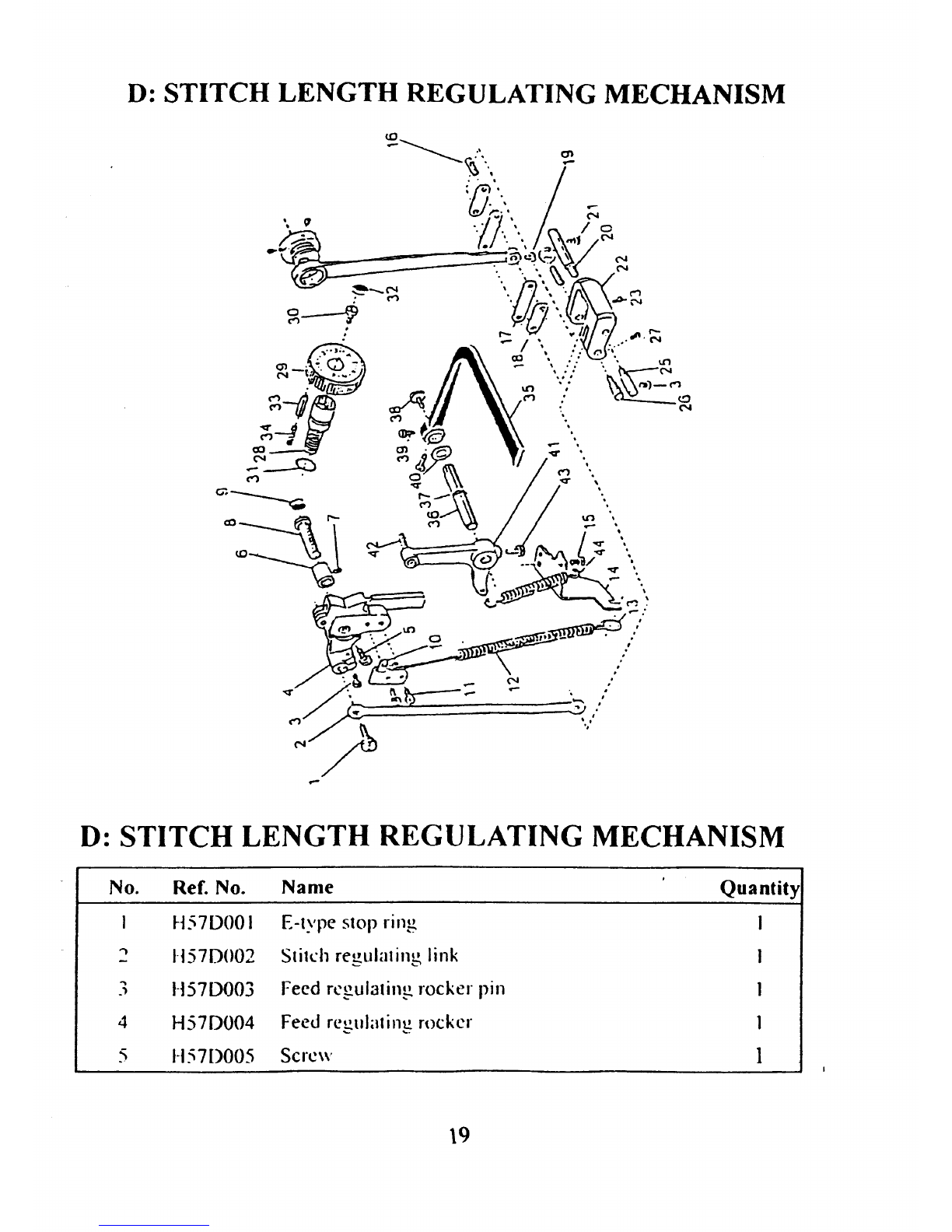

D:

STITCH

LENGTH

REGULATING MECHANISM

D:

STITCH

LENGTH

REGULATING MECHANISM

No. Ref. No.

Name

4

5

H57DOO

I E-type stop ring

H57D002

l-l57D003

Stih:h regula1 ing link

Feed regulating

rocker

pin

H57D004

Feed

regulating

rocker

1-157[)005

Sere\\·

\9

Quantity

I

From the library of: Superior Sewing Machine & Supply LLC

Table of contents