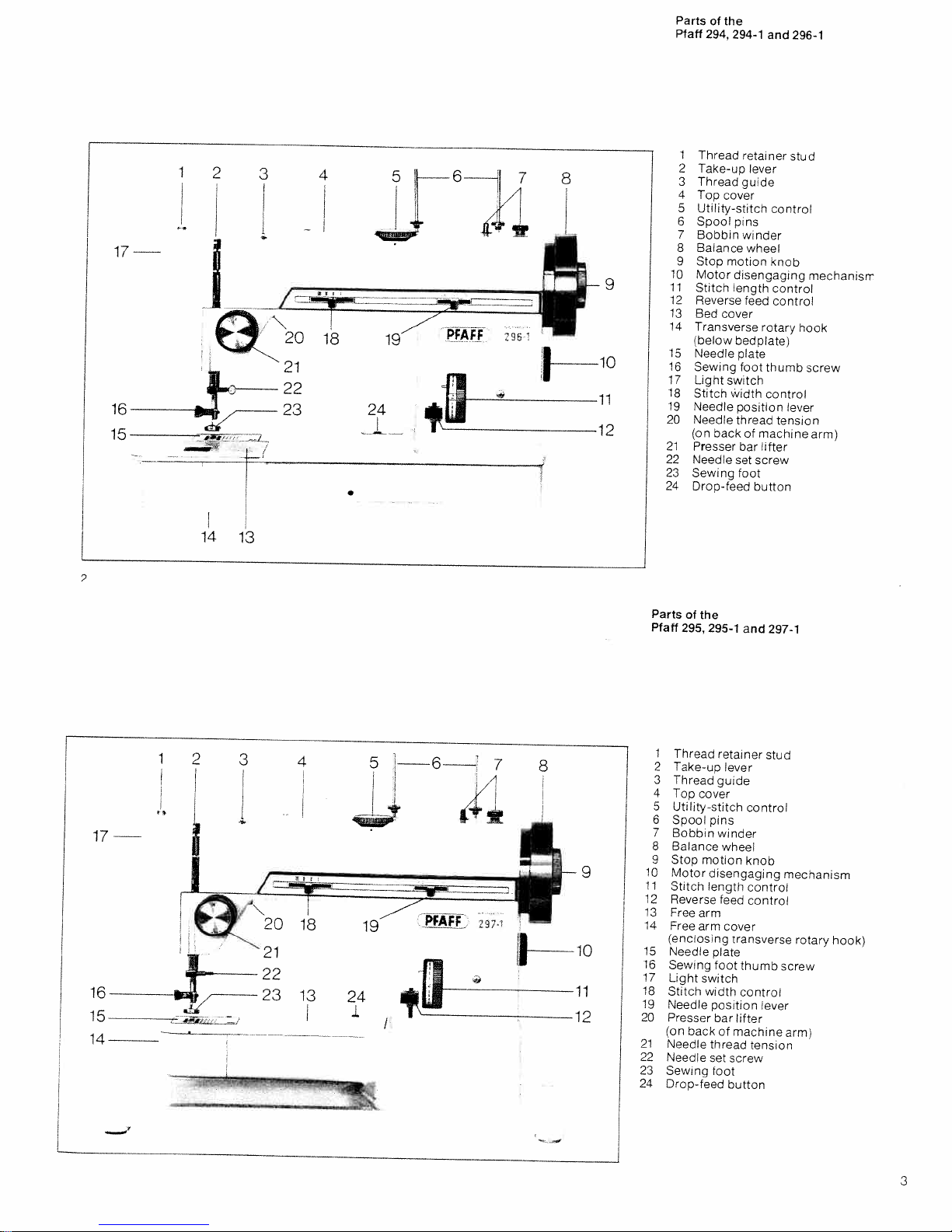

Pfaff 294 User manual

Other Pfaff Sewing Machine manuals

Pfaff

Pfaff 3734-2/01 User manual

Pfaff

Pfaff 3538-30/02 User manual

Pfaff

Pfaff expression 150 User manual

Pfaff

Pfaff 487 User manual

Pfaff

Pfaff Embroidery Mode-Stitch-Out User manual

Pfaff

Pfaff PowerLine 2231 Manual

Pfaff

Pfaff 1163 User manual

Pfaff

Pfaff Creative 2140 User manual

Pfaff

Pfaff 3334 User manual

Pfaff

Pfaff hobby GrandQuilter 1200 User manual

Pfaff

Pfaff hobbylock 4762 User manual

Pfaff

Pfaff 2481-980/30 PLUSLINE User manual

Pfaff

Pfaff 8330 User manual

Pfaff

Pfaff 1243-712/02 User manual

Pfaff

Pfaff creative 7560 User manual

Pfaff

Pfaff 2483-980/31 User manual

Pfaff

Pfaff Punching Machine Hobby 350p User manual

Pfaff

Pfaff Creative Vision Technical manual

Pfaff

Pfaff 1243 Guide

Pfaff

Pfaff Automatic 260 User manual