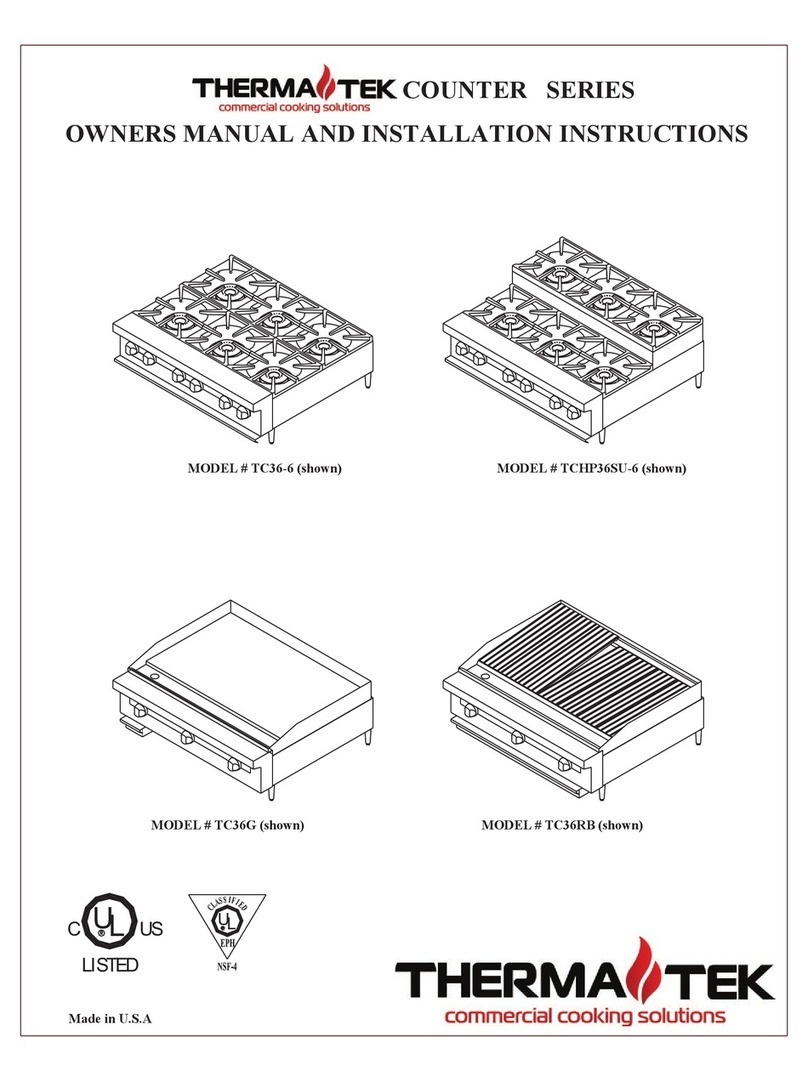

Therma-tek TMD36-6-1 Restaurant Series Specification sheet

RESTAURANT SERIES

OWNERS MANUAL AND INSTALLATION INSTRUCTIONS

U

LISTED

U

Made in U.S.A

CLUS L

MODEL # TMD36-6-1 (shown)

INTRODUCTION/ SAFETY PRECAUTIONS

Thank you for choosing your new THERMA-TEK Equipment. Our Products are designed to be safe and

reliable when properly cared for and used reasonably. Your service agency or dealer recommends periodic

inspections. Installation, maintenance, and repairs should be performed by your local authorized service

agency. This equipment is not intended for home use.

This equipment is for commercial use by trained professionals familiar with commercial cooking

equipment. It is the responsibility of the Supervisor or equivalent person to ensure that users wear

suitable protective clothing and safety gear. Caution: some parts of the equipment become very hot and

will cause burns if accidentally touched.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

FOR YOUR SAFETY

If you smell gas:

1. Shut off gas to appliance.

2. Extinguish any open flame.

3. If odor continues, immediately call your gas

supplier.

Consult your local gas supplier for instructions to be followed in the event you smell gas.

Post these instructions in a prominent location.

WARNING:IMPROPER INSTALLATION, ADJUSTMENT ALTERATION, SERVICE AND/OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ THE

OWNERS/INSTALLERS MANUAL THOROUGHLY BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

CALIFORNIA PROPOSITON 65 –WARNING

The burning of gas cooking fuel generates some by-products which are on the list of substancesknownby the State of

California to cause cancer or reproductive harm. California law requires businessesto warn customers of potential exposure to

such substances. To minimize exposure to thesesubstances,always operatethis unit according to theowners/installation

manual, ensuring you provide good ventilation when cooking with gas.

PLEASE RETAIN THESE INSTRUCTIONS FOR FUTURE REFERENCE

1

INSTALLATION AND SAFETY GUIDELINES

IMPORTANT

Safe and satisfactory operation of your equipment depends on its proper installation. Installation must

conform to local codes, or in the absence of local codes with the National Fuel Code ANSI Z223.1 (latest

edition).

All THERMA-TEK appliances are shipped with a gas pressure regulator packed with the unit. All units are

adjusted, tested, and inspected at the factory prior to shipment.

After uncrating, immediately check the equipment for visible signs of shipping damage. If such damage has

occurred, do not refuse shipment, but contact the shipper and file appropriate freight claims.

GENERAL

Installation of this equipment should be made by licensed and authorized personnel.

A manual gas shut-off valve must be installed in the gas supply (service) line ahead of the appliance

and gas pressure regulator installed in the gas stream for safety and ease of future service.

The gas pressure regulator supplied must be installed on the appliance prior to connecting the

equipment to the gas line. Failure to install a regulator will void the equipment warranty and result

in a potentially hazardous condition.

The appliance and its individual shut off valve must be disconnected from the gas supply system

during any pressure testing of that system in excess of ½ PSI.

The appliance must be isolated from the gas supply system by closing its individual shut off valve

during any pressure testing of the gas supply piping system at test pressure equal to or less than ½

PSI.

Please contact the factory, the factory representative, or a local authorized service company to

perform maintenance and repairs.

RATING PLATE

Information on this plate includes the model and serial number. When communicating with the factory

about a unit or requesting special parts or information, this information is required for proper identification.

Other information on the plate is the BTU/hr input of the burners, gas pressure in inches WC, and whether

the unit has orifices for natural or propane gas. Rating plate is located behind the lower front panel.

IMPORTANT: The appliance must be connected only to the type of gas identified on the rating plate.

GAS CONVERSION

We recommend that the appliance be ordered from the factory for the type of gas at the installation site.

When gas conversion is necessary contact the factory for a proper gas conversion kit.

2

INSTALLATION AND SAFETY GUIDELINES

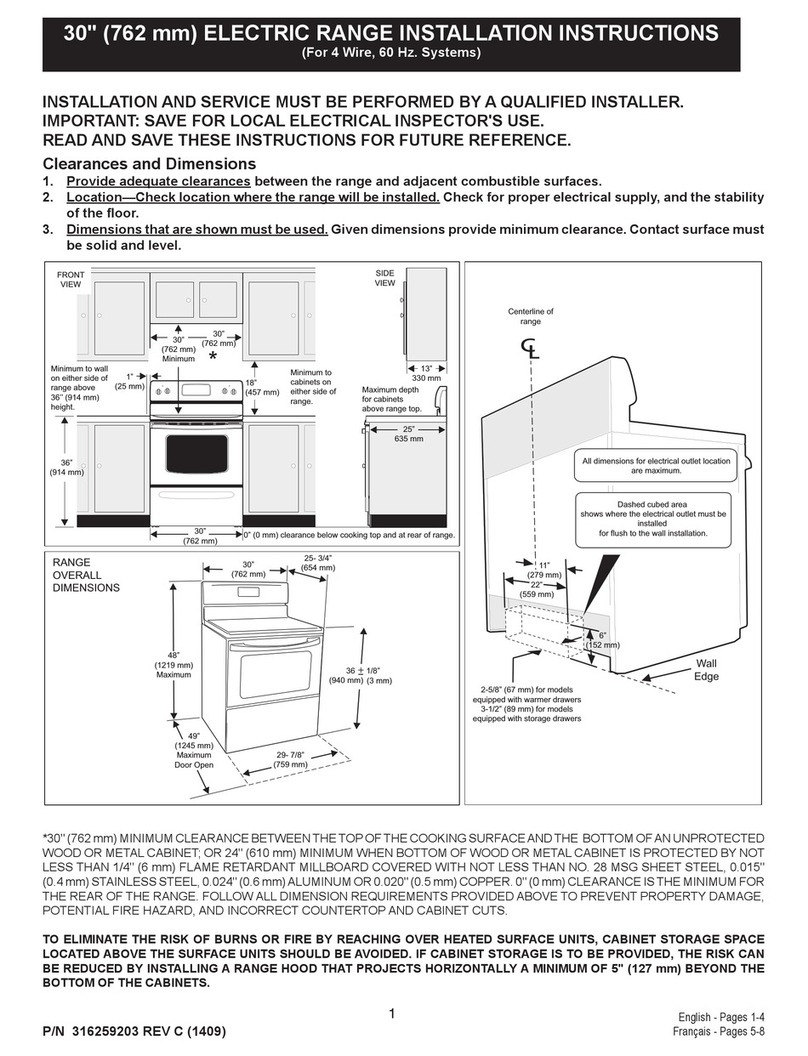

CLEARANCES

The unit must be kept clear of all combustibles.

The unit must be installed with the 6” legs or casters supplied for proper operation.

Minimum clearance from combustible construction:

Side Back

oOpen top 12” 6”

oHot Top 6” 6”

oGriddle 6” 6”

oBroiler 6” 6”

Minimum clearance from non-combustible construction: 0” Side, 0” Back

LEVELING

A carpenter’s spirit level should be placed on the cooking surface and the unit leveled side-to-side, and front

to back. If it is not level, burner combustion may be erratic or the unit may not function efficiently.

AIR SUPPLY AND VENTILATION

The appliance must be installed under a ventilation hood.

The area around the appliance must be kept clear to avoid any obstructions of the flow of combustion and

ventilation air as well as for ease of maintenance, service, and proper appliance operation. Keep clearance

for openings into the combustion chamber and adequate air supply. Means must be provided for any

commercial, heavy duty-cooking appliance to exhaust combustion wastes to the outside of the building.

Air movement should be checked during installation. Strong exhaust fans in the hood or in the overall air

conditioning system can produce a slight draft in the room, which can interfere with pilot or burner

performance. If pilot or burners problems persist make up air openings or baffles may have to be provided

in the room.

Filters and drip troughs should be part of any industrial hood, but consult local codes before constructing

and installing any hood. The duct system, exhaust hood, and filter bank must be cleaned on a regular basis

and kept free of grease.

ALTITUDE

The appliance input rating (BTU/hr) is for elevations up to 2000 feet. For elevations above 2000 feet, the

rate should be reduced 4% for each 1000 feet above sea level. The correct orifices are installed at the

factory if the operating altitude is known at the time of sale.

3

INSTALLATION AND SAFETY GUIDELINES

GAS CONNECTION

The gas supply (service) line must be at least the same size or larger than the inlet line of the appliance.

THERMA-TEK restaurant series equipment is supplied with a ¾” NPT Schedule 40 inlet. Sealant on all

pipe joints must be resistive to LP gas.

MANUAL SHUTOFF VALVE

A manual shut-off valve must be installed in the gas service line ahead of the appliance and regulator in the

gas stream and in a position where it can be reached quickly in the event of an emergency. The manual shut-

off valve is supplied by the installer.

PRESSURE REGULATOR

All commercial cooking equipment must have a pressure regulator on the incoming service line for safe and

efficient operation, since pressure may fluctuate on local demand. A regulator is supplied with the

appliance. Failure to install a pressure regulator will void the equipment warranty. The regulators are

adjusted at the factory, 5.0” WC for natural gas, and 10.0” WC for propane gas. Ensure the supply pressure

is within the following range: Natural Gas 6.0” WC to 13.0” WC / Propane Gas 11.0”WC to 13.0” WC.

Only qualified service personnel with proper test equipment must make any adjustments to the regulators.

RIGID CONNECTIONS

Double check any installers supplied gas pipes visually and blow them out with compressed air to clear any

dirt particles, threading chips, or any other foreign matter before installing a service line. Those particles

will clog orifices when gas pressure is applied. All connections must be sealed with a joint compound for

LP gas, and tested with a soapy water solution before lighting any pilots.

FLEXIBLE COUPLINGS, CONNECTORS AND CASTERS

If the unit is to be installed with flexible coupling and or quick disconnect fittings, the installer must use a

heavy duty commercial flexible connector at least ¾” NPT (with suitable strain relief) in compliance with

the standard for connectors for movable gas appliances, ANSI Z21.69-1987 and Addenda Z2.169a-1989 (or

latest edition) or connectors for movable appliances, CAN/CGA-6.16 (or latest edition) and quick

disconnect device must comply with the standard for quick disconnect devices for use with gas fuel,

ANSI Z21.41-1989 (or latest edition) or quick disconnect devices for use with gas fuel, CAN1-69 (or latest

edition). Adequate means must be provided to limit the movement of the appliance. Domestic connectors

are not suitable.

When the appliance is supplied with casters and is connected to the supply piping by means of a connector

for movable appliances, and if disconnecting the restraint is necessary, this restraint must be reconnected

after the appliance is returned to its original installation position. The strain relief is a cable attached to the

rear of the appliance.

4

RESTAURANT RANGE BACKGUARD MOUNTING INSTRUCTIONS

KIT INCLUDES:

(2) PN 31079 BACKGUARD SUPPORT

(4) PHILLIPS HEAD SHEET METAL SCREWS

FIGURE 1: SHELF AND BACKGUARD MOUNTING ASSEMBLY TO RANGE

FIGURE 2: STEP ONE DIAGRAM

FIGURE 3: PN 31079 BACKGUARD SUPPORT ASSEMBLY TO EXISTING PART

FIGURE 4: STEP 2 DIAGRAM

5

FIGURE 2

STEP 1

REMOVE BACK PANEL FROM SDHS BY

REMOVING(6) PHILLIPS HEAD

SCREWS AND (2) 7/16” HEX HEAD

BOLTS AS SHOWN IN FIGURE 2.

FIGURE 3

FIGURE 4

STEP 2

FLANGE EXISTS ON RANGE AT THE

LOCATION DIRECTED BY ARROW. REMOVE

(2) EXISTINGSHEET METAL SCREWS FROM

FLANGE AND ATTACH BACKGUARD

SUPPORT HERE WITH EXISTING SCREWS AS

SHOWN IN FIGURE 3. USE (2) PHILLIPS

HEAD SHEET METAL SCREWS FROM KIT TO

SECURE ASSEMBLY TO SHELF UPRIGHT

AND INNER BURNER AS SHOWN IN FIGURE

4. BOX SIDE PROCEDURE IS DONE TO

BOTH SIDES OF SDHS.

NOTE: WHEN LOCATING HOLES FOR

PLATE, BE SURE SDHS IS STRAIGHT AND

PLUMB.

REINSTALL BACK PANEL.

EXISTINGFLANGE

BACKGUARD

SUPPORT

(2) EXISTING

SHEET METAL

SCREWS

FIGURE 1

INITIAL START-UP

All THERMA-TEK appliances are adjusted and tested before leaving the factory. Adjustments and

calibrations may be necessary upon installation to meet local conditions, low gas characteristics; problems

caused by rough handling or vibration during shipping, and are to be performed only by qualified service

personnel. These adjustments are the responsibility of the customer and or dealer and are not covered by

our warranty.

Check all gas connections for leaks with a soapy water solution before lighting pilots. Do not use an open

flame to check for leaks. Putting an open flame beside a new gas connection is extremely dangerous.

Before lighting any pilots, make sure that burner valves and thermostats are in the off position.

LIGHTING THE PILOTS

CAUTION: When lighting the pilots and checking for leaks, do not stand with your face close to the

Combustion chamber.

OPEN TOP:

Remove top grates

Make sure pilot adjust valve located on the manifold is open.

Light the pilot and adjust flame to approximately ½”.

GRIDDLE/HOT TOP:

Looking through slot in the valve panel, locate pilot lighting holes in the burner front shield.

Make sure pilot adjust valve located on the manifold is open.

Light the pilot and adjust flame to approximately 3/4” high.

BROILER:

Remove grates.

Make sure pilot adjust valve located on the manifold is open.

Light the pilot and adjust to approximately ¾” high.

OVEN:

Access the pilot behind the lower front panel by lifting the panel upward and rotating forward.

Locate the oven safety and depress and hold the red button on the safety.

Repeatedly push the igniter button until the pilot lights.

Continue to hold the red button on the safety until pilot stays lit, approximately 30 seconds.

If the pilot goes out, turn all knobs to the off position, and wait 5 minutes before trying to relight the

pilot.

SHUTDOWN

Nightly shutdown: Turn burner valves and thermostat to off position, pilots will remain lit.

Complete shutdown: Turn burner valves and thermostats to off position. Turn main gas supply to

range off.

6

OPERATING INSTRUCTIONS

BEFORE USE

All units are wiped clean with solvents at the factory to remove any visible signs of dirt, oil or grease

remaining from the manufacturing process.

Open Tops & Broilers

The top grates should be removed and washed before use. With these removed it will be possible to remove

plastic ties holding the burners in place for shipment.

Hot Top

The hot top is made of cast iron and should be seasoned before use. To season, pour a small amount of

cooking oil on the top. With a cloth, spread the oil over the entire surface to create a thin film. Wipe off

any excess oil with a cloth. Turn burner on very low and allow top to heat up gradually for about 2 hours.

Repeat this procedure a second time before regular use. This will resist cracking of the cast iron and ensure

a longer life.

Griddle

New griddles should be seasoned as follows:

1. Clean the griddle surface thoroughly with hot soapy water to remove the protective oil coating wiped

on at the factory.

2. Rinse with a mixture of ¼ cup vinegar to one-quart water.

3. Spread unsalted shortening or liquid frying compound evenly over the entire griddle surface.

4. Turn all griddle burners to medium or thermostats to 350 degrees and wait until the shortening

begins to smoke, then turn the burners off.

5. Rub the now melted shortening into the griddle surface with a cloth covering the entire surface.

6. Let the griddle cool, then repeat steps 3,4, & 5.

7. When the griddle is cool after the second seasoning, wipe it once again with a thin film of shortening

or cooking oil.

Oven

Before using the new oven be sure all packing material is removed from the oven. Remove any plastic ties

that may have been used to hold the oven racks in place for shipping. Wipe down the oven interior of any

dirt or debris that may be left from shipping. On initial lighting, turn the oven to 250 degrees and operate

for one hour, then reset the thermostat to its maximum and operate for another hour. This will burn off any

solvents remaining on the unit. At the end of this second hour, turn the thermostat off, open the door and let

cool.

7

OPERATING INSTRUCTIONS

OPERATING SUGGESTIONS

Open Tops

Open top burners are quickly lighted and require no preheating time. Light only as many burners as needed.

Hot Top

Heat the hot top thoroughly before using. During slow periods the top can be kept warm with the burners

turned partially down.

Griddle

Heat the griddle thoroughly before using. During slow periods the top can be kept warm with the burners

turned partially down, or heat only the portion of the griddle required.

Broiler

Allow the grates to thoroughly heat before using. During slow periods heat only the portion required.

Oven

Allow time to preheat ovens before using (25 min. at 400 F). If used properly, the automatic temperature

control will cut gas costs. Do NOTrun on maximum heat all the time. Turn the thermostat down to 250 F

when the oven is idling, or turn it off when not in use.

Moderate oven temperatures will produce better food, reduce shrinkage and keep maintenance costs down.

Using a low temperature for roasting (about 325 F) will reduce meat costs by reducing shrinkage. A pan of

water may be placed on the oven bottom. This water supplies humidity to reduce shrinkage. If necessary,

add water during roasting.

8

CARE AND CLEANING

Any piece of equipment works better and lasts longer when properly maintained. Cooking equipment is no

exception. Your THERMA-TEK appliance must be kept clean during the workday and thoroughly cleaned

at the end of the day.

OPEN TOP

Remove grates and burners and wash thoroughly with hot soapy water. Be sure to clean burner ports

by using a piece of wire

Make sure air shutter openings are clear of any debris.

Make sure pilot flashtube is clear.

Empty crumb trays.

HOT TOP

Wipe the top while still warm with a soft damp cloth or other grease removing material to remove

spillovers, grease etc. before they burn in. A crust on top of the range looks unsightly and slows

down speed of cooking because it reduces the flow of heat to the utensil. If necessary scrape the top

with a nylon scraper.

GRIDDLE

Scrape with a nylon griddle scraper to remove cooked on spills. Use a fine-grained stone only when

absolutely necessary.

Wipe away any griddle stone dust and food particles with a cloth.

Wash with hot soapy water, and then rinse with vinegar and water solution.

Then rinse again with clear water.

Re-oil with shortening or liquid frying compound.

Remove grease can, empty, and clean it thoroughly with hot soapy water.

Never flood the griddle with cold water. This promotes griddle warping and can cause the griddle

plate to crack if continued over a long period of time.

BROILER

Remove large pieces of food residue and carefully scrape spillovers from the drip tray below the

cooking surface.

Cast iron grates should be scraped with a wire brush frequently, and periodically soaked in hot water

to remove grease from the pores of the cast iron. Never expose the grates to extreme heat for the

purpose of burning off excess grease. This practice will shorten the life of the grates.

The lava rock in the Char-rock broiler are highly porous and relatively self cleaning. High heat will

effectively clean and burn off grease. The lava rock should be turned over about every week

depending on the amount of cooking being done and the type of food being prepared.

OVEN

Wipe oven door often during the workday with a damp cloth.

At the end of the workday wipe the oven interior with a damp cloth.

Soften any built up debris by soaking with a damp cloth. Scrape if necessary with a nylon scraper.

STAINLESS STEEL

All stainless steel body parts should be wiped regularly with hot soapy water during the day and with

a liquid cleaner designed for this material at the end of each day. Do not use steel wool, abrasive

cloths, cleansers, or powders to clean stainless steel surfaces. If it is necessary to scrape stainless

steel to remove encrusted materials, soak in hot water to loosen the material, and then use a nylon or

wood scraper to loosen debris. Never use a spatula, knife or any other metal tool to scrape stainless

steel. These tools will scratch the stainless steel.

9

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

SOLUTION

Burner flame to large

Incorrect pressure setting or

orifice

Check pressure setting and orifice.

Burner flame soft and yellow

tipping

Insufficient primary air

Check air shutter setting.

Flame lifts off burner ports

Excessive primary air

Check air shutter setting.

Flame lights back to orifice

Excessive primary air

Check air shutter setting.

Delayed ignition

1) Pilot flame too small

2) Burner ports blocked

3) Incorrect air shutter setting

4) Incorrect pressure setting

5) Pilot lighter tube dirty or

blocked

1) Check pilot flame length.

2) Clean burner ports.

3) Check air shutter setting.

4) Check pressure setting.

5) Clean tube.

Pilot burner will not ignite

1) Pilot blocked or dirty

2) Pilot adjusting screw closed

1) Clean pilot.

2) Open & adjust flame length.

Griddle too hot or not hot enough

Thermostat out of calibration

Check calibration.

Oven too hot or not hot enough

Thermostat out of calibration

Check calibration.

Oven pilot burner will not ignite

1) Pilot orifice is blocked

2) Flame length too short

3) Loose thermocouple

connection

4) Faulty thermocouple

5) Faulty flame safety device

1) Clean pilot orifice and lines.

2) Check flame length & adjust.

3) Tighten connection.

4) Replace thermocouple.

5) Replace safety valve.

HOW TO OBTAIN SERVICE

For warranty service, contact your local THERMA-TEK authorized service agency. Provide him or her

with the Model #, Serial #, date of installation, and a brief description of the problem. If you need assistance

locating the authorized service agency in your area, contact your local dealer. He or she will have a listing

of authorized dealers in your area, or on the web www.therma-tek.com

We want you to remain a satisfied customer. If a problem arises that cannot be resolved to your satisfaction,

please contact our customer service at:

570-455-3000

570-455-9491 (fax)

877-THERTEK (toll free)

Or e-mail us at info@therma-tek.com

For Technical support call: 570-455-3000

10

The Therma-Tek Corporation warrantsitsnewproduct (s) to be free fromdefectsin

material andworkmanship for aperiodof one(1) year fromthe originaldateof

purchase, not toexceedeighteen (18)monthsfromshipment fromthe Factory to

Dealer or Owner–User providedproofof purchaseandinstallation datebeing

providedto Therma-TekCorporationprior to workbeingperformedby an

AuthorizedTherma-TekService agency.Thiswarrantyshall be subject to the

Followingconditionsandlimitations.

1. This warrantyislimitedtoproduct (s) soldto the original commercial user.

2. The liabilityof Therma-Tek under this warrantyislimitedto, at Therma-Tek’s

option,the replacement or repair ofanypartfoundby Therma-Tekor an

authorized service agency to notbe as warrantedherein, providedthatwritten

notice of defectsshall be suppliedto Therma-Tekwithin fifteen(15) daysof its

occurrence.

3. Therma-Tekshall bear normallaborandshippingchargesincurredin such repair

or replacement to theextentthatsuch isperformedwithina fifty(50) milesfrom

an office of an authorizedservice agency of Therma-Tek,except that such

obligation tobear labor chargesshallnotapply to productsor partsinstalled

outside the continental UnitedStates. Shouldservice be requiredat times which

normally involve premiumlabor rates,the Owner-User shall be chargedfor the

difference betweennormal service/shipping rates andsuch premium/shipping

rates. All warrantedpartswill be shipped standardground; anythingother than

groundwill be at the expense of Owner-User.

4. Therma-Tek shall have noobligation astoany product (s) whichhavebeen

misapplied, (includinginstallationforresidential use), mis-handled, damaged,

abused, subjectedto harsh chemical actionor poor waterquality,modifiedby an

unauthorized service personnel,damagedby flood, fireor otheractsofGodor

which have the serial number removedor altered.

5. Adjustmentssuch ascalibrations, airshutteradjustment andadjustmentstopilots

andburners, conversions, leveling, tighteningof fasteners orutility connections,

are the responsibility ofthe Owner-User(customer), Dealer orCertifiedLicensed

installer andnot that of Therma-Tek.

6. Thesewarranty periodsratherthanone(1) year periodhereinprovidedfor other

parts shall applyforthe product (s) listed.

Porcelainenamel andpaint–90daysfrom purchase/installation.

Rubber seals, door seals, chain mechanisms, light bulbsandgaskets–90 daysfrom

purchase/installation.

Cast-iron parts–90 daysfrompurchase/installation.

Sight glass, spark Ignitors, andbroiler briquettesanddrip shields–90daysfrom

purchase/installation.

Mobile Food Truck/ Trailer–equipmentwill have 30 Dayswarrantyafterpurchase

for any Therma-Tek product (s) installedon mobile kitchens;or usedfor Mobile

FoodService.

All service issuesneedto be accompaniedby proofof purchaseandcopyof

certification from gas installer’s receipt of compliance/ installation.

7. Therma-TekRange AuthorizedService Agencies under contract guarantee

Warrantywork within thirty(30) daysforreplacementpartsand/or issues after

Installation andreceiptof service rendered. Therma-Tek Range guarantees

Replacementpartsandorservicelabor for ninety(90) daysafterservice receipt

For service work beingperformedby an AuthorizedService Agency andunit

Beingrepairedandgoodworkingcondition. AuthorizedService Agencymay

Require a credit cardbefore enteringpremises fornon-warrantedissues.

8. This states the exclusive remedyagainst Therma-Tekrelatingtothe product(s)

Whetherin contractor in tort or under any otherlegaltheory,andwhether

Arisingout of warranties, representations, instructions, installationsor defects

From any cause.

9. Thiswarrantyandthe liabilitiesset forthherein areexclusiveandin lieuof

Allof their liabilities andwarranties,expressedor implied, includingbut not

Limitedto, impliedwarrantiesor merchantability andfitnessforparticular

Purpose andconstitutes the only warrantyof Therma-Tekwith respect tothe

Product (s).

10. Therma-Tekshall notbeliable, whetherin contract or in tortor under any

Other legaltheory,forlossof use, revenueor profit, orfor substituteuse of

Performance,forincidental indirect, or specialorconsequential damagesor

For any other lossof costof similartype.

WARRANTY REQUIREMENT

For reliable operation and for your own safety, this professional cooking equipment must be installed by a

certified/ licensed contractor.

Failure to comply will void any written or implied warranty.

Should the equipment require service during the standard warranty period, the receipt proving certified

installation?

Must be made available to Therma-Tek Range for verification.

If installation was not performed be a certified/ licensed contractor, be prepared to submit a major credit card

For payment for proper installation prior to service.

TERMS AND CONDITIONS

Terms: Net 30 days subject tocredit approval.All amounts past due are subject to 1.5% permonth service charge will be appliedto all invoices 30 days

Or more past due.

FOB: Factory

Prices:All prices are subject tochange without notice. Prices do not include sales or any other local statetax.

Shipments:Shipments must beinspected for damaged cartons and shortages promptly noteduponreceipt and also noted on delivery receipt. All

Shipments shall be inspectedfor hidden or concealed damage and noted and reportedwithin ten (10) days tocarriers and request an

Inspectionat once.

Therma-Tek’s responsibility for shipments ceases with acceptance by carriers and to Dealer or Owner-User.Once product is received free

And clear; Therma-Tek is not responsiblefor any hidden or concealed damages for equipment or part(s). Noclaims for damaged or missing

Will be recognized unless writtennotice to Therma-Tek within ten(10) days of receipt. Therma-Tek is not responsible of repair of damaged

Goods created during transit,delivery and installation or created by acts of God.

Goods: Returned goods are subject toa 20% re-sticking charge and the cost of reconditioning. Return Authorization (“RA”) number for all returns must

Be placed on label and shippedback to Therma-Tek. Merchandise without an RA number will not be accepted. All authorizedreturns must be

Sent freight pre-paid.All orders over sixty (60) days will not be accepted. Customunits built to buyerspecifications may not be returnedor

Cancelled.

Rush Shipments: Ordersrequiringnext, 2nd or 3rd day priority shipments must be placed by 1:00 PM EasternStandard Time. Rush shipment cannot be

Guaranteed.

Note: Since continuing product improvement is a Therma-Tek policy, the factory reserves the right to change specifications, designs and material

Without notice.

THERMA-TEK TERMS OF SALE AND ORIGINAL EQUIPMENT WARRANTY FOR

INSTALLATIONIN THE U.S.A. ORIGINAL WARRANTY

Table of contents

Other Therma-tek Range manuals

Popular Range manuals by other brands

Thermador

Thermador Pro Grand PD30 Care and use manual

Electrolux

Electrolux EI30GF35JSA Use & care guide

Frigidaire

Frigidaire CGLEF379GC installation instructions

Whirlpool

Whirlpool 98014106 installation instructions

Kenmore

Kenmore 790.9258 Use & care guide

Frigidaire

Frigidaire FEF326A Factory parts catalog