THERMA Big Dipper 40000 Series User manual

40000 Series Big Dipper®

Technical Support Instructions

2 • info@thermaco.com • www.big-dipper.com • 1-800-633-4204 Copyright 2014 • Big Dipper® Thermaco, Inc®

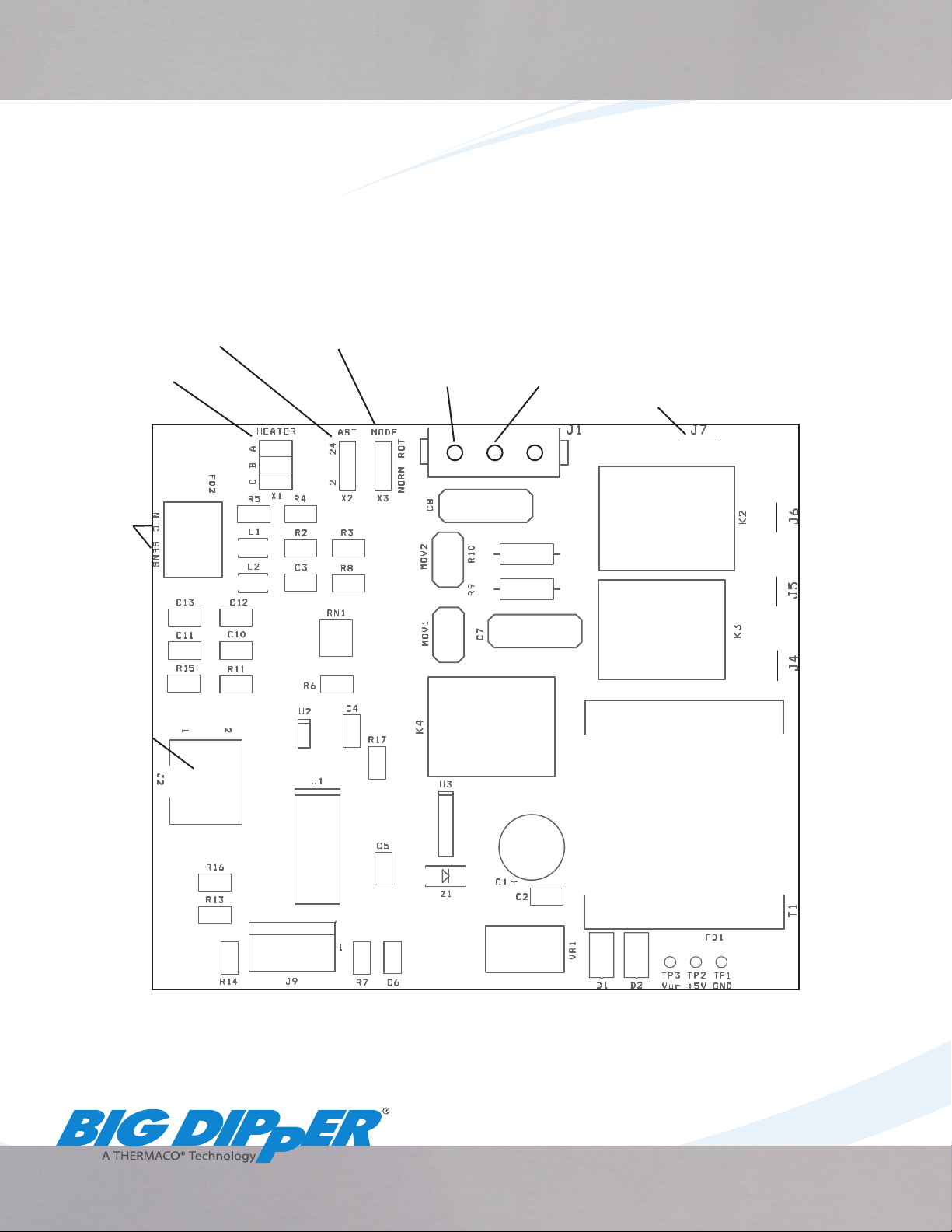

Board Diagram for 40000 Series Big Dipper

Printed Circuit Board

The 40000 Series Big Dipper uses a Digital Control Timer with pre-set skim times and frequencies hard

programmed into a circuit board within the Center Lid Assembly. Below you will nd a diagram of

the board, standard settings for various modes and the procedures for changing these settings on the

board.

Heater Settings

(page 3)

AST Modes

(page 3) Skim Operation

Settings (page 4)

Ribbon Cable

(to Push Button

Interface)

Heater Connection

Motor

Connection

Board Power

(115 V )

Board Power

(220-240 V)

Neutral

(to Power

Supply Cord)

Thermistor

Connections

AST Solenoid

Connection

Copyright 2014 • Big Dipper® Thermaco, Inc®. • 3info@thermaco.com • www.big-dipper.com • 1-800-633-4204

Heater Settings

There are three separate options for heater operation in the 40000 Series Big Dipper. Settings are enabled

by moving the jumper to the correct position on the jumper block marked HEATER.

Simultaneous Heat Operation (Standard)

Units Ship with jumper in Position B, which results in Simultaneous Heater Operation meaning

the Heater will activate anytime the motor is engaged.

Fluid Preheat Operation

To activate Fluid Preheat setting, move jumper to Position C on the jumper block using needle

nose pliers. In this setting, heater will activate prior to skim cycle, which will begin once the

liquid temperature has reached 130º F or after a maximum of 2 hours has passed. The heater

will continue to operate under Thermistor control until skim cycle is complete.

No Heater Operation

To deactivate heater, move jumper to Position A. In situations with low water turnover or

grease production, a heater may not be necessary. Contact a Thermaco representative before

deciding to deactivate heater operation.

AST Settings

The AST Settings only aect operation of the unit when the AST Solenoid is wired to the board. This

comes standard in the AST line of Big Dipper Units and the setting chosen determines how often and

for how long the AST function operates.

2 Hour Interval (Standard for W-750-AST and W-1250-AST Models)

In this setting, used with W-750-AST and W-1250-AST Models, the AST Feature will operate for

15 seconds every 2 hours, ushing incidental solids from the system. The jumper will be placed

on the lower two jumper pins to activate this setting.

24 Hour Interval (Standard for W-250-AST)

In this setting, used with the W-250-AST, the AST Feature will operate for 10 seconds every 24

hours, ushing incidental solids from the system. The jumper will be placed on the upper two

jumper pins to activate this setting.

Board Settings for 40000 Series Big Dipper

NOTICE:

This document contains information on changing the settings inside the Center Lid Assembly of a 40000

Series Big Dipper. DISCONNECT POWER TO CENTER LID ASSEMBLY BEFORE MAKING CHANGES.

Contact a Thermaco representative before making changes to settings.

Use needle nose pliers to remove and replace jumpers.

4 • info@thermaco.com • www.big-dipper.com • 1-800-633-4204 Copyright 2014 • Big Dipper® Thermaco, Inc®

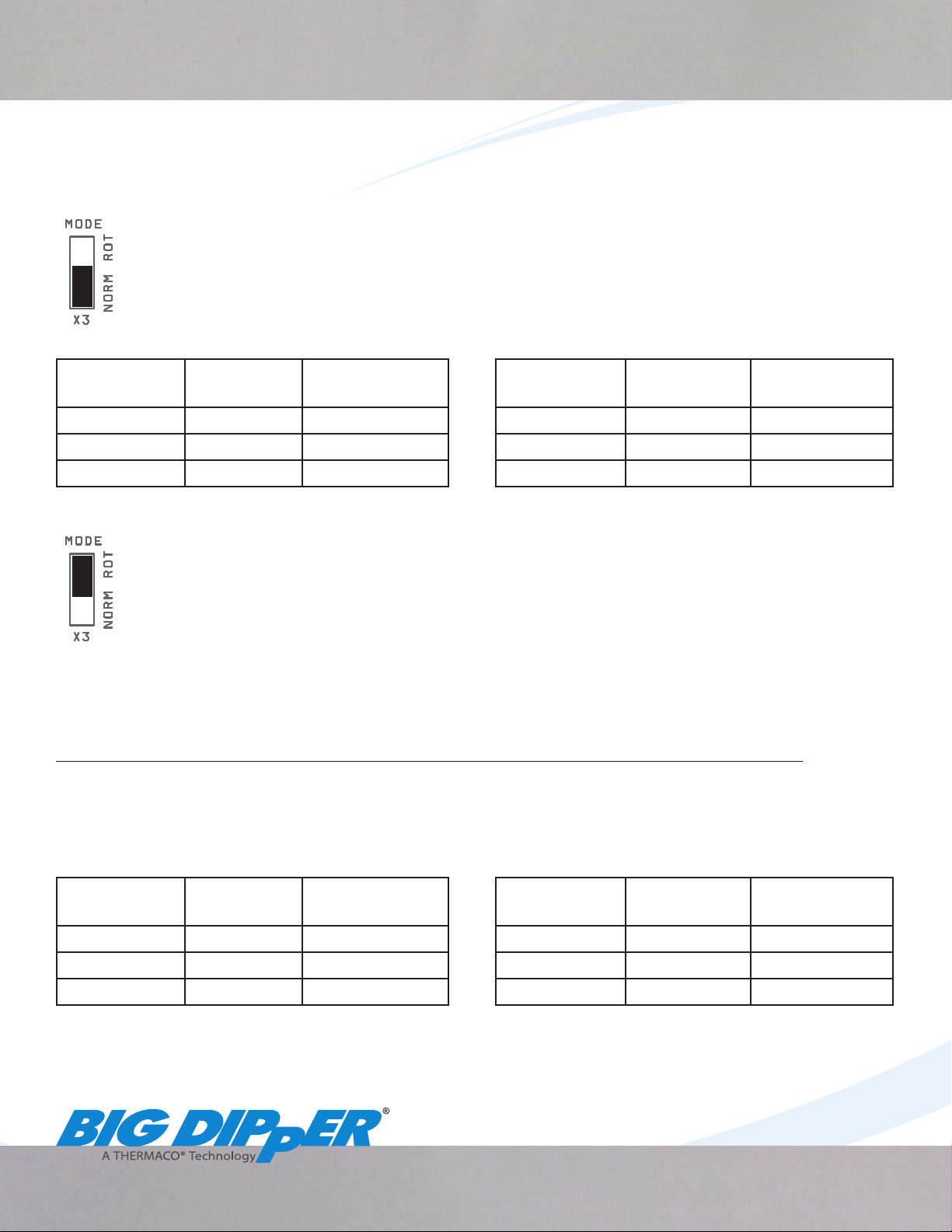

Skim Operation Settings

There are two separate options for timer operation in the 40000 Series Big Dipper. Settings are enabled

by moving the jumper to the correct position on the jumper block marked MODE.

Normal Time-Based Operation

IS and AST Big Dippers ship in Normal Timer Operation which includes both Default and

Extreme Skim Modes with the jumper on the lower two pins closest to “NORM” on the jumper

block.

Default Mode Extreme Mode**

Button

Selected Skim Time Delay Between

Skims*

Button

Selected Skim Time Delay Between

Skims*

Light (I) 15 Minutes 76 Hours Light (I) 90 Minutes 19 Hours

Moderate (II) 30 Minutes 19 Hours Moderate (II) 120 Minutes 19 Hours

Heavy (III) 60 Minutes 19 Hours Heavy (III) 120 Minutes 9.5 Hours

Rotisserie/Thermistor Operation

Big Dipper Models shipped with a Supplemental Water Supply (SWS) for use with Rotisseries

and Combi-Ovens are preset in Rotisserie Mode with the jumper on the upper two pins

closest to “ROT” on the jumper block. When this jumper position is selected, normal, time-

based skimming is discontinued and operation is controlled by rises in temperature. When

the temperature increases by 15º F or more, the skim cycle is immediately initiated. The skim time is

determined by the mode selected and operates for the duration designated in the table below. Toggling

between default and extreme modes is achieved by the same method described previously.

If no temperature change occurs during the setting’s maximum delay between skims (see tables

below), the Big Dipper reverts to operating in standby mode and operates at the preset skim frequency.

If a Supplemental Water Supply (SWS) is used in conjunction with this mode, the SWS will operate

whenever the motor is engaged.

Default Mode Extreme Mode**

Button

Selected Skim Time Delay Between

Skims*

Button

Selected Skim Time Delay Between

Skims*

Light (I) 30 Minutes 6 Hours Light (I) 30 Minutes 2 Hours

Moderate (II) 60 Minutes 6 Hours Moderate (II) 60 Minutes 2 Hours

Heavy (III) 90 Minutes 6 Hours Heavy (III) 90 Minutes 2 Hours

* Delay between Skims is the time from the start of the 1st skim to the start of the next skim. This is the maximum amount of time the unit will go between

skims in Rotisserie Operation if a temperature change of 15º F or greater does not occur.

**Access Extreme Mode by interrupting power from unit (disengage safety switch or unplug from electrical socket) and then holding down Heavy (III)

Button while resuming power supply to unit. To return to Default Mode, interrupt power and hold down Light (I) Button while supplying power.

Board Settings for 40000 Series Big Dipper

Copyright 2014 • Big Dipper® Thermaco, Inc®. • 5info@thermaco.com • www.big-dipper.com • 1-800-633-4204

Board Settings Quick Reference Guide

IS Unit Jumper Settings

At right are standard jumper settings for the Printed Circuit Board on the

Internal Strainer Line of Big Dipper Units.

HEATER: Jumper on Position B for Silmutaneous Heat

AST: N/A

MODE (Skim Operation): Jumper on NORM for Normal Time-Based Operation

W-250-AST Jumper Settings

At right are standard jumper settings for the Printed Circuit Board on the

W-250-AST.

HEATER: Jumper on Position B for Silmutaneous Heat

AST: Jumper on upper two pins; AST function operates 10 seconds every 24 hours

MODE (Skim Operation): Jumper on NORM for Normal Time-Based Operation

W-750-AST and W-1250-AST Jumper Settings

At right are standard jumper settings for the Printed Circuit Board on the

W-750-AST and W-1250-AST.

HEATER: Jumper on Position B for Silmutaneous Heat

AST: Jumper on lower two pins; AST function operates 15 seconds every 2 hours

MODE (Skim Operation): Jumper on NORM for Normal Time-Based Operation

Rotisserie Operation Jumper Settings (for use with SWS)

At right are standard jumper settings for the Printed Circuit Board on Big

Dipper units shipped with Supplemental Water Supplies for use with

Rotisseries or Combi-Ovens.

HEATER: Jumper on Position B for Silmutaneous Heat

AST: N/A

MODE (Skim Operation): Jumper on ROT for Rotisserie/Thermistor Operation

6 • info@thermaco.com • www.big-dipper.com • 1-800-633-4204 Copyright 2014 • Big Dipper® Thermaco, Inc®

Push Button Interface

Three separate silicone momentary contact buttons for

Light (I), Moderate (II), and Heavy (III) skimming modes

and a Start Button for testing and immediate operation.

Built-in LED’s behind buttons indicate mode chosen and

blink during operation.

Startup

**Before applying power to unit, always make sure tank is full of

water**

1. Upon applying power to the unit, all lights will activate

for 1 second.

2. If the (I) Button blinks 4 times, the unit is operating in

Default Mode.

3. If the (III) Button blinks 4 times, the unit is operating in Extreme Mode.

4. The last setting chosen will remain illuminated. See corresponding chart (page 4) to determine skim

time and frequency chosen.

Operation

1. During a skim cycle, the skim setting will remain illuminated.

2. The Start Button will light up during a skim cycle.

Error Codes

In Error Code events, all four lights on the Push Button Interface will ash in one of the following

sequences:

1. 3 Flashes - There is no information coming from the thermistor. Check to ensure the wire is properly

connected to the board and there are no frays in the wires. If wiring is correct, replace thermistor.

2. 4 Flashes - The thermistor is reading an extremely high temperature inside the tank, meaning the

water level inside the unit has dropped below the heater. Check to verify the tank is full of liquid

and cycle power. If error code repeats despite the heater sitting in liquid, replace the thermistor.

3. 5 Flashes - There is a voltage out of range on the printed circuit board. Verify that all wiring

connections are secure and there are no frayed wires inside the Center Module. If wiring is correct,

printed circuit board (PCB-2) will need to be replaced.

Light Codes for 40000 Series Big Dipper

VOICE 336-629-4651 FAX 336-626-5739

PO BOX 2548, ASHEBORO, NC 27203

646 GREENSBORO STREET

DESTROY THIS DRAWING, IT IS THE SOLE PROPERTY OF THERMACO, INC. AND MUST BE RETURNED UPON REQUEST.

OF THIS DRAWING DOES CONSTITUTE AN IMPLIED AGREEMENT BETWEEN THERMACO, INC. AND THE HOLDER OF THIS DRAWING. DO NOT

WRITTEN CONSENT FROM THERMACO, INC. POSSESSION OF THIS DRAWING DOES NOT CONSTITUTE THE RIGHT TO MANUFACTURE. POSSESSION

THIS DRAWING CONTAINS PROPRIETARY AND PATENTED MATERIAL. THIS DRAWING MAY NOT BE REPRODUCED IN WHOLE OR IN PART WITHOUT

.XXX +/- 0.015

.XX +/- 0.03

Decimals

+/-1°

Angular

Tolerances

Dimensions are in inches

Unless otherwise specified

MATERIAL (UNLESS NOTED)

FINISH (UNLESS NOTED) PART NO.

CHECKED

ENGINEERING

DRAWN DATE

A

THIRD ANGLE PROJECTION

RELEASE DATE

REVISIONS

ZONE REV DESCRIPTION DATE APPROVED

SCALE SHEET OF

SIZE REV. NO. DWG NO.

Heavy Setting (III):

Use for Steakhouses,

Buffets, Heavy Grease

producing sites.

Start Button: Press

to begin a cycle early

or to test operation..

Light Setting (I):

Use for small cafes,

coffee and ice cream

shops.

Moderate Setting (II):

Use for Quick and Full-

Service restaurants.

Table of contents

Other THERMA Ventilation Hood manuals

Popular Ventilation Hood manuals by other brands

Kleenmaid

Kleenmaid KCRHSO6010 Instructions for use and warranty details

Bosch

Bosch DFS097K51 User manual and assembly instructions

Zanussi

Zanussi ZFG215S user manual

Küppersbusch

Küppersbusch KD 9550 Instruction booklet

Faber

Faber CRISTAL Installation instruction

Multikomplex

Multikomplex SLT966-EM Installation, Use and Maintenance Instruction