TURBOMAX Use and Care Manual with Installation Instructions July 2014 Page

4

Introduction

The important safeguards and instructions

appearing in this manual are not meant to

cover all possible conditions and situations

that may occur. It should be understood that

common sense, caution and care are factors,

which cannot be built into every product.

These factors must be supplied by the

person(s) caring for and operating the unit.

LOCAL INSTALLATION REGULATIONS

This water heater must be installed in

accordance with these instructions and must

conform to local, or in the absence of local

codes, with the current edition of the National

Plumbing Code and the National Electric Code.

In any case where instructions in this manual

differ from local or national codes, the local or

national codes take precedence.

DECISIONS REQUIRED BEFORE

INSTALLATION

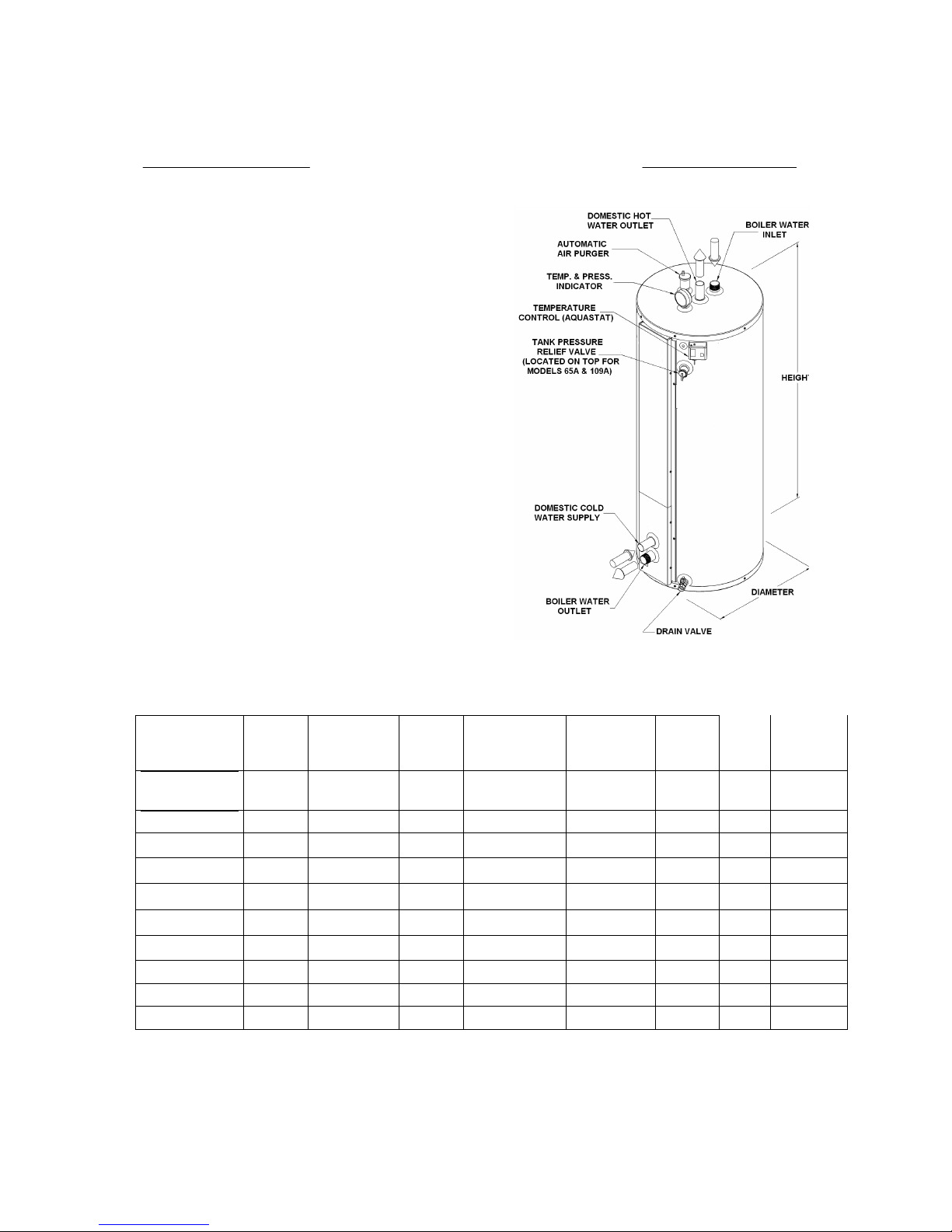

The tank of the Turbomax water heater (boiler

water) is factory shipped with a 30psi (207kPa)

pressure relief valve except on models109,

65ASME and 109ASME where it is factory set at

50psi (344kPa). If the water application requires

a higher operating pressure on the tank and If

local jurisdictions permit it, this valve can be

change by a higher pressure rated valve (max

150psi or 200psi on ASME models). But, on an

installation used to provide hot water for

domestic use, the tank pressure must always

remain lower than the pressure of the domestic

water supply specially on applications where a

potentially toxic heat transfer solution is used

inside the Turbomax tank

In some jurisdictions the boiler’s operating

pressure must be limited to 30 psi (207 kPa) by

a safety relief valve. When a higher operating

pressure level is needed, select a boiler which is

certified to operate at the required pressure.

The boiler’s output rating must be within the

heater’s recommended sizing guide

specifications. Too high an output rating may

cause a boiler short cycling condition.

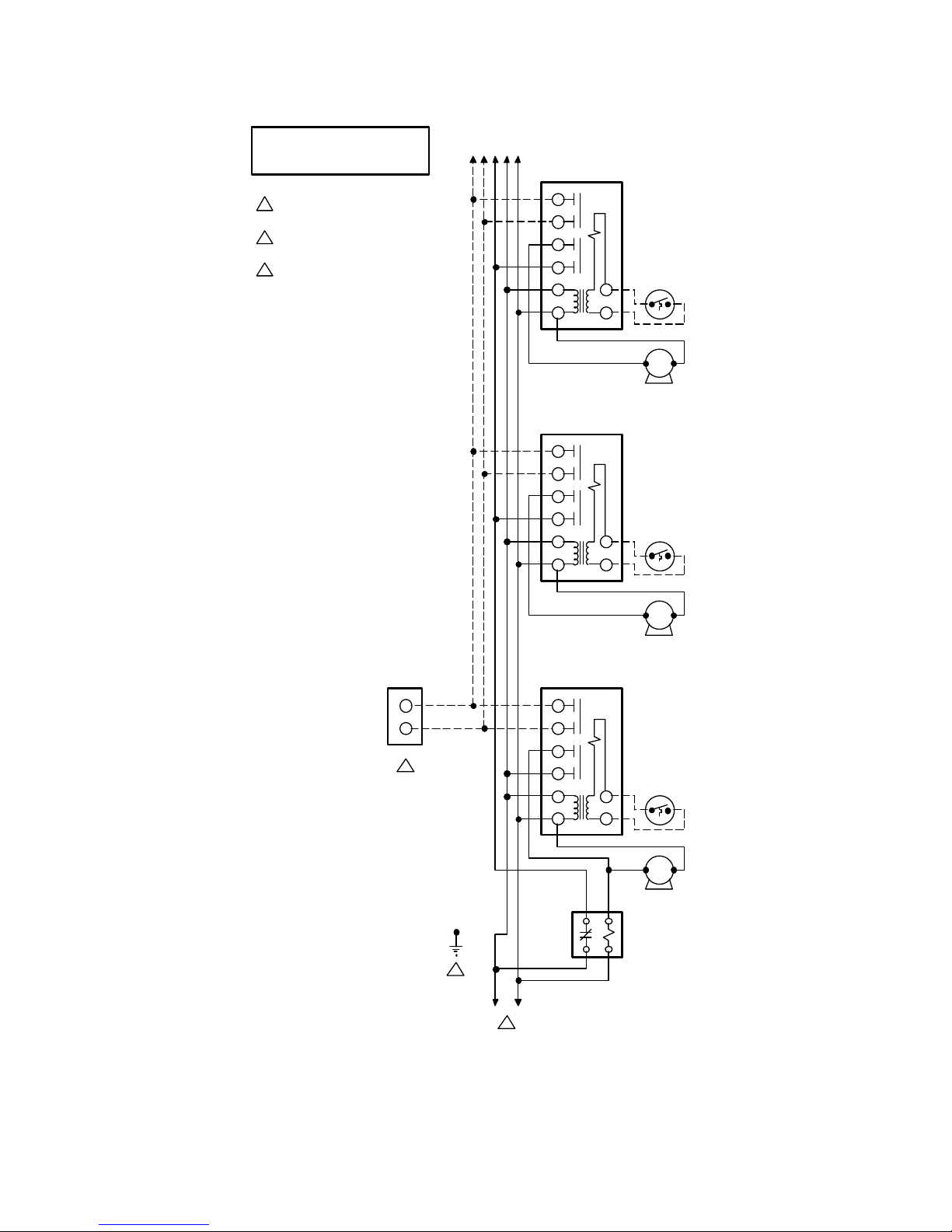

Where the boiler’s output is used to supply

space heating and domestic water heating, two

options are available when wiring the controls.

The first option uses a priority relay. When the

aquastat of the water heater calls for heat, the

relay shuts off the space heating zones, giving

priority to producing domestic hot water. Any

demand for space heating is postponed until the

water heater has reached a preset level. This

delay in supplying the space heating zones is

usually not noticed by those occupying the living

space. The water heater gets adequate hot

water flow from the boiler to maintain the full

rated delivery of domestic hot water.

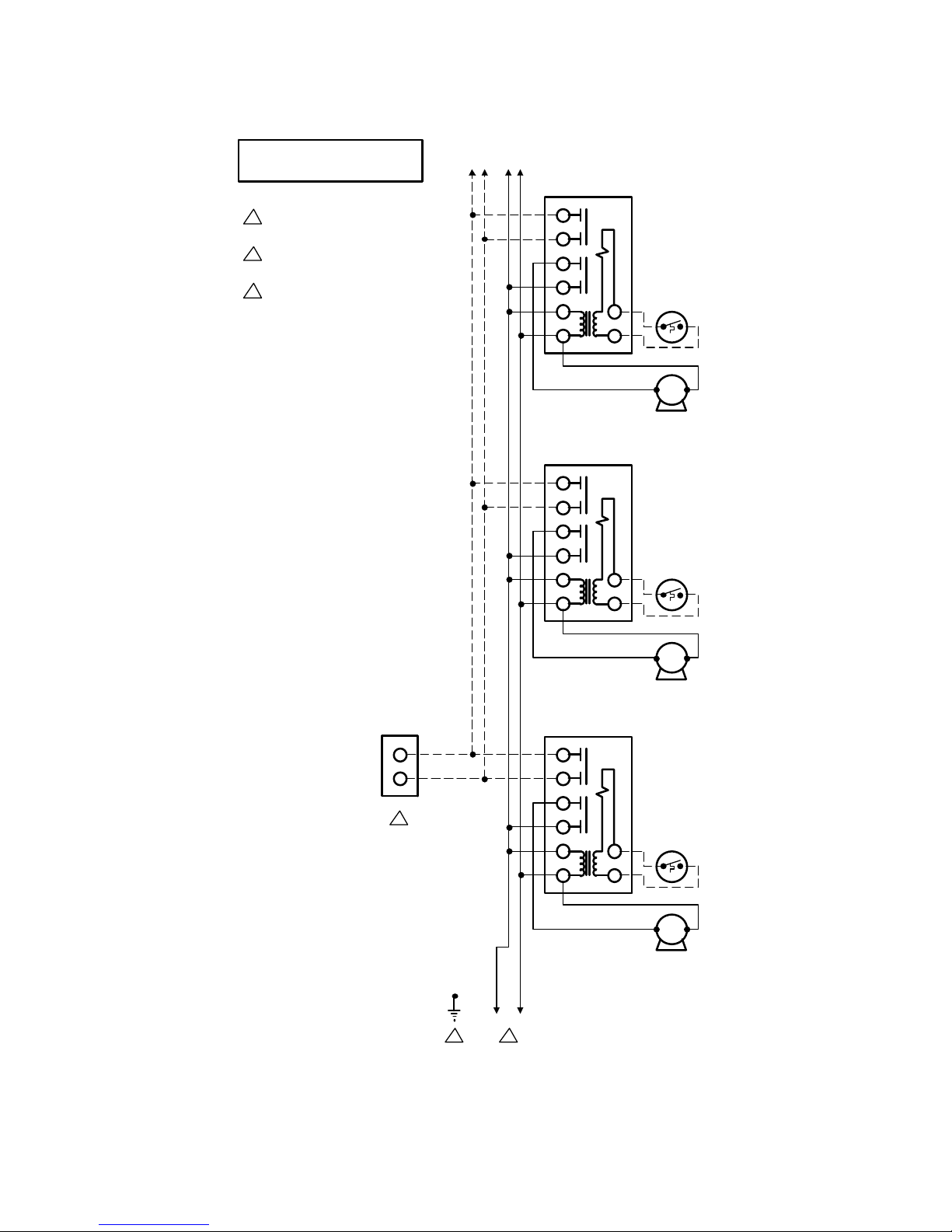

In the second option, the water heater will be

supplied as just another heating zone. This

means that if all space heating zones call for hot

boiler water at the same time, the water heater

may not be supplied with enough hot boiler

water to “recover” adequately. The delivery of

domestic hot water will be diminished. This is

not a problem when the boiler output is sized

adequately for both loads.

The flow of hot boiler water to the water heater

can be controlled with either a pump or a

motorized valve. If a zone valve is to be used,

the space heating system circulator must have

an adequate flow rate to allow proper heat

transfer of BTUs from the hot boiler water stored

in the tank to the domestic water flowing inside

the water heater’s heat exchanger. Be sure the

space heating zone valve chosen has maximum

pressure drop to insure proper boiler water flow

to the heater. The recommended way to provide

adequate boiler water flow through the water

heater is to use a separate dedicated circulator.

This option may be used even though the

heating system utilizes zone valves.

The heat transfer medium must be water or

other non-toxic fluid having a toxicity rating

or class of 1, as listed in Clinical Toxicology

of Commercial Products, 5

th

edition

LOCATION

The water heater should be installed in a clean,

dry location as close as practical to the boiler or

the heat source. Long hot water lines should be

insulated to conserve water and energy. The

water heater and water lines should be protected

from exposure to freezing temperatures.

TURBOMAX

®

water heaters must be installed

vertically. Use the adjustable feet to level the

unit.

The water heater must be located or protected

so it is not subject to physical damage, for

example, by moving vehicles, area flooding, etc.

WARNING

!

CAUTION

!