Titan Lifts HD2P-11000ACX Instruction manual

1

®

INSTALLATION, OPERATION,

& MAINTENANCE MANUAL

FOLLOW THIS MANUAL CAREFULLY TO ENSURE THE MACHINE WILL

FUNCTION CORRECTLY AND PROVIDE MANY YEARS OF DEPENDABLE SERVICE.

FAILURE TO FOLLOW THESE INSTRUCTIONS AND SAFETY WARNINGS MAY

RESULT IN PERSONAL INJURY OR PROPERTY DAMAGE. KEEP THIS MANUAL IN

A SAFE DRY PLACE FOR FUTURE REFERENCE.

MODEL:

HD2P-11000ACX

11,000 LB CAPACITY 2 POST LIFT

To Our Valued Customers:

Thank you for purchasing a Titan Lifts® product. We hope this high quality equipment provides you with years of

dependable service.

It is unfortunate that rare situations may occur with the products you purchase from Titan Lifts®. We value your

business as well as the trust you have and need to maintain your relationship with us. Titan Lifts® carries liability

coverage that may protect our customers if a situation does occur. However, as in all accidents there must be

proof of liability for a claim to be made. Our insurance company requires the following procedures be observed in

order to consider a claim:

A. The claimant must contact the Titan Lifts® distributor immediately with the facts of the situation.

B. If any equipment is damaged, including vehicles or shop equipment, Titan Lifts® must be given the

opportunity to send and impartial representative to the site for proper assessment of the situation.

C. The Vehicle cannot be moved until either an impartial representative has reviewed the accident or clear

and precise pictures are taken that reect all the pertinent information for an impartial representative to be able

to access the information from a distance. Titan Lifts® or its representatives must approve the pictures before

anything can be moved.

D. If any potential liability is determined on behalf of Titan Lifts®, two estimates must be submitted for

damages to be reimbursed.

It is imperative that the claimant complies with these procedures, because without proper assessment of the situ-

ation a claim will be denied.

ARBITRATION NOTICE

The installation or use of this equipment shall constitute an acknowledgement that the user agrees to resolve any

and all disputes or claims of any kind whatsoever, which relate in any way to the equipment, by way of binding

arbitration, not litigation. No suit or legal action may be led in any state or federal court. Any arbitration shall be

governed by the Federal Arbitration Act, and administered by the American Mediation Association, Indianapolis

Indiana. The maximum amount that an arbitrator may award and all damages shall not exceed the retail value of

this equipment.

WARRANTY NOTICE

This equipment must be installed by a “Professional Installer” assembled and used in the manner according to

the documentation provided to be covered by warranty.

Damaged or missing components must be reported within 72 hours of receipt to your freight carrier and to the

distributor. Claims must be led to cover cost.

If you have any questions or if we can be of any further assistance, please don’t hesitate to contact a Titan Lifts®

representative at 1-888-908-4826. Thank you for the opportunity to continue to serve your lift equipment needs.

®

PO Box 7069 Greenwood, IN 46142

1.888.908-4826 FAX (317) 215.2770

www.titanlifts.com

TITAN MARKETING, LLC

3

CONTENT

1. Safety ..........................................................................Page 1

1.1 Introduction ...................................................................................Page 1

1.2 Safety Instructions for Commissioning..........................................Page 1

1.3 Safety Instructions for Operation...................................................Page 1

1.4 Safety Instructions for Maintenance..............................................Page 3

1.5 Risks ............................................................................................. Page 3

1.6 Description ....................................................................................Page 4

2. Unpacking and set-up .................................................Page 5

2.1 Delivery & check of packages .......................................................Page 5

2.2 Lifting & handling...........................................................................Page 5

2.3 Preparation....................................................................................Page 5

3. Specications .............................................................Page 6

4. Floor Requirements.....................................................Page 6

4.1 Select the site area .......................................................................Page 6

4.2 Floor Requirements.......................................................................Page 6

4.3 Concrete and Anchoring Information.............................................Page 7

4.4 Anchoring tips................................................................................Page 8

5. Installation Instructions ........................................Page 8-10

6. Operation Instructions .............................................Page 11

6.1 Defects / Malfunctions................................................................. Page 11

6.2 Controls....................................................................................... Page 11

6.2.1 Up Controls .............................................................................. Page 11

6.2.2 Safety Lock Control.................................................................. Page 11

6.2.3 Lowering Control ......................................................................Page 12

6.3 Operation .................................................................................... Page 12

7. Maintenance..............................................................Page 14

7.1 Maintenance Schedule................................................................Page 14

7.1.1 Daily .........................................................................................Page 14

7.1.2 Weekly......................................................................................Page 14

7.1.3 Monthly.....................................................................................Page 15

7.1.4 Bimonthly ................................................................................. Page 15

7.1.5 Yearly .......................................................................................Page 15

7.1.6 Every Other Year...................................................................... Page 16

7.2 Maintenance by the Operator......................................................Page 16

7.2.1 Hydraulic System .....................................................................Page 16

7.2.2 Greasing Points........................................................................Page 17

7.2.3 Operation and Wear Checks .................................................... Page 17

7.2.4 Lift Stability...............................................................................Page 17

7.3 Cleaning ......................................................................................Page 17

8. Troubleshooting ........................................................Page 18

9. Owner / Employer Responsibilities ...........................Page 19

10. Diagrams Fig. 1-11 .............................................Page 20-25

11. Parts Diagrams ..................................................Page 26-27

12. Diagram Fig. 16 .......................................................Page 28

1

1.SAFETY

INSTRUCTIONS

1.1 INTRODUCTION

WARNING: READ ENTIRE MANUAL AND COMPLY WITH ALL SAFETY AND

SERVICE PRECAUTIONS. DEATH, PERSONAL INJURY AND / OR PROPERTY DAMAGE

MAY OCCUR IF INSTRUCTIONS ARE NOT FOLLOWED CAREFULLY.

Personal injury and property damage incurred due to non-compliance with these safety

instructions are not covered by the product liability regulations.

1.2 SAFETY INSTRUCTIONS FOR COMMISSIONING

• The lift may be installed and commissioned by authorized service personnel only.

• The standard lift version may not be installed and commissioned in the vicinity of

explosives or ammable liquids, outdoors or in moist rooms (e.g. car wash).

1.3 SAFETY INSTRUCTIONS FOR OPERATION

• Read this entire manual.

• Load should not exceed rated capacity for this lift – 11,000 lbs. (2,750 lbs per lift arm)

• Only trained authorized personnel over the age of 18 years should operate the lift.

• Indoor use recommended.

• Always lift the vehicle using all four arms.

• Never use the lift to raise one end or one side of vehicle.

SYMBOLS

FAILURE TO COMPLY WITH INSTRUCTIONS COULD RESULT IN

PERSONAL INJURY.

FAILURE TO COMPLY WITH INSTRUCTIONS COULD RESULT IN

PROPERTY DAMAGE.

IMPORTANT INFORMATION.

2

• Maintain a safe working environment. The work area should be clean, dry, clutter free,

and sufciently lit.

• Vehicle doors should be closed during the raising and lowering cycles.

• Closely watch the vehicle and lift during the raising and lowering cycles.

• Do not operate the lift in explosive atmospheres, such as in the presence of ammable

liquids, gases, or dust. Power equipment can create sparks which may ignite ammables.

• Keep hands, tools, and other extremities from under carriage and moving parts.

• Never operate this lift with someone on it.

• Do not allow anyone on the lift or inside a raised vehicle.

• Keep children and bystanders away from work area. Do not let children operate or play

on lift.

• Wear proper safety attire. Do not wear loose tting clothing while operating lift. Long hair,

jewelry and sleeves should be secured.

• Never leave the lift unattended while under a load.

• Do not operate this lift if under the inuence of drugs, alcohol, or medication. Operator

must be alert at all times when using heavy lift equipment.

• Comply with all applicable accident prevention regulations.

• Only use the vehicle manufacturer’s recommended lifting points.

• After positioning the vehicle, apply the parking brake.

• Use caution when removing or installing heavy vehicle components which may result in

center-of-gravity displacement.

• Use this lift only for the work it is intended. Do not use this product for an application for

which it was not designed. Misuse can lead to personal injury and/or property damage.

WARNING: Prior to completely raising the vehicle, raise the vehicle 6” off the ground

and check the adapter pads for solid contact by performing the “BUMPER TEST”. Walk

around the back of the vehicle and push up and down on the bumper. The vehicle will rock,

but should not at any time lose contact with the pads. If the vehicle is bouncing off the pads

or feels at all unstable, you should lower it back to the ground and reposition the pads to

balance the load. Repeat this process until the vehicle is completely stable.

WARNING: Use this lift only in well ventilated areas. Carbon monoxide exhausted

from running vehicle engines is a colorless, odorless fume that, if inhaled, can cause serious

personal injury or death.

WARNING: People with pacemakers should consult their physician(s) before using

this product. Operation of electrical equipment in close proximity to a heart pacemaker could

cause interference or failure of the pacemaker.

WARNING: This product contains or produces a chemical known to the State of

California to cause cancer and birth defects (or other reproductive harm). (California Health

& Safety Code 25249.5 et seq.)

3

1.4 SAFETY INSTRUCTIONS FOR MAINTENANCE

• Maintenance or repair work should be done by authorized service personnel only.

• Work on the electrical equipment should be done by certied licensed electricians only.

• Ensure that ecologically harmful substances are disposed of in accordance with the

appropriate regulations.

• To prevent the risk of damage, do not use high pressure / steam jet cleaners or caustic

cleaning agents.

• Do not replace or override the safety devices.

1.5 RISKS

WARNING: Risks the personnel could encounter, due to an improper use of the lift,

are described in this section.

CRUSHING RISKS

During lowering of runways and vehicles, personnel must not be within the area

covered by the lowering trajectory. The operator must be sure no one is in danger before

operating the lift.

RISK OF THE VEHICLE FALLING FROM THE LIFT

Vehicle falling from the lift can be caused when the vehicle is improperly placed on platforms,

and when its dimensions are incompatible with the lift or by excessive movement of the

vehicle. To avoid injury in this situation, immediately exit the work area.

BUMPING RISK

When the lift is stopped at relatively

low height for working, the risk of

bumping against projecting parts

occurs.

WARNING

!

Avoid excessive

rocking of vehicle

while on lift.

WARNING

!

Remain clear of lift

when raising or

lowering vehicle.

WARNING

!

Keep feet clear of

lift while lowereing.

WARNING

!

Do not override

self-closing lift

controls.

WARNING

!

Position vehicle

with center of

gravity midway

between adapters.

WARNING

!

Clear area if vehicle

is in danger of

falling.

WARNING

!

Avoid bumping your

head on lift or

vehicle.

WARNING

!

Avoid pinch points

on moving parts

during operation.

WARNING

!

Avoid excessive

rocking of vehicle

while on lift.

WARNING

!

Remain clear of lift

when raising or

lowering vehicle.

WARNING

!

Keep feet clear of

lift while lowereing.

WARNING

!

Do not override

self-closing lift

controls.

WARNING

!

Position vehicle

with center of

gravity midway

between adapters.

WARNING

!

Clear area if vehicle

is in danger of

falling.

WARNING

!

Avoid bumping your

head on lift or

vehicle.

WARNING

!

Avoid pinch points

on moving parts

during operation.

WARNING

!

Avoid excessive

rocking of vehicle

while on lift.

WARNING

!

Remain clear of lift

when raising or

lowering vehicle.

WARNING

!

Keep feet clear of

lift while lowereing.

WARNING

!

Do not override

self-closing lift

controls.

WARNING

!

Position vehicle

with center of

gravity midway

between adapters.

WARNING

!

Clear area if vehicle

is in danger of

falling.

WARNING

!

Avoid bumping your

head on lift or

vehicle.

WARNING

!

Avoid pinch points

on moving parts

during operation.

WARNING

!

Avoid excessive

rocking of vehicle

while on lift.

WARNING

!

Remain clear of lift

when raising or

lowering vehicle.

WARNING

!

Keep feet clear of

lift while lowereing.

WARNING

!

Do not override

self-closing lift

controls.

WARNING

!

Position vehicle

with center of

gravity midway

between adapters.

WARNING

!

Clear area if vehicle

is in danger of

falling.

WARNING

!

Avoid bumping your

head on lift or

vehicle.

WARNING

!

Avoid pinch points

on moving parts

during operation.

WARNING

!

Avoid excessive

rocking of vehicle

while on lift.

WARNING

!

Remain clear of lift

when raising or

lowering vehicle.

WARNING

!

Keep feet clear of

lift while lowereing.

WARNING

!

Do not override

self-closing lift

controls.

WARNING

!

Position vehicle

with center of

gravity midway

between adapters.

WARNING

!

Clear area if vehicle

is in danger of

falling.

WARNING

!

Avoid bumping your

head on lift or

vehicle.

WARNING

!

Avoid pinch points

on moving parts

during operation.

WARNING

!

Avoid excessive

rocking of vehicle

while on lift.

WARNING

!

Remain clear of lift

when raising or

lowering vehicle.

WARNING

!

Keep feet clear of

lift while lowereing.

WARNING

!

Do not override

self-closing lift

controls.

WARNING

!

Position vehicle

with center of

gravity midway

between adapters.

WARNING

!

Clear area if vehicle

is in danger of

falling.

WARNING

!

Avoid bumping your

head on lift or

vehicle.

WARNING

!

Avoid pinch points

on moving parts

during operation.

WARNING

!

Avoid excessive

rocking of vehicle

while on lift.

WARNING

!

Remain clear of lift

when raising or

lowering vehicle.

WARNING

!

Keep feet clear of

lift while lowereing.

WARNING

!

Do not override

self-closing lift

controls.

WARNING

!

Position vehicle

with center of

gravity midway

between adapters.

WARNING

!

Clear area if vehicle

is in danger of

falling.

WARNING

!

Avoid bumping your

head on lift or

vehicle.

WARNING

!

Avoid pinch points

on moving parts

during operation.

WARNING

!

Avoid excessive

rocking of vehicle

while on lift.

WARNING

!

Remain clear of lift

when raising or

lowering vehicle.

WARNING

!

Keep feet clear of

lift while lowereing.

WARNING

!

Do not override

self-closing lift

controls.

WARNING

!

Position vehicle

with center of

gravity midway

between adapters.

WARNING

!

Clear area if vehicle

is in danger of

falling.

WARNING

!

Avoid bumping your

head on lift or

vehicle.

WARNING

!

Avoid pinch points

on moving parts

during operation.

4

1.6 DESCRIPTION

This lift is a 11,000 lbs. capacity, two-column lift. The safety system in this lift is attached

to the back of the carriage to provide a single point release that saves time when operating.

This lift is equipped with heavy-duty bearings and driven by two heavy-duty BL646 leaf

chains, one per side. The hydraulic cylinders used are greater than 3” in diameter, providing

40% more force than the traditional 2-1/2” diameter cylinders.

An electrical-hydraulic power unit included with the lift will provide up to 3000 Psi of

hydraulic pressure to actuate the cylinders.

Please read the Safety Procedures and operation instruction in this manual before

operating the lift.

Proper installation is very important. To minimize the chance of making an error in

installation, please read this manual thoroughly before beginning installation. Check with

building owner and/or architect’s building plans when applicable. The lift should be located

on a level oor with 6” 3000 psi concrete sufciently cured for at least 30 days.

This is a vehicle lift installation / operation manual and no attempt is made or implied

herein to instruct the user in lifting methods particular to an individual application. Rather, the

contents of this manual are intended as a basis for operation and maintenance of the unit

as it stands alone or as it is intended and anticipated to be used in conjunction with other

equipment.

Proper application of the equipment described herein is limited to the parameter detailed

in the specications and the uses set forth in the descriptive passages. Any other proposed

application of this equipment should be documented and submitted in writing to the factory

for examination. The user assumes full responsibility for any equipment damage or personal

injury that occurs as the result of alteration of the equipment described in this manual or any

subsequent damages.

5

2. UNPACKING, & SET-UP

Only skilled personnel who are familiar with the lift and this manual shall be allowed to carry

out lifting, handling, transport and unpacking operations.

2.2 LIFTING AND HANDLING

When loading/unloading or transporting the equipment to the site, be sure to use suitable

loading (e.g. cranes, trucks) and hoisting means. Be sure to hoist and transport the

components securely so that they cannot drop, taking into consideration the package’s size,

weight, center of gravity, and its fragile parts.

2.3 PREPARATION

The installation of this lift is relatively simple and can be accomplished by 2 men in a few

hours. The following tools and equipment are recommended:

1. ISO-32, AW-32, or AW-46 hydraulic oil or other premium quality ATF DEXRON-III /

MERCON

2. Chalk Line and Tape Measure

3. Rotary Hammer Drill with 3/4” Drill Bit. Core Drill Rebar Cutter recommended

4. Transit and a 4’ Level

5. Sockets and Open Wrench set, 1/2” thru 1-1/2”(1-1/8”for 3/4” Anchors)

6. Vise Grips

7. Torque Wrench

2.1 DELIVERY AND CHECK OF PACKAGES

When the lift is delivered, carefully unpack the lift making sure all the parts have been

included. Check for possible damages due to transport and storage; verify that what is

specied in the conrmation of order is included. In case of damage in transit, the customer

must immediately inform the carrier of the problem.

Remove the lift and all parts from delivery pallet and place on a clean, solid, at surface.

Packages must be opened paying attention not to cause damage to people (keep a safe

distance when opening straps) and parts of the lift (be careful the objects do not drop

from the package when opening).

LIFT AND HANDLE ONLY ONE PACKAGE AT A TIME

6

3. SPECIFICATIONS

Model Description Capacity Lifting Time Overall Height Overall Width Between Posts

HD2P-

11000ACX

Clear Floor/

Symmetric 11,000 lbs 50 sec. 142” - 146” 137 3/8” 110 3/4”

4. FLOOR REQUIREMENT

These notes are for your guidance prior to installation

4.1 SELECTING THE SITE AREA

1. Make sure that adequate space and height is available.

2. Check for ceiling clearance (lifting height plus vehicle height).

3. Check for clearance in front and rear of vehicle on lift.

4. Check for overhead garage door clearance.

4.2 FLOOR REQUIREMENTS

Do not use the lift on any asphalt surface. Make sure the lift is used on a dry, oil/grease

free, at level CONCRETE surface capable of supporting the weight of the lift, the vehicle

being lifted, and any additional tools and equipment. The concrete oor surface should

have a minimum thickness of 6”. The concrete must have a minimum strength of 3,000 PSI,

and should be aged at least 30 days prior to use. Do not use the lift on concrete expansion

seams or on cracked, defective concrete. There should be no cracks in the slab within a

minimum of 36” of the base plate location.

WARNING: SPECIFICATIONS OF CONCRETE MUST BE ADHERED TO.

FAILURE TO DO SO COULD CAUSE LIFT FAILURE RESULTING IN PERSONAL

INJURY OR DEATH. THE FLOOR SHOULD BE A REINFORCED CONCRETE SLAB

NOT LESS THAN 6” (152.4MM) THICK WITH THE COMPRESSIVE STRENGTH OF

THE CONCRETE NO LESS THAN 3,000 PSI (20.68MPA).

DANGER: FOR CORRECT INSTALLATION OF THE LIFT, THE FLOOR MUST

BE FLAT AND LEVEL. CHECK WITH STRAIGHT EDGE AND LEVEL. IF A FLOOR

IS OF QUESTIONABLE SLOPE, CONSIDER A SURVEY OF THE SITE AND/OR THE

POSSIBILITY OF POURING A NEW LEVEL CONCRETE SLAB.

7

IMPORTANT: NEW CONCRETE MUST BE ADEQUATELY CURED AT LEAST

30 DAYS MINIMUM. NO LIABILITY FOR ANY DAMAGES WILL BE ACCEPTED

SHOULD YOU INSTALL THE LIFT ON AN UNSUITABLE FLOOR.

4.3 IMPORTANT CONCRETE AND ANCHORING INFORMATION

1. Concrete shall have compression strength of at least 3,000 PSI and a minimum thickness

of 6”. Measure the length of the supplied anchor bolts in order to achieve a minimum anchor

embedment of 3 1/4”. If the top of the anchor exceeds 2” above the oor grade, you DO NOT

have enough embedment.

2. Before drilling 3/4” dia. holes in concrete oor using holes in column base plate as guide,

make sure the hole distance from the edge is not less than 6”. Hole to hole spacing should

not be less than 6 1/2” in any direction. Concrete thickness should be a minimum of 6”.

3. DANGER: DO NOT Install on asphalt or other similar unstable surface. Columns

are supported only by anchoring in oor.

4. Shim each column base until each column is plumb. If one column has to be elevated to

match the plane of the other column, full size base shim plates should be used (Reference

Shim Kit). Torque anchors to 150 ft-lbs. Shim thickness MUST NOT exceed 1/2”. Adjust the

column extensions plumb.

5. If anchors do not tighten to 150 ft-lbs. installation torque, replace concrete under each

column base with a 4’ x 4’ x 6” thick 3,000 PSI minimum concrete pad keyed under and ush

with the top of existing oor. Let concrete cure at least 30 days before installing lifts and

anchors.

8

5. INSTALLATION INSTRUCTIONS

PLEASE READ THESE INSTRUCTIONS BEFORE STARTING TO OPERATE THE LIFT.

STEP 1: After unloading the lift, place it near the intended installation location.

STEP 2: Remove the shipping bands and packing materials and the power unit from the lift.

STEP 3: Open the wrapping from the upper column and carefully remove the parts from

inside. Unbolt the column from the shipping brackets. Unbolt the up-rights (1) from the

columns (2) and assemble them to the columns based on any height restrictions.

STEP 4: Once the lift location is decided, chalk the center line in the bay and ensure the

proper lift placement is observed from walls and obstacles. Also check the ceiling height for

clearance in this location.

STEP 5: Unpack the cylinders and open the oil port on each cylinder by unscrewing the

black plastic cap. Move the carriage up about 20” to 25”. Next, carefully slide the cylinder

inside from the bottom of the carriage. The oil port will face the backside of the column and

the notch on the bottom of cylinder will t into the hole in the center of the base plate.

STEP 6: Position the columns facing each other 137 3/8” between outside base plates.

4.4 ANCHORING TIP SHEET

1. Use a concrete hammer drill with a carbide tip, solid drill bit the same diameter as the

anchor, 3/4”. (.775 to .787 inches diameter). Do not use excessively worn bits or bits

which have been incorrectly sharpened.

2. Keep the drill in a perpendicular line while drilling. Do not ream the hole or allow the drill

to wobble.

3. Let the drill do the work. Do not apply excessive pressure. Lift the drill up and down

occasionally to remove residue to reduce binding.

4. Drill the holes deep enough to accommodate the embedment calculations for the

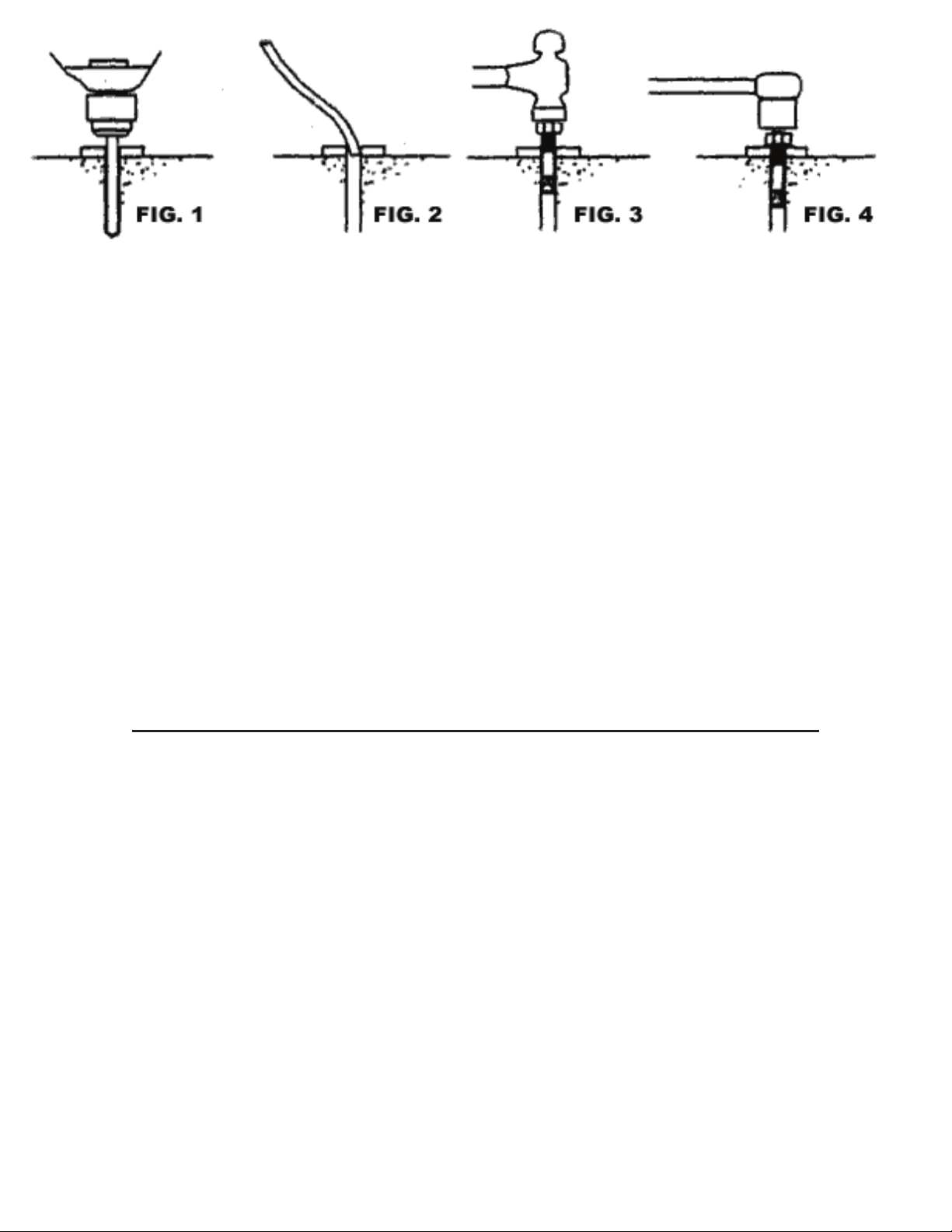

supplied anchors (Fig. 1).

5. For better holding power blow dust from the hole (Fig. 2).

6. Place a at washer and hex nut over threaded end of anchor. Thread the nuts onto the

anchor bolts where the tops of the nuts are just above the tops of the bolts and carefully

tap the anchor (Fig. 3). Do not damage threads. Tap anchor into the concrete until nut

and at washer are against base plate. Do not use an impact wrench to tighten. Tighten

the nut (Fig. 4). Two or three turns on average concrete (30-day cure). If the concrete is

very hard only one or two turns may be required.

9

NOTE: THE POWER UNIT COLUMN IS REFERRED TO AS THE MAIN SIDE COLUMN

AND THE NONPOWER UNIT COLUMN IS REFERRED TO AS THE OFFSIDE COLUMN.

STEP 7: Using a 3/4” diameter concrete drill bit, drill the anchor holes in the main side

column, installing anchors as you go. Use a block of wood or rubber mallet to drive anchor

bolts in.

STEP 8: Using a level, check column for side-to-side plumb and front-to-back plumb. If

needed, use 3/4” washers or shim stock, placing shims under the base plate and around the

anchor bolt. This will prevent bending the column bottom plates. Tighten 3/4” anchor bolts to

150 ft-lbs. of torque. NOTE: DO NOT USE IMPACT WRENCH.

STEP 9: Using a tape measure, measure from back corner of the base on the main side

column to the opposite back corner of the offside column to ensure columns are square.

Using the dimensions, install the overhead beam to the top of the columns BEFORE drilling

the anchors for the offside column to ensure the column is plumb.

STEP 10: This cross beam has two pieces (11 & 24) to be connected by four bolts (13) in the

center of the beam. Be sure to bolt them together by installing the bolts from inside the cross

beam to avoid interference with the cables during lift operation. Install the overhead cross

beam. Bolt the cross beam together with the columns.

STEP 11: Using a level, plumb the offside column. Repeat steps 7 & 8 for offside column

installation.

STEP 12: Connect the safety release cable between the two latches (Fig. 5). Check to make

sure the tension of the cable is tight. Pull the single point safety lock release handle several

times and check the tension again by making sure both latches release at the same time

when the handle is pulled.

STEP 13: Mount the power unit on the main side column to the power unit bracket using four

5/16” bolts and nuts. Install the “T” tting (87) with o-ring on the power unit. Install the 6” pipe

(91) into the backside of the main column cylinder (power unit side). Connect the 90-degree

hydraulic tting (90) on the other end of the 6” pipe (91). Connect one end of the short

hydraulic hose to one side of the “T” tting and the other end to the 90 degree elbow. Place

the long hose (98) across the overhead beam to the opposite column, then down the side

and connect to the tting on the other column cylinder.

STEP 14: Connect the equalizing cables (Fig. 3). Do not tighten at this step of assembly.

NOTE: The cable stud that connects to the front right corner of the carriage should be

connected rst by pulling the stud through the carriage hole and up where it is easy to be

held by locking pliers. Pull the stud back into place after threading at least 1/2” of the stud

past the lock nut. Connect the other ends to the rear right corners of the carriage with at

least 1/2” of thread showing past the lock nut (cables run on inside of carriage). It may be

necessary to manually raise both carriages above the cylinder to provide enough space to

use the locking pliers. Make sure the carriage is engaged in the LOCK position.

10

STEP 15: Adjust the carriage cable tension. This is accomplished by tightening the near nut

on top of each carriage. The near carriage adjustment nut adjusts the opposite post carriage

height. The left post carriage nut adjusts the right column carriage, and the right column

carriage nut adjusts the left column carriage. Adjust each cable to approximately 1/2” side-to-

side play. Check the latch releases to insure the carriage is still engaged in the appropriate

latch.

STEP 16: Install the half moon gear locks on each swing arm. Position the swing arms on the

carriages using the included 1 1/2” diameter pins (2 short for the front arms and 2 long for

the rear arms). Check for proper engagement of the arm lock – the rack on the lock should

fully engage the gear on the arm.

STEP 17: Remove the ll cap from the power unit and ll the oil tank reservoir. To ll the oil

tank reservoir, the lift must be completely lowered. Fill the oil tank with a premium quality

ISO-32, or AW-46 Hydraulic Oil, or premium quality ATF-DEXRON-III / MERCON.

STEP 18: Make the electrical hookup to the power unit. (220V Single Phase). It is

recommended that a 220 Volt, 30 Amp twist lock plug be installed in the power line just

ahead of the power unit. Size wire for 30-amp circuit.

Warning: The wiring must comply with local code. Have a certied electrician make

the electrical hook-up to the power unit. Protect each circuit with time delay fuse or circuit

breaker; 208V-230V single phase. 60 Hz 30 amp.

STEP 19: Install the shut-off mechanism for the 11000ACX model (Fig. 4). Install limit switch

(16) and height-limit lever (12) to the bottom of the cross beam support.

STEP 20: Do not place any vehicle on the lift at this time. Cycle the lift up and down several

times to insure latches click together and all air is removed from the system. Insure all

hydraulic ttings are tight and not leaking. To lower the lift, latch releases must be manually

released. Latches will automatically reset once the lift ascends approximately 17” from base.

If latches click out of sync, tighten the cable on the one that clicks rst.

WARNING: DO NOT PERFORM ANY MAINTENANCE OR INSTALLATION

OF ANY COMPONENTS WITHOUT FIRST ENSURING THAT ELECTRICAL POWER

HAS BEEN DISCONNECTED AT THE SOURCE OR PANEL AND CANNOT BE

REENERGIZED UNTIL ALL MAINTENANCE AND/OR INSTALLATION PROCEDURES

ARE COMPLETED.

DANGER: DO NOT RUN POWER UNIT WITHOUT FLUID. DAMAGE TO PUMP

CAN OCCUR. THE POWER UNIT MUST BE KEPT DRY. DAMAGE TO POWER UNIT

CAUSED BY WATER OR OTHER LIQUIDS SUCH AS DETERGENTS, ACID ETC., IS

NOT COVERED UNDER WARRANTY.

11

6. OPERATION INSTRUCTIONS

WARNING: LIFT OPERATION BY TRAINED AUTHORIZED PERSONNEL

OVER 18 YEARS ONLY. APPLY THE PARKING BRAKE AFTER POSITIONING THE

VEHICLE ON THE LIFT. DO NOT ALLOW ANYONE TO STAY IN LIFT AREA DURING

RAISING AND LOWERING CYCLES. CLOSELY WATCH THE VEHICLE AND THE

LIFT DURING RAISING AND LOWERING CYCLES. OBSERVE THE RATED LOAD

CAPACITY AND LOAD DISTRIBUTION. DO NOT ALLOW ANYONE TO CLIMB ON

LIFT OR STAY INSIDE VEHICLE. AFTER RAISING THE VEHICLE FRAME 6”, STOP

AND CHECK ADAPTERS FOR SECURE CONTACT. PERFORM BUMPER TEST(PG.2).

MAKE SURE THE VEHICLE DOORS ARE CLOSED DURING RAISING AND

LOWERING CYCLES.

WARNING: IN CASE OF DEFECTS OR MALFUNCTIONS SUCH AS JERKY

LIFT MOVEMENT OR DEFORMATION OF THE SUPERSTRUCTURE, SUPPORT OR

LOWER THE LIFT IMMEDIATELY. CONTACT QUALIFIED SERVICE PERSONNEL.

WARNING: PAY CLOSE ATTENTION WHEN SETTING THE LOCKS. THE

LOCKS MUST BE A LEVEL MATCH SET IN ORDER TO AVOID A VEHICLE TILT.

WARNING: ALWAYS LOCK THE LIFT BEFORE GOING UNDER THE

VEHICLE. NEVER ALLOW ANYONE TO GO UNDER THE LIFT WHEN RAISING OR

LOWERING.

6.1 DEFECTS / MALFUNCTIONS

6.2 CONTROLS

Once the up button is actuated, the lift moves up until the button is released or the limit stop

is reached.

6.2.1 UP CONTROL

6.2.2 SAFETY LOCK CONTROL

The safety latch mechanism will “Trip Over” as the lift raises and drop into each safety latch

stop. To lock the lift you must press the lowering handle on the power unit (Fig. 1) to relieve

the hydraulic pressure and let the safety locks engage into a level locked position.

12

Fig. 1

Fig. 2

NOTE: It is normal for an empty lift to lower slowly

- it may be necessary to add weight.

6.2.3 LOWERING CONTROL

Press the up button enough to allow the safety locks to be disengaged.

Pull and hold down the safety lock release handle (Fig. 2) to release

the safety locks.

Warning: Always make sure both locks disengage

when lowering.

While engaging the safety lock release handle by pulling down, press

the lowering handle (Fig. 1) until the lift is completely lowered.

6.3 OPERATION

WARNING: FAILURE TO OPERATE THE LIFT ACCORDING TO THIS MANUAL

MAY CAUSE DAMAGE TO THE LIFT, PROPERTY DAMAGE AND/OR PERSONAL

INJURY.

1. Before driving a vehicle onto the lift make sure the lift is fully lowered. Before driving a

vehicle onto the lift, position the lift arms outward. Do not hit or run over the lifting arms, as

this could damage the vehicle and/or lift. Make sure the lift is fully lowered before moving the

vehicle over the lift. NOTE: It is recommended to swing both arms outward pointing toward

the front of the lift prior to loading a vehicle into the 11000ACX.

2. Drive the vehicle over the lift while keeping the vehicle parallel with the lift and aligning

the center of gravity of the vehicle with the center of the lift. NOTE: The “Center of Gravity”

(COG) of the vehicle is the balance point at which there is equal weight in front of and behind

the COG, and equal weight on both sides of the COG. The COG is not necessarily the

dimensional center of the vehicle, but is often slightly toward the engine from the dimensional

center of the vehicle.

3. Turn off the vehicle’s engine and engage the parking brake of the vehicle.

4. Read the vehicles owner’s manual to identify the recommended vehicle lifting points.

5. Prepare the work area according to this manual. Move the lifting arms inward, and

position the rubber pads to contact with the vehicle manufacturer’s recommended lifting

points.

IMPORTANT: PLACE THE FOUR RUBBER PADS UNDER EDGE OF VEHICLE

AT THE FOUR JACK POINTS.

6. Once the lifting arms have been positioned under the vehicle lifting points, operate the

power switch to make contact and lift the vehicle slightly. Test to make sure the vehicle is well

balanced and the contact between the rubber pads and vehicle lifting points are secure by

performing the “BUMPER TEST.” (pg. 2) Then proceed to lift the vehicle to the desired height.

13

7. WARNING: Do not lift the vehicle if you cannot establish secure and level

lifting points. Do not use sub-standard shims or other devices in place of approved and

recommended rubber pad adapters. Never use the lift without the rubber pads in place on

each plate and in contact with the lifting points of a vehicle.

8. Press up button and raise vehicle to desired height. Do not go under vehicle until load

rests on level safety locks.

10. While lifting the vehicle a clicking sound should be noticeable which indicates the safety

mechanism is operating. If this sound is not heard, immediately cease using the lift and call

an authorized service agent.

9. When lift reaches maximum height, a limit switch will come into operation and stop the lift.

When lift has stopped, press and hold the lowering handle (Fig. 1) until load rests on level

safety locks.

11. Once the repair work to the vehicle is complete, make sure to remove all tools, safety

jack stands, and materials from under the vehicle and lift. Also, make sure the work area is

clear and it is safe to lower the vehicle.

12. Lower vehicle by pressing the Up button to disengage the safety locks. Pull and hold

down the safety lock release handle (Fig. 2) to release the safety locks then press the

lowering handle (Fig. 1) until the lift is completely lowered.

13. Move the lifting arms outward, out of the path of the vehicle. Clear all bystanders, and

any objects from work area and direction of vehicle.

14. Disengage the vehicle parking brake. Start the vehicle’s engine, and drive the vehicle off

the lift slowly and carefully.

WARNING: THE OPERATOR MUST BE TRAINED AND AUTHORIZED TO

OPERATE THE LIFT.

WARNING: DO NOT GO UNDER VEHICLE UNDER ANY CIRCUMSTANCES

WHILE VEHICLE IS BEING RAISED OR LOWERED.

WARNING: LOAD MUST BE EVENLY DISTRIBUTED BETWEEN BOTH

LIFTING PLATFORMS. IF LOAD IS UNBALANCED, REPOSITION VEHICLE. DO NOT

LOWER ON TO LOCKS AT DIFFERENT HEIGHTS.

14

7. MAINTENANCE

WARNING: DISCONNECT THE POWER BEFORE SERVICING THE LIFT.

IMPORTANT: THE MAINTENANCE INTERVALS INDICATED BELOW APPLY

TO AVERAGE WORKSHOP USE. THE LIFT SHOULD BE INSPECTED MORE

FREQUENTLY FOR SEVERE USE APPLICATIONS.

7.1 MAINTENANCE SCHEDULE

It is important to keep the lift clean, dry, and well maintained by establishing a periodic

preventive maintenance program to ensure trouble-free operation and long service life.

7.1.1 DAILY

1. Check safety locking mechanism is functioning correctly.

2. Check safety lock audibly and visually while in operation.

3. Check safety latches for free movement and full engagement with rack.

4. Inspect the condition of rubber lifting pads and replace as necessary if worn or torn.

5. Check hydraulic connections, and hoses for leakage.

6. Check chain connections - Bends, cracks - and looseness.

7. Check cable connections - Bends, cracks - and looseness.

8. Check for frayed cables in both raised and lowered positions.

9. Check snap rings at all rollers and sheaves.

10. Check bolts, nuts, and screws and tighten.

11. Check wiring & switches for damage.

12. Keep base plate free of dirt, grease or any other corrosive substances.

13. Check oor for stress cracks near anchor bolts.

14. Check swing arm restraints.

7.1.2 WEEKLY

1. Check anchor bolts torque to 150 ft-lbs for the 3/4’’ anchor bolts.

NOTE: DO NOT USE IMPACT WRENCH.

2. Check oor for stress cracks near anchor bolts.

3. Check hydraulic oil level.

4. Check and tighten bolts and nuts, and screws.

5. Check cylinder pulley assembly for free movement or excessive wear on cylinder yoke or

pulley pin.

6. Check cable pulley for free movement and excessive wear.

15

7.1.3 MONTHLY

1. Check safety mechanism operation.

2. Check condition of shafts, shaft locks and bushings.

3. Check overall cleanliness.

7.1.4 BIMONTHLY

1. Check condition of extensions and lubricate.

2. Check oil leaks from cylinders.

3. Check oil leaks at pipe joints.

7.1.5 YEARLY

Service and safety inspection on the lift must be performed by a competent person. This

inspection must be recorded. If the 12 month service and safety inspection is not performed,

the warranty is null and void.

1. Lubricate chain.

2. Grease rub blocks and column surface contacting rub blocks.

3. Change the hydraulic uid. A good maintenance program makes it mandatory to keep

hydraulic uid clean. Operating temperature, type of service, contamination levels,

ltration, and chemical composition of uid should be considered. If operating in harsh

dusty conditions, shorter interval may be required.

The following items should only be performed by a trained maintenance expert.

• Replace hydraulic hoses.

• Replace chains and rollers.

• Replace cables and sheaves.

• Replace or rebuild air and hydraulic cylinders as required.

• Replace or rebuild pumps / motors as required.

• Check hydraulic and air cylinder rod and rod end (threads) for deformation or damage.

• Check cylinder mount for looseness and damage.

Relocating or changing components may cause problems. Each component in the system

must be compatible; an undersized or restricted line will cause a drop in pressure. All valve,

pump, and hose connections should be sealed and/or capped until just prior to use. Air

hoses can be used to clean ttings and other components. However, the air supply must be

ltered and dry to prevent contamination. Most important - cleanliness - contamination is the

most frequent cause of malfunction or failure of hydraulic equipment.

16

7.2 MAINTENANCE BY OPERATOR

1. All moving parts have been lubricated at the factory and should be re-lubricated before

the rst use and at least once every six months to prevent damage.

7.2.1 HYDRAULIC SYSTEM (FIG. 3)

1. Check the uid level with the lift fully lowered and add uid as required. Use premium

quality ISO-32, AW-32, or AW-46 hydraulic oil, or premium quality ATF DEXRON-III/

MERCON.

2. Visually check all hydraulic hoses and connections for tightness before each use to

ensure proper working condition.

3. Lightly oil the cylinder rods at least once every six months or when they become dry.

IMPORTANT: AFTER CLEANING WORKSHOP FLOOR OR LIFT, TO

MAINTAIN HOIST EFFICIENCY WE ADVISE TO LUBRICATE LIFTING ARM

LOCKING MECHANISM, AND SAFETY LOCKING MECHANISM. CHECK SAFETY

LOCKING MECHANISM IS FUNCTIONING CORRECTLY.

7.1.6 EVERY OTHER YEAR

Hydraulic oil should be replaced.

17

7.2.2 GREASING POINTS

Slide Tracks:

The carriage assembly slide tracks should be greased every six months (or more

frequently in case of noise generation).

Slightly grease the slide tracks over their whole length using a brush.

7.2.3 OPERATION AND WEAR CHECKS.

1. Examine lift for structural cracks, bends, or other signs of damage prior to each use. Do

not use this product if worn or damaged.

2. Check that the safety locking mechanism is functioning correctly.

3. Check that the safety lock is audibly and visibly operating correctly.

4. Check the oor for stress cracks near the anchor bolts.

7.2.4 LIFT STABILITY

1. Every six months check the nuts of all bolts for correct installation torque.

2. Retighten them as required. NOTE: DO NOT USE AN IMPACT WRENCH.

7.3 CLEANING

DANGER: DO NOT USE HIGH PRESSURE / STEAM JET CLEANERS OR

CAUSTIC CLEANING AGENTS.

RISK OF DAMAGE!

1. PERIODICALLY WASH OFF AGGRESSIVE SUBSTANCES AND TREAT THE LIFT

WITH OIL OR WAX SPRAY.

2. REPAIR THE DAMAGE TO THE PAINTWORK IMMEDIATELY TO PREVENT

CORROSION. THE RAL NUMBER IS AVAILABLE THROUGH THE

MANUFACTURER.

Table of contents