TKR Group PG 5-8 User manual

81 29 2 208 034

Granule jet blasting device

PG 5–8

Owner‘s Manual

Translation of the original instructions

This instruction manual is protected by copyright. No use outwith the strict limitations of copy-

right legislation without the consent of the manufacturer is permitted, this rendering the offen-

der liable to criminal prosecution. This applies likewise for the extraction of individual illustrations

and the use of texts in extract form.

3

1. Information regarding this manual 4

2. Permitted operators 4

3. Pictograph key 5

1. Use for intended purpose 6

2. Danger sources 6

3. Safety devices on the equipment 8

4. Safety measures at the installation site 10

1. Unpacking the device 11

2. Identification and description of the device

components 11

3. Device components 12

4. Technical Data 14

1. Operation of the granule jet blasting device 15

2. Granule jet blasting device

preparation and connection 16

3. Filling with blasting material 18

4. Connect vacuum adapter to vacuum cleaner 22

5. Attach blasting lance to handle 23

6. Starting the cleaning process 24

7. Blasting 25

8. Cleaning the inlet valves and the inlet channel 26

9. Taking the device out of service 28

1. Maintenance / cleaning 29

2. Spare parts and accessories for the PG 5–8

granule jet blasting device 32

3. Warranty conditions 34

4. EU Declaration of Conformity 35

1.

2.

3.

4.

5.

3

Other languages, spare parts

and accessories:

www.tkr-service.com

44

1.1 Information regarding this manual

Legislation stipulates that users must be trained in the use of

manually operated blasting equipment.

The granule jet blasting device corresponds with the state of

technology. To ensure that the equipment operates safely, it

must be operated in a proper and safe manner.

In the interests of quality assurance, we reserve the

unrestricted right to proceed to technical modifications arising

out of further developments in technology and product

improvements, without prior notification.

Read the instruction manual carefully before using the device.

All handling necessary to ensure correct operation is descri-

bed in the instruction manual.

No work methods other than those expressly approved by the

manufacturer may be used.If faults occur during operation of

the device, they must be remedied by trained experts only.

The owner/operator of the machine must make the ope-

rating instructions available to the operator and ensure

that they have been read and understood. Only then

may the operator start up the device.

Note

State-of-the-art

Technical

modifications

Read

instruction

manual

Handling

Faults

1.2 Permitted operators

55

1.3 Pictograph key

Several sections of these operating instructions are marked

with internationally recognised warning signs, danger notes and

general prohibition signs. Please comply with all notes and safety

rules!

The individual pictographs are explained in the following.

Instruction manual

general instructions

Observe the general

instructions

Wear face mask

Wear hearing protection

Wear gloves

Wear protective clothing

Warning

General source of danger

Warning

System under pressure

Risk of hearing damage

Warning - noise with high sound

pressure level

Follow all in-

structions and

safety rules

Please note the following.

Arrow to clarify

pressing together

Arrow indicating direction

For further information

see chapter...

Audibly engage

Shorten

Blow out with air

Clean with air/granule mixture

66

2.1 Use for intended purpose

The granule jet blasting device complies with the machi-

nery directive 98/37 EC and is used for processing the

surface of metal using a grainy blasting material, that is

blasted onto the surface that is being processed. The

blasting material is transported using compressed air.

The GP 5-8 granule jet blasting device is used for removing

carbonized material from the inlet channel and valves of combu-

stion engines.

The jet blasting device may only be operated in combination

with the vacuum adapters that are approved for the relevant

engine type and a vacuum cleaner with sufficient suction po-

wer.

Unauthorised modifications or changes to the device are not

permitted for safety reasons.

The granule jet blasting device is safe if used for its correct pur-

pose.

If it is used incorrectly and/or negligently by untrained

personnel, serious injuries could be caused by the es-

caping granules.

The blasting probe must never be used without the

provided vacuum adapter and vacuum equipment with

adequate power.

Never direct the blasting probe at persons or look into

the opening of the blasting probe. Risk of injury!

2.2 Danger sources

7

The device must only be operated using hoses that are appro-

ved for the purpose of use and the operating pressure of the

device.

The device may only be used by trained personnel.

Never throw or drop the granule jet blasting device.

The granule jet blasting device may only be used at ambient

temperatures of between 5 °C and 50 °C.

The granule jet blasting device must not be used in potentially

explosive areas!

The device must never be operated without suitable protective

clothing, such as a safety mask and safety shoes. Risk of injury!

Before carrying out maintenance or cleaning work and

always before filling the device with granules, the com-

pressed air supply must be disconnected and the device

depressurised.

The granule jet blasting device may only be operated with com-

pressed air.

The granule jet blasting device must always be set up on

a level surface or the floor of the workshop. The device

must not be set up on tables, workbenches or other ob-

jects. (Container is under pressure!)

Hoses and supply lines must be routed in such a way that they

cannot be damaged or become trapped! The hoses must also

be routed in a way that prevents people from tripping over

them.

Chapter 5.1

Chapter 2.4

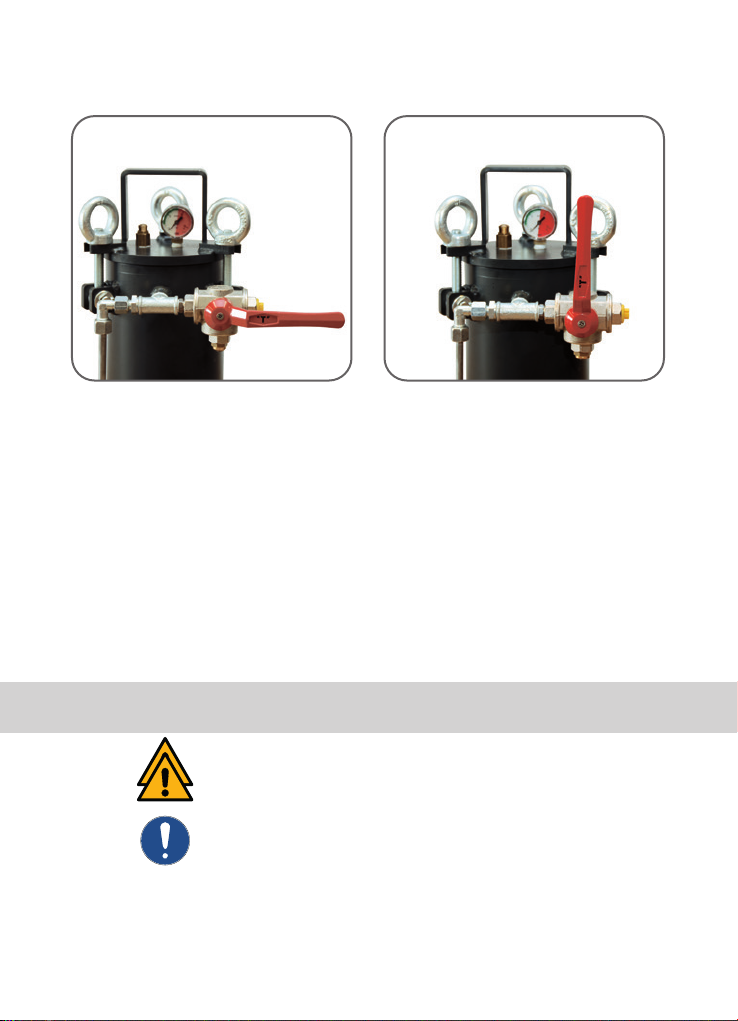

2.3.1 2.3.2

8

2.3 Safety devices on the equipment

There is a 3-way ball valve on the granule container that ap-

plies compressed air to the container and the control system in

the operating position.

In the „Off“ position the container and the control system are

depressurised.

Item B:

work item

Item A:

relieve

Fig. 2.3.1

Fig. 2.3.2

If a control function fails, the device must be taken out

of service immediately and repaired by a trained expert!

There is a pressure gauge on the granule container. The

maximum operating pressure of the device may never

exceed 8 bar. A safety valve is installed on the granule

container that controls the maximum operating pressu-

re of the device. The valve opens at pressure of approx.

8.5 bar.

7

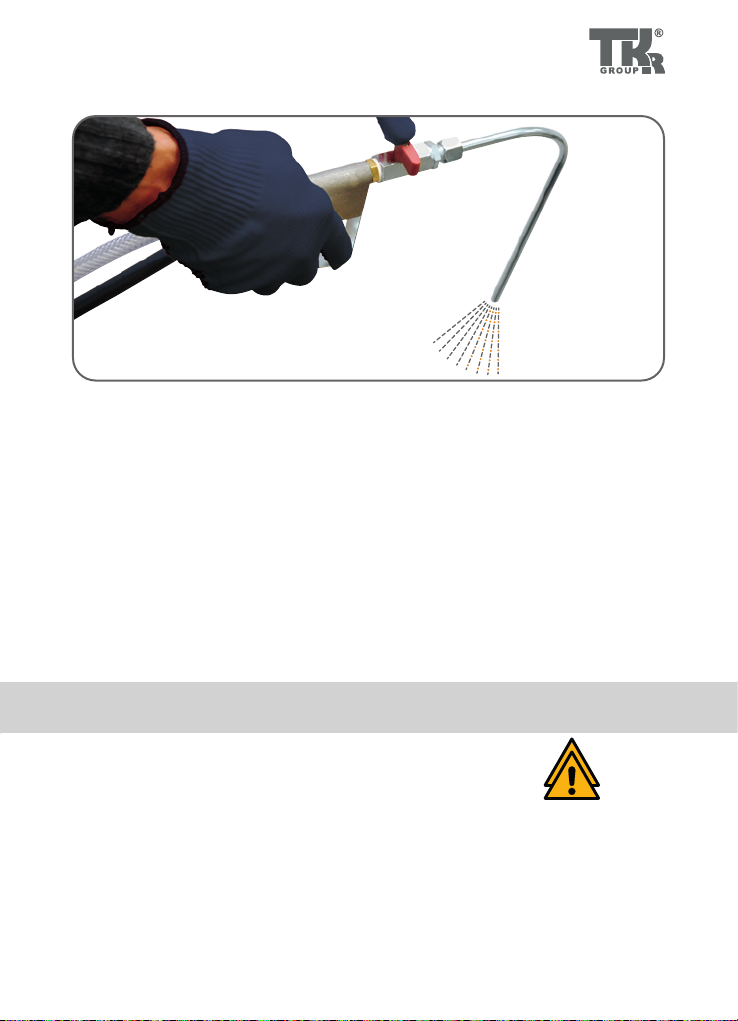

2.3.3

9

There is a 2-way ball valve on the handle of the blasting lance.

This can be operated if a control function fails. If the ball valve

is closed, no air or other blasting material can exit from the

lance.

If the safety equipment malfunctions, the device must

be taken out of service immediately! The device should

undergo preventive maintenance at least once per an-

num by a specialist company!

Fig. 2.3.3

2.4.1

10

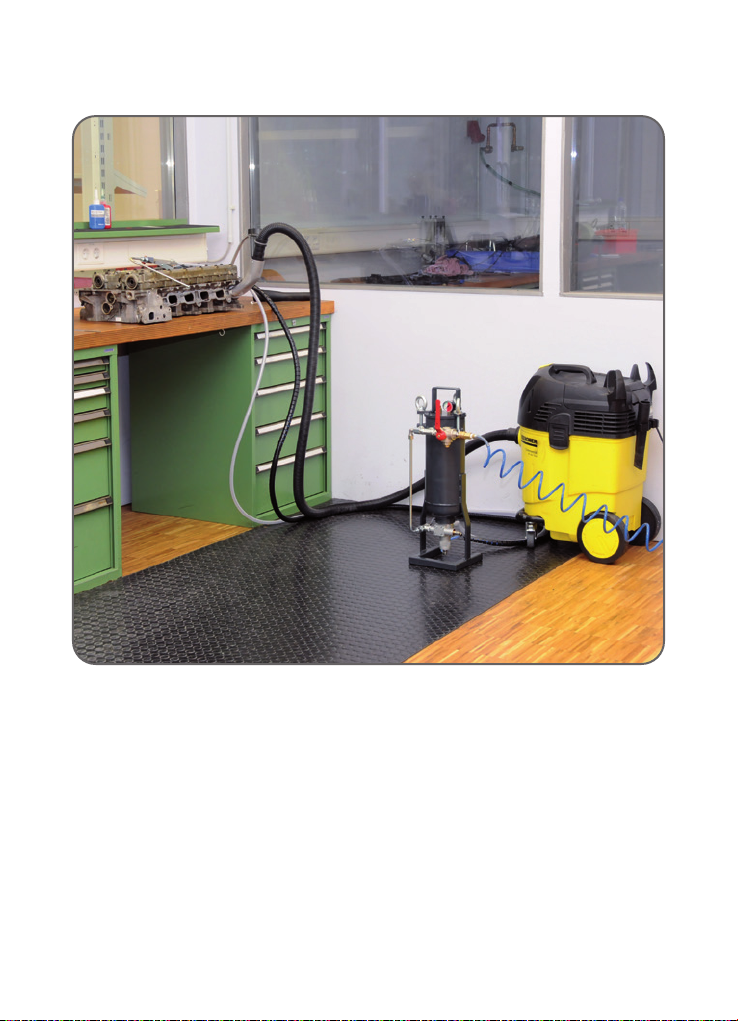

2.4 Safety measures at the installation site

The surface on which the device is installed must be level, load-

bearing and stable in accordance with the weight of the device.

The device may only be used in combination with the suction

adapters that are provided for the respective motor type and

an adequately dimensioned vacuum cleaner.

Hoses and supply lines must be routed so that they do not

damage the device and cannot become trapped! The hoses

must also be routed in such a away that they cannot be trip-

ped over.

Fig. 2.4.1

3 .1.1

11

3.1 Unpacking the device

• Place box on a level surface

• Open box and carefully remove the

device

• Check the accessories

- Operating instructions

- Granule container with connected

hose package and handle

- Straight blasting lance

- Angled blasting lance

- Possibly other accessories,

see delivery note

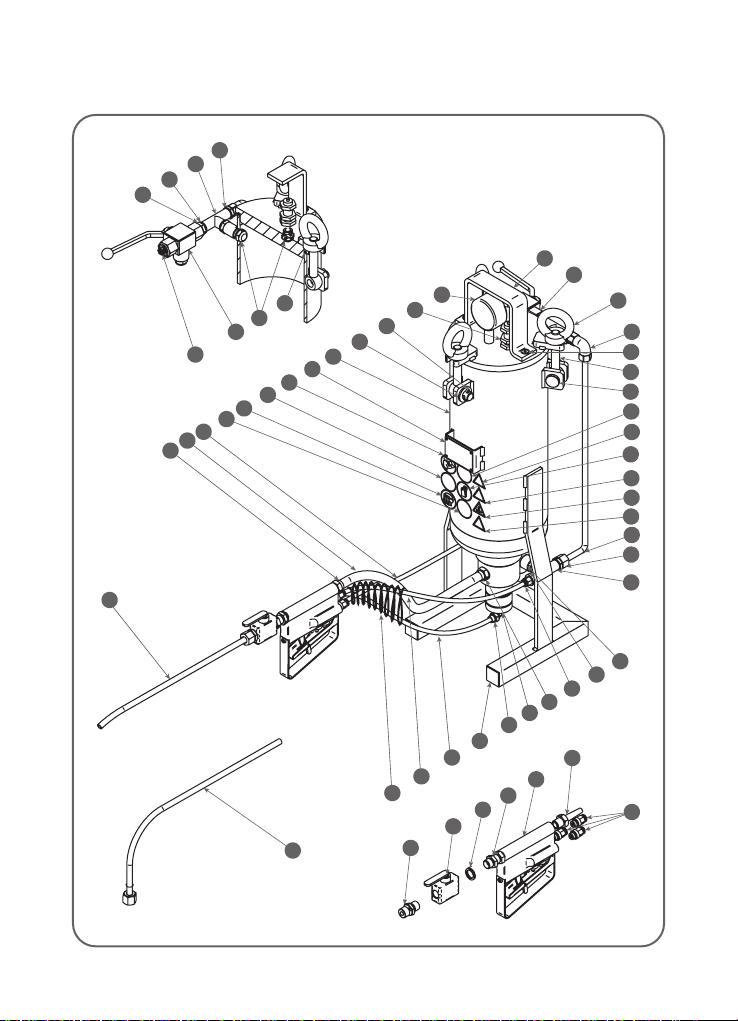

Granule blasting material container with 3-way ball valve, gra-

nule control valve, compressed air control valve, pressure gau-

ge and safety valve.

Hose package with granule transportation hose, and three

colour-coded control hoses.

Handle with 2-way ball valve and connection for the blasting

lance. The control function in the handle is activated using

two control valves connected in series. The operating lever

is equipped with a safety device to prevent unintentional reacti-

vation.

3.2 Identification and description of

the device components

Main elements

of the granule

jet blasting

device

32

38

31

34

21

20

9

22

24

49

18

25

37

27

7

28

7

12

42

46

43

47

45

48

15

26

19

3

1

13

2

17

6

33

44

41

40

39

51

50

30

5

35

10

11

49

18

14

15

36

16

4

17

23

29

8

3.3.1

12

3.3 Device components

13

No. Title

1 Eye bolt

2 Annular nut

3 Pin

4 O-ring

5 Split pin

6 Handle

7Control block

8 PVC hose Ø 14 mm

9 Handle

10 Relief valve

11 Pressure gauge Ø 50 mm

12 Kapsto plastic cover

13 Countersunk screw

14 Double nipple

15 T-piece

16 Exhaust valve

17 3-way ball valve

18 Straight threaded male

connector

19 Ermeto pipe 8x1

20 Bulkhead nipple

21 2-way ball valve

22 Threaded nozzle

23 Nozzle, straight

24 Straight insert nuts

25 Elbow fitting

26 Screw-in fitting

27 Straight male connector

28 Double nipple

No. Title

29 Elbow fitting connection

30 Disc

31 Hose, black Ø 6 mm

32 Hose, blue Ø 6 mm

33 Hose, transparent Ø 6 mm

34 Nozzle, bent

35 Granule container

36 Kapsto sealing screw

37 Press nipple

38 Protective hose

39 Follow manual

40 Observe the general information

41 Wear face mask

42 Wear ear protection

43 Wear gloves

44 Wear protective clothing

45 Warning! System under

pressure

46 Warning! General source of

danger

47 Warning against damage to

hearing

48 Warning against high levels of

noise

49 PVC washer for 1/4“

connection

50 Hose clamp

51 Type plate

290

620

2

3

1

3.4.1

14

3.4 Technical Data

Length 290 mm

Width ca. 280 mm

Height 620 mm

Max. operating pressure 8 bar

Container volume 5 l

Weight 15.5 kg

Hose package working length 4 m

Length and weight without hoses

1 = Control air, transparent hose

2 = Main air, black hose

3 = Granules supply, blue hose

Blasting lance, 3/3-way

straight control valve

Blasting lance,

bent

15

4.1 Operation of the granule jet

blasting device

• Fill with blasting material.

• Connect vacuum adapter to vacuum device.

• Attach blasting lance to handle.

• Connect granule jet blasting device to the

compressed air supply.

• Start the cleaning process.

• Blasting with air / blowing out.

• Blasting with air/granule mixture / cleaning.

• Cleaning the inlet valves and the inlet channel.

• Taking device out of service.

• Maintaining the granule jet blasting device.

Always check the condition of the hoses before starting

up the device!

Stop using defective hoses immediately. Risk of injury!

4.2.1 4.2.2

4.2.4

G1/4“

4.2.3

G1/4“ R1/4“

Ø 6 mm

16

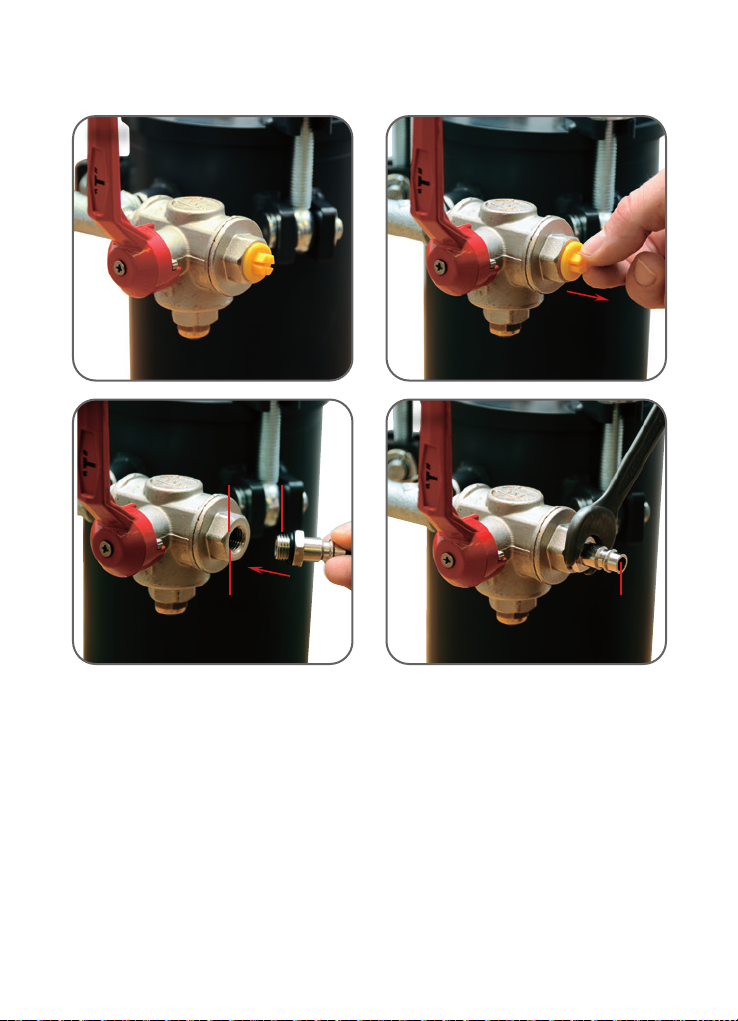

4.2 Granule jet blasting device preparation

and connection

The device is supplied from the factory without a compressed

air coupling. The ball valve has a connecting thread with a

female thread of G ¼“. The thread is fitted with a closing cap.

Insert a suitable compressed air connection with seal into the

thread.

Remove the closing cap.

Tighten the compressed air connection using a suitable tool.

Fig. 4.2.1

Fig. 4.2.2

Fig. 4.2.3

Fig. 4.2.4

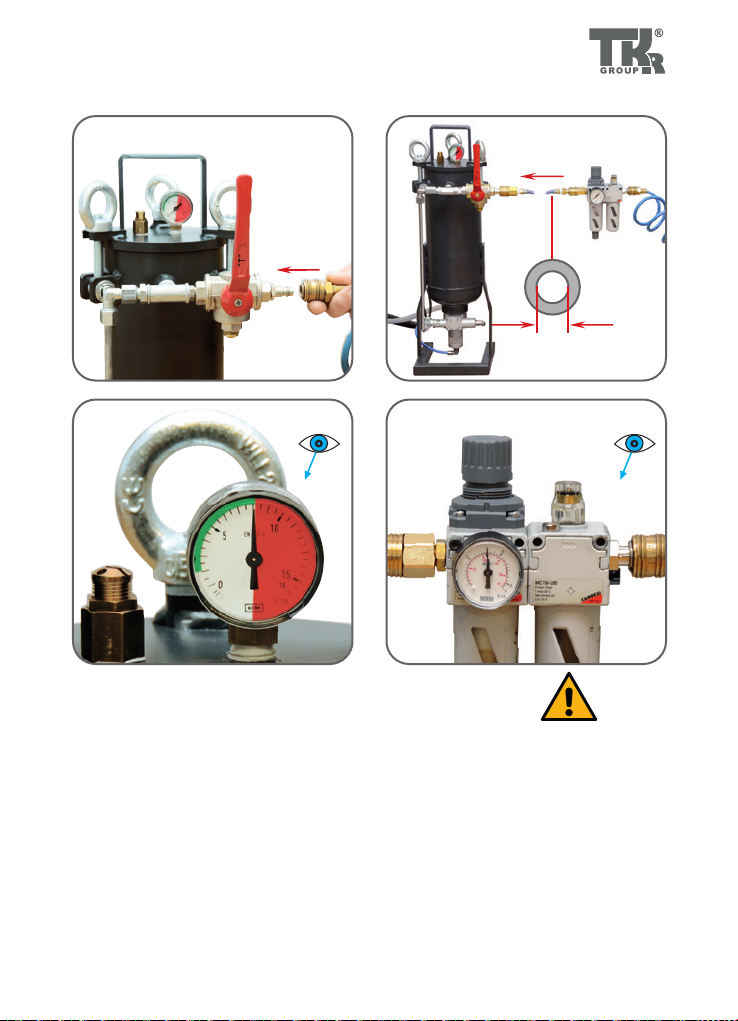

4.2.5 4.2.6

≥ Ø 6 mm

4.2.84.2.7

17

The device may only be operated using dry, oil-free

compressed air!

The granule jet blasting device may only be operated

with an external supply unit with variable operating

pressure!

The operating pressure of the device should be bet-

ween 6 and 8 bar, and may never exceed an operating

pressure of 8 bar!

Fig. 4.2.6

Fig. 4.2.7

Fig. 4.2.8

6–8 barmax. 8 bar

4.3.24.3.1

4.3.3

18

4.3 Filling with blasting material

Fig. 4.3.1

3-way ball valve in „Relieve“ position

Fig. 4.3.2

Pressure gauge must not be indicating

any pressure

Fig. 4.3.3

Undo eye bolts and swivel out swivel-

ling screw fitting

Attention! Device may only be filled if container is de-

pressurised and the air supply line has been discon-

nected.

4.3.6

4.3.4 4.3.5

20–30 mm

19

Only blasting material that has been approved by the

manufacturer may be used: Cleaning granulate.

The blasting material must be free of impurities.

Never re-use blasting material.

Fig. 4.3.4

Remove lid of container

Fig. 4.3.5

Filling with granules

Fig. 4.3.6

Max. filling level 20–30 mm below air

inlet connection

4.3.8

4.3.7

20

4.3 Filling with blasting material

Check device for leaks!

If compressed air is leaking from the device, the working

process must be interrupted and the cause thereof

remedied!

Check lid seal. Seal must be clean and must not be damaged.

Place lid on container.

Fit swivelling screw fitting.

Tighten eye bolts by hand.

3-way ball valve in „Relieve“ position

Fig. 4.3.7

Fig. 4.3.8

Fig. 4.3.9

Fig. 4.3.10

Fig. 4.3.11

Table of contents