TMT BX500 User manual

Software Version:

PS19033F

1

TMT BX500/800 24V slider motor STEP-BY-STEP instruction manual

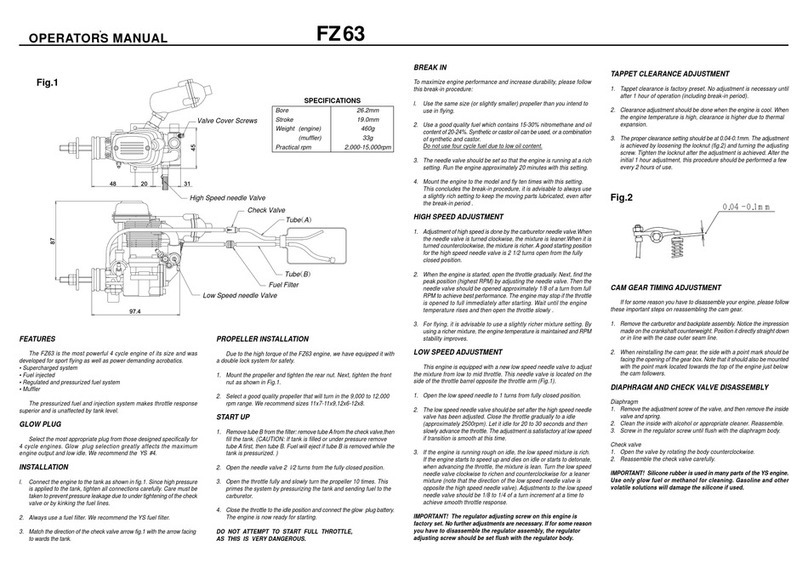

Preparation of the Concrete Ground Surface (Base) for Motor Mounting.

Make sure that the ground surface for the motor installation is solid and level with a minimum of

100mm thickness. A good concrete base is paramount to the proper operation of the auto gate

system. The motor mounting plate is 170mm deep x 250mm wide or roughly the size of an A4 page.

If installing cables place these 250mm out from your wall/post and approx. 200mm in from the

corner of the wall/post. Position the motor mounting plate (side nearest the gate) approx. 150-

160mm from the wall/post and approx. 50mm in from your post driveway corner point.

NOTE: You may need to raise the motor to allow the gear rack to fasten properly to your gate

bottom rail. Check this first by placing a gear rack length on top of the sprocket of the motor

alongside the gate and allow for the fastener thickness after installation. Open/close the gate as the

gate may have a bend in it.

55mm

50mm

Motor

Gate

Post

Top View Base Footprint

250mm

m

170mm

m

50mm

55mm

Software Version:

PS19033F

2

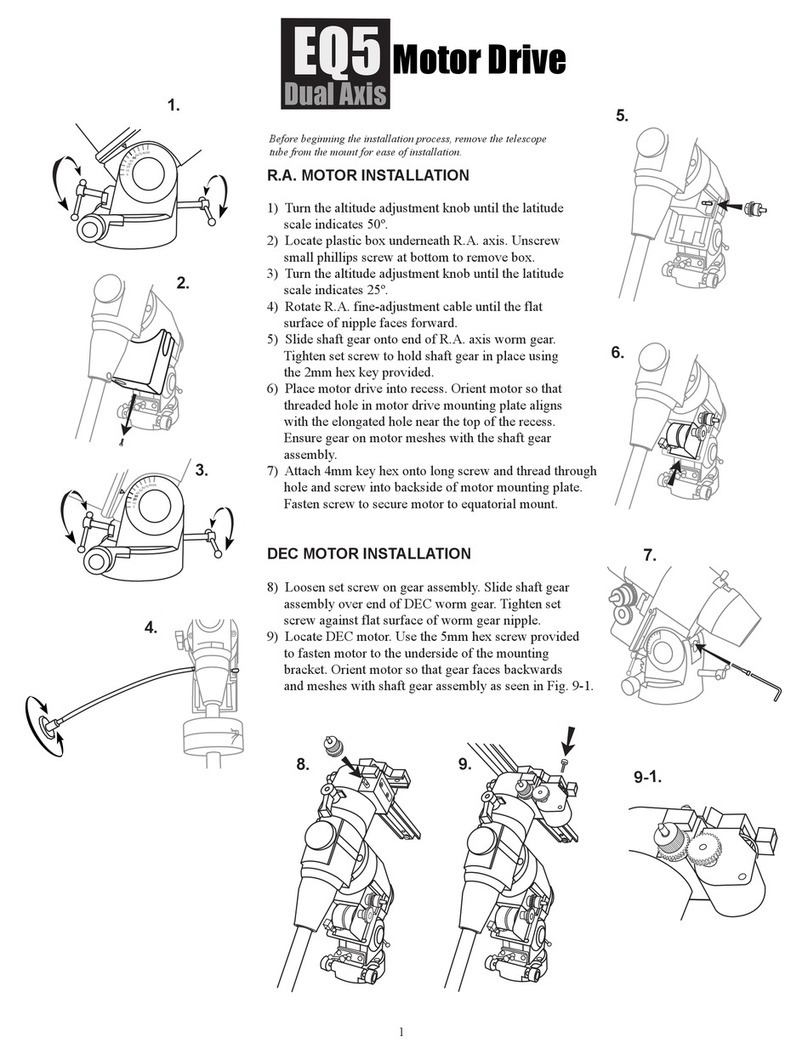

Install “Physical Gate Stops”

Physical Gate Stops MUST be installed at each end of your gate. If the Limit Switch on the boxer

motor fails to stop a gate cycle, the Gate Stops will prevent gate falling off the guide rollers and

causing possible injury or damage.

Installing the gear rack to the gate:

For your gate to function smoothly you will need to install the gear rack correctly. The outcome is to

have a 2mm gap between your sprocket and the valley of the gear rack throughout the length of the

gate. Temporarily raise the motor by another 2mm using washer spacers or adjusting the motor

plate height. Remove spacer washers or lower the mounting plate by 2mm once all the gear rack is

installed and secure motor mounting nuts.

NOTE: We recommend you leave extra gear rack over hanging (approx. 100mm) until after you have

mounted the “silver limit cams” and tested the operation of the automation. Only then cut off any

extra with a hacksaw. The gear rack has a steel rod inserted in the nylon casting for strength. Do not

fasten where wheels may be contacted as this will increase gate moving resistance dramatically. If

the fastening screws of the gear rack contact the sprocket cover, it is more than likely due to an

extra-long gate length, bend in the gate or a slight variation in the wheel track alignment. You can

remove the sprocket cover without altering the performance of the opener.

Step 1: Release the auto gate to emergency release by rotating the clutch lever at the front of the

motor so that the gear wheel rotates freely for the alignment and installation of the gear-

rack.

Step 2: Lay all gear rack (on the ground) along the length of the gate. Check end rack supports for

best position of a gear rack lug each side of the sprocket at the fully open/close.

Step 3: Rest the first gear rack on the motor sprocket and ensure that the gear rack is level. Fasten

the gear-rack onto the gate using the fastenings provided.

Step 4: Move the gate 1m or the length of the gear rack and repeat step 3 until all gear-rack have

been installed.

Step 5: Remove the Washer / Spacer from the Motor, and the gap of 2mm between the gear wheel

and the gear rack is automatically achieved.

Step 6: Check to ensure consistent meshing between the gear racks with the gear wheel over the

entire length of the gate. Loosen the screw on the gear-rack to adjust the position of the

gear rack if necessary.

Software Version:

PS19033F

3

Important Note: Motor Sprocket and Gear Rack life depends almost entirely on their correct

meshing.

Installing “Limit Cams” a must do!

Limit Cams (2 x silver brackets) MUST be installed at each end of your gate Gear Rack. Supplied is a

right (SX) and a left (DX) when installed they are designed to trigger the Limit Switch spring pole to

stop the gate cycle BEFORE contact with physical gate stops.

Removing control board plastic protective cover

Make sure the clutch lever is in the down position. The grey plastic cover that helps protect the

control board from water and insects. Remove using your left hand index finger to pull back and

away the tab in on the left top corner. The cover is semi-hinged on the right side. Be careful not to

dislodge the antenna wire at the bottom.

DESCRIPTION OF THE DEVICE

2mm

gap

Software Version:

PS19033F

4

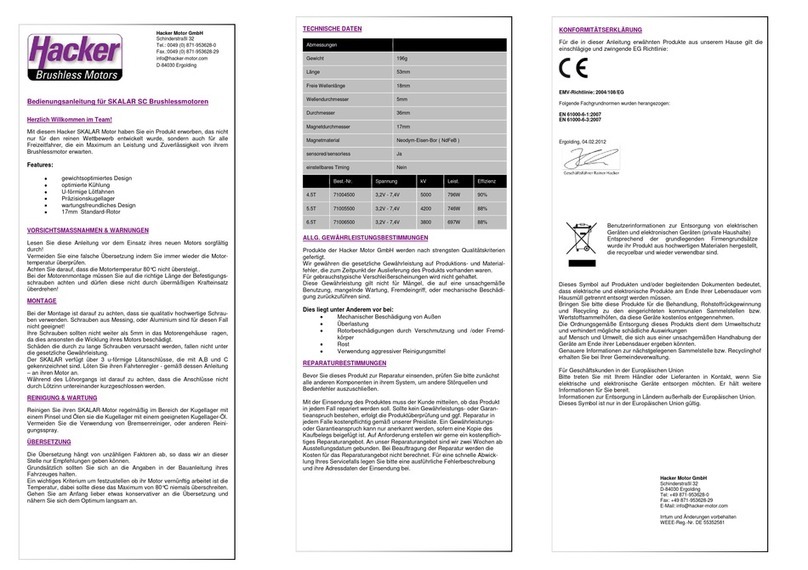

PCB Layout

RF-LEARN

UP

DOWN

SET

Software Version:

PS19033F

5

QUICK SET UP

The board is factory programmed for a standard gate setup with the motor positioned on the left of

the driveway looking at the gate from inside your property. If your motor is on the left of the

driveway you only need to tune your remote and complete “System learning” and it’s all good to go.

If it is on the right then you will need to set up the programme functions below to change motor

direction.

Software Version:

PS19033F

6

Tuning remotes

Locate the “RF LEARN” button which is the top button on right side of the control board.

Step 1: Press and hold RF LEARN for 3 seconds, the LED will show CS.

Step 2: Press button A on your remote for 2 seconds.

CS signal flashes 3 time on the control board to confirm

the tuning process is completed.

Remove the memories of the remotes

Press and hold down the RF LEARN button for 10 seconds till the LED shows CC.

Pedestrian mode using your remote

Your control board is pre-set to activate the pedestrian mode or partial opening cycle using ONLY

your remote button B. You can adjust the time the gate opens using the LED screen FA function.

To remove the pedestrian function, switch to FH-0 function to turn it OFF.

Using an optional stand-alone receiver.

Use button A (open-stop-close) & B (partial open) for first gate opener, connect the stand alone

receiver to the second gate or garage door and use button C (open-stop-close) on the same remote.

How to use your remote to change Auto Close function:

To turn ON/OFF Auto Close: Long press “D” key for two seconds. The gate will get to fully open

position and all the operation will be locked until long press the “D” key for 2 seconds again to

activate the auto close function again.

Note: Auto close function can ONLY be adjusted when gate is in the fully open or closed position.

You cannot adjust it when the motor is running.

MUST DO: Systems Learning

“Systems learning” will allow the Control board to register your gate factors such as operational

resistance, opening/closing cycle times, speed etc.

NOTE: Gate must be closed!

Warning: Check that both fully open and full closed “limit cams” are in place on the gear rack and

are functioning correctly. Check both fully open and fully closed physical stops are securely in place.

Before starting system learning you must first have a working transmitter. On the control board

press the RF Learn button (TOP BUTTON on the right) once until the blue LED light shines. On your

remote press the top LEFT button once…. Blue light flashes to confirm tuning of remote.

Software Version:

PS19033F

7

Step 1: The LED display will show –Lmeans the system learning haven’t been completed yet, follow

below steps

Step 2: Simultaneously press the “Set” and the “Down” button (4th BUTTON FROM TOP) for 3

seconds until the LED display shows from –Lto LE

Step 3: You now have less than 10 seconds to press the left top button of your remote to activate

the motor opening cycle and systems learning will be commenced. LED display shows LP to start

system learning process, DO NOT interrupt this operation by press the remote or any other button

on the control panel until the motor finish running

Step4: Once the LED display shows CP means the system learning is completed

Warning: Gate will start moving so keep clear of moving parts.

Step 4: Gate will commence an open cycle until “Open Cam” contacts with “Limit Switch” and stops

the motor. A second or 2 later the gate will start a close cycle until “close cam” contacts “Limit

Switch” and stops the motor. “System-Learning” is now complete.

How to use the LED Screen to set functions of the motor

To adjust the functions such as motor speed, strength of motor, auto close time, you can

programme the system using the LED screen found in the top right of the control board. At stand-by

mode the screen is blank to save energy if the batteries are only operating the board.

There are 2 segments to the screen of which can be controlled by the use of the lower 3 buttons

down the right side UP (2nd from top) SET (3rd from top) and DOWN (bottom). When changing

functions, the first segment is generally a letter and segments 2 is numbers. When the power is first

connected to the board you will see “-L” on the screen for 10 seconds then turns blank which is

standby. To start the programming, you must first decide what function you want to change. Let us

use the auto-closing function 2 as an example.

Step 1: Press and HOLD the SET button for 3 seconds (-L) and release when the screen shows 1 in

segment 1.

Step 2: To change between 1 and 2, press the UP or DOWN button. Once the function 2 is chosen,

then press SET to enter the second layer, to adjust from 20 to 28. IF you want to turn off the

auto-closing function, when LED screen show 20 (No auto-closing) press SET to confirm, then

the LED screen will change back to 2.

Step 3: Wait about 10 seconds or press Button A on the remote (top left one) and the screen will

revert to standby again. Programme completed.

Programme Gate “Opening Direction”

There are 2 locations that you can install your gate motor. Looking at your gate from inside your

property is the motor to be installed on your left or right of the driveway? The LEFT Side (default

setting) 11 is the most popular with the motor sprocket rotating counter-clockwise (looking from the

control board side of the motor at the sprocket) opening the gate from the right to the left.

Software Version:

PS19033F

8

Right Side install has the motor sprocket rotating clockwise opening the gate from the left to the

right. You will need to change the programme “Opening Direction” to “12”.

NOTE: Gate opener will always do an open cycle when first powered up.

Quick guide to LED screen:

-L

The systems learning process has not been completed.

LE

The system is in its learning mode and awaiting learning instructions.

LP

The system is currently learning a new process.

CP

The system learning process has been completed.

OP

The gate is on opening procedure

CL

The gate is on closing procedure

SP

The gate has stopped

HINTS:

Test the gate opener is working correctly before connecting option devices.

If the gate loads up on your physical stops and stops this will affect the reliability of the gate

operation. Adjust the limit cams so the gate stops BEFORE the safety stopper/ end catcher on

completion of a cycle.

Reduce the speed of medium to heavy gates. Add a deceleration to the program. Increase the amps

to the motor if the gate stops mid-point in a cycle. The dip switches on the right of the panel should

be all to the right which is ON.

You can now connect optional devices by removing the terminal block (pulls off) first and inserting

your wires in the correct location as per the labels. This is so you do not blow the system up

accidently.

Batteries: 2 x 12VDC gel filled batteries are fitted above the motor. When connected in series they

will produce 24VDC. Batteries are connected with a link cable between negative of one battery with

positive of the second battery. The remaining positive and negative are connected to the control

board using the clip on connector. Always check the correct position of the battery connector to the

control board has red to +.

Software Version:

PS19033F

9

LED Display

Definition

Function

Value

Description

1

Operation

Direction

11

Open to LEFT

The function can adjust the

direction of gate opening.

The factory setting is "11".

12

Open to RIGHT

2

Auto-Closing

20

No automatic closing

This function can cause the gate

to close automatically after the

paused time.

The factory setting is "20”

Press and hold “D” key for 2

second can turn of the auto-

closing function. The gate will

be opened and locked, until

next press and hold “D” key

21

5 seconds

22

15 seconds

23

30 seconds

24

45 seconds

25

60 seconds

26

80 seconds

27

120 seconds

28

180 seconds

3

Safety Device

Function Mode

31

Please refer to page 14, F3 settings

1. The factory setting is “31”.

32

33

4

Opening

Operation Speed

41

50% operating speed; 50% learning speed

The function can adjust the

running speed of motor.

The factory setting is "44".

42

70% operating speed; 50% learning speed

43

85% operating speed; 50% learning speed

44

100% operating speed; 50% learning speed

5

Closing

Operation Speed

51

50% operating speed; 50% learning speed

The function can adjust the

running speed of motor.

The factory setting is "54".

52

70% operating speed; 50% learning speed

53

85% operating speed; 50% learning speed

54

100% operating speed; 50% learning speed

6

Deceleration

Point

61

75%

The

default setting is “61”.

62

80%

63

85%

64

90%

65

95%

7

Deceleration

Speed

71

80%

The

default

setting is “73”

72

60%

73

40%

74

25%

8

Opening

Overcurrent

Setting

81

4A

The function can adjust the

running force of motor to be

compatible with the gate weight.

The default setting is "85".

WARNING

: The maximum

overcurrent for 500kg motor is 10A, it

may have the potential risk if the

adjustment over 10A current.

82

5A

83

6A

84

7A

85

8A

86

9A

87

10A

88

11A

89

12A

81

13A

Software Version:

PS19033F

10

9

Closing

Overcurrent

Setting

91

4A

The function can adjust the

running force of motor to be

compatible with the gate

weight.

The default setting is "95".

WARNING

: The maximum

overcurrent for 500kg motor is 10A, it

may have the potential risk if the

adjustment over 10A current.

92

5A

93

6A

94

7A

95

8A

96

9A

97

10A

98

11A

99

12A

9.1

13A

A

Pedestrian Mode

A0

Function OFF

The function can adjust the time

of opening partially.

The default setting is "A2".

A1

3 seconds

A2

6 seconds

A3

9 seconds

A4

12 seconds

A5

15 seconds

A6

18 seconds

C

Flashing Light

C0

The motor and flashing light will operate at

the same time.

If the motor stops by over

current or limit switch, the

flashing light will keep blinking

for 1 minute.

The default setting is “C0”

C1

Followed with FC-0, the flashing light will keep

blinking for1 minute after the motor stop

C2

Followed with FC-0, the flashing light will keep

blinking for 10 minutes after the motor stop

E

Overcurrent

Reaction

E0

Stop

The default setting is "E3".

The reverse function only

operates 3 times and stops.

If the gate reverses, the auto-

closing function will be

cancelled.

E1

Reverse 1 second and stop

E2

Reverse 3 seconds and stop

E3

Reverse to the end

F

Main Operation

Key

F1

A Key

The default setting is "F1".

F2

B Key

F3

C Key

F4

D Key

H

Pedestrian

Function

H0

No function

The default setting is "H2".

H1

A Key

H2

B Key

H3

C Key

H4

D Key

J

External Device

Key

J0

No function

The default setting is "J3".

J1

A Key

J2

B Key

J3

C Key

J4

D Key

L

Photocell 1

Activation

L0

Function OFF

The default setting is "L0".

L1

Function ON

P

Photocell 2

Activation

P0

Function OFF

The default setting is "P0".

P1

Function ON

U

PCB Stop Terminal

Activation

U0

Function OFF

The default setting is "U0".

U1

Function ON

Software Version:

PS19033F

11

External terminals for Accessories

Connecting Exit Button: Terminal 10 (Pb) and 11 (GND) to activate open/stop/close.

Connecting Intercom and keypads: Terminal 10 (Pb) and 11 (GND) to activate open/stop/close.

Terminal 5 (+13.75) is positive 13v and 6 (GND) is the negative.

Connecting probes and loop detectors: Terminal 13 (OPEN) and 11 (GRD) to activate

open/stop/close. Terminal 5 (+13.75) is positive 13v and 6 (GRD) is the negative.

Connecting the IR beams:

Important Note: Once beams are installed you must turn the beam function on through the

parameter setting L (beam connect to Terminal 7 Ph1) and P (beam connect to Terminal 8 Ph2). We

recommend you install an earth wire from GND terminal 3 to the base of the motor housing to

increase the performance of the beam and reduce interruption of the photo beam frequency.

The system is factory set to be used without the beams fitted so there is no need to “loop” terminal

7 (PH1) to ground as this is done electronically. To Install IR Beams you will need power to the IR

beams. Terminal 6 (GND) is negative and terminal 9 (PH+) is positive 12-13v DC. Connect the NC of

the IR Beam to Terminal 7 (Ph1) and the COM of the IR Beam to terminal 6 (GND). When the beam is

A.

PB Terminal Function

A.1

Open-Stop-Close-Stop

1.

Default setting “A.1”.

A.2

Open only

A.3

Pedestrian mode

C.

Open Terminal

Function

C.1

Open-Stop-Close-Stop

1. Default setting “C.2”.

C.2

Open only

C.3

Pedestrian mode

Software Version:

PS19033F

12

broken you will have a green LED on the control board. Gate will stop and re-open but will not be

able to close until the green Led goes out.

Antenna

The Boxer is fitted with a tuned antenna positioned on top of the control board mounting plate. Be

careful not to damage the antenna wire that passes through the control board cover and connects to

the terminal block in the bottom right corner of the control board. You can remove the antenna

when working on the control board and replace when finished. Position the earth wire to the GRD

and the centre core wire to ANT (top connector).

Boxer Troubleshooting

Issue:

Solution:

Parts to look at:

No power on

the board.

-The batteries are 24v DC

-The transformer is 24v AC

-Check the transformer is plugged in and ON.

-At the motor check that the power cable is

connected through the fuse under the battery

box (black pull out fuse holder).This will be 24v

AC

-Removed the cover from the control board.

-Press your remote to see if the blue LED shines.

This will tell you that the power is on at the

control board.

-Check there is 24V AC flowing to the board at

the larger white connector block on the control

board.

-Check batteries are 24v DC on the small white

connector block at the control board.

-Removing optional extras such as beams to see

if they are faulty by simply removing the top

long green connector block from the control

board. when remove the beams need to change

and check the FL and FP (ph1/ph2) need to OFF

Hit the “set” button on the far right to make

sure it hasn’t gone into standby mode.

Fuse

Battery

Transformer

Batteries not

charging

-Check the cable from the batteries are

connected to the control board (marked “BAT”)

via the small white connector block.

-Check your transformer is switched “on” and

you have 24v AC at the control board large

white connector block.

-

Software Version:

PS19033F

13

-Check transformer fuse under the battery box.

-Check wires are making contact correctly inside

the fuse connector block.

-Check battery cable connectors have not

separated from the wire cable.

Board will not

programme a

system learn

or has not

completed a

system learn.

LED will show

as -L

-Check remote is correctly learnt.

-If you have led lights shining on the control

board this means photo beams and other

devices are active and will prevent a system

learn.

If you have no photocell or any emergency

device connected to the PCB terminal, the LED

indicate next to the LED display should be OFF,

IF it’s on check the FH and FJ is set to OFF

Always check the wire connections to the PCB

first especially the limit switch to the PCB board

-Make sure you hold the set button down long

enough.

-Check limit cams (silver plates mounted on the

nylon gear rack) stop the gate before the gate

reaches the ground mounted stop and the

catcher.

-Other optional extras can sometimes drain too

much power from the board and cause power to

be lost to the screen. Remove all external

accessories such as photo beams, exit button etc

by pulling the long green connector block from

the control board.

-Redo the system learning : -L means the system

is unlearn

> press SET & DOWN and make sure the LED shows LE

> OK?

> using the remote to complete the system learning

the LED shows from LE to LP > OK?

Once the system learning is completed the LED shows

OP

Re-connect optional devices such as photo beam and

etc and test after each is installed. (the corresponding

FH and FJ have to be changed once connected)

Board

Power sources

Remotes not

working

-Check the remote battery is not flat by pressing

the remote… a bright blue light shines at the top

of the remote.

-Re program remotes by pressing the RF learn

button until a blue light next to it comes on.

Press the remote ONCE (2 seconds) and the

board LED should flicker. Now wait until the light

RF Learn button

Software Version:

PS19033F

14

goes off (10 seconds) test remote with a 2

second press.

-When programming remotes press the top left

button ONLY. The rest of the buttons will

program themselves in with it.

-You can only program in one remote or device

at a time.

Control board

Locked –up

-If you change the speed of the motor after you

have done “Systems Learning” you may find the

control board will “lock-up”. You will need to

repeat “systems learning”

-The replacement FUSE for the control board and

can be found in the middle of the board under

the black fuse cover.

Transformer

fuse.

Board fuse.

Auto-close not

working.

-Make sure you don’t have any extras such as

beams or probes that are keeping the gate

open. Remove then retest.

-Ensure the programming for the auto close has

been done correctly.

-Check to see if anyone or anything is sending the

gate a signal from either remotes, keypads, exit

buttons etc.

Optional devices

Gate only able

to open or

close

-Unscrew 3 screws on the cover by the limit

switch. Make sure switches are not stuck in

position. If so get a screwdriver etc push it in

and it will pop out.

Software Version:

PS19033F

15

Open for 2 seconds

Software Version:

PS19033F

16

34100-193-09-A

This manual suits for next models

1

Table of contents

Popular Engine manuals by other brands

Volvo Penta

Volvo Penta TAD734GE manual

Volvo Penta

Volvo Penta D3 290/DP installation instructions

HAIMA

HAIMA HM484Q Service manual

R.A. Lister

R.A. Lister SR4 Instruction book & parts catalogue

TERASAKI

TERASAKI TemBreak PRO TPMC16S Operator's instruction manual

Westerbeke

Westerbeke 12C- TWO Operator's manual