The following procedure should only be performed by an adult utilizing extreme caution. While attempting this

procedure, individuals should wear rubber gloves, eye protection, and have water available in case the

electrolyte solution comes into contact with skin or eyes. Children should not attempt to complete this

procedure, and should NOT be allowed near the area when attempting to fill the battery. This procedure should

be completed first so that the battery is charged when the kart assembly is complete

: POISON - CAUSES SEVERE BURNS

Contains sulfuric acid. Avoid contact with skin, eyes, and clothing.

To prevent accidents, rinse the empty electrolyte solution container

- If solution comes in contact with the skin, flush the area with

- If solution is swallowed contact a physician immediately.

- If solution comes in contact with the eyes flush with water for

fifteen minutes. Get immediate medical attention.

KEEP OUT OF REACH OF CHILDREN

- This procedure should be performed in a location out of reach of children and animals.

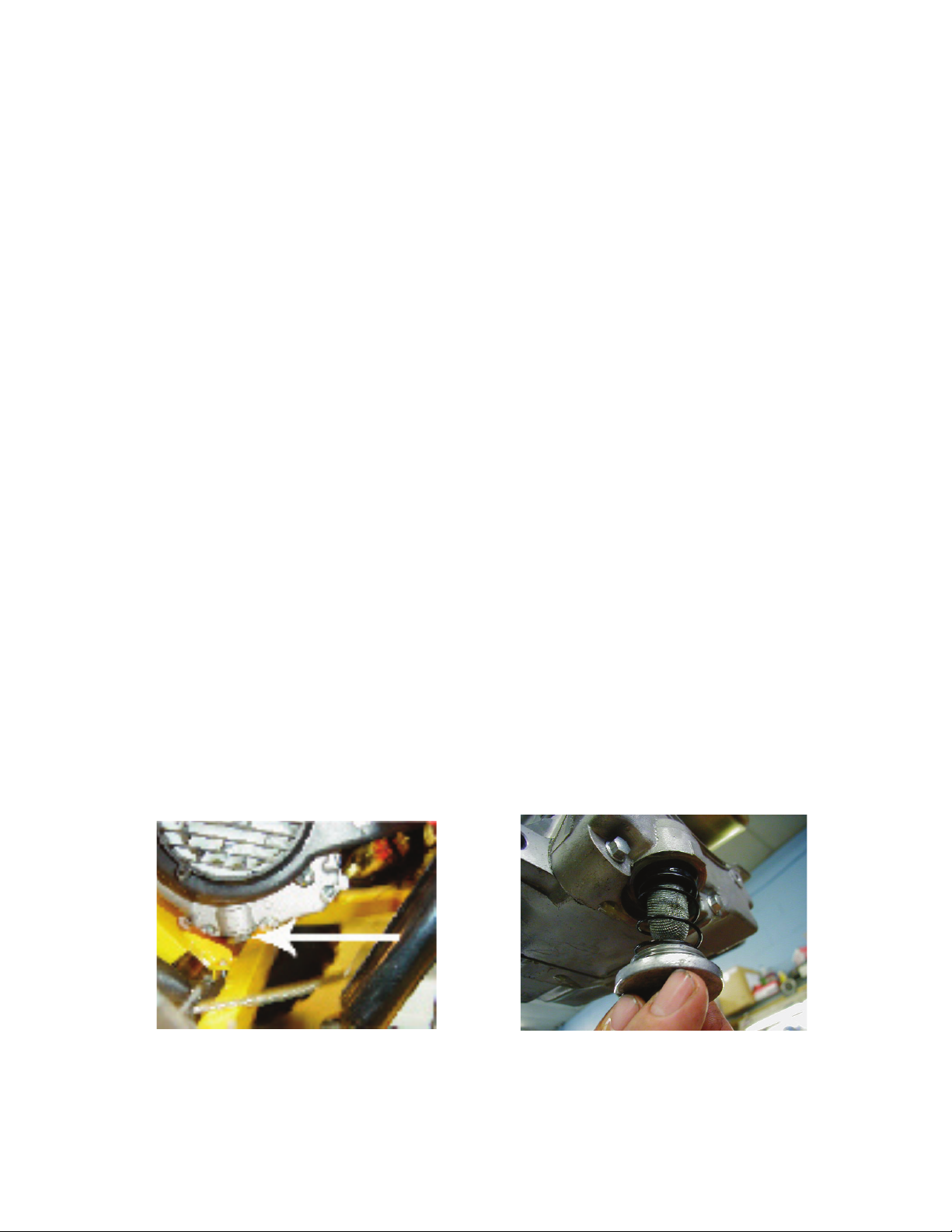

- Remove the battery and the electrolyte solution from the shipping crate.

- Place the battery on a level surface and remove the metallic sealing from the top.

- Holding the electrolyte container upside down so the sealed openings are facing the ground, align each sealed

opening of the bottles with the corresponding openings on top of the battery terminal.

- Strongly push the electrolyte container into the openings of the battery terminal so that the all of the seals on

the electrolyte container break, allowing electrolyte solution to flow into the battery. Do NOT attempt to

puncture the electrolyte container unless the six sealed openings are properly aligned with the six openings on

the top of the battery terminal.

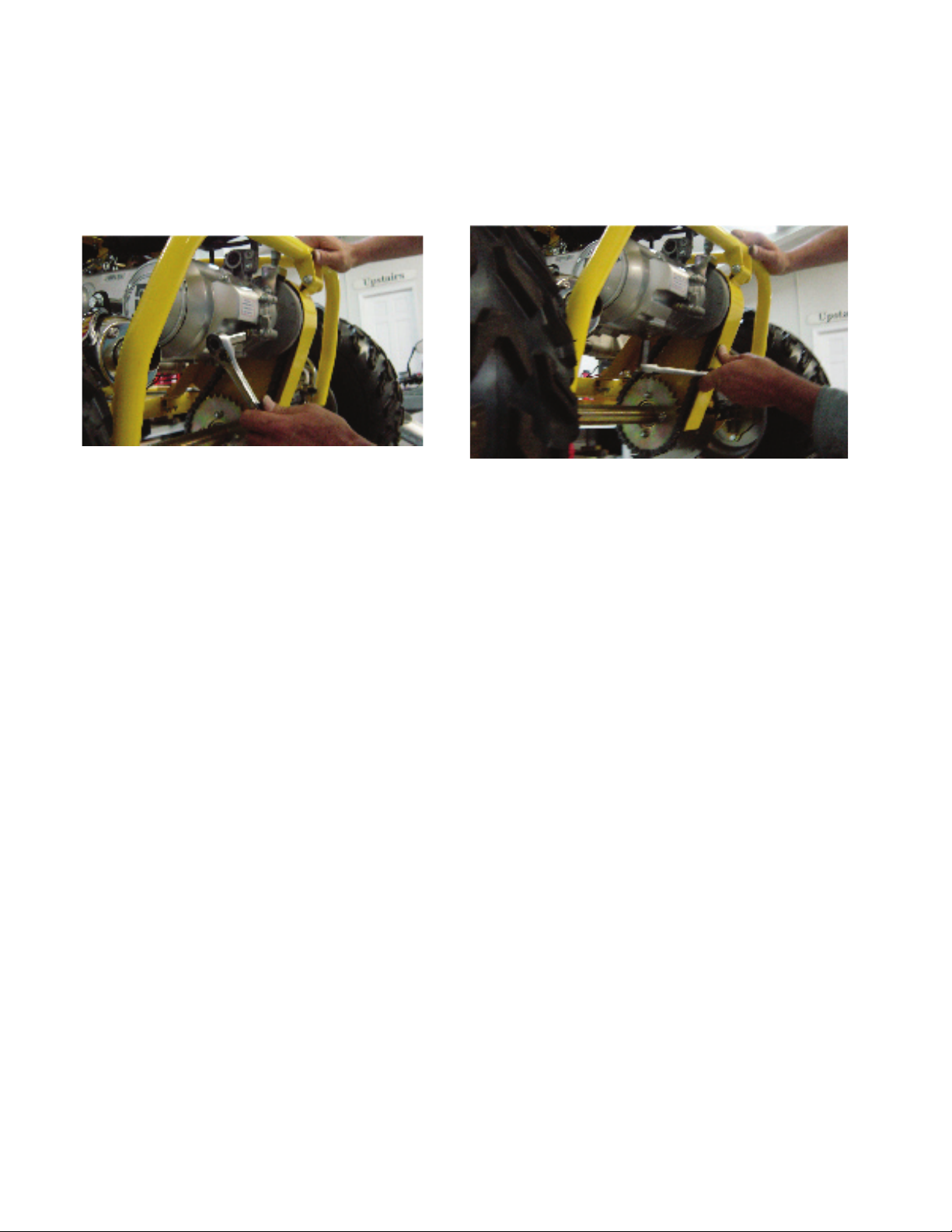

- Air bubbles will begin rising from each opening of the electrolyte solution when they are punctured.

- If air bubbles are not rising in each individual tube, tap the top side of the electrolyte bottles.

- Leave the electrolyte bottles in their draining position until all of the electrolyte solution has drained. Do

NOT attempt to remove the electrolyte bottles while they are draining.

- Do NOT attempt to puncture or cut any part of the electrolyte container.

- Do NOT allow children near the battery at any point during the installation process.

- When the electrolyte solution has finished draining, pull the bottles gently from the top of the battery terminal

and properly discard in a location out of reach of children or animals.