TOOLSPACE XW-1204 User manual

Model: XW-1204

12V CORDLESS POLISHER

Dear Customer,

Thank you for your purchase.

Your purchase means the world to us.

If you have any questions, we are here to service you.

lf the product you received is damaged or has quality

problems, please contact us through Email below and

attach product pictures of related problems,we will

reply to you as soon as possible,and provide you with

the best solution.

Email: TOOLSPACE01@outlook.com

Best regards,

Toolspace Customer Service Team

1

2

3

4

5

6

7

8

9

10

11

12

1

13

14

Check the actual product for detail attachment.

5

7

6

A

13 1

C

12

E

7

8

9

B

14

D

1 2

2

F

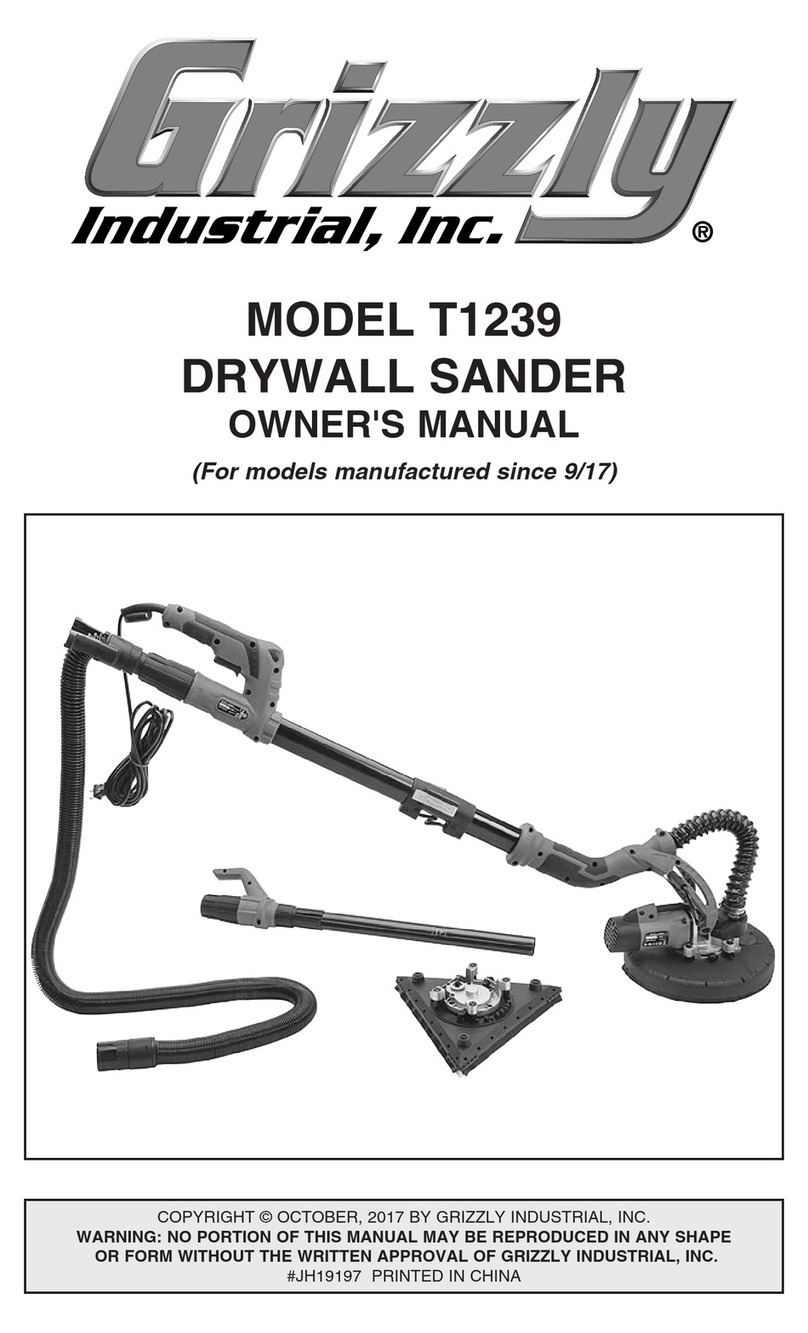

Scope of delivery / Part list

Safety

1. Spindle lock button

2. Speed selector switch

3. Battery level indication

4. Shift lock

5. Handle

6. Battery latch

7. Battery

8. Charger

9. Charge indicator lamp

10. Polishing attachment

11. Sanding paper

12. On/Off switch

13. Polishing / grinding plate

14. Additional handle

Reading and storing the user manual

This user manual is an integral part of this 12 V Li-Ion cordless polishing machine

(hereafter referred to only as the "polishing machine" or "product"). It contains important

information on safety, usage and maintenance. Please read the user manual carefully

before using the polishing machine. Pay particular attention to the safety instructions

and warnings. Failure to follow the instructions given in this manual may result in

serious injury or damage to the polishing machine. Always include the user manual

when you give the polishing machine to others. Keep this manual in a safe place for

future reference. The digital form of this operating manual is also available from the

service department of the manufacturer.

Proper use

The polishing machine is intended for private

and DIY use only for the following purposes:

-For polishing painted surfaces;

-For sanding wood, plastic and other similar

materials using a suitable sanding paper.

All other applications are expressly ruled out

and are considered as unintended use. The

manufacturer cannot be held responsible for

damage or injury caused by misuse of the

product. Examples of misuse are given in the

following non-exhaustive list:

- Using unsuitable accessories

- Using non-original spare parts.

- Incorrect operation or misuse.

- Non-observance of the operating manual.

- Repairs performed by unauthorised third

party workshops.

- Power cuts or faults caused by non-

observance of electrical regulations.

- Use and maintenance of the polishing

machine by someone who is not familiar with

the polishing machine and/or who lacks

suitable experience.

- Commercial, non-industrial or industrial use

of the polishing machine.

Use the accessories according to these

instructions. Failure to follow the instructions

given in this user manual may result in

serious injuries and loss of warranty. Comply

with applicable local or national regulations

concerning the use of this polishing machine.

Do not make any modifications to the polishing

machine. Any modification to the polishing

machine may be dangerous and is prohibited.

Residual risk

Residual risks cannot be completely ruled out

even in case of proper use. Due to the nature of

the polishing machine, the following risks may

arise:

- Health issues resulting from vibration, if the

cordless polishing machine is used for an

extended period of time, or is not operated

and maintained properly,

- Injury and property damage caused by parts

flung out or tool attachment breakage,

- Health hazards as a result of working with

toxic or harmful materials (e.g. asbestos).

General safety instructions for

power tools

WARNING!

Read all the warnings and safety

instructions carefully.

Failure to follow the

warnings and safety instructions may result

in electric shock, fire and/or serious injuries.

Retain all the warnings and safety

instructions for future reference.

The term "power tool" in the safety

instructions refers to your mains-operated

(corded) power tool or battery-operated

(cordless) power tool.

1) Work area safety

a) Keep your work area clean and well lit.

Disorderly or inadequately lit work areas

can lead to accidents.

b) Do not work with the power tool in

potentially explosive atmospheres

containing flammable liquids, gases or

dusts.

Power tools create sparks which

may ignite the dust or fumes.

c) Keep children and other people out of

the area when operating the power tool.

Distractions can cause you to lose control

of the power tool.

2) Electrical safety

a) The power tool's mains plug has to

fit the socket. The plug should not

be modified in any way. Do not use

any adapter plugs with the earthed

(grounded) power tools.

Unmodified

plugs and matching sockets will reduce

risk of electric shock.

b) Avoid bodily contact with earthed

objects such as pipes, radiators, ovens

and refrigerators.

There is an increased

risk of electric shock when your body is

earthed.

c) Keep power tools out of rain and wet

environments.

Water entering a power

tool will increase the risk of electric

shock.

d) Do not use the power cord for purposes

for which it is not intended, such as

carrying or hanging up the power tool,

and do not pull the cord to disconnect

the tool from the mains. Keep the power

cord away from heat, oil, sharp edges

or moving parts.

Damaged or entangled

power cords increase the risk of electric

shock.

e) When operating the power tool

outdoors, use only extension cords

suitable for outdoor use.

Using an

extension cord suitable for outdoor use

reduces the risk of electric shock.

f) If you need to use the power tool in

a damp environment, use a residual

current protection device.

Using a

residual current protection device reduces

the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing

and use common sense when operating

a power tool. Do not use a power

tool while you are tired or under

the influence of drugs, alcohol or

medication.

A moment of inattention

while operating power tools may result in

serious injury.

b) Wear personal protective equipment and

always use safety goggles.

Protective

equipment such as dust mask, non-

skid safety shoes, hard hat, or hearing

protection used for appropriate conditions

will reduce personal injuries.

c) Prevent unintentional start-up. Ensure

the switch is in the off-position before

connecting to power source and/or

battery pack, picking up or carrying the

tool.

Carrying power tools with your finger

on the switch or connecting it to the

mains with the switch in on-position, may

result in accidents.

d) Remove any adjusting tools or keys

before you switch the power tool on.

A

tool or a key left in a rotating part of the

power tool may result in injuries.

e) Avoid working with your body in an

unusual position. Ensure proper footing

and balance at all times.

This enables

better control of the power tool in

unexpected situations.

f) Wear appropriate clothing. Do not wear

loose clothing or jewellery. Keep your

hair and clothing away from moving

parts.

Loose clothes, jewellery or long

hair can be caught in moving parts.

g) If dust extraction and collection

units can be installed, they have to be

connected and used properly.

Use of dust

collector can reduce dust-related hazards.

4) Power tool use and care

a) Do not overload the power tool. Use

power tools that are intended for your

work.

The correct power tool will do the

job better and safer at the rate for which it

was designed.

b) Do not use the power tool if the switch is

faulty.

A power tool which can no longer

be switched on and off is dangerous and

has to be repaired.

c) Disconnect the plug from the socket

and/or remove the battery before

making any adjustments, changing

tool bits or accessories or putting the

power tool away.

Such preventive safety

measures reduce the risk of starting the

power tool accidentally.

d) Store power tools out of the reach of

children when not in use. Do not allow

persons unfamiliar with the power tool

or these instructions, to operate the

power tool.

Power tools are dangerous in

the hands of inexperienced users.

e) Maintain the power tools and tool bits

carefully. Ensure the moving parts are

functioning correctly and do not getting

stuck. Check if parts are broken or so

badly damaged that that the power

tool's functions are impaired. Get

damaged parts repaired before using the

power tool.

Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained tools with sharp

cutting edges are less likely to get stuck

and are easier to control.

g) Use your power tool, accessories and

bits etc. according to these instructions.

Consider your working environment and

the type of job you wish to do.

Using

power tools for applications other than

those intended can lead to dangerous

situations.

5) Usage and handling the cordless power

tool

a) Charge batteries only using chargers

recommended by the manufacturer.

Charging batteries in a charger intended

for other types of battery can result in fire.

b) Use only batteries designed for use with

the power tool.

The use of other batteries

can lead to injury or fire.

c) When not in use, keep the battery away

from staples, coins, keys, nails, screws

or other metal objects which could

bridge the contacts on the battery.

A

short circuit between the battery contacts

can lead to burns or fire.

d) Fluid can leak from the battery if the

machine is used incorrectly. Avoid any

contact with any fluid which may leak

from the battery. Wash your skin with

water should the fluid come into contact

with your skin. Should the fluid come

into contact with your eyes, rinse with

water and seek medical attention.

Fluid leaking from batteries can lead to

irritation or burns.

6) Service

a) Have your power tool repaired only

by qualified personnel and only with

original spare parts.

This will ensure that

the safety of the power tool is maintained.

Safety instructions for all

applications

a) This power tool is designed for use

as a sander and polishing machine.

Read all safety warnings, instructions,

illustrations and specifications

provided with this power tool.

Failure

to follow all instructions listed below

may result in electric shock, fire and/or

serious injury.

b) This power tool is not suitable for

grinding, working with wire brushes

and cutting.

Using the power tool for

other purposes than it is designed for

can cause danger and injuries.

c) Do not use accessories which

are not specifically designed

and recommended by the tool

manufacturer.l.

Just because the

accessory can be attached to your power

tool, it does not assure safe operation.

d) The permissible speed of the tool has

to be at least equal to the maximum

speed specified on the power tool.

Accessories running faster than their

rated speed can break and fly apart.

e) Outer diameter and thickness of the

tool have to match the dimensional

specifications of your power tool.

Incorrectly sized accessories cannot be

adequately guarded or controlled.

f) Tool bits with threaded insert have

to exactly match the threads of the

grinding spindle. When using tool

bits, which are mounted using the

flange, the hole diameter of the tool

bit has to match the diameter of the

flange.

Tool bits that are not fixed

properly to the power tool will rotate

unevenly, vibrate excessively and may

cause loss of control.

g) Do not use damaged tool bits. Before

each use inspect the accessory such as

abrasive wheels for chips and cracks,

backing pads for cracks, tear or excess

wear, wire brushes for loose or cracked

wires. If power tool or application tool

(planer blade) is dropped, inspect

for damage or install an undamaged

application tool. After inspecting

and installing the tool bit, position

yourself and bystanders away from the

plane of the rotating tool and run the

power tool at maximum no-load speed

for one minute.

Damaged accessories

will normally break apart during this

test time.

h) Wear personal protective equipment.

Depending on application, use face

shield, safety goggles or safety

glasses. As appropriate, wear dust

mask, hearing protectors, gloves

and workshop apron capable of

stopping small abrasive or workpiece

fragments.

The eyes have to be

protected from foreign objects that are

generated and ejected by the various

applications. The dust mask or respirator

must be capable of filtrating particles

generated by your operation. Prolonged

exposure to high intensity noise may

cause hearing loss.

i) Keep others at a safe distance from

your work area. Anyone entering

the work area must wear personal

protective equipment.

Fragments of

the workpiece or of a broken tool may

be thrown out and cause injury beyond

immediate area of work.

j) Hold the power tool only by its

insulated gripping surfaces when

performing an operation where

the fitted accessory may contact

hidden wiring or its own cord.

Cutting

accessory contacting a "live" wire may

make exposed metal parts of the power

1) General safety instructions for

sanding and polishing:

tool "live" and shock the operator.

k) Never put the power tool down before

the tool bit stops completely.

The

spinning accessory may grab the surface

and pull the power tool out of your

control.

l) Do not allow the power tool to run

while carrying it.

Accidental contact

with the spinning accessory could snag

your clothing, pulling the accessory into

your body.

m) Clean your power tool’s ventilation

slots regularly.

The motor’s fan will

draw the dust inside the housing and

excessive accumulation of powdered

metal may cause electrical hazards.

n) Do not operate the power tool near

flammable materials.

Sparks could

ignite these materials.

o) Do not use tool bits that require liquid

coolant.

Using water or other liquid

coolants may result in electrocution or

shock.

Additional safety instructions for

all applications

Kickback is a sudden reaction to a pinched

or snagged rotating tool bit such as

sanding disc, sanding pad, wire brush etc.

Snagging or blocking causes the rotating

tool bit to stop abruptly. This in turn causes

the uncontrolled power tool to be forced

in the direction opposite to the tool bit’s

rotation at the blocked point.

For example, if an abrasive disc is snagged

or pinched in the workpiece, the edge of

the disc that is entering into the pinch

point can dig into the surface of the

material causing the disc to climb out or

1) Kickback and corresponding safety

instructions:

kick out. The disc may either jump toward

or away from the operator, depending on

direction of the disc’s movement at the

point of pinching. Abrasive discs may also

break under these conditions.

Kickback is the result of using the power

tool in an incorrect or improper manner.

Kickback can be avoided by taking

appropriate precautions, as described

below:

a. Maintain a firm grip on the power

tool and position your body and arm

to allow you to resist kickback forces.

Always use the additional handle, if

provided, for maximum control over

kickback or torque reaction during

start-up.

The operator can control

torque reactions or kickback forces, if

proper precautions are taken.

b. Never place your hand near the rotating

tool bit.

Accessory may kickback over

your hand.

c. Do not position your body in the area

where power tool will move if kickback

occurs.

Kickback will propel the tool

in direction opposite to the disc’s

movement at the point of snagging.

d. Use special care when working corners,

sharp edges etc. Avoid bouncing and

snagging the accessory.

Corners, sharp

edges or bouncing have a tendency to

snag the rotating accessory and cause

loss of control or kickback.

e. Do not use chains or serrated saw

blades.

Such tool bits frequently cause

kickback and loss of control over the

power tool.

Additional safety instructions for

sanding

Additional safety instructions for

polishing

a. Do not use excessively oversized

sanding disc paper. Follow

manufacturers recommendations,

when selecting sanding paper.

Larger

sanding paper extending beyond the

sanding pad presents a laceration hazard

and may cause snagging, tearing of the

disc or kickback.

a. Do not leave any loose parts of the

polishing cover, especially fastening

cords. Stow or shorten the fastening

cords.

Your fingers or the workpiece may

get caught in loose, rotating fastening

cords.

Safety instructions for chargers

a) Never connect a battery pack that is

damaged in any way to the charger.

There is a danger of electric shock.

b) Do not misuse the charger! The charger

is only intended for charging the

battery pack Mod. XW-120302C, 2000

mAh. Misuse may result in fire or a fatal

electric shock.

c) WARNING! Do not charge non-

rechargeable batteries with the

charger. Not following this instruction

results in hazards.

d) Damaged mains plug or connecting

cables have to be replaced by the

manufacturer of the power tool or

his customer service department to

prevent hazards.

e) The charger, but not the cordless

drill, can be operated by children

from 8 years of age and above, as well

as by people with reduced physical,

sensory or mental capacities or who

lack knowledge or experience, if they

have been supervised or instructed

regarding safe use of the device, and

understand the resultant dangers.

Children should not play with the

device. Cleaning and user maintenance

shall not be performed by children

without supervision.

f) Do not expose the cordless drill and

the charger to rain or moisture. Water

ingression can result in an electrical

shock and damage the device.

Checking the product and scope of

delivery

Before Use

WARNING!

Do not use the polishing machine in

potentially explosive atmospheres.

Use the polishing machine only in

ambient temperatures between 10 -

40°C.

Disconnect the polishing machine

from the power source before

making any settings, mounting or

replacing accessories and carrying out

maintenance.

• Take the polishing machine and accessories

out of the packaging

• Check that the delivery is complete (see

section “Scope of delivery / Description of

parts”).

• Check the polishing machine and accessories

for damages.

• Do not use the polishing machine if it is

damaged or parts are missing. Contact the

manufacturer via the service centre listed on

the warranty card.

WARNING!

Risk of suffocation! There is a risk of

suffocation by ingestion or inhalation of

films. Keep the packaging film out of the

reach of children.

Inserting /removing the battery

(Fig. A)

• Insert the battery 7into the handle 5

until it locks in place.

• To remove the battery, press the battery

unlocking latch 6and slide the battery out

of the handle.

• Remove the battery 7from the handle, as

described in chapter "Inserting / Removing

the battery".

• Insert the battery into the battery holder of

the charger 8.

• Connect the plug of the charger to a suitable

mains socket. The red charging light 9

is on.

• After about 3 - 5 hours, the red charging

indicator light goes out. The green charging

indicator light lights up when the charging is

completed.

• Disconnect the charger from the mains socket

after charging is complete.

• To remove the battery, press the battery

release button and take it out of the charger.

NOTE!

Ambient temperature for operation:

10 - 40° C.

Charging the battery (Fig. B)

NOTE!

Ambient temperature for charging: 0 - 40° C

Use only the batteries mentioned below:

Model XW-1204

Rated voltage 12 V

Capacity 2000 mAh

Idling speed 1. Speed 0 - 2600 rpm

2. Speed 0 - 7800 rpm

CAUTION!

When charging and during high loads on

the polishing machine, the battery gets

heated up. Always allow the battery to

cool down to room temperature before

you charge the battery.

The charger becomes warm and may buzz

slightly during charging. This is normal

and does not indicate a fault.

WARNING!

For safety reasons the additional handle

14 should always be used.

Mount the sanding or polishing

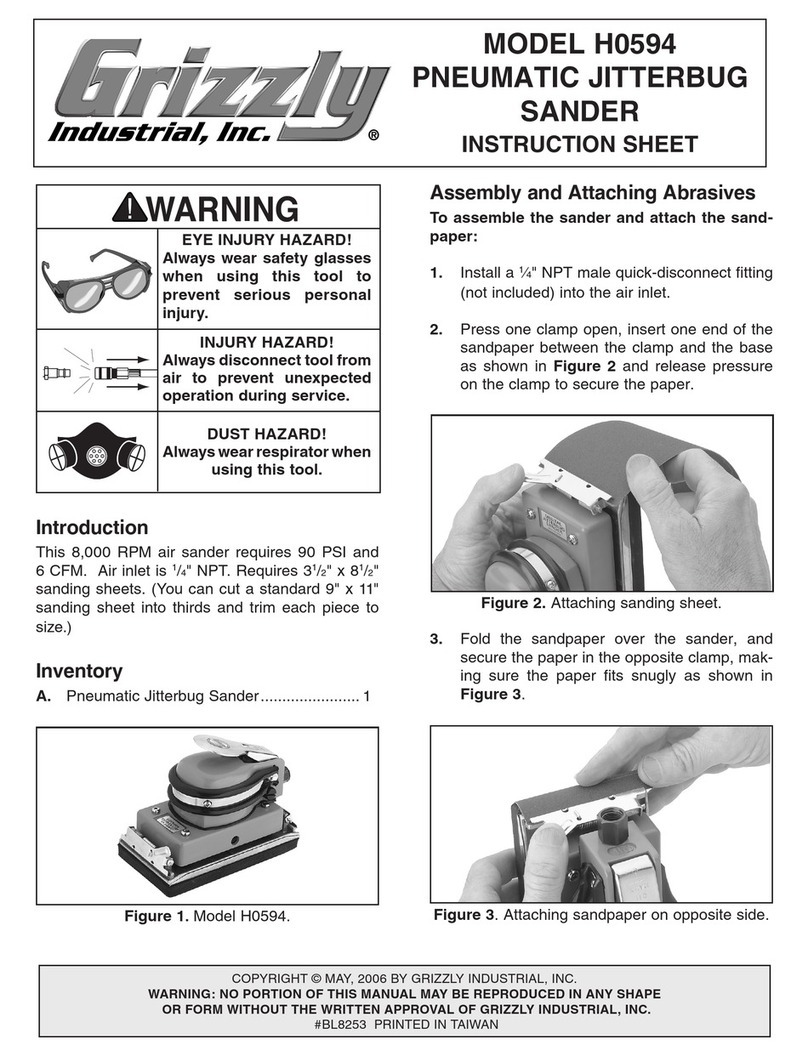

attachment mount (Fig. C)

Mounting / removing the

additional handle (Fig. D)

Checking the battery level

To check the charging status, the battery level

indicator

3

lights up when you press the on /

off switch.

The charging status is indicated as follows:

- All 3 LEDs light up: Battery is charged

- 2 LEDs light up: Battery is partially charged

- 1 LED lights up: Battery needs to be charged

The additional handle is provided with an external

thread.

• Push the spindle lock button up

1

.

• Mount the polishing / sanding plate

13

by

turning it clockwise.

• Select the appropriate sanding or polishing

attachment.

• To remove proceed in the reverse order.

• Fix the additional handle in clockwise direction

to the left or right on the top of the tool

depending on the work.

The speed can be infinitely adjusted by varying

the pressure exerted on the trigger.

NOTE!

Ensure that the tool shaft and the tool

holder are free from dust and lightly grease

the shaft before inserting it into the chuck.

This extends the service life of the chuck and

the polishing machine.

NOTE!

Check the battery level regularly to avoid

deep discharges.

NOTE!

The polishing machine is locked if the shift

lock

4

is on the right side.

NOTE!

Change speeds only when the drill spindle

has come to a complete stop. (Risk of

damage to the gears)

Use

Switching on / off (Fig. E)

Speed selection (Fig. F)

Switching on:

• Press the On / Off switch

12

.

Switching off:

• Release the On / Off switch.

Speed selection switch in position 1:

• 1. Speed (marked as L for low speed) 0 - 2600

rpm

Speed selection switch in position 2:

• 2. Speed (marked as H for high speed) 0 -

7800 rpm

Always ensure that the speed selection

switch

2

properly locks into position 1

or 2.

NOTE!

Only use special wax and polish suitable for

machines. Make sure that the workpiece to

be machined never comes into contact with

the polishing / grinding plate.

Sanding and polishing

• Mount the required sanding attachment on the

polishing / sanding plate.

• Switch on the product and run it with moderate

pressure on the workpiece using circular,

transverse or longitudinal movements.

• Mount the required polishing attachment

10

on the polishing / sanding plate.

• Make sure that the selected polishing

attachment is not contaminated and always

mounted exactly in the centre on the polishing

/ sanding plate.

• Check if the polishing attachment is firmly

attached before switching on.

• Switch on the product and run it with moderate

pressure on the workpiece using circular,

transverse or longitudinal movements.

Sanding

Polishing

For sanding, use the appropriate sanding papers

11

. The various sanding attachments are easy to

change by means of the Velcro.

For rough finish, a coarse grit and for fine finish

a fine grit is recommended. The optimum grit can

be determined by carrying out a sanding test.

For polishing, use the appropriate polishing

attachments

10

. The various polishing

attachments are easy to change by means of the

Velcro.

Work instructions

CAUTION!

Do not apply excessive force on the

product.

Excessive pressure may damage

the product or its accessories and increases

the risk of injury.

For this reason is it

important to always grip the product

firmly with two hands and maintain a

stable posture.

Always secure your workpiece in a vice or

in any other clamping device for sanding.

Secure particularly large workpieces

against sliding or support them properly.

Selecting the appropriate sanding

as you need

• Clean the polishing machine with a moist cloth.

Never use strong and / or abrasive cleaning

agents or solvents. Allow all the parts to dry

completely.

• The contact points on the battery and charger

have to be kept clean. Disconnect the charger

by unplugging it from the power supply before

cleaning. Remove the battery before cleaning

the polishing machine.

• Ensure that the ventilation slots are not

blocked and clean the housing of the polishing

machine regularly with a soft cloth.

• Remove the attachment before storage (see

chapter "Mounting the sanding or polishing

attachment").

• Remove the battery before putting the drill

away (see chapter "Inserting / removing the

battery").

• Clean the polishing machine before storage.

• If the polishing machine is not being used,

keep it in a safe, cool, dry and well-ventilated

place, out of the reach of children.

• Store the polishing machine and the battery at

an ambient temperature of 0 - 45° C.

• Store the accessories after use in the storage

case.

• Make it that the polishing attachment rests

completely on the polishing surface.

• Glue plastic parts to avoid colour changes.

• Polish in the shade and never polish hot

varnish.

CAUTION!

When charging and during high loads on

the polishing machine, the battery gets

heated up. Always allow the battery to

cool down to room temperature before

you charge the battery.

Make sure that liquids do not get inside

the polishing machine.

Tips for polishing

Maintenance, cleaning,

storage and transport

WARNING!

Disconnect the mains plug of the

charger and remove the battery of the

polishing machine before carrying out

any adjustment, maintenance, repair

or cleaning. To do this, remove the tool

being used.

Maintenance

Cleaning

Cleaning

The polishing machine requires very little

maintenance.

Only use spare parts / accessories from the

manufacturer or authorised and qualified

workshops.

Repairs should only be carried out by qualified

technicians or by an authorised service centre.

Qualified technicians must have relevant

training and experience, be familiar with the

design and construction requirements of the

product and understand and follow the safety

regulations.

• Remove the attachment before transport (see

chapter "Mounting the sanding or polishing

attachment").

• Remove the battery before transporting the

drill (see chapter "Inserting / removing the

battery").

• Always carry the polishing machine using the

handle provided for this purpose.

• Use the original packaging and secure the

polishing machine in place during transport.

Transport

Troubleshooting

Problem Possible cause Rectification

Polishing machine does

not start.

Battery empty. Charge the battery.

Problem with battery contacts. Slide the battery into the guide on the

polishing machine handle. The battery

has to click into place audibly.

Shift lock is in locked position. Press the shift lock 4to the left to

unlock it.

Polishing machine

is running but the

polishing / sanding

plate is not rotating.

Speed switch is not engaged. Press the speed switch 2to position 1

or 2 until it engages fully.

Battery does not

charge.

Battery charger is faulty. Replace the charger.

WARNING!

Safety measures have to be defined

to protect the operator based on an

estimate of the vibration load during

actual usage conditions (in this case all

the parts of the operating cycle have to

be considered, such as times when the

power tool is turned off, and those where,

the tool is turned on, but is running

without load).

Depending on the way the tool is used

and the operating conditions, the

following safety precautions have to be

taken for the safety of the operator:

- Try to avoid exposure to vibration as much as

possible.

- Only use proper accessories.

- Wear anti-vibration gloves when using the

polishing machine.

- Follow the instructions on maintenance and

care of the polishing machine given in this

manual.

- Avoid using the polishing machine at a

temperature below 10°C and over 40°C.

- Plan your work in such a way so that you do

not have to use vibrating tools over several

days.

Disposal of packaging

Dispose of packaging separately.

Dispose of card and paper in waste

paper, plastic at collection points.

Disposal of the product

Disposal of batteries /

accumulators

The symbol with crossed-out dustbin on

batteries and accumulators indicates

that they should not be disposed of

along with household waste at the end

of their service life. If the batteries or

accumulators contain mercury (Hg), cadmium

(Cd) and lead (Pb), you can find the respective

chemical symbol below the crossed out dustbin.

Check the local and national regulations if

there is a legal obligation to return used

batteries and accumulators after use. You can

do this mostly free of charge at the retailer

or in another collection centre near you. The

addresses of appropriate collection points

can be obtained from your city or municipal

authorities.

Batteries may contain substances that are

harmful to the environment and human

health. Be very careful when handling lithium-

containing batteries because of the specific

risks. The separate collection and recycling

of used batteries and accumulators prevents

adverse effects on the environment and human

health.

Please avoid generating waste from used

batteries as much as possible, e.g. by preferring

batteries with a longer service life or using

rechargeable batteries. Please avoid littering

public places by not carelessly leaving batteries

or electrical and electronic equipment

containing batteries. Please consider ways to

reuse a battery instead of disposing of it, such

as reconditioning or repairing the battery.

This symbol indicates that this product

may not be disposed of together with

domestic waste in compliance with the

(2012/19/EC) directive pertaining to

waste electrical and electronic devices

(WEEE). This product should be handed over at

an designated collection point. This can occur,

for example, by returning it when a similar

product is purchased or by handing it in at an

authorised collecting point for the recycling of

waste electrical and electronic equipment.

Owing to potentially hazardous substances that

are frequently contained in waste electronic

equipment, incorrect handling of waste

equipment may have a negative impact on the

environment and on the health of human

beings. By disposing of this product correctly,

you are also contributing towards an efficient

use of natural resources. Information on

collection points for used equipment can be

obtained from your local authority, the public

waste disposal authority, an authorised

institution for the disposal of used electrical

and electronic equipment or the waste

collection services. Dispose of the product and

packaging in an environmentally friendly

manner.

Remove the battery before disposing the

product.

Recycling

Table of contents

Popular Sander manuals by other brands

Rupes

Rupes BR106AE Operating and maintenance instructions

Powermatic

Powermatic OES9138 Operating instructions and parts manual

Bosch

Bosch 1294VSK Operating/safety instructions

Makita

Makita DPO500 instruction manual

Milwaukee

Milwaukee POS 13 Original instructions

Chicago Electric

Chicago Electric 90820 Assembly and operating instructions